Long endurance monitoring of tectonic motion

Subduction zones are tectonic plate collision boundaries where typically higher density oceanic crust is being pushed under continental crust. This is one of the most important processes in the evolution of the Earth’s morphology.

The challenge

Subduction zones comprise extremely large thrust faults, known as megathrusts, and are the source of the world’s most dangerous volcanoes and earthquakes. In between larger earthquakes, megathrusts comprise complex heterogeneous distributions of locking and therefore strain accumulation.

On land, GPS and laser observations enable precise geodetic measurements. Until recently, the inability to undertake cost-effective complementary observations subsea in the outermost subduction zone offshore, has been a critical flaw. This is where much of the elastic strain build-up and release occurs. Improving scientific understanding of the seafloor movement in these regions is an important basis for future seismic hazard assessment.

The solution

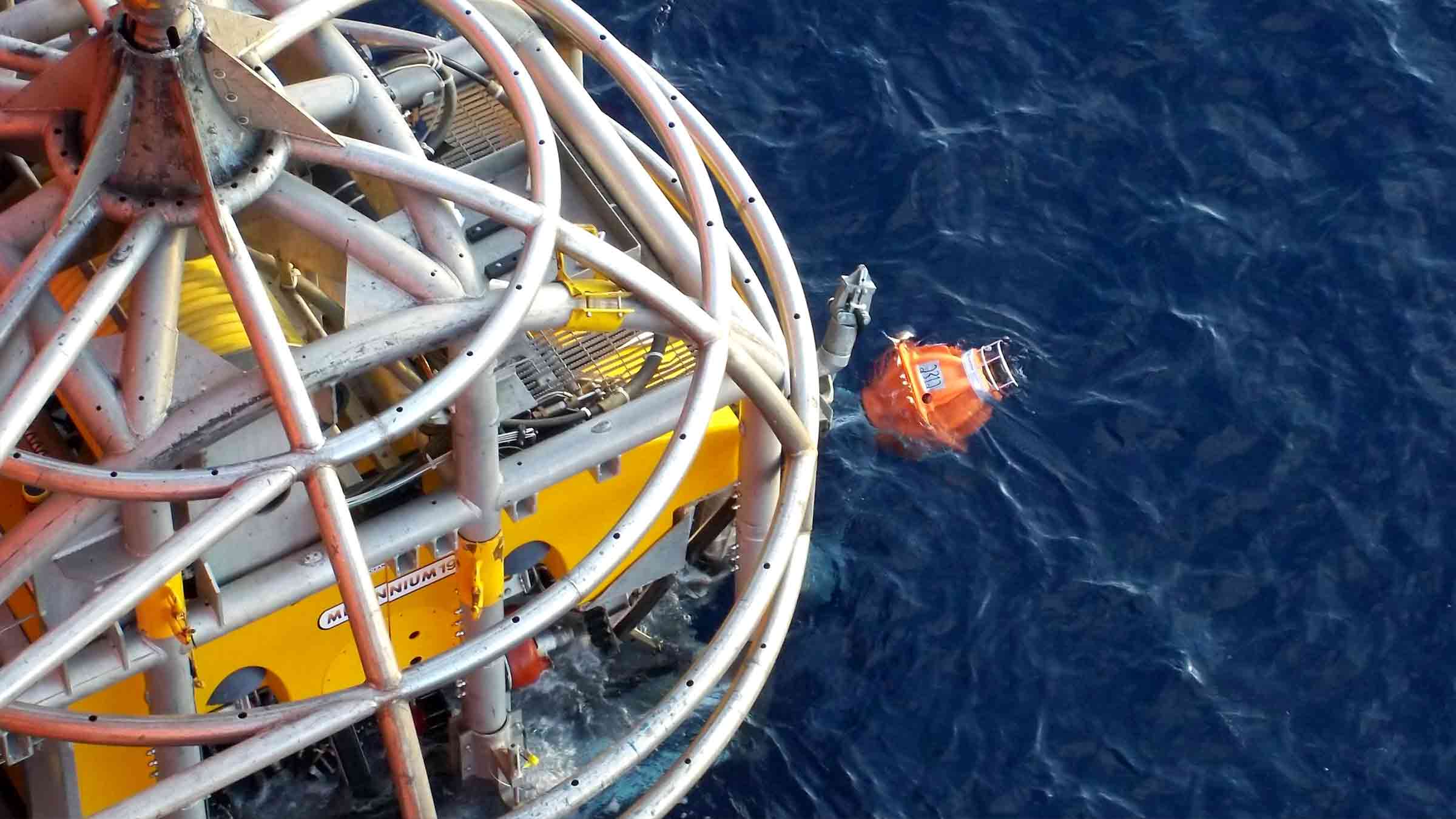

In response to this challenge, Sonardyne has worked with a number of research institutes, including GEOMAR, to supply networks of Autonomous Monitoring Transponders (AMTs ) – seabed instruments that are capable of taking hundreds of thousands of stable, highly precise geodetic observations, safely log the data and on command, wirelessly transmit it up to the surface.

Originally developed for the offshore industry to precisely measure vertical and horizontal seabed displacements caused by reservoir depletion, AMT is a long-life (up to five years depending configuration), deep-rated acoustic instrument fitted with high resolution pressure, sound velocity and temperature sensors. All of this is built around our 6G hardware platform and Wideband 2 digital signal technology.

AMTs run a fully automated logging regime gathering acoustic travel time (range) between neighbouring units, pressure, sound velocity, temperature and tilt data at intervals defined by the user. A passing AUV, vessel of opportunity, gateway buoy or unmanned surface platform can harvest data on demand and at any point, the user may amend the logging regime of any or all of the AMTs, using the bi-directional communications link.

GEOMAR have now deployed three AMT seabed arrays in Chilean seas. The largest array is the Geodetic Earthquake Observatory on the SEAfloor (GeoSEA) project, offshore northern Chile on the Nazca-South American plate boundary.

The last rupture resulting in a major earthquake at the array location was in 1877. This was identified as a seismic gap prior to the 2014 Iquique/ Pisagua 8.1 magnitude earthquake.

Nevertheless, the southern portion of the segment remains unbroken by recent earthquake activity and so, with the two plates converging at a rate of around 65 millimetres per year, new tension is being continuously built up. ‘Therefore the region is a focus site for seismologists to understand strain build-up prior to an earthquake,” says Professor Kopp

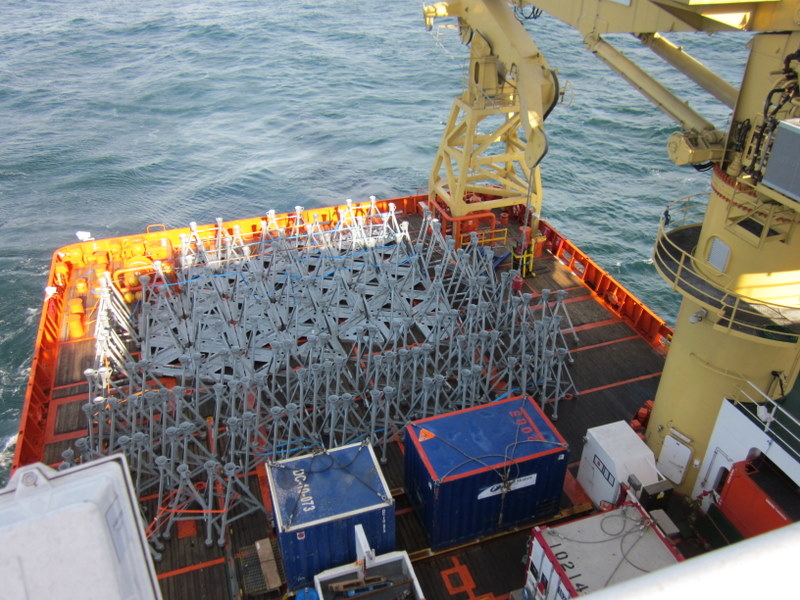

The GeoSEA array consists of 23 AMTs deployed from the German Research Vessel Sonne in late 2015 and comprises three sub-arrays that monitor different sections of the megathrust. The tectonic nature of the seabed gives rise to a variety of complex topographies.

Sonardyne’s in-house Survey Support Group worked closely with scientists from GEOMAR to plan the subarray layouts. Positioning of the AMTs were based on multibeam data collected during the preceding research leg. Precise placement in the order of a few tens of metres was required and in one case, an AMT had to be sited on a ledge on the side of a ridge that was only 50 metres wide and 150 metres long.

The first area is located on the middle continental slope between the main trench and the Chile coast and consists of eight transponders laid in pairs on a stairway-like feature of four topographic ridges at a depth of around 2,800 metres. The ridges, which are surface expressions of faults at depth, are approximately 100 metres high with around an 800 metre flat area between.

On the opposite (seaward) side of the trench from Chile, a further five AMTs were deployed in depths approaching 4,100 metres to monitor extension across plate bending related normal faults. Here, faulting of the Nazca Plate is caused by stretching of its surface as it is pushed downwards under the South American plate, and thus the fault lines are relatively new and active. The AMTs were laid at the intersection of multiple fault lines separating three or four blocks, with two being placed on the same block to provide a sound speed reference baseline.

The deepest area, located between 5,100 and 5,400 metres deep, is on the lower continental slope and comprises a circular pattern of eight AMTs surrounding two central instruments. This pattern provides a variety of short and long baselines to measure diffuse strain build-up in a highly faulted area made up of separate geological blocks, which are under high compression.

