Improved MCM operations using multi-aperture sonar

The evolving requirements from world navies are challenging innovators to improve mine-hunting capabilities. In the face of declining budgets, navies want to improve percentage clearances, minimise risk by removing more personnel from minefields and get the job done quicker. With growing budget restrictions, it’s easier said than done.

The challenge

Uncrewed systems are the preferred choice for navies in support of mine countermeasure (MCM) operations. The first navy to deploy these operationally was the US in Operation Iraqi Freedom. Here an early version of the Mk 18 Mod 1 “Swordfish” underwater vehicle was used in support of mine clearance operations.

Since then, many navies have acquired small, man-portable systems to conduct operations in very shallow waters and larger systems for operations in deeper waters. The performance of the Royal Australian Navy’s Bluefin-9 and the medium-sized Bluefin-12 unmanned underwater vehicles (UUVs) has demonstrated that ocean robots have a significant role to play in MCM missions.

These kinds of underwater vehicles succeed because they provide a stable platform in which to mount payload sensors and do a great job of surveying the seafloor, at a constant height from the sea bottom. However, while operating, their data is stored within the system until it can be recovered and the data uploaded to a computer. This leads to delays in completing the operation. One way to combat this is to use uncrewed surface vessels (USVs) to complement their underwater cousins. This enables real-time access to data and facilitates a faster tempo for operations. Just like the underwater vehicles, to be successful a USV needs to provide a stable platform for its payloads and get them close to the seafloor.

The solution

Sometimes the solution is already there, all you need to do is piece it together. Equinox uses existing technologies as building blocks to create a new solution for improving MCM operations.

Solstice mine-hunting sonar

The first building block used to create Equinox is Solstice. Our Solstice was designed by our sister company, Wavefront, to deliver the ultimate mine-hunting side-scan sonar. Solstice uses a proprietary array design and multiple apertures to improve the signal-to-noise ratio performance, capturing stunning imagery at longer ranges than other sonars at the same frequency. Typically operating at 750 kHz it scans a 200 m swath and delivers a brilliant along-track resolution of 0.15°.

One example available in the public domain shows Solstice was able to both detect and identify lobster pots across a 200 m swath. These man-made targets are typically smaller than mines so constitute a great target, illustrating that Soltice is more than capable of the MCM sonar task.

However, to make Solstice work when deployed from a USV several technologies need to come together. First and foremost, it needs a stable platform capable of keeping Solstice at a set height from the seabed as it travels through the water. This is where the next building block, ScanFish 3D, comes in.

