Hydrostatic pressure testing

Putting your technology to the ultimate test

Our hydrostatic testing facility is the most reliable and cost-effective way to validate the integrity of subsea equipment in ultra-deepwater operating environments.

At a glance

Full technical and engineering support available on-site

Simulate depths down to 6,300 metres (20,670 feet)

Set up for heavy lifting with a 2.5 tonne crane

Maximum working pressure – 630 bar (9,137 psi)

Full test reports provided and documentation provided

Large chamber size - 0.76 m internal diameter, 2 m internal length

Our services add value to your operations

Find out more about how we can help you

Benefits of this service for your operations

For energy

Hydrostatic testing is the most reliable and cost-effective way to validate the integrity of subsea equipment before it is deployed in the field where failure has significant implications.

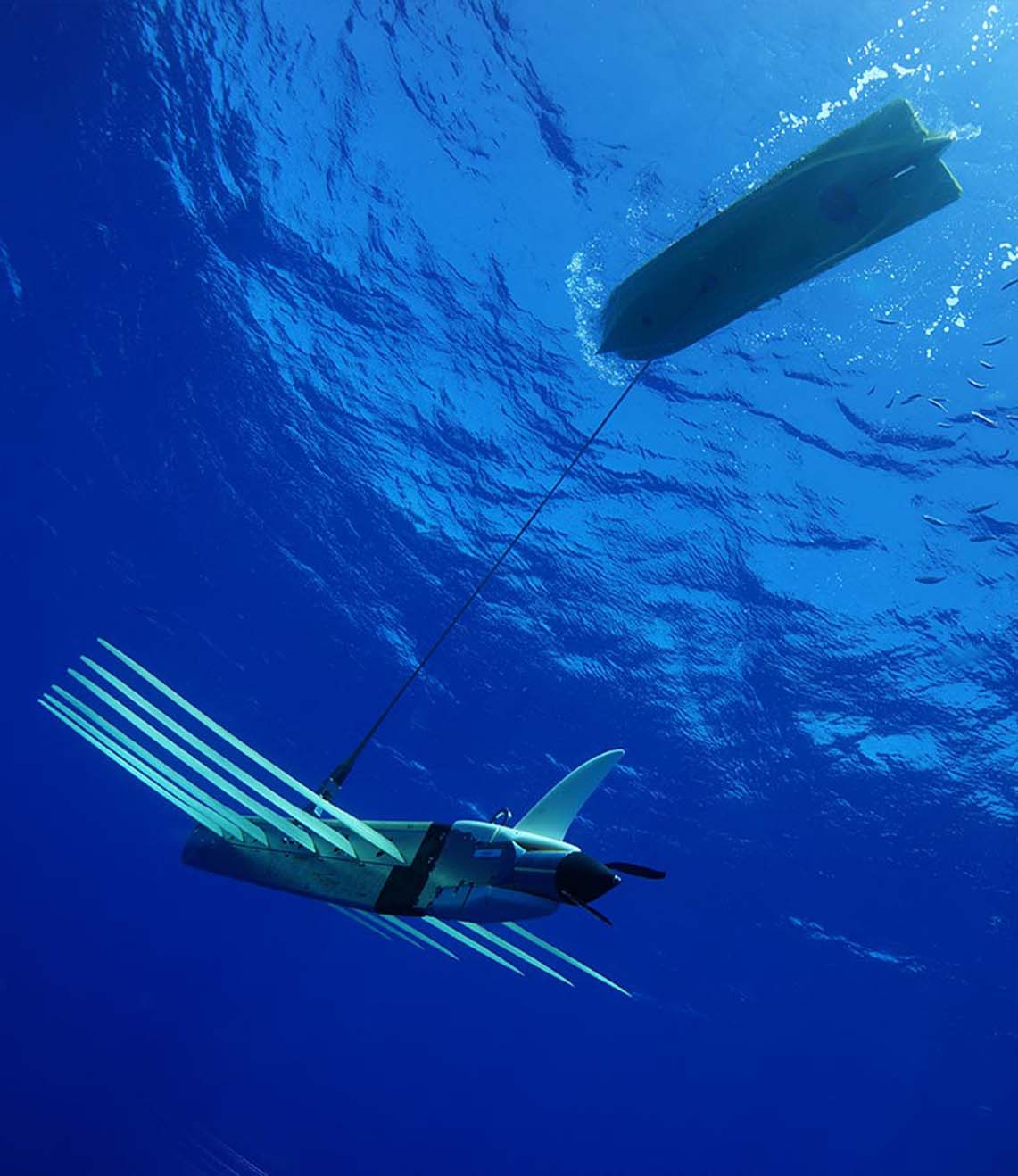

For defence

Specialist military technology requires specialist evaluation and that’s where our facility can help; making sure it is safely pushed to the limit so that your teams can rely on it.

For science

We can test your science equipment to 6,300 metres (20,670 feet, 630 bar) to simulate exploring and gathering data from some of the deepest places on the planet.