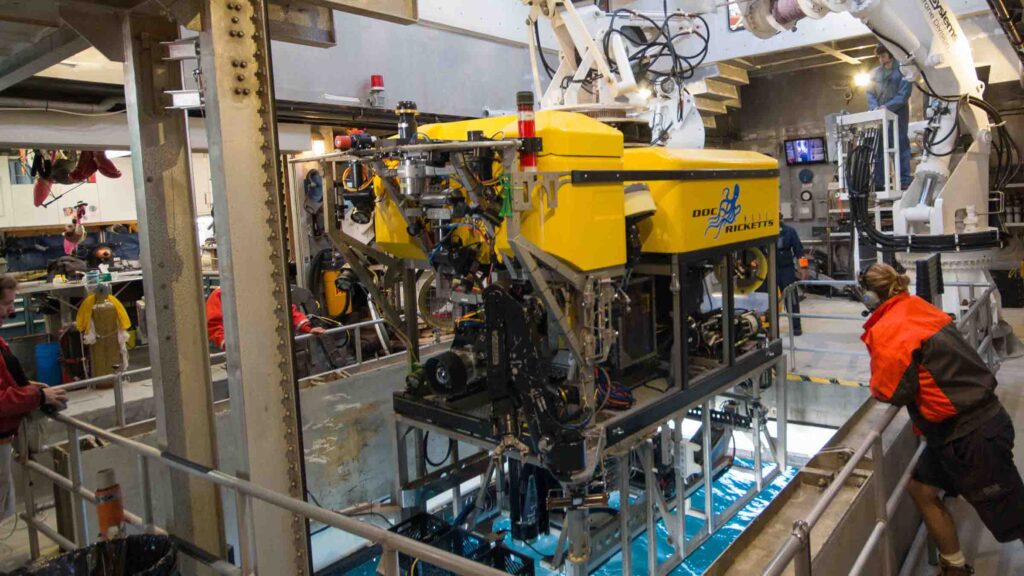

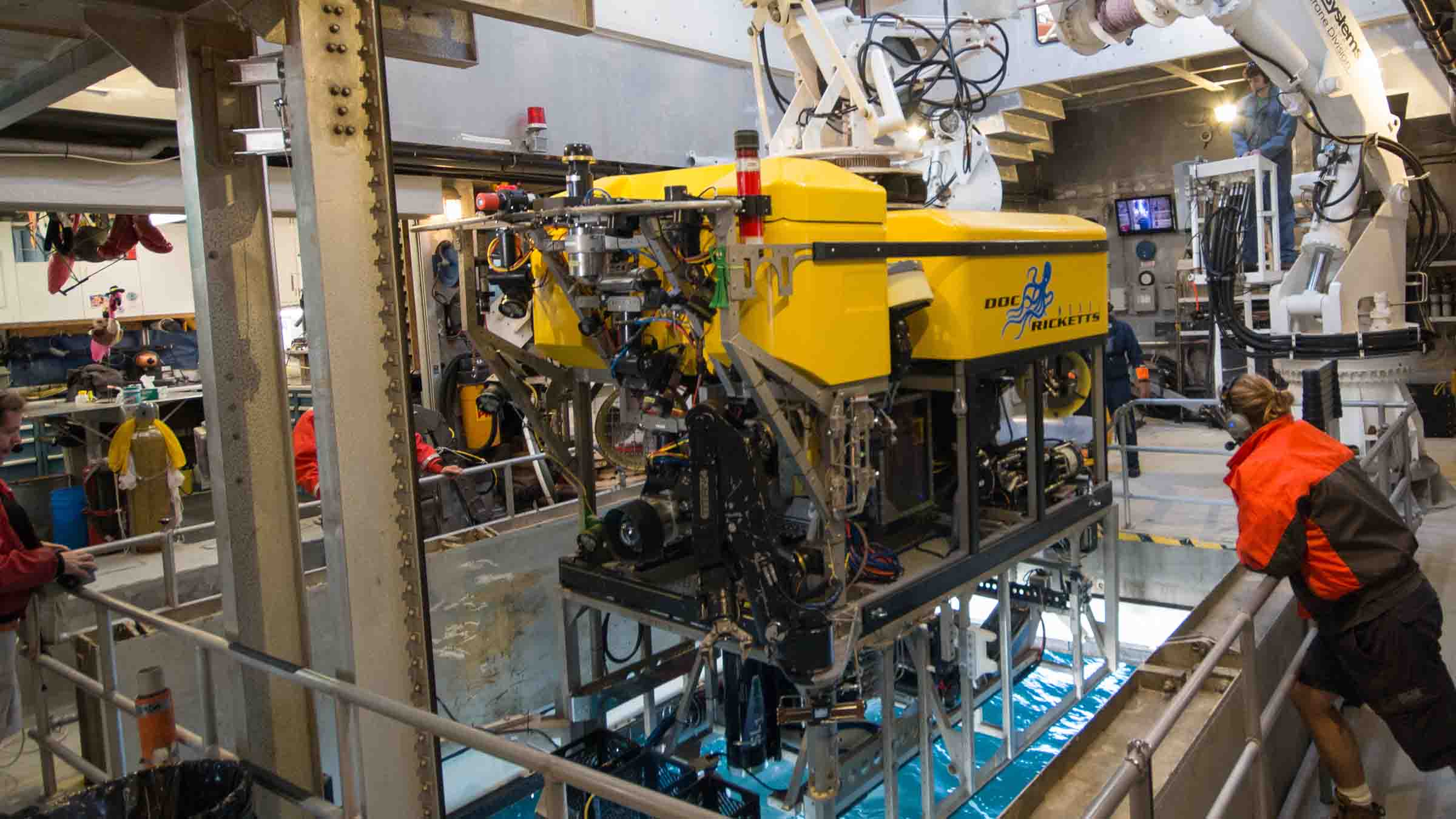

To cope with these extreme conditions, the AMTs used for the GeoSEA project are 6,000 metre-rated Lower Medium Frequency (LMF 14-19 kHz) omnidirectional units. Sampling at rates between one and a half and three hours, the GeoSEA AMTs are planned for an initial three and a half year deployment. However, the four metre high seabed frame in which each unit sits enables it to be easily removed by ROV, returned to the surface to allow its battery to be exchanged then placed back in the frame in the same position – giving scientists the option of extending the survey if required.

The results

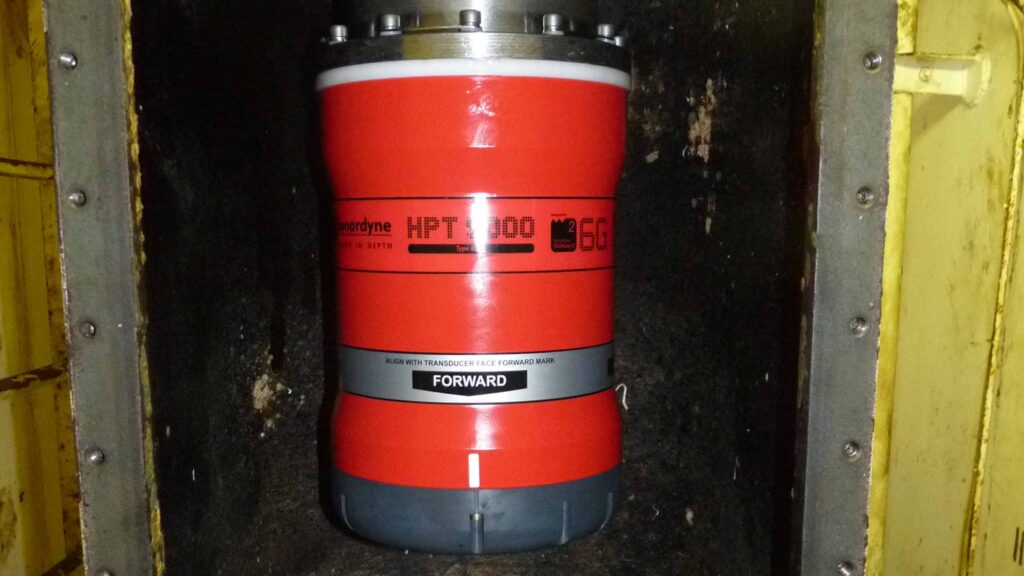

Since initial deployment, data from the array has been recovered by a US research ship using a Sonardyne HPT 7000 dunking modem deployed over the side, as well as GEOMAR’s GeoSURF Wave Glider, equipped with a 6G acoustic communication module fitted in its hull.

“Overall, our experience with Sonardynes instruments is superb and our results have been beyond our expectations. It has been a pleasure for us to work with infrastructure that we can fully rely on.” Professor Kopp from GEOMAR commented.

The success of the AMT’s performance in the Nazca-South American plate boundary arrays has resulted in two smaller arrays in the Sea of Marmara off Turkey and on the submerged flanks of Mount Etna. Although the results of these surveys were yet to be published at the time of writing, scientists were excited by the new opportunities Sonardyne’s technology offers.

GEOMAR’s Doctor Dietrich Lange summarises that, “With this approach, we are taking a new path in earthquake research since previously, measurements of a few millimetres, were hardly possible.”

Deepwater structure installation made easy

For five decades, we’ve been working to make subsea developments safer, cleaner and more efficient than ever before. Our aim is always to mitigate risk for our partners, reduce the complexity of deepwater structure installations and increase efficiencies so projects cost less and teams spend less time offshore.

The challenge

When offshore contractor China Offshore Fugro Geosolutions (COFG) approached us looking for ways to improve the installation of multiple deepwater structures, we were excited to support their operation. The project required the installation of four pipeline end terminations. Measuring up to 15 m long, 10 m high and weighing as much as 45 tonnes each, the challenge was to accurately place each structure efficiently and reduce the time needed for the project to be completed.

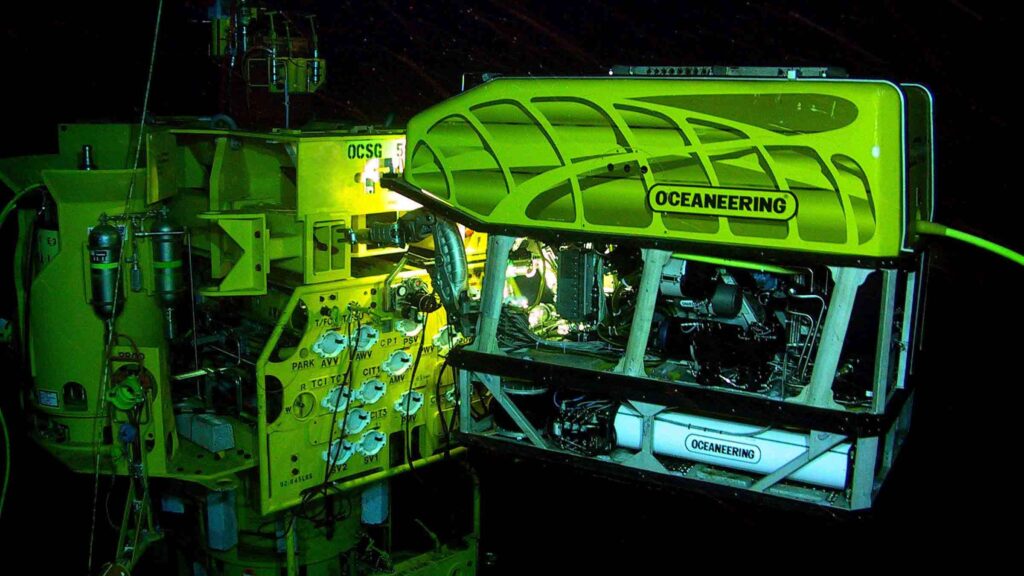

These kinds of deepwater installations are usually done by installing a gyro frame and placing a subsea gyro into it, with a battery, a modem, sound velocity sensor, and maybe also a depth sensor. These then need to be wired up, turned on, and fingers crossed that it’ll all work. The various connections, components and necessary wiring between each, create multiple opportunities for things to go wrong.