EIVA’s ScanFish 3D

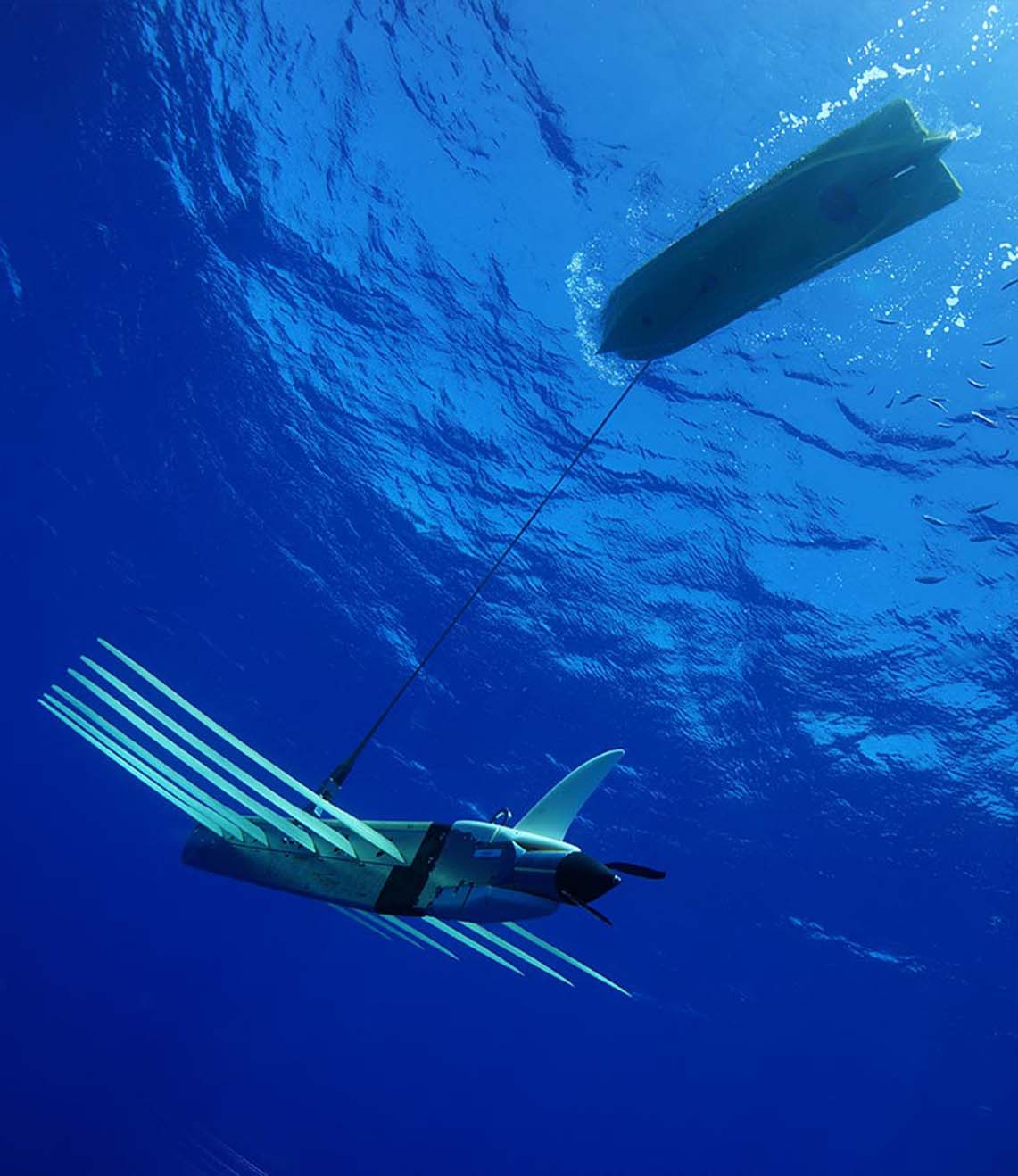

Our other sister company EIVA manufactures ScanFish 3D. The ScanFish 3D is a trusted ROTV platform capable of sailing through the water at a constant height from the seafloor. Designed to be both very stable when surveying and highly dynamic when needing to surface at high speed, there is no need to constantly pay cable in or out to adjust the height.

ScanFish 3D can carry a significant payload and is stable enough for Solstice to excel. Strong enough to be equipped with navigation instruments to accurately geo-reference the data, the platform demonstrates performance similar or better than an AUV, keeping an almost constant heading, pitch and roll as the AUV gathered data.

This means that the sonar data can be acquired at the sweet spot for the sensor at 7.5m from the seafloor. Once the data has been gathered, it needs to be georeferenced. This leads us to the next Equinox building block, SPRINT INS.

SPRINT INS minimising position errors

Typically, navies require a 5 m (DRMS) absolute position error for any contact surveyed during mine-hunting operations. The requirement is driven by both the technical limitations of the solutions used to date and the assumption that to re-acquire a target within that position error is achievable. However, in challenging environments, a 5 m error translates as time wasted in the actual process of re-acquiring and identifying the contact.

Commercial-off-the-shelf (COTS) instruments solve this problem effectively at a lower cost. Using a SPRINT INS aided by a Doppler velocity log and a Mini-Ranger 2 ultra-short baseline (USBL) system, Equinox can localise targets within 1 m (DRMS). This decreases uncertainty in MCM missions while improving tactics and the tempo of operations.

Inertial navigation is inherently self-contained, robust and with very good short-term accuracy, but it can drift over time. Therefore, the INS is aided with complementary acoustic positioning, i.e. the DVL and USBL, to provide long-term accuracy and robustness. Conversely, the additional integrity offered by the integration of the INS significantly reduces operational delays during periods of challenging subsea acoustic conditions, such as aeration and noise. In addition, the heading accuracy reported by SPRINT minimises lever-arm effects for targets at the furthest range from the sonar. This is a large source of error in towed sonar systems.

Extensive trials have taken place to test the navigation accuracy achieved by the combination of instruments that form Equinox. In one trial, two bicycles were lowered to the seafloor. They were placed at known positions and were used to establish the navigation accuracy of the system. The results demonstrated the performance to be less than 1 m (1 DRMS), as expected.

With the performance of the combined systems delivering far better than expected results, there is just one last building block needed to complete the solution; the software that stitches it all together.

NaviSuite Kuda

Completing the system is NaviSuite Kuda software, which is used to plan, monitor, and process the data from the Equinox system. NaviSuite Kuda has also been developed by EIVA and is another COTS system used by hydrographers worldwide to run their underwater projects.

To plan a survey, the user defines the sailing route and run lines by simply selecting the area that needs to be surveyed. The software generates a plan that can be fed directly to the USV control software (or to a skipper if using a crewed vessel).

During an MCM mission, NaviSuite Kuda continuously updates the vessel and ScanFish 3D position in real-time. The navigation and Solstice data is processed and displayed on the screen enabling an operator or automatic target recognition (ATR) algorithm to review it as it is being gathered. The information can then be used to inform the next stage of the mission while the survey is taking place.

The results

The critical advantage that Equinox offers over competing systems is that it is made from combining products that retail as COTS. This means its component parts have been deployed in thousands of mobilisations and have been proven, time and again, to meet or reduce error margins.

Equinox selects best of breed COTS to deliver a step up in capability. The result is improved performance compared to standard side-scan sonar systems, improved navigation accuracy several times better than any other system in the public domain, and at a price exceedingly lower than competing products that have been specifically designed to conduct mine-hunting operations.

For a navy this means an enhanced ability to mobilise a capability quickly, using components that can be easily looked after and maintained and feeding into existing training programmes and a community of existing users.

Have you got a similar project?

Challenge us to solve your problem