Deepwater data analytics – asset monitoring at the edge

Client: Oceaneering

Thousands of kilometres of pipeline, flowline, and interconnecting spool pieces are installed on the world’s sea and ocean floors. They create vast networks and their design can be complex, having to account for a huge array of variables, from water depth to expected flow composition and behaviour.

The challenge

Sometimes, it’s not always possible to account for all of the variables that an oilfield infrastructure is subject to. This can lead to issues. External vortex induced vibration (VIV) or internal flow induced vibration (FIV), which can sometimes be caused by slugging. Slugging is created by variable or irregular flow of gas and fluids through risers, pipelines, flowlines or spool pieces.

These issues can cause problems for process equipment, impact production efficiency and, critically, accelerate pipeline fatigue. This has knock-on effects for design life. It can even cause pipelines to be displaced, entrenched or erode the supports they stand on.

When FIV occurs, pipeline engineers need all the information they can get about just how much this is happening and to what degree. This enables them to re-calculate the remaining fatigue life of the infrastructure and decide on the best remediation methods. Unfortunately, monitoring exactly what is happening – what forces the pipelines, flowlines or spool pieces are being subjected to – can be challenging, especially in deep water.

International subsea engineering company Oceaneering International Inc. was asked by an operator to solve this exact problem. They had a number of spool pieces deployed in more than 1,000 metres of water, running between riser bases and flowline termination assemblies. They were being subjected to sudden and frequent slugging movements.

These movements had already resulted in new spool piece supports having to be installed. The operator’s engineers needed to assess the resilience of the new supports and learn more about the vibration the spool pieces were encountering. The challenge was that no motion monitoring sensors had been fitted prior to commissioning. The solution would need to provide accurate and accessible data using a technique that was not cost-prohibitive to install and operate.