The solution

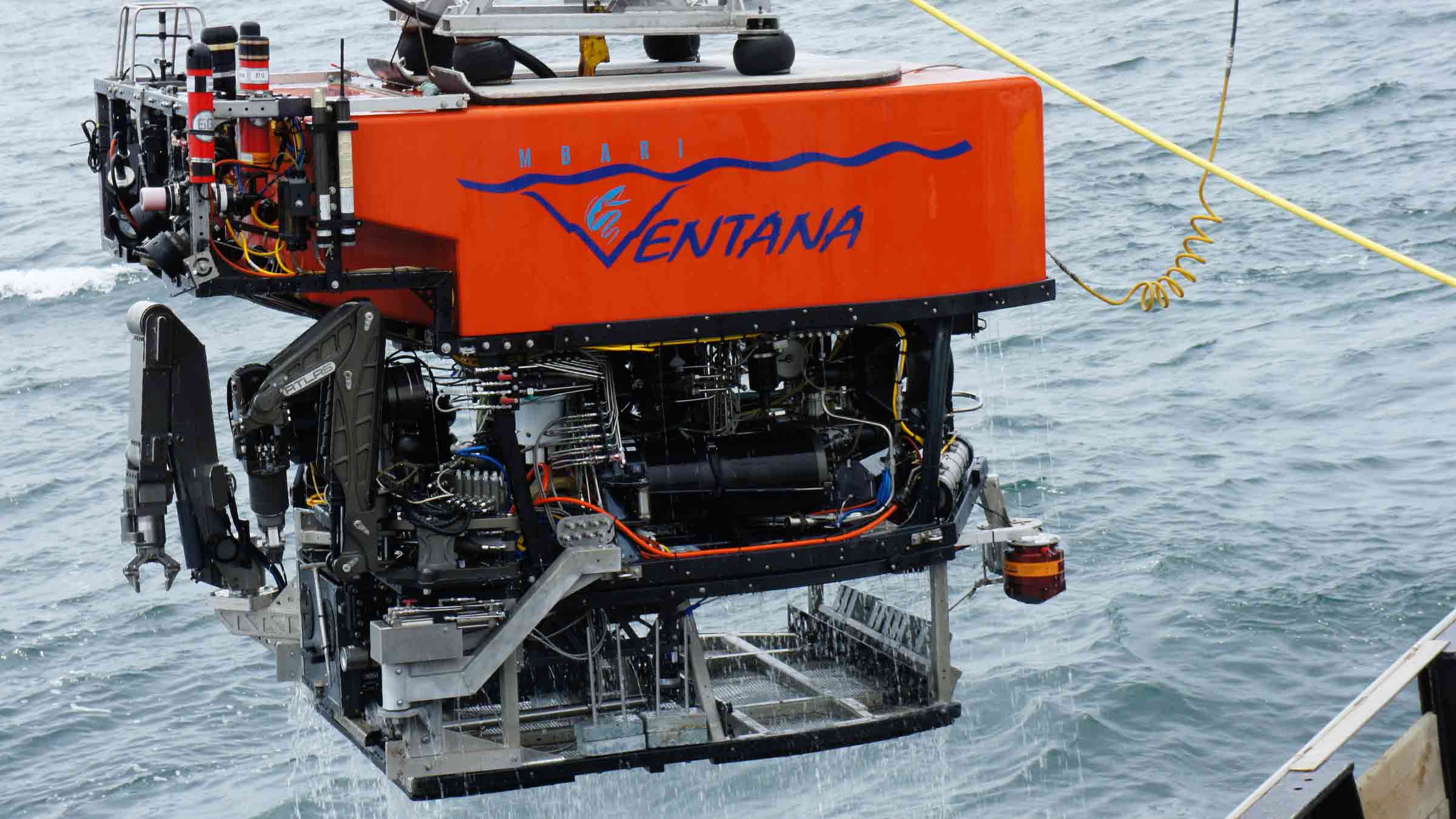

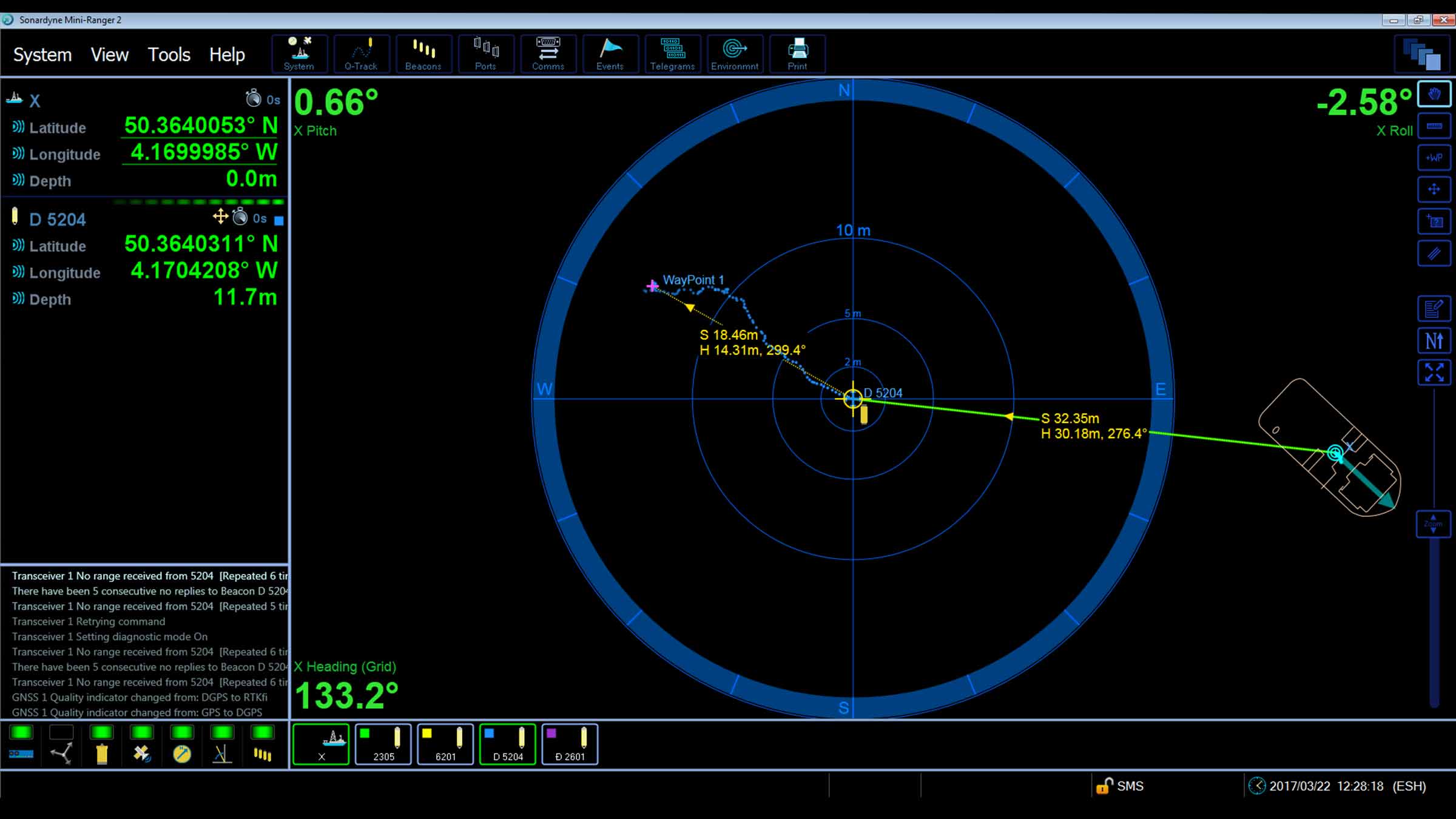

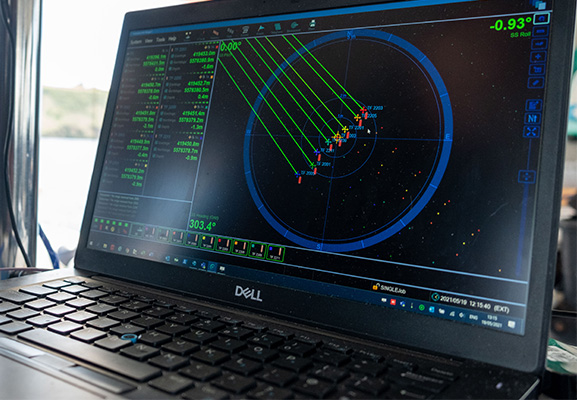

Gyro Compatt 6 is a compact and versatile positioning transponder with a subsea gyro used to simplify structure positioning. From one instrument everything can be monitored and controlled from the topside using our Ranger 2 6G Ultra-Short BaseLine (USBL) positioning system or Fusion 1 or 2 Long BaseLine (LBL) software. What’s more, it’s quick to recharge on deck, making it a perfect choice for multi-structure installation campaigns.

