Rewriting the subsea survey rules

Client: i-Tech 7

The underwater survey and construction sector is necessarily risk-averse. The potential negative impact from downtime, rectification events or environmental damage caused by changes to procedures and methods can be burdensome. The result is a preference for tried and true methods, techniques and equipment.

The challenge

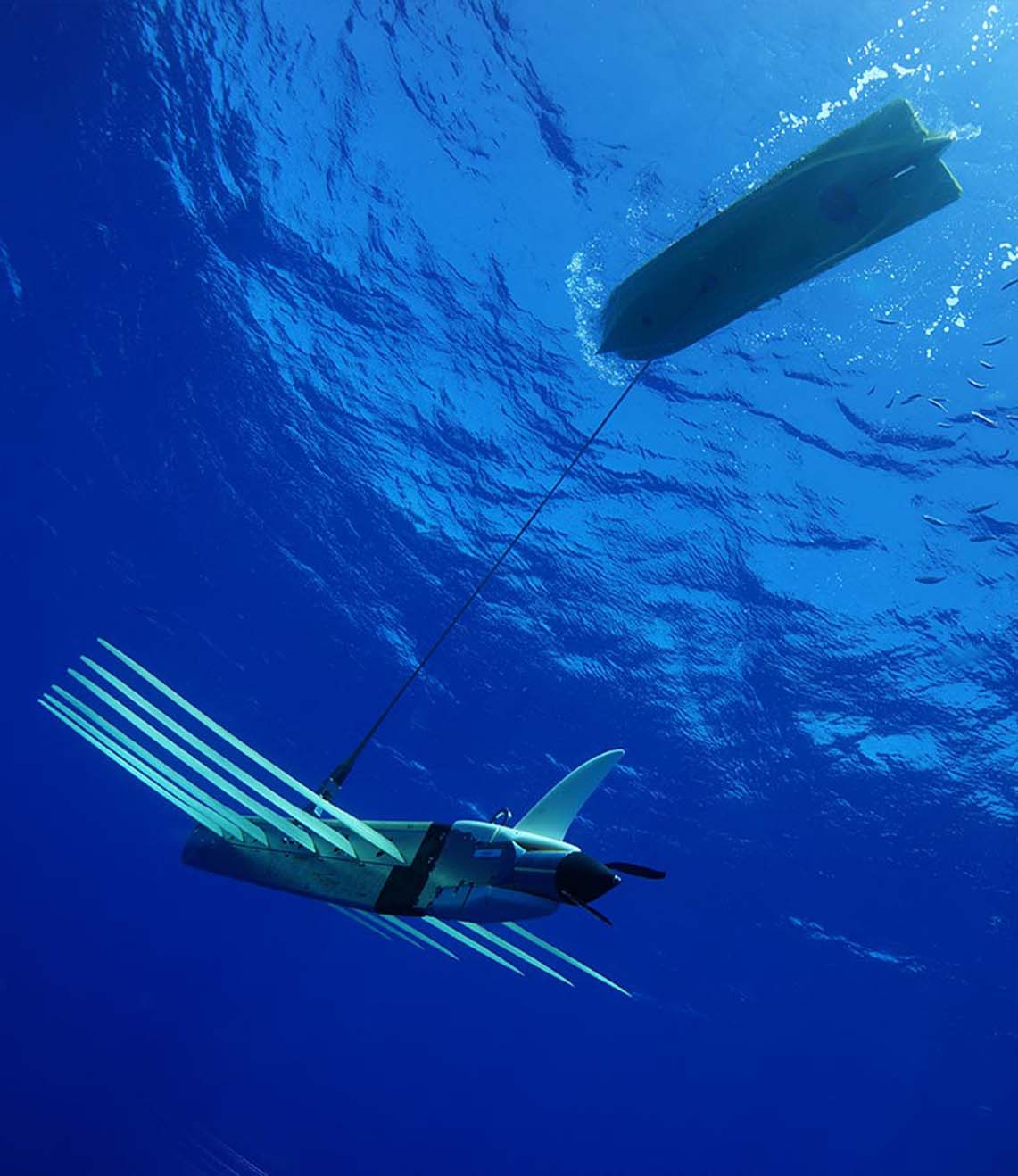

In recent years, different combinations of subsea positioning technologies have been used in support of survey and construction projects. Whilst delivering an incremental improvement, they have also resulted in increased complexity in integration and operation. Separate inertial navigation systems (INS) and Long BaseLine (LBL) solutions require integration via online navigation software. Along with this, there is the added complication of the physical mounting, calibration and interfacing of INS and Doppler velocity logs (DVL) on remotely operated vehicles (ROVs).

The increased complexity adds cost in training and support, as well as increasing risk through having to control many separate parts from different vendors.

There is clearly a need to be smarter and more efficient. Reducing vessel days increases safety and lessens our environmental footprint. There is no need to lose the accuracy or reliability of subsea positioning or increase the complexity of operations either. If both the number of Compatts needed for an LBL pipeline installation array and calibration routine could be reduced, days – not just hours – of vessel time would also be lowered as would the entire complexity of such projects.

The solution

i-Tech 7 adopted our Fusion 2 all-in-one software platform for their INS and LBL operations.

This allowed them to take advantage of the Fusion 2’s real-time simultaneous localisation and mapping (SLAM) capability. Choosing to operate a sparse LBL can deliver a reduction of Compatts. However, if the sparse array cannot be calibrated using traditional LBL baseline calibration, the benefit may be lost. Extra time for performing additional ‘box-ins’ or collecting data to perform post processed SLAM positioning of the Compatts becomes necessary.

