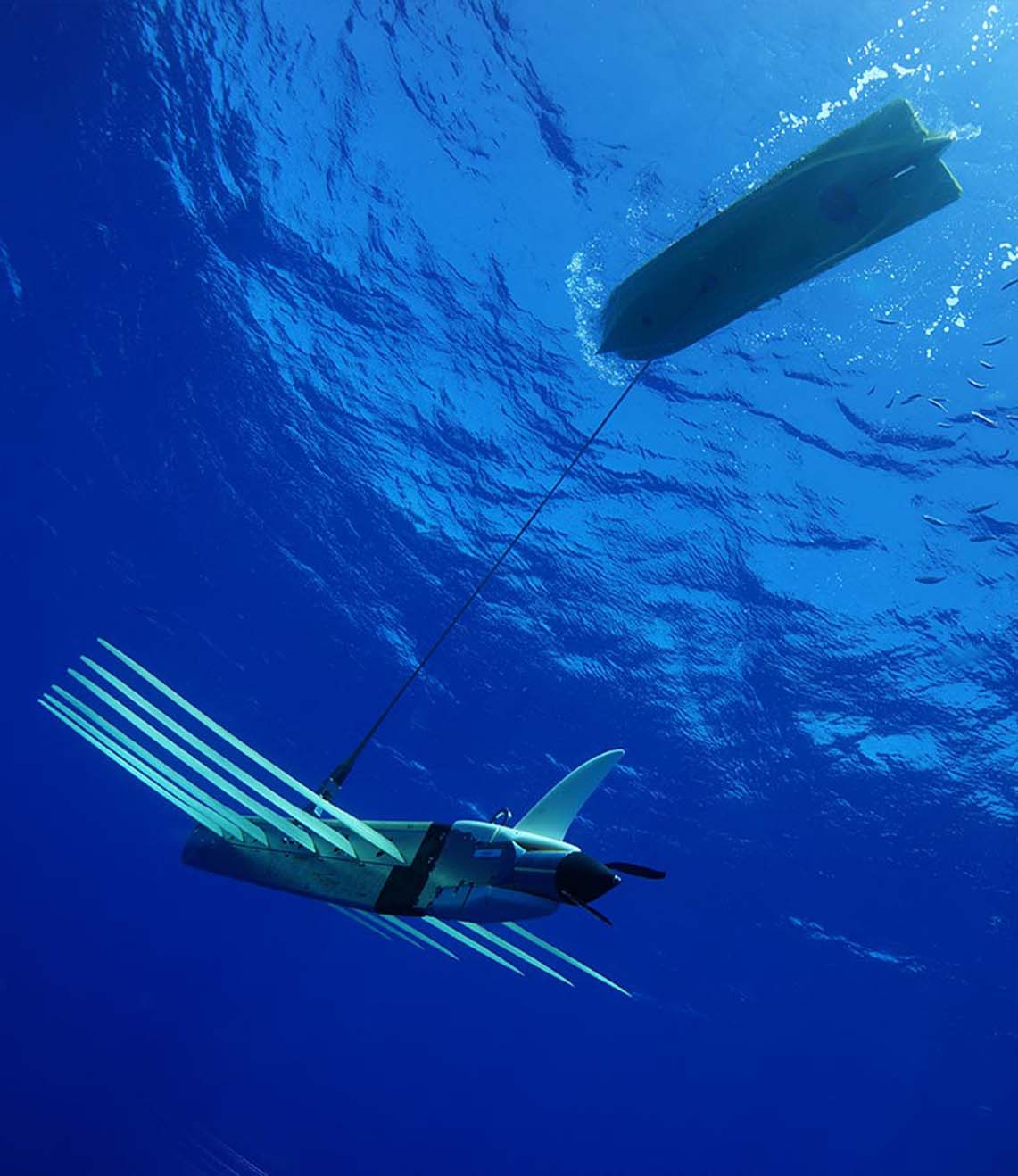

Robotic inspections ensure fish nets are securely anchored.

Aquasky Ltd

With precise positioning a priority in fish farm mooring maintenance, Aquasky Ltd needed a reliable tracking system for their remotely operated inspection vehicle (ROV). Find out how Micro-Ranger 2 proved equal to their challenge.

