What makes a successful bundle tow?

Since 1993, we’ve worked with seabed-to-surface engineering, construction and services contractor, Subsea 7, supplying them with acoustic monitoring and positioning technology to support the tow-out and installation of prefabricated pipelines for the North Sea.

Since 1993, we’ve worked with seabed-to-surface engineering, construction and services contractor, Subsea 7, supplying them with acoustic monitoring and positioning technology to support the tow-out and installation of prefabricated pipelines for the North Sea.

The start of this year was no different and in the last few weeks, one 3.8 kilometre bundle for a field 300 kilometres north-east of Aberdeen and two 2.47 kilometre bundles for a UK based operator have been delivered. Pipeline bundles integrate all the components (valve work, pipeline and control systems) required to operate a field within one single steel carrier pipe. Incorporating everything within one structure offers substantial cost savings as offshore operations are minimised.

Each pipeline bundle is assembled at Subsea 7’s unique onshore fabrication facility at Wick, Scotland where rail tracks run from almost eight kilometres inland straight into the sea.

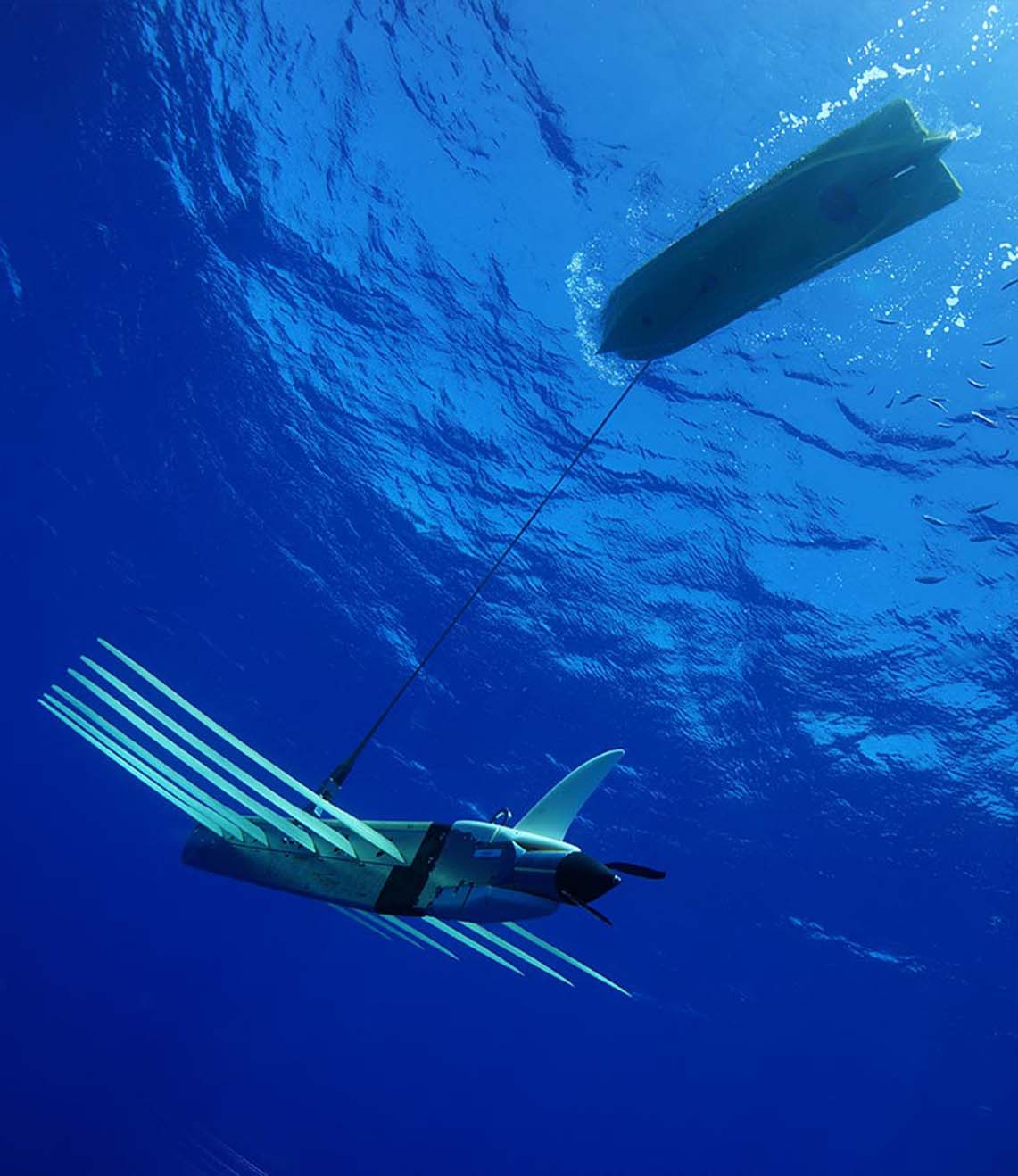

Once assembled, each bundle is pulled off the beach and transported to its offshore location suspended between two tow vessels. All stages of launch, tow and laydown on the seabed require continuous real-time monitoring of the bundle assembly to prevent unnecessary strain and stress being placed upon it.