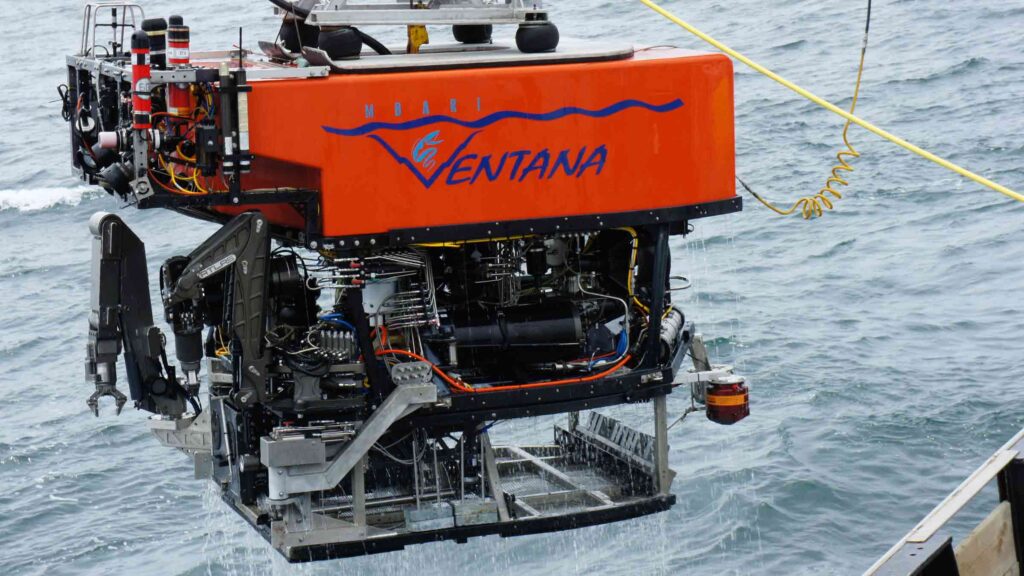

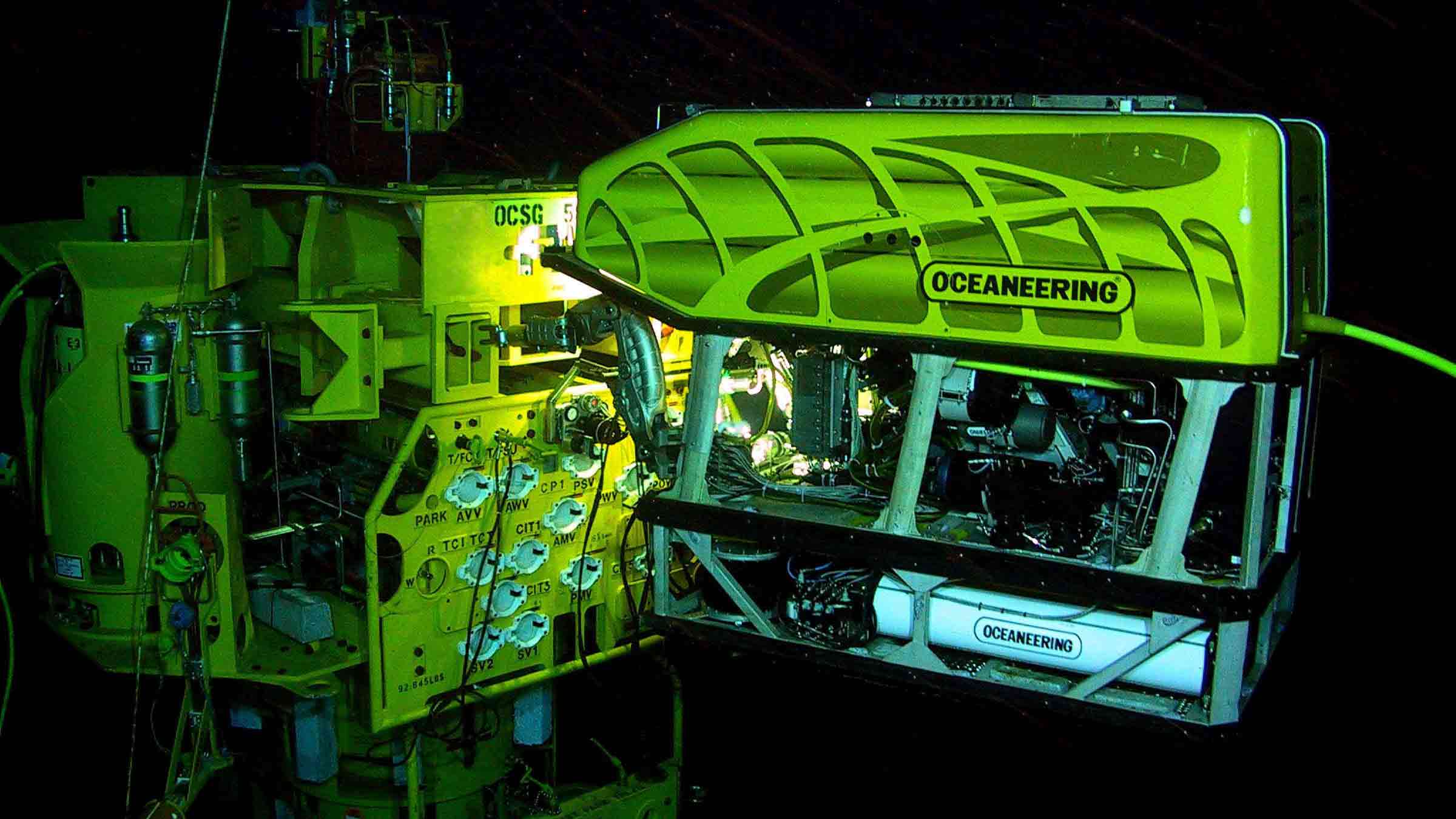

Onboard the HSYS 201, COFG already use our Ranger 2 USBL positioning system, our Fusion LBL software and a ROVNav 6 transceiver onboard their ROV, all of which work seamlessly with our 6G USBL family of products, of which the Gyro Compatt 6 is a part.

This compact unit is much more than a positioning transponder. The unit combines an LBL transponder Wideband acoustic positioning, Lodestar attitude and heading reference sensor (AHRS), a depth sensor and sound velocity, plus an integrated high-speed acoustic modem. By combining these technologies into one small unit, a single yet highly versatile and easy to install instrument can provide high update rate wireless attitude, heading, heave, surge, sway, pressure, sound speed and acoustic positioning of any subsea object.

There is no need for the traditional gyro frame and subsea gyro technique and all the wiring and crossing of fingers that goes along with it. By deploying the Gyro Compatt 6, ranges from the LBL array can be gathered in real time by a ROVNav 6 LBL ROV transceiver onboard the ROV, and, in turn, tracked in the LBL array.

The results

With just the Gyro Compatt 6 installed and secured for structure monitoring, COFG’s installations were successfully carried out on the Liuhua 29-1 gas field development in water depths ranging from 520 m to 1120 m, between mid-October and the end of November 2019. Each of the four installations was made much easier – with reduced stress, fewer complications and in less time.

Jia Wu, Operation Manager, Engineering Survey Division at China Offshore Fugro Geosolutions (Shenzen) Co. was pleased with how their Gyro Compatt 6 performed.

“This all-in-one system offers us the biggest advantage for the operation, being easier to use, smaller in size and more efficient for preparation,” he says. “It is more convenient to secure as well as recover and does not require wiring between components, compared with a conventional gyro basket (transponder plus battery plus gyro).”

Do you need to simplify a deep water structure installation project? Speak with an expert today.

Greater efficiency, lower overheads, with underwater autonomy in deepwater seismic

Shell Brasil, in partnership with Petrobras, Sonardyne and Brazilian research institute SENAI CIMATEC are working together to bring a step-change to 4D seismic data gathering in Brazil’s deepwater pre-salt region.

Discover how we’re collaborating to develop innovative autonomous technology that will make monitoring these challenging deepwater fields more efficient, with fewer people and lower environmental footprint.

Scroll down to read this case study in Portuguese.

The challenge

Seismic data is an essential part of offshore field development activity, especially to support proactive reservoir management and production optimisation. Techniques for gathering this data have evolved dramatically over the decades; from the use of marine streamers for large exploration seismic campaigns to the now routine use of remote operated vehicles (ROV) to deploy ocean bottom nodes (OBN) for high-resolution imaging of pre-salt reservoirs.

Yet, gathering seismic data for pre-salt reservoir imaging remains intensive work. It involves large, costly and carbon-emitting crewed vessels for deployment and recovery of, typically, thousands of nodes. As an example, for a 10-month campaign over one of Brazil’s giant pre-salt fields, a node handling vessel could emit close to 10,000 tons of CO₂. Costly and complex operations can mean a reduction in frequency of surveys, including of those done to gather what’s called time lapse or 4D seismic data, which is required to monitor the pre-salt reservoirs.

Shell and Petrobras came to us believing that there could be a lower-cost, more sustainable, way of acquiring 4D seismic data, as well as other parameters such as seafloor subsidence, to help better monitor reservoirs. They also saw this could be done with a lower environmental footprint and while keeping more people safe.

The solution

Together, Shell Brasil, Petrobras, and Sonardyne joined forces with SENAI CIMATEC to develop an advanced seismic data acquisition system under a Brazilian National Agency of Petroleum, Natural Gas and Biofuels (ANP) promoted research and development project.

At its core is an On-Demand Ocean Bottom Node, or OD OBN. This semi-permanent seabed system is used for the acquisition of high resolution seismic and seafloor subsidence data.

Like conventional seabed nodes (OBN), each OD OBN contains three geophones and one hydrophone, a data recording system, batteries and a highly accurate clock. The sensors detect pressure waves emitted by an airgun source, usually towed by a ship, as they are reflected upwards towards the seabed from the underlying layers of rock surrounding the reservoir.

Unlike conventional nodes, these OD OBNs remain on the seabed, down to 3,000 m, gathering seismic data for up to five years. This significantly reduces the cost of repeated ocean bottom seismic campaigns, as the node handling vessel is removed from the operations. It also reduces the impact on the environment and marine ecosystems.