This isn’t the case with real-time SLAM. The number of Compatt transponders used to create the ‘sparse’ LBL array is reduced and the calibration of those Compatts is managed by flying the ROV through the array and acquiring the necessary observables to SLAM the array. With careful planning, this real-time SLAM process can be done during other ROV survey operations, such as pre-lay surveys. This removes the entire baseline calibration work flow from the project schedule.

Co-locating our SPRINT INS with a separate DVL onto i-Tech 7’s ROVs was the first step in reducing the complexity of these operations. Using SPRINT enabled the optimisation of sparse LBL operations, reducing the number of Compatts required for an LBL array by 50-66%, with the post-processing SLAM calibrations being managed by us.

The SLAM calibration technique was run alongside arrays with full LBL sections and sparse LBL arrays which were SLAM calibrated. When results were compared they showed centimetric agreement, proving real-time SLAM gives near traditional LBL levels of precision and accuracy.

All the experience and knowledge gained since i-Tech 7’s first use of our SPRINT INS in 2012 has enabled us to build SLAM calibration routines directly into Fusion 2. That step has taken the simplification to a new level. Real-time SLAM operations in i-Tech 7’s 2019 project have far more efficient trajectories than previous operations.

The results

Between August and November 2019, a minimum of 11 vessel days were saved across five separate i-Tech 7 deep water (1,000-1,500 m) projects in the US Gulf of Mexico. Thanks to Fusion 2’s real-time SLAM capability, operators were able to access first oil faster.

Having already reduced the number of Compatts needed for an array – by reducing how much time is spent deploying them and calibrating them – the time allocated on project schedules for the lengthy box-in routines required in a traditional array can also be reduced, if not completely negated.

In fact, following a pre-lay survey, an offshore manager asked one of i-Tech 7’s offshore surveyors how long the array calibration would take before pipelay operations could start. The answer? It had already been done.

i-Tech 7 and Subsea 7 have proved the simplification of pipeline installation projects can be smarter, more efficient, quicker and safer. What’s more, they help lessen the overall environmental footprint of major subsea installation projects. This can all be done without losing positioning accuracy or reliability.

Have you got a similar project?

Challenge us to solve your problem