MRAMS is a high-accuracy solution for monitoring the differential angle between a drilling riser and blowout preventer (BOP) to reduce excessive wear on wellheads.

At a glance

Helps prevent costly damage to riser and BOP

Provides clear information for users to maintain riser angles within operational limits

Integrated USBL acoustic positioning for DP reference

Designed for deep water operations

Standalone system or integrated with Marksman LUSBL

Suitable for

Real-time monitoring for drilling operations

Want to know more?

A bubble-type display provide drilling teams with easy to visualise riser/BOP movement

MRAMS provides output compatible with all makes of DP system

MRAMS hardware is built on our 6G platform ensuring reliable performance in noisy acoustic conditions

MRAMS uses two DPT 6 transponders; one riser mounted, one BOP mounted

Benefits of MRAMS for your operations

Real-time

MRAMS provides high update, low latency data updates ensuring you know exactly what is happening

Cable-free

Unlike expensive cabled solution which are vulnerable to damage, MRAMS is a wireless acoustic solution

Easy to use

Simple and intuitive software Provides clear and unambiguous data on a riser’s angle and profile

Overview

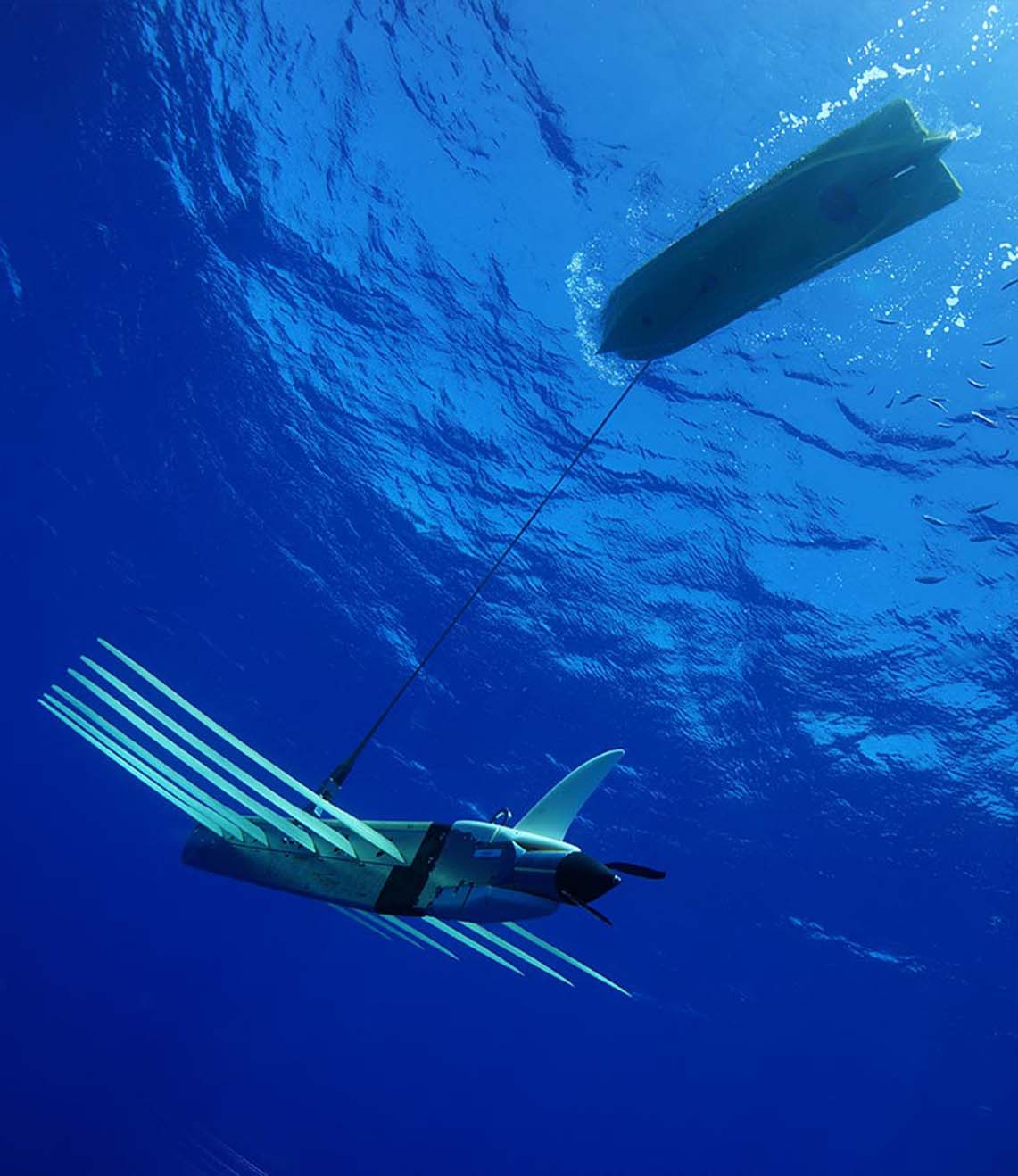

Designed for use from both Dynamically Positioned (DP) and moored drilling rigs, MRAMS uses our low-risk, field-proven 6G hardware and Wideband 2 acoustic technology to maintain an uninterrupted wireless data link between a rig and BOP, even in the high-noise environments typically associated with drilling operations.

Developed from field proven components, MRAMS is based on the integration of our USBL acoustic positioning technology and BOP-mounted transponders fitted with high resolution inclinometers. This provides clear and unambiguous data on the vessel’s position and riser angle status.

MRAMS comprises of four key elements; a Navigation Sensor Hub (NSH) and computer for controlling the transmission and decoding of acoustic signals, a vessel-based HPT 5000 or HPT 7000 transceiver which acts as an interrogator/receiver and responds to commands from the NSH, and a pair of DPTi 6 transponders; one fitted to the riser and one fitted to the BOP.