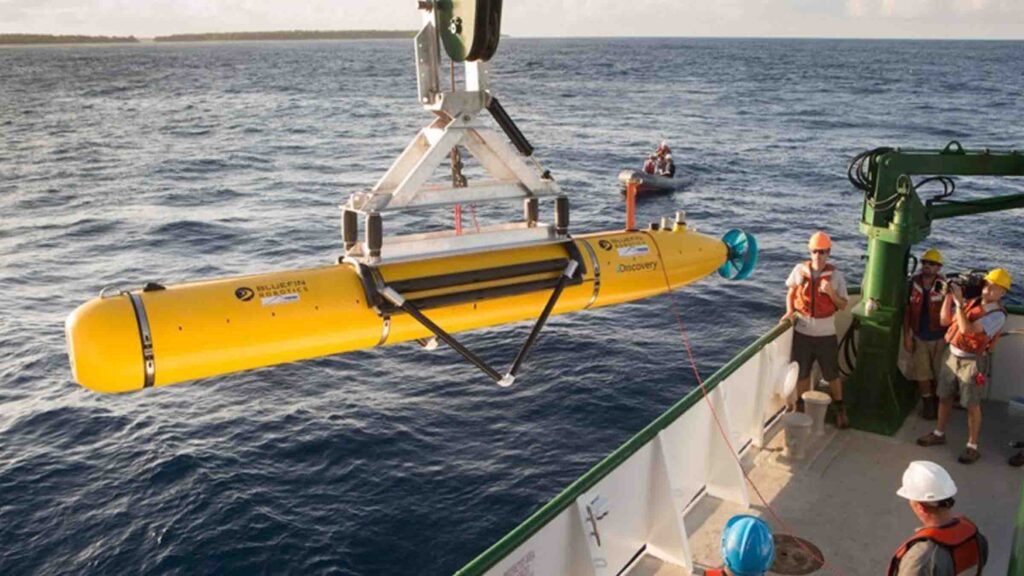

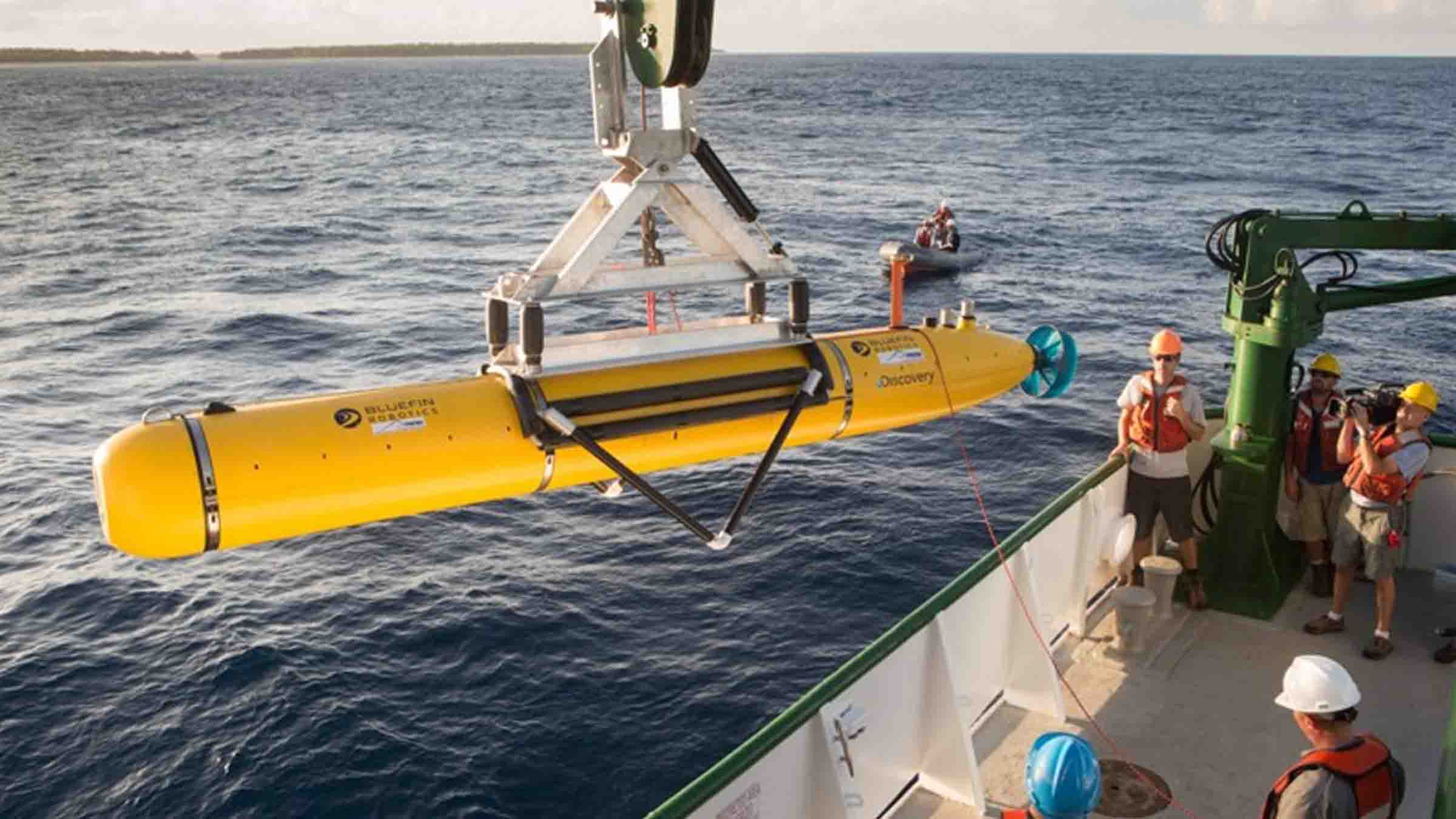

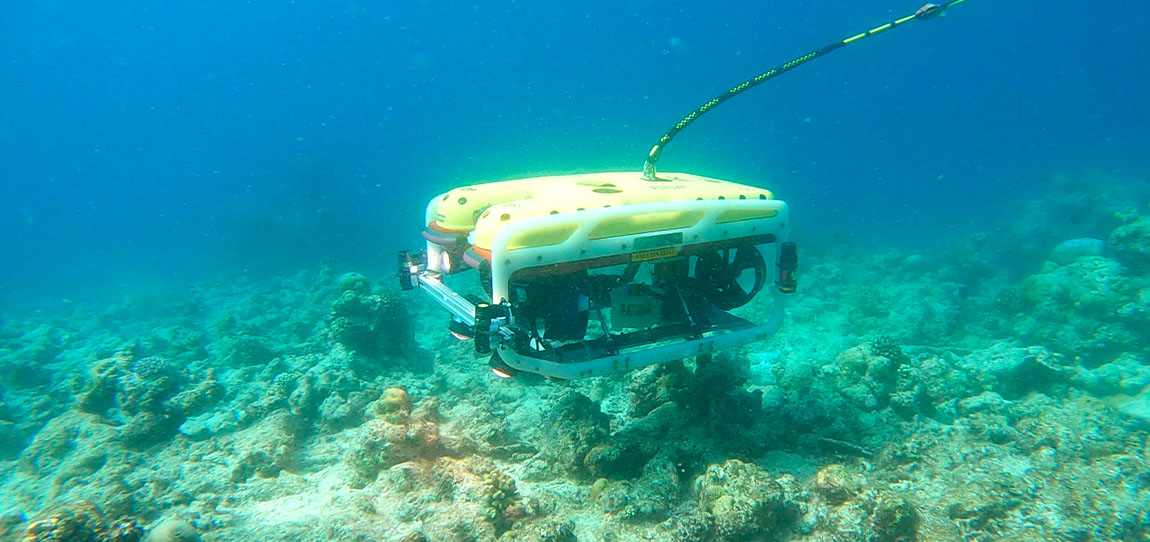

The activation of the nodes, verification of subsidence event alarms, calibration of internal clocks and harvesting of seismic data will be performed using an autonomous underwater vehicle (AUV) called Flatfish developed, in a closely interlinked ANP project, by partners Shell Brasil, Petrobras, SENAI CIMATEC and Saipem.

Flatfish will find each node using Sonardyne’s 6th generation (6G) of acoustic positioning systems. Our acoustics will also support data telemetry with the nodes, for health checks, configuration and acoustic time synchronization. The Flatfish will then hover above each node, in turn. Using an extremely high bandwidth and energy efficient laser-based variant of Sonardyne´s BlueComm optical communications device, it will wirelessly harvest many gigabytes of seismic data in just a few minutes.

This variant uses two rapidly modulated lasers to produce simultaneous bi-directional communications over more than five meters range. It is optimised for peak data transfer performance, with speeds of over 600 megabits per second demonstrated. This makes it excellent for harvesting large amounts of data from seabed nodes.

“Using OD OBN in combination with Flatfish, a 4D seismic campaign in the pre-salt may be executed in a simpler manner, with lower operational cost, lower risk of human exposure and lower environmental impact,” says Jorge Lopez, Manager of Subsurface Technology at Shell Brasil. “On top of this, the nodes also measure seafloor deformation and can continuously monitor for possible subsidence events that may occur during the production of the field.”

The results

In the first phase of the OD OBN project, eight fully functional prototype nodes were built. These comprised of two different concept types and were designed and built by SENAI CIMATEC in Salvador, Bahia together with Sonardyne Brasil.

In 2021, initial tests of seismic data recording were conducted at the Sapinhoá pre-salt field offshore Brazil and interoperability tests between the nodes and the Flatfish AUV were performed in shallow water in Trieste, Italy.

A very intensive laboratory and offshore testing and demonstration program is being conducted over the next 18 months to ensure the OD OBN system meets its operational requirements. This program will increase the maturity of the solution, with tests in pre-salt fields for recording seismic data with the OD OBN prototypes and the communication and data harvesting AUV missions.

In the next phase of the project, starting later in 2022, Shell and Petrobras will sign a new agreement to manufacture 600 nodes and deploy them for three years of reservoir monitoring in a Brazilian pre-salt field.

Maior eficiência, baixo custo de operação, para sísmica em águas profundas através de autonomia submarina

A Shell Brasil, em parceria com a Petrobras, a Sonardyne e o instituto de pesquisa brasileiro SENAI CIMATEC estão trabalhando juntos para trazer uma mudança radical na coleta de dados sísmicos 4D na região do pré-sal em águas profundas do Brasil.

Descubra como estamos colaborando para desenvolver tecnologia autônoma inovadora que tornará o monitoramento desses desafiadores campos em águas profundas mais eficiente, com menos pessoas e menor impacto ambiental.

O desafio

Os dados sísmicos são uma parte essencial da atividade de desenvolvimento de campos offshore, especialmente para apoiar o gerenciamento proativo de reservatórios e a otimização da produção. As técnicas para coletar esses dados evoluíram dramaticamente ao longo das décadas; desde o uso de streamers marinhos para grandes campanhas sísmicas de exploração até o uso rotineiro de veículos operados remotamente (ROV) para implantar nós de fundo oceânico (OBN) para imagens de alta resolução de reservatórios do pré-sal.