The solution

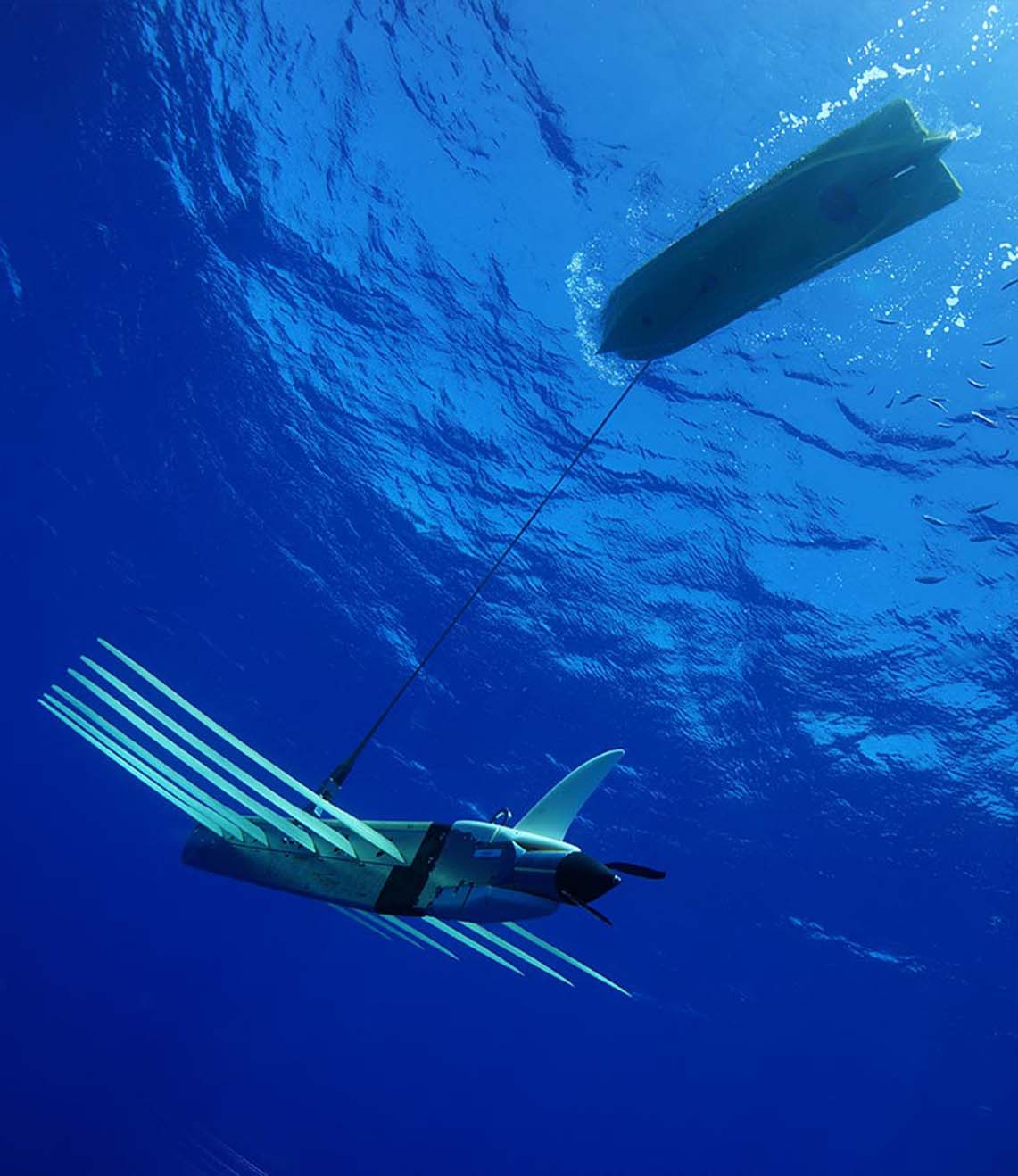

Oceaneering’s solution used an innovative, wireless approach with Sonardyne’s Subsea Monitoring, Analysis, and Reporting Technology (SMART) sensor as a key element of the project.

SMART sensors are, well, smart. They contain low-power MEMs-based (micro-electric mechanical systems) inertial measurement units (IMUs), subsea processing power and integrated acoustic modem capabilities. This means they can autonomously measure, log and process high-frequency, pipeline or spool piece acceleration and angular rate motion over pre-programmed monitoring intervals.

Importantly, SMARTs, which can be integrated with many different subsea sensors to suit a wide variety of applications, process data at source. This is then sent as small statistical summary packets of data – based on parameters set by the user – through the water column to a surface transceiver. This method reduces the need to send time-series, or raw, data up to the surface for analysis, which prolongs battery life, maximizes bandwidth availability and provides useful information to engineers faster. It’s edge analytics and subsea communication technology in one battery-powered autonomous compact unit. And it’s able to work on extended deployments down to 7,000 metres water depth.

For the high-frequency motion, SMARTS were installed on each spool piece at a location between the riser and flowline termination assemblies. To monitor lower frequency movement on one of the spool pieces, another Sonardyne technology was used: Autonomous Monitoring Transponders(AMTs).

AMTs are most commonly used for long-term survey and monitoring tasks where instruments are needed for acquiring acoustic ranges and sensor data without surface control. They time-stamp data and log it internally, to be retrieved when it’s needed at the surface.

By creating a Long BaseLine (LBL) array of “static” AMTs, to which “mobile” AMTs installed on a spool piece and fitted with sound velocity sensors can range, highly precise measurements of any horizontal movement of that spool piece can be monitored and logged. By fitting the mobile AMTs with Digiquartz pressure transducers, vertical motion could also be tracked accurately within the array.

Before installing the SMARTs and AMTs, Oceaneering surveyed the seabed location. This was done to determine the LBL array design and SMART and mobile AMT positioning. Oceaneering designed and built ROV-installable spool monitoring clamps. This allowed the SMARTs and AMTs to be easily attached to the spool pieces. For the LBL array, four AMTs were placed in tripod stands at predefined locations for optimal ranging.

Following installation, confirmation that all the SMARTs and AMTs were working and a post-installation survey, the autonomous and intelligent instruments were then just left to do their work. A huge benefit of both instruments’ design is that they can be left unattended for three years thanks to their internally monitored lithium primary cells.

Anyone with these instruments deployed in their field has a choice in how to collect the data generated. If it’s close to a topside facility, they can deploy a Sonardyne Dunker 6 transceiver permanently, via a deployment pole for the duration of the monitoring, or temporarily over-the-side, via a winch or A-frame.

If the subsea infrastructure is more remote, they could periodically send a support vessel or an unmanned autonomous surface vessel with a Dunker 6 to harvest the data. For this project, while the site was deep, it was close enough to the customer’s production facility. Oceaneering chose temporary deployments, using the Dunker 6 from an onboard crane, as and when data collection was required.

The results

Since commissioning in the summer of 2018, continuous SMART monitoring of the spools, at four-minute intervals has taken place. Packets of data from both SMART and AMT devices, including raw runtime data, have routinely been sent to the surface. Once received, it has been analysed and used in predictive modelling. This has enabled the operator to calculate the accumulated fatigue and remaining operational design life of their assets.

Gaining access to the spools’ motion characteristics has been invaluable to the operator. It’s data they would have been expensive to access through other means. It has led to a deeper understanding of each spool’s motion frequency, rotation angles and cycle times. Where previously the operator had concerns about the remaining operational life of the spools, they now know the operational life is within the limits of the productive life of the field.

This is a great result for the operator, but also for Oceaneering and Sonardyne. By working together we were able to find a cost-effective and viable solution for the operator and future customers with similar challenges. By combining our expertise and flexible instruments as an integrated solution, the supply chain is able to tackle operators’ deepest challenges, quite literally.

Authors

Christopher Boler

Project Manager – Subsea Projects Group, Oceaneering

Stephen Auld

Global Business Manager, Sonardyne International Ltd.

Have you got a similar project?

Challenge us to solve your problem