Overview

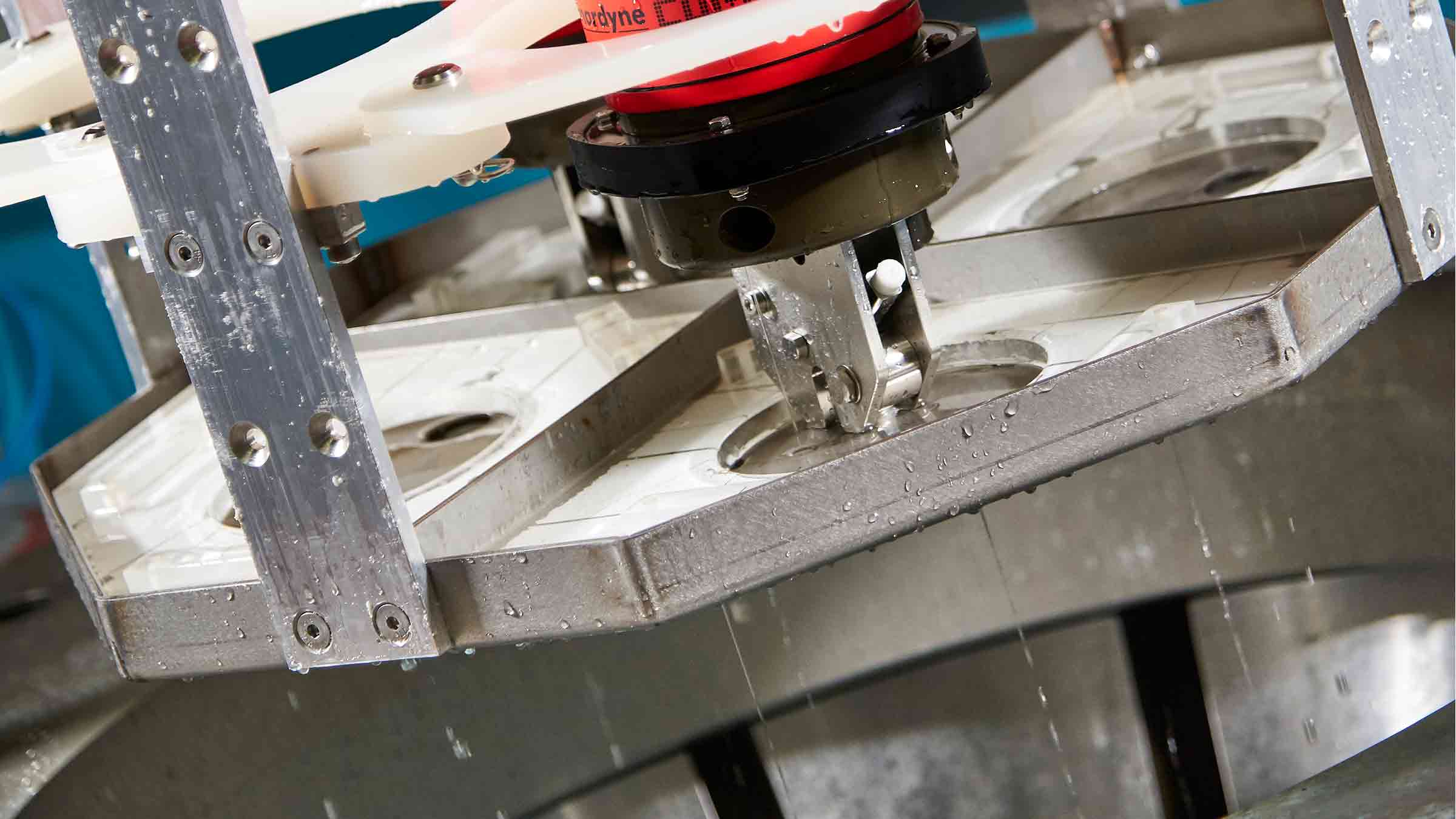

Our hydrostatic pressure chamber, one of the largest of its type in UK, is available to put your underwater products and systems to the ultimate test – over 6,000 metres water depth infact. It’s helped test everything from sports cameras to industrial sensors, and it can be hired to help you too.

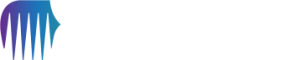

With an internal diameter of 0.76 metres and an internal height of 2 metres, the chamber can accommodate large single instruments or multiples of smaller instruments at the same time. Equipment under test can be interfaced via six breakout ports which can be adapted to suit client specific connectors, allowing full communications with the equipment whilst under pressure. The chamber is filled with tap water mixed with a corrosion inhibitor.

Test against your industry standards

The control system for the chamber can be programmed to meet the requirements of specific industry standards including pressure cycling, ramping and holding. Ramp rates of up to 50 bar/min can be programmed and pressure inside the chamber logged. A dedicated engineer supervises all testing activities and can provide you with a full report which includes applied pressure graphs, test certificates and photographic records.

Equipment can be easily unloaded by forklift and manoeuvred into position by a motorised, remotely controlled overhead crane rated to 2.5 tonnes. Guest Wi-Fi access is available, along with technical advice from Sonardyne’s highly experienced electro-mechanical design engineers if required.

Why this service

Specifications

-

6,300 max simulated depth (630 bar, 9,137 psi)

-

168 hours dwell time

-

Custom connectors can be used via 100mm breakthroughs

-

Automatic ramp and hold with 40 separate profile operations

-

Calibrated pressure transducers and full data logging capability

-

Pressurisation / de-pressurisation control rates of 10 to 50 bar/min

What’s included

-

Fixed priced per day

-

Half day minimum hire

-

Exclusive use of the facility during your hire period

-

Dedicated engineer to run your test

-

Access to our guest facilities; including free Wi-Fi

-

Expert, friendly advice on hand

Products tested include

-

Consumer sports cameras

-

Underwater enclosures

-

Industrial sensors

-

Dive watches

-

Underwater cables

Logistics

-

Secure, dedicated test facility

-

Facility conveniently located close to major transport routes

-

Easy unloading; forklift and 2.5 tonne crane in operation

-

Full technical and engineering support available on-site

-

Remote participation of testing possible