No entanto, a coleta de dados sísmicos para imagens de reservatórios do pré-sal continua sendo um trabalho intensivo. Envolve embarcações tripuladas grandes, caras e emissoras de carbono para implantação e recuperação de, normalmente, milhares de nós. Como exemplo, para uma campanha de 10 meses em um dos campos gigantes do pré-sal brasileiro, uma embarcação de manuseio de nós pode emitir cerca de 10.000 toneladas de CO₂. Operações caras e complexas podem reduzir a frequência de levantamentos, inclusive daqueles feitos para coletar o lapso temporal que é chamado de dados sísmicos 4D, necessários para monitorar os reservatórios do pré-sal.

A Shell e a Petrobras nos procuraram acreditando que poderia haver uma forma mais barata e sustentável de adquirir dados sísmicos 4D, além de outros parâmetros, como subsidência do fundo do mar, para ajudar a monitorar melhor os reservatórios. Eles também viram que isso poderia ser feito com um impacto ambiental menor e mantendo mais pessoas seguras.

A solução

Juntos, Shell Brasil, Petrobras e Sonardyne uniram forças com o SENAI CIMATEC para desenvolver um sistema avançado de aquisição de dados sísmicos em um projeto de pesquisa e desenvolvimento promovido pela Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP).

Em seu núcleo está um On-Demand Ocean Bottom Node, ou OD OBN. Este sistema semipermanente do fundo do mar é usado para a aquisição de dados sísmicos de alta resolução e subsidência do fundo do mar.

Assim como os nós convencionais do fundo do mar (OBN), cada OD OBN contém três geofones e um hidrofone, um sistema de gravação de dados, baterias e um relógio de alta precisão. Os sensores detectam ondas de pressão emitidas por uma fonte do tipo airgun, rebocada por um navio, à medida que são refletidas para cima em direção ao fundo do mar a partir das camadas subjacentes de rocha ao redor do reservatório.

Ao contrário dos nós convencionais, os OD OBNs permanecem no fundo do mar, até 3.000 m, coletando dados sísmicos por até cinco anos. Isso reduz significativamente o custo de repetidas campanhas sísmicas no fundo do oceano, uma vez que a embarcação de manuseio de nós é removida das operações. Também reduz o impacto no meio ambiente e nos ecossistemas marinhos.

A ativação dos nós, a verificação dos alarmes dos eventos de subsidência, a calibração dos relógios internos e a coleta dos dados sísmicos serão realizados por meio de um veículo submarino autônomo (AUV) denominado Flatfish, desenvolvido em um projeto ANP estreitamente interligado, pelos parceiros Shell Brasil, Petrobras, SENAI CIMATEC e Saipem.

O Flatfish encontrará cada nó usando a 6ª geração (6G) de sistemas de posicionamento acústico da Sonardyne. Nossa acústica também suportará telemetria de dados com os nós, para verificações de integridade, configuração e sincronização de tempo acústico. O Flatfish irá então pairar acima de cada nó, por sua vez. Usando uma largura de banda extremamente alta e uma variante baseada em laser com eficiência energética do dispositivo de comunicação óptica BlueComm da Sonardyne, ele coletará sem fio muitos gigabytes de dados sísmicos em apenas alguns minutos.

Esta variante usa dois lasers modulados rapidamente para produzir comunicações bidirecionais simultâneas em um alcance de mais de cinco metros. Ele é otimizado para desempenho de transferência de dados de pico, com velocidades demonstradas de mais de 600 megabits por segundo. Isso o torna excelente para coletar grandes quantidades de dados de nós do fundo do mar.

“Usando OD OBN em combinação com o Flatfish, uma campanha sísmica 4D no pré-sal pode ser executada de forma mais simples, com menor custo operacional, menor risco de exposição humana e menor impacto ambiental”, afirma Jorge Lopez, Gerente de Tecnologia de Subsuperfície da Shell Brasil. “Além disso, os nós também medem a deformação do fundo do mar e podem monitorar continuamente possíveis eventos de subsidência que podem ocorrer durante a produção do campo”.

Os resultados

Na primeira fase do projeto OD OBN, doze nós protótipos totalmente funcionais foram construídos. Estes são compostos por dois tipos de conceito diferentes e foram projetados e construídos pelo SENAI CIMATEC em Salvador, Bahia em conjunto com a Sonardyne Brasil.

Em 2021, os testes iniciais de registro de dados sísmicos foram realizados no campo do pré-sal de Sapinhoá no litoral brasileiro e os testes de interoperabilidade entre os nós e o Flatfish AUV foram realizados em águas rasas em Trieste, Itália.

Um intenso trabalho em laboratório e um programa de demonstração e testes offshore estará sendo realizado nos próximos 18 meses para garantir que o sistema OD OBN atenda aos seus requisitos operacionais. Este programa aumentará a maturidade da solução, com testes em campos do pré-sal para registro de dados sísmicos com os protótipos OD OBN e as missões AUV de comunicação e coleta de dados.

Na próxima fase do projeto, a partir do final de 2022, a Shell e a Petrobras assinarão um novo acordo para fabricar 600 nós e implantá-los para três anos de monitoramento de reservatórios num campo do pré-sal brasileiro.

What is possible

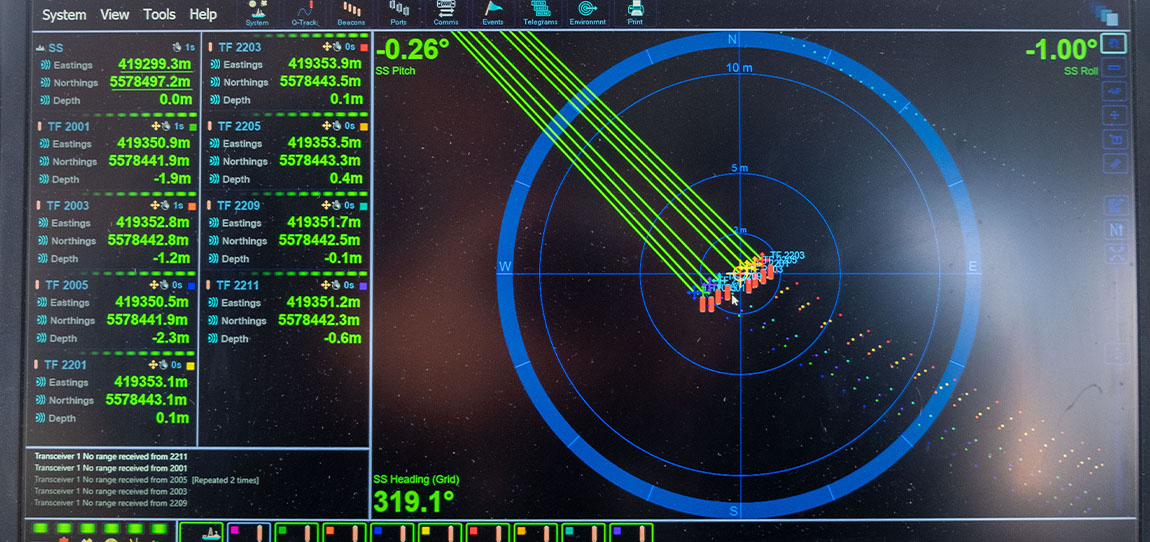

Ranger 2 comes with an impressive list of features including our award-winning 6G (sixth generation) acoustic hardware platform and Sonardyne Wideband 2 digital signal architecture. It provides stable and repeatable acoustic position referencing for your ship’s DP system, including those from GE, Kongsberg, MT, Navis, Thrustmaster and Wärtsilä.

As your needs grow and become more complex, bolt-on software packs unlock additional capability and protect your investment. Take the DP pack and enable your acoustic ranging to be aided by our inertial navigation technology (DP-INS). Add the robotics pack and commanding a swarm of up to 99 AUV’s is at your fingertips.

Ranger 2 can do even more, it also supports robust two-way data telemetry, allowing you to control our range of seafloor deployed, long-endurance sensors and recover your all-important data.

Track everything, in any depth, from any vessel

Why choose it?

- Tracks multiple targets to 11 km;

- Compatible with all makes of DP system – GE, Kongsberg, MT

- System accuracy: when fully optimised it will deliver 0.04% of slant range

- Works with a global inventory of pre-deployed Sonardyne 6G hardware

- Configurations available for USV and temporary vessel installations

- Valuable features included as standard

- Bolt-on packs available for growth with your operations and ambitions

- Developed and supported by a company with over 50 years of experience in innovative underwater technology

Learn more about Ranger 2 USBL

The kit

Transceivers

Our High Performance Transceiver (HPT), is available in a range of different designs to suit your operations whether they are in deep or shallow water or over a long layback.

HPT 5000 / 7000 are acoustic and telemetry transceivers designed for use with Ranger 2 USBL system. HPT 5000 enables targets to be tracked over a wide range of water depths; HPT 7000 is optimised for noisy DP drilling or construction vessels and in deep water.

HPT 5000 offers full hemispherical acoustic coverage so is a popular choice for tracking multiple targets (ROVs, AUVs, towfish, seafloor sensors) over a wide range of depths and elevations. The unit is also suitable for dynamic positioning reference on survey, research and offshore support vessels.

HPT 7000 is engineered for ultra-deepwater operations, tracking targets far below (rather than to the side of) a vessel, and for high vessel noise operating environments such as those typical of DP, drilling and construction where activity from thrusters is liable to cause signal interference.

If you need a solution for a vessel of opportunity, our pre-calibrated, all-in-one Gyro USBL transceiver is perfect. Lighter, smaller and just as capable, our second-generation Gyro USBL transceiver works seamlessly with Ranger 2 to track the position of your subsea targets from a USV, vessel of opportunity or from a pipelay vessel’s stinger over extreme ranges.

- All-in-one instrument; combined 6G acoustic transceiver and AHRS

- Choose between standard or ‘plus’ variants to suit your project’s specifications

- Optimises the performance of Ranger 2; eliminates lever arm offsets, pole bending and ship flexing errors

- Calibrated in-water before delivery – saving you time; install it and go to work

Transponders

The flexibility of the Ranger 2 family is further extended by our range of transponders to support a wide variety of your operations. WMT is a high-power transponder capable of operations to 7,000 m, while AvTrak 6 is our most capable acoustic vehicle instrument, combining the functions of a USBL transponder, LBL transceiver and modem for demanding applications such as AUV command and control.