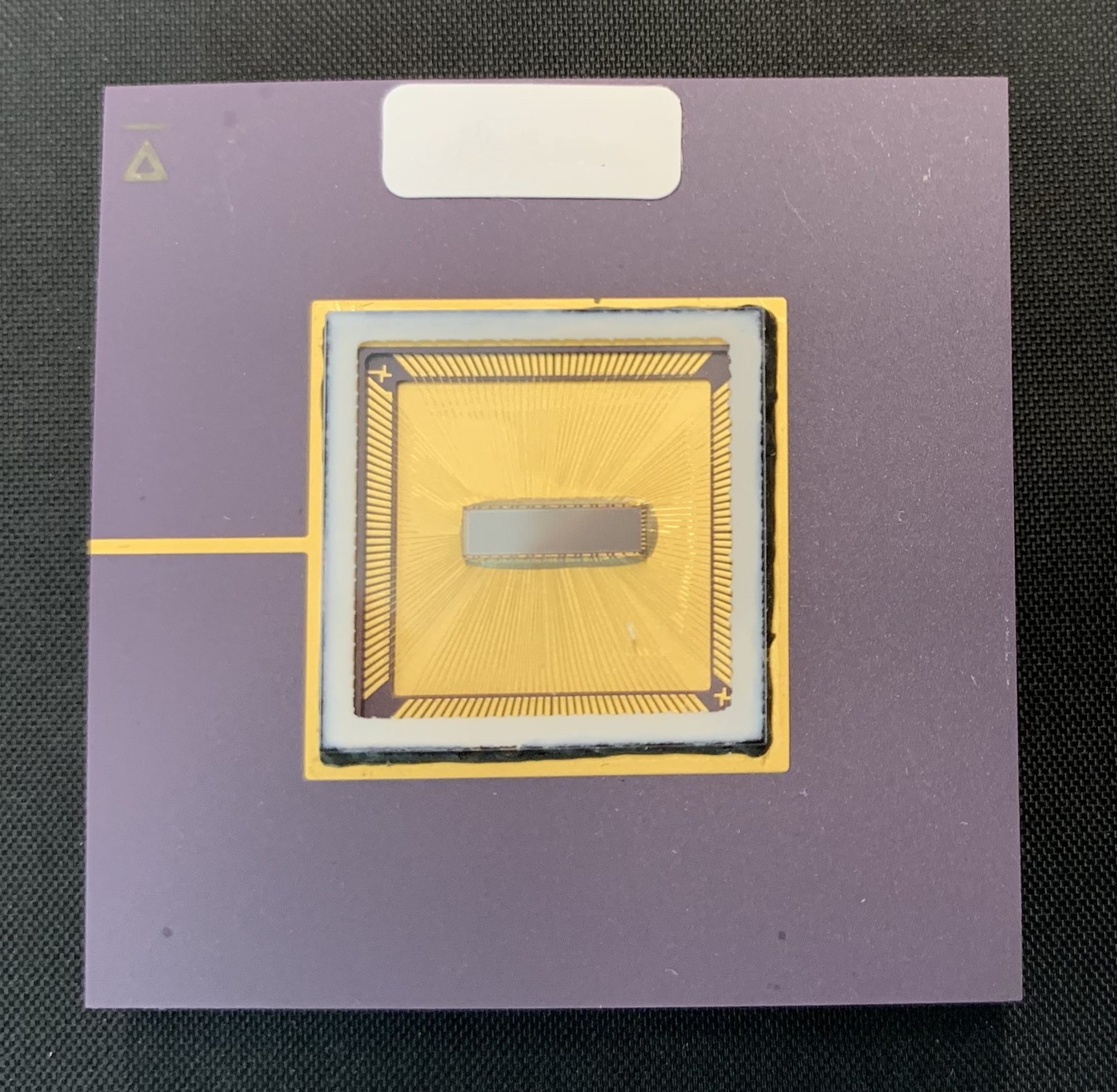

Depth, heading, internal pressure and tow wire angle all need to be checked. To achieve this, specially configured Compatt 6 transponders are installed at regular intervals down the entire length of each bundle. Each one is fitted with a Data Highway Module (DHM) which interfaces with the bundle’s own internal data highway. This allows each Compatt to measure depth at its location and then communicate the data, via the data highway, to a designated ‘master’ Compatt mounted on the bundle.

Heading data for each bundle is collected by three pipe-mounted subsea Lodestar AHRS units – each interfaced to a Compatt. Additionally, two pressure sensors provide carrier pressure at each end of the bundle and one sensor provides tow wire angle; all are interfaced to the bundle’s highway – again via the Compatts’ DHM.

Heading data for each bundle is collected by three pipe-mounted subsea Lodestar AHRS units – each interfaced to a Compatt. Additionally, two pressure sensors provide carrier pressure at each end of the bundle and one sensor provides tow wire angle; all are interfaced to the bundle’s highway – again via the Compatts’ DHM.

During a tow, the master Compatt 6 acoustically transmits data every 20-40 seconds to a towfish deployed from the survey vessel. Software developed by Subsea 7 provides the Tow Masters with a graphical representation of the bundle’s catenary, together with a histogram of its depth. This enables the actual in-flight profile and shape of the bundle to be regularly updated, and allows the Tow Masters to make operational adjustments during transportation to the field. It also ensures it ‘flys’ at the required depth to avoid submerged objects.

Upon arriving on-site, the bundle is correctly oriented using acoustics, before the bundle is vented to allow it to settle on the seabed.

Commenting on another successful season with Subsea 7, Nick Street, Senior Projects Manager at Sonardyne said, “We’ve now clocked up our 20th project using 6G; a great track record and one we hope keep building upon in the future.”

Want to find out more about this article?

Speak to an expert