On command from the NSH one of three angles can be measured; the Riser, the BOP or Differential Riser/BOP angle. The angles are measured and transmitted to the surface using acoustic telemetry. The data is decoded by the transceiver and transmitted to the NSH which uses the elapsed time from command transmission to reply and phase comparison to enable the vessel’s position relative to the BOP and riser to be determined.

During drilling operations, the riser and BOP angles are continuously measured by each DPTi 6 and the differential riser/BOP angle calculated. The angles are transmitted up to the vessel above using high speed digital acoustic telemetry, where they are received by the HPT transceiver, decoded, and then displayed on the bridge or drill floor. The vessel’s position and bearing relative to the BOP is also calculated and the information displayed to the dynamic positioning operator or barge engineer. They use the data to steer the rig and return the riser flex joint back to vertical.

In addition to its stand-alone capability in accurately monitoring the riser and BOP differential angle during drilling operations, MRAMS integrates seamlessly with our dynamic positioning (DP) reference system, Marksman, to provide reliable and accurate vessel positioning for mobile drilling units.

Why invest

Design

-

Operating depth range 3,000 m

-

Robust two-way communications

-

Medium Frequency (18-36 kHz)

-

Compatible with all makes of DP system

Hardware list

-

2 x DPTi 6 transponders

-

Riser mounting buckets

-

HPT transceiver (5000 or 7000)

-

Marine Computer (running MRAMS software)

-

Navigation Sensor Hub (NSH)

DPTi 6 at a glance

-

High accuracy inclinometer range: ±90°

-

Accuracy: 0° to ±15° = ±0.05°; 0° to ±45° = ±0.2°

-

Depth rated to 3,000 m

-

Tilt Switch ±30-45°

-

Strain Gauge Pressure Sensor ±0.01%

-

High Precision Strain Gauge (Optional) ±0.01%

Support

-

Work side-by-side with our project and applications group from concept to deployment

-

Systems are manufactured and tested before delivery at our world-class in-house facilities

-

Comprehensive and flexible training for system operators

-

24-hour support, whenever and wherever you are in the world