Discover Ranger 2 in action

A new world of multi-robot ocean exploration

Read moreOptimising shallow water positioning for combined magnetometer and hydrographic surveys

Read moreLong-endurance AUV development with shallow water simplicity

Read morePerformance

• Up to 0.04% of slant range system accuracy

• Up 99 targets tracked, sequentially

• Up to 11,000 m tracking range (LMF)

• 1 Hz position update rate

• Supports all industry standard DP telegrams

• Supports acoustically aided INS

Acoustics

• MF frequency (20–34 kHz) or LMF (14-19.5 kHz)

• Compatible with a wide range of 6G transponders

• Supports Sonardyne Messaging Service for data exchange up to 9,000 bps

• Sonardyne Wideband 2 acoustics for reliable performance in both shallow and deep-water environments

Ownership

• ITAR Controlled: No

• Warranty: 1 year return to Sonardyne service centre

• UK Export Licence: Required

• What’s in the box: HPT 5000 / 7000 / Gyro USBL, deck cables, software, manual

Overview

• Can be used for both survey and construction phases

• Configurable to work in the LMF band enabling you to track targets to beyond 11 km

• Supports complex tracking scenarios such as structures and vehicles with multiple transponders and multiple remote offsets

Specifications table

| Feature | Specification |

|---|---|

| Design | The most powerful USBL system on the market |

| Incorporates 30 years of USBL innovation and know-how | |

| Recommended for installation on large vessels and USVs | |

| Global vessel track record; offshore, research, cable-lay, salvage and naval | |

| Shares common platform with other Sonardyne USBLs | |

| Performance | Up to 0.04% of slant range system accuracy |

| Up to 99 targets tracked, simultaneously | |

| Up to 11,000 m tracking range (LMF) | |

| 1 Hz position update rate | |

| Support all industry standard DP telegrams | |

| Supports acoustically-aided INS | |

| Acoustics | MF frequency (20-34 kHz) or LMF (14-19.5 kHz) |

| Sonardyne Wideband 2 digital acoustics for reliable performance in both shallow and deep environments | |

| Supports Sonardyne Messaging Service for data exchange up to 9,000 bps | |

| Compatible with a wide range of 6G transponders |

Frequently asked questions

Planning 6G beacon deployments

CASIUS calibration recommendations

What is a USBL and how does it work?

How to use Auto Discover to scan the water for unknown transponder addresses

How to format the sound speed profile for Marksman and Ranger 2

How to use HPR418BCD telegrams for DP

How to mount and extract an ISO image

How to track an underwater locator beacon

How to Compensate for Responder Latency

How to set up an SSB_LBP Telegram

Marksman/Ranger 2 DP INS indicator sequence explained

How to create an alarm to warn that the transceiver deployment pole has been left deployed

How to import waypoints into Ranger 2

How to enter Transceiver & Lodestar Offsets for Optimised USBL

Frequency management is obsolete. Here’s why.

How to set up Responder Mode

Opening a .DJF file on Sonardyne De Novo Job Viewer

How to Skip Telemetry Options in Rangers 2 and Marksman LUSBL

What should I do if my Sonardyne security dongle expires or reports a problem?

How to Capture a cef in Marksman and Ranger 2

How to download or upload files using Filezilla

Why am I getting old / incorrect data from my GyroCompatt 6+?

How to turn on a Lodestar Gyro Compatt using Ranger 2 or Fusion 2

I’m outputting a GGA from Fusion 2 / Ranger 2 to NaviPac but the position isn’t appearing in the correct location?

Health check for your acoustic system

How do I mark where my RT 6-1000 is deployed?

Will Compatt 6+ work with Ranger 2 and Marksman?

The transponder isn’t replying to interrogation or commands

Can I get USBL position updates from my AUV with Ranger 2/ Mini-Ranger 2?

How quickly can I start tracking beacons with Ranger 2?

Has anyone ever installed an echosounder and Ranger 2 USBL transceiver directly beside each other? Would this work?

Can I perform a USBL verification in shallow water without an ROV to deploy or recover the beacon?

How do USBLs work?

Which USBL Deployment Machine is most suitable for my vessel?

Advantages of using Ranger 2 for ROV tracking

When to use Depth Aiding

What’s new in Micro Ranger 2?

What to consider when mounting acoustic transducers

What acoustic address should I use for my USBL transponder

What do my CASIUS results tell me about my USBL calibration

Calibration tips for Ranger 2 USBL systems

How to align Gyro USBL to the vessel frame of reference

How to interface Ranger 2 into a 3rd party survey system

How can an uncrewed system interact with Ranger 2 software?

How can I synchronise a clock on my AUV to a GNSS reference using Ranger 2?

What is Telemetry Tracking, and why would I need it?

How to release an RT 6 acoustic release transponder using Ranger 2

How to set up an update rate in Ranger 2

How to set the operating range in Ranger 2

How to configure sound speed in Ranger 2

Ranger 2 – How to release an RT6 acoustic release transponder

Software and firmware

Software and control hardware

How to enter Transceiver & Lodestar Offsets for Optimised USBL

How to set up Responder Mode

Opening a .DJF file on Sonardyne De Novo Job Viewer

What’s new in Micro Ranger 2?

What do my CASIUS results tell me about my USBL calibration

How to release an RT 6 acoustic release transponder using Ranger 2

How to set up an update rate in Ranger 2

Top tips

How to Skip Telemetry Options in Rangers 2 and Marksman LUSBL

What should I do if my Sonardyne security dongle expires or reports a problem?

How to Capture a cef in Marksman and Ranger 2

How to download or upload files using Filezilla

Which USBL Deployment Machine is most suitable for my vessel?

Advantages of using Ranger 2 for ROV tracking

When to use Depth Aiding

What to consider when mounting acoustic transducers

What acoustic address should I use for my USBL transponder

Calibration tips for Ranger 2 USBL systems

How to align Gyro USBL to the vessel frame of reference

Datasheets

Manuals and quick start guides

Technical bulletin

Overview

When it comes to USBL and LUSBL transceivers, one model does not fit all situations and vessels. For Ranger 2 and Marksman installations, our High Performance Transceiver (HPT) is available two primary configurations.

HPT 5000

HPT 5000 offers full hemispherical acoustic coverage so it’s a popular choice for tracking multiple targets (ROVs, AUVs, towfish, seafloor sensors) over a wide range of depths and elevations. The unit is also suitable for dynamic positioning reference on survey, research and offshore support vessels.

HPT 7000

HPT 7000 is engineered for ultra-deepwater operations, tracking targets far below (rather than to the side) of a vessel, and also high vessel noise operating environments, as those typically encountered on DP drilling and construction where aeration from thrusters is liable to cause signal interference.

Both models of transceiver fully support 6G LBL operations using Fusion 2 LBL software. They are also highly capable acoustic communications modems, able to interrogate, command and recover data payloads from deployed Sonardyne instruments including AMTs and Fetch. Supporting telemetry rates of up to 9,000 bps minimises the time a vessel has to wait on location to recover data, as well as supporting LBL operations.

HPT 5000/7000s are also available in Gyro USBL configurations offering calibration-free installation and use.

At a glance

- Use with Ranger 2 USBL and Marksman LUSBL systems

- Can also be used to communicate and harvest data from Sonardyne sensors

- Hemispherical (HPT 5000) or directional (HPT 7000) arrays to suit your vessel and application

- Can be deployed other-the-side, through-tube or through-hull

- Suitable for new-build vessels or USBL/LUBL upgrade for your existing vessel

All HPTs are built on our 6G technology platform with multi-element processing to enable transponders to be positioned more precisely, more quickly and more robustly due to improvements in signal processing algorithms and array design.

Functionality such as ‘Discovery Mode’ enables vessels equipped with Ranger 2 and Marksman to enter an offshore area and automatically detect previously deployed transponders (including their configured address and channel), making simultaneous operations using shared seabed arrays possible.

Manufactured in aluminium-bronze, HPTs are intended to be fitted temporarily or permanently to a vessel’s through-hull or over-the-side pole. HPT 5000s (including Gyro USBL 5000s) have also been fitted to large USVs for uncrewed missions controlled from over-the-horizon.

For specialist applications, inverted USBL, LMF frequency and extreme depth range HPT transceivers are also available. Please get in contact to discuss your requirements.

Ranger 2 in action

Optimising shallow water positioning for combined magnetometer and hydrographic surveys

Read moreAutonomous robots prepare to storm the ocean depths

Autonomous robots prepare to storm the ocean depths

A new world of multi-robot ocean exploration

Read moreSpecifications table

level, vessel noise, water depth, mechanical rigidity of the transceiver deployment machine, SV knowledge and proper calibration of

the total system using CASIUS.

| Feature | Type 8142-001 | Type 8142-002 (deepwater optimised unit) | |

|---|---|---|---|

| Operational frequency | MF (20–34 kHz) | MF (20–34 kHz) | |

| Transceiver performance |

Operating range | Up to 7,000 m | Up to 7,000 m |

| Acoustic coverage | Up to ± 90° | Up to ± 90º Optimised for deep water (depending on frequency of operation) |

|

| Range precision | Better than 15 mm | Better than 15 mm | |

| Positioning repeatability | All transceivers tested to better than 0.1% of slant range 1 Drms | All transceivers tested to better than 0.07% of slant range 1 Drms | |

| Transmit source level (dB re 1 µPa @ 1 m) | 200 dB | 200 dB | |

| Tone Equivalent Energy (TEE) | 206 dB (13 JA) | 206 dB (13 JA) | |

| Electrical | 48 V dc (±10%), Typical 15 W, Max 120 W |

48 V dc (±10%), Typical 15 W, Max 120 W |

|

| Communication | RS485, baud rate switchable, ethernet 100 Mbps |

RS485, baud rate switchable, ethernet 100 Mbps |

|

| Operating temperature | -5 to 40°C | -5 to 40°C | |

| Storage temperature | -20 to 45°C | -20 to 45°C | |

| Mechanical construction | Aluminium bronze | Aluminium bronze | |

| Dimensions (length x diameter) | 322 x 225 mm | 391 x 310 mm | |

| Weight in air/water | 26.7/15.3 kg | 46.9/29.0 kg | |

| Options | Tilted array adaptor | Tilted array adaptor |

Frequently asked questions

How to clean a transceiver array face

How to enter Transceiver & Lodestar Offsets for Optimised USBL

HPT Deployment Tests

Has anyone ever installed an echosounder and Ranger 2 USBL transceiver directly beside each other? Would this work?