The challenge

In aquaculture, second only to the welfare of the fish, the maintenance and exact positioning of the nets and their moorings is critical. With specific areas set aside for fish farms, it’s important that the nets don’t drift out of place or into shipping lanes. To maximise production, fish farmers need to moor as many nets as possible within their area whilst ensuring the moorings don’t damage each other. All of this requires careful and precise placement and inspection, which is where Aquasky Ltd excel.

Aquasky Ltd first operated as a small diving company servicing local fish farms along the west coast of Scotland. During 2011/13 it branched out into moorings inspections using a Videoray Pro 5 ROV. They continued to grow and now provide their services to all the major fish farm companies operating in Scotland plus some others abroad.

As the aquaculture industry has grown so has the size and complexity of its subsea equipment. Aquasky Ltd use an ROV to inspect mooring lines and anchors is to verify their integrity and location. The number of anchors can vary from 26 to over 60 for each site depending on the size of the farm.

We needed an accurate positioning system that continues to work as mooring lengths increase and in a noisy subsea environment. Having used other cheaper systems, the Micro-Ranger 2 is the only one able to consistently supply reliable positions for anchors at the 300m length currently used by the farms we service.

Steve Barlow, Founder, Aquasky Ltd

Accurate identification of anchor positions is essential. Farmers must ensure assets remain within their lease areas as moving outside can lead to suspension of the lease, with significant financial impact.

It is also essential to maintain separation between moorings to prevent any damage. Anchors being incorrectly positioned can result in the following causes of mooring failure: –

- Anchor chains rubbing through the mooring ropes.

- Mooring ropes contacting rocky reefs and rubbing through.

- Moorings being positioned where the anchors cannot locate firmly into the seafloor, for example on clean rock.

In the event of mooring failure, movement of the cages can initially result in the nets coming into contact with the submerged farm grid system. The nets are then squashed, and the fish are forced into a very small area with reduced oxygen available, resulting in them becoming stressed and dying.

In the event of catastrophic failure, cages can break away and drift ashore or out to sea, resulting in the fish escaping into the wild population.

As part of the inspection process, Aquasky provide their clients with detailed reports confirming the location and condition of the moorings.

In order to meet their requirements, Aquasky needed a positioning system that was accurate, compact enough to fit on a small ROV, reliable and portable so that it could be transported to and used in all of their clients’ locations, including those abroad

Featured in this story

Micro-Ranger 2 USBL

The solution

Portable and quick to mobilise, our Micro-Ranger 2 USBL system can be used from any waterside location or vessel to track divers, underwater vehicles and equipment. Ideal for using in lochs and challenging water.

It is our smallest ever underwater tracking system. Everything is engineered to fit in one medium-sized carry case. Apart from a laptop to run the software, nothing else is needed and the size is so small, it can be carried on a plane. Perfect for when Aquasky find work outside of Scotland.

For their anchor and mooring inspections, Aquasky attach a Micro-Ranger 2 Nano transponder to their ROV which then travels around the fish farms. A transceiver is mounted on a vessel nearby and acoustic signals between the transponder and transceiver are used to establish the ROV’s, and therefore the anchor / moorings, position. This position can be displayed for in-water tracking and output in real world co-ordinates for interfacing into external chart plotting systems for the clients reports.

“We needed an accurate positioning system that continues to work as mooring lengths increase and in a noisy subsea environment. Having used other cheaper systems, the Micro-Ranger 2 is the only one able to consistently supply reliable positions for anchors at the 300m length currently used by the farms we service.“ Steve Barlow, Founder, Aquasky Ltd

The results

By adding Micro-Ranger 2 to their subsea inspection tool kit, Aquasky Ltd are able to provide a service that has become the industry standard for fish farm inspections. Their use of an ROV means that inspections are quicker, safer and less expensive than traditional diver inspections. Using Micro-Ranger 2 ensures that the ROV never gets lost and provides accurate data which is vital for the inspection reports.

Aquasky’s use of our Micro-Ranger 2, is a great example of its versatility for application in a different marine market sector. Using it for their ROV operations has allowed Aquasky to set the industry standard for fish farm monitoring and inspections. We are delighted to have supported them in doing this and look forward aiding their future operations.

Alan MacDonald, Head of Sales, UK, Europe and Africa, Sonardyne

If you have a similar challenge that needs a subsea tracking solution, give us a call.

Micro-Ranger 2 USBL Stats

- Up to 5% of slant range system accuracy

- Up 10 targets tracked, sequentially

- 995 m maximum tracking range

- 3 Hz position update rate

Have you got a similar project?

Challenge us to solve your problem