How do USBLs work?

Does the HPT’s main connector need any maintenance?

When to use Depth Aiding

What acoustic address should I use for my USBL transponder

How to interface Ranger 2 into a 3rd party survey system

STP files

Software and firmware

Software and control hardware

Datasheets

Did you know?

Both HPT 5000 and 7000 are available in Gyro USBL configurations

Overview

The instrument is a turn-key solution comprised of carefully selected high grade and highly reliable inertial sensors integrated into in-house designed inertial measurement unit (IMU).

The selected inertial sensors are the standard for commercial aviation with a proven 20+ year track record. These sensors have a highly desirable characteristic being insensitive to vibration, temperature changes and having very limited initial errors. The result is a system which is highly suitable for the marine environment where performance, robustness and data integrity need to be available from initialisation, even during the harshest conditions.

Lodestar requires no external aiding and settles robustly in dynamic conditions in less than five minutes. On-board data storage and backup battery functionality ensures continued operation and eliminates the risk of data loss even if communications or external power are lost. Power-pass through to external aiding sensors is supported to ease integration requiring only a single cable for comms and power.

If a full INS solution is required, Lodestar can easily be field upgraded to a SPRINT system (apart from Lodestar 200). This makes the Lodestar a flexible and future-proof solution for both ROV guidance and survey applications.

Lodestar has a proven track record spanning more than 10 years in the field in diverse applications from ROV guidance and autopilot to demanding survey applications. The instrument is available in 4,000 and 6,000 metre depth ratings with a variety of connector options and configurations.

At a glance

- Designed to aid subsea vehicle guidance: AUVs, ROVs and UUVs

- Uses high quality Honeywell gyro and accelerometers

- Sensors available in three performance levels: 200, 300 and 500

- Fast settling time so you can get straight to work

- Integrated DVL option available; Lodestar-Nav

- Factory upgradeable to SPRINT INS

Lodestar-Nav 200

Lodestar-Nav 200 provides all-in-one navigation solution for subsea vehicles by combining a Lodestar 200 AHRS with our Syrinx Doppler Velocity Log (DVL) and a high accuracy pressure sensor in a single housing. This saves cost, payload space and the complexity of integrating and operating separate sensors from different vendors.

Lodestar-Nav is pre-calibrated providing the ROV pilots with a robust and reliable solution, even in the most challenging operational scenarios, without needing to worry about sensor offsets.

Syrinx DVL inside that provides a large altitude range and high precision at all altitudes; this combines the best of 300 and 1200 kHz DVLs. Each DVL transducer is fitted with a full depth rated water block to ensure protection of the internal components and easy replacement if damaged.

Lodestar-Nav can be interfaced via a single connection and/or the DVL can be interfaced separately depending on requirements. Continuous on-board data storage supports post-mission diagnostics and post-processing.

Size

Measuring just 260 mm tall, the 4,000 m rated titanium housing allows easy fitment to any subsea vehicle. 6,000 m housing option.

Long life sensors

Lodestars and SPRINTs use Honeywell-supplied RLGs and inertial sensors with 400,000 MTFB, which have been proven in over 20 years in commercial aircraft.

Connectivity

Most Lodestars can be upgraded to SPRINT in the field as your requirements grow so there’s no need to remove and re-install a different instrument.

Specifications

| Feature | Lodestar 300 | Lodestar 500 | |

|---|---|---|---|

| Depth rating | 4,000 / 6,000 m | 4,000 / 6,000 m | |

| Performance | |||

| Heading | 0.2° | 0.1° | |

| AHRS settle time | <5 minutes in dynamic conditions | <5 minutes in dynamic conditions | |

| Roll and pitch | 0.01° | 0.01° | |

| Power | |||

| Power requirement | 20–50 V dc, 15 W nominal, 35 W maximum | 20–50 V dc, 15 W nominal, 35 W maximum | |

| Power pass through | 3 x for external aiding sensors (up to 3A per sensor) | 3 x for external aiding sensors (up to 3A per sensor) | |

| Back up battery type/life | Li-ion/5 minutes | Li-ion/5 minutes | |

| Data/Comms | |||

| Data storage | 8 GB internal memory | 8 GB internal memory | |

| Serial ports/protocol | 4x RS232 or RS485 | 4x RS232 or RS485 | |

| Other ports | 1x Ethernet, 4 triggers | 1x Ethernet, 4 triggers | |

| Output rate | Up to 100 Hz | Up to 100 Hz | |

| Output telegrams | Industry standard AHRS/INS telegrams including acceleration and rotation rates | Industry standard AHRS/INS telegrams including acceleration and rotation rates | |

| Mechanical | |||

| Connectors | 4x Seacon / Seanet, 1x Seacon / Seanet | 4x Seacon / Seanet, 1x Seacon / Seanet | |

| Mechanical construction | Titanium | Titanium | |

| Dimensions (diameter x height) |

4,000 m (Seacon) | 205 x 260 mm | 205 x 260 mm |

| 6,000 m (Seacon) | 205 x 280 mm | 205 x 280 mm | |

| 4,000 m (Seanet) | 205 x 250 mm | 205 x 250 mm | |

| Weight in air/water | 4,000 m | 18.5/11.5 kg | 18.5/11.5 kg |

| 6,000 m | 22/14 kg | 22/14 kg | |

| Environmental | |||

| Operating temperature | -20 to +55°C | -20 to +55°C | |

| Storage temperature | -20 to +60°C | -20 to +60°C | |

| Shock rating | 22 g, 11 ms half sine | 22 g, 11 ms half sine |

Frequently asked questions

SPRINT, SPRINT-Nav, Lodestar and Lodestar-Nav troubleshooting

How to connect to the Lodestar within a Gyro USBL via an NSH

How to enter Transceiver & Lodestar Offsets for Optimised USBL

What cables do I need for my Lodestar?

How do I mate and calibrate a DVL to my Lodestar?

Can I power my subsea instruments with Lodestar or SPRINT?

How do I mate and calibrate a SPRINT or Lodestar to my Syrinx DVL?

What’s the difference between FOG and RLG?

STP files

Software and firmware

Software and control hardware

Manuals and quick start guides

Technical bulletin

Did you know?

Lodestar is highly optimised for cost, size, weight and power (C-SWaP)

Reassuringly reliable Ranger 2

Ranger 2 is more than just an acoustic tracking and positioning system. It goes way beyond tracking; it can be part of a dynamic positioning system, it supports robust two-way data communication with a range of seafloor sensors to collect data, it can support AUV command and control and will even release seabed moorings.

Ranger 2 can even be run from an uncrewed surface vehicle (USV) enabling truly remote, autonomous operations. Whether your mission involves seabed surveys, offshore energy site inspections or commanding a fleet of AUVs, Ranger 2 can help you expand them over the horizon and to the edges of your imagination.

It comes with an impressive list of standard features, our award-winning 6G (sixth generation) acoustic hardware platform and Sonardyne Wideband 2 digital signal architecture. The flexibility of the Ranger 2 family is further extended by our range of 6G transponders to support a wide variety of applications.

Why should you invest?

Our Ranger 2 family gives you the versatility you need, at the investment level you can afford, to get your project completed quickly and efficiently. It’s engineered like no other USBL on the market. Adaptable, scalable and always compact, there is a Ranger 2 USBL to suit any size vessel or project. As your needs grow, bolt-on software packs unlock additional capability and protect your investment. Whichever size suits you best, they will always be compatible with our full range of 6G transponders and many other vessel systems.

Micro-Ranger 2 USBL

The ‘baby’ of the Ranger 2 family and the ideal entry-level USBL, Micro-Ranger 2’s compact size contradicts its impressive performance. It may be our smallest underwater tracking system to date, but it will have a big impact on your operations.

Never used a USBL system before? No problem. Micro-Ranger 2 is simple to setup and use.

Need to know where your targets are? Micro-Ranger 2 has them covered. Precision, ease of use and versatility come as standard. It’s built around the same market-leading hardware and digital acoustic technology you’ll find in our family of deep water USBL systems, but for significantly less cost and complexity.

For the full picture of what your Micro-Ranger 2 USBL is capable of, please visit its dedicated product page.

Mini-Ranger 2 USBL

Mini-Ranger 2 is our mid-level USBL target tracking system, perfect for nearshore operations; UXO surveys, search and recovery and structure inspections. With a 995 m operating range, extendable to 4,000 m, it can track up to ten underwater targets simultaneously, including divers, towed instruments, ROVs and AUVs.

Choose to add the Marine Robotics software pack and it will communicate with subsea robotic platforms, sharing positions and exchanging data.

A compact, easily installed, system it’s your ideal choice for temporary installation on small survey vessels, as well as USVs.

For the full picture of what your Mini-Ranger 2 USBL is capable of, please visit its dedicated product page.

Ranger 2 USBL

Ranger 2 is the largest USBL in the family and the most powerful USBL on the market. Able to simultaneously track up to 99 targets with up to 11,000 m range, it is anything but standard.

Recommended for installation on large vessels and USVs, Ranger 2 incorporates over 30 years of our USBL innovation and know-how. It has a global vessel track record and is used for offshore energy, research, cable-lay, salvage and naval operations, to name but a few.

Sharing a common platform with other Sonardyne USBLs, Ranger 2 supports all industry standard DP telegrams and acoustically aided inertial navigation systems (INS).

For the full picture of what your Ranger 2 USBL is capable of, please visit its dedicated product page.

6G

Our 6th generation (6G) technology provides faster, secure and robust data communications from seabed to surface . This gives you speedier updates on the location of your assets and access to your vital data.

Wideband

Our wideband technology enables digital high-throughput data, range resolution and accuracy with low latency. Teamed with our 6G it gives you fast, reliable, accurate data over greater distances.

Robotics

Uncrewed, autonomous surface and underwater vehicles are increasingly used for coastal, deep sea and over-the-horizon operations, reducing costs, risks and carbon footprint. Thats why we have a dedicated “bolt on” pack for our Ranger 2 to enhance your robotics operations.

Dynamic positioning

We’ve been engineering high integrity position reference systems for dynamically positioned vessels since the early 1990s. Our USBL, LUSBL and SPRINT- INS products provide dynamic positioning solutions for a range of vessels and environments.