Greater efficiency, lower overheads, with underwater autonomy in deepwater seismic

Shell Brasil, in partnership with Petrobras, Sonardyne and Brazilian research institute SENAI CIMATEC are working together to bring a step-change to 4D seismic data gathering in Brazil’s deepwater pre-salt region.

Discover how we’re collaborating to develop innovative autonomous technology that will make monitoring these challenging deepwater fields more efficient, with fewer people and lower environmental footprint.

Scroll down to read this case study in Portuguese.

The challenge

Seismic data is an essential part of offshore field development activity, especially to support proactive reservoir management and production optimisation. Techniques for gathering this data have evolved dramatically over the decades; from the use of marine streamers for large exploration seismic campaigns to the now routine use of remote operated vehicles (ROV) to deploy ocean bottom nodes (OBN) for high-resolution imaging of pre-salt reservoirs.

Yet, gathering seismic data for pre-salt reservoir imaging remains intensive work. It involves large, costly and carbon-emitting crewed vessels for deployment and recovery of, typically, thousands of nodes. As an example, for a 10-month campaign over one of Brazil’s giant pre-salt fields, a node handling vessel could emit close to 10,000 tons of CO₂. Costly and complex operations can mean a reduction in frequency of surveys, including of those done to gather what’s called time lapse or 4D seismic data, which is required to monitor the pre-salt reservoirs.

Shell and Petrobras came to us believing that there could be a lower-cost, more sustainable, way of acquiring 4D seismic data, as well as other parameters such as seafloor subsidence, to help better monitor reservoirs. They also saw this could be done with a lower environmental footprint and while keeping more people safe.

The solution

Together, Shell Brasil, Petrobras, and Sonardyne joined forces with SENAI CIMATEC to develop an advanced seismic data acquisition system under a Brazilian National Agency of Petroleum, Natural Gas and Biofuels (ANP) promoted research and development project.

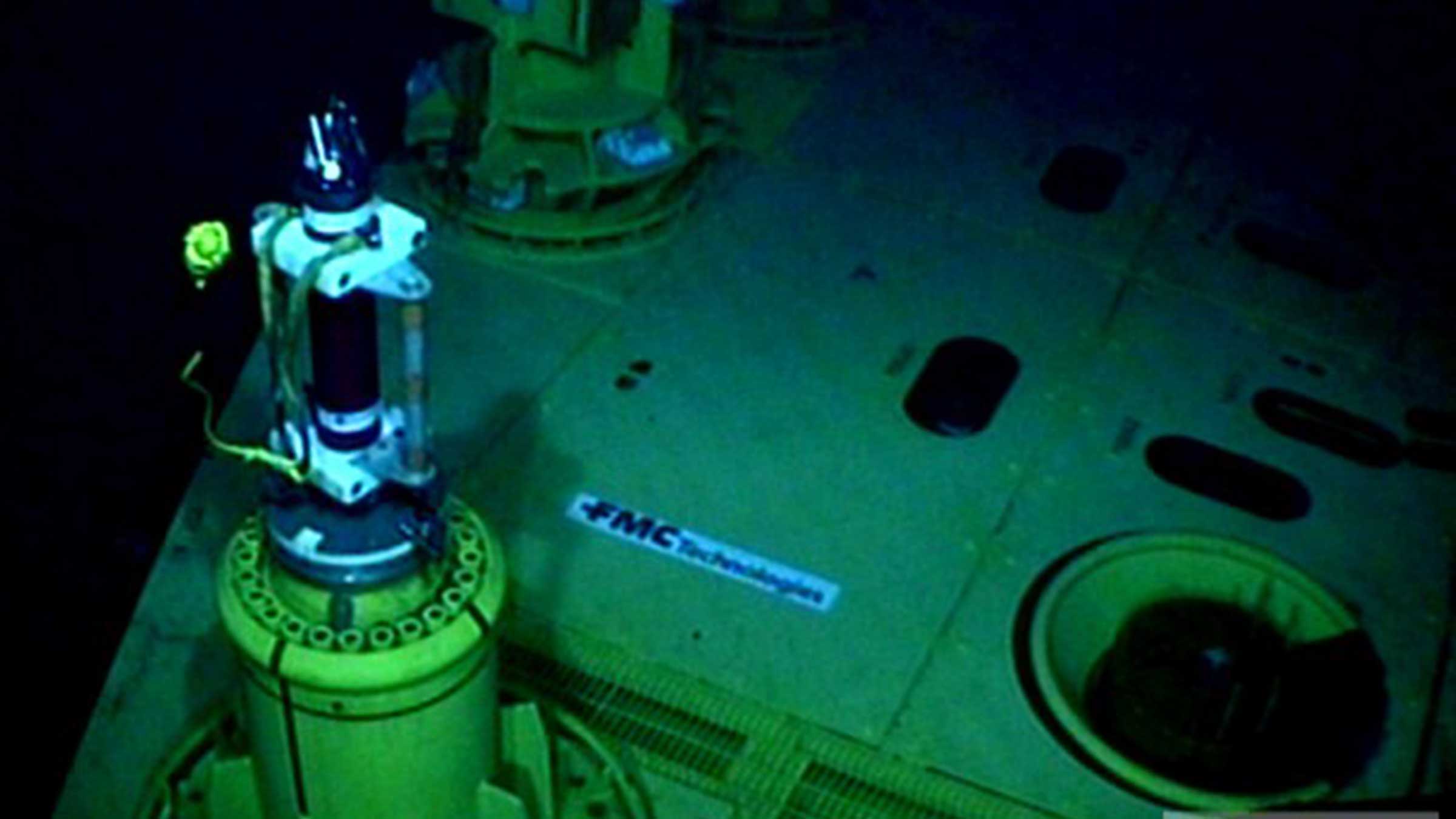

At its core is an On-Demand Ocean Bottom Node, or OD OBN. This semi-permanent seabed system is used for the acquisition of high resolution seismic and seafloor subsidence data.

Like conventional seabed nodes (OBN), each OD OBN contains three geophones and one hydrophone, a data recording system, batteries and a highly accurate clock. The sensors detect pressure waves emitted by an airgun source, usually towed by a ship, as they are reflected upwards towards the seabed from the underlying layers of rock surrounding the reservoir.

Unlike conventional nodes, these OD OBNs remain on the seabed, down to 3,000 m, gathering seismic data for up to five years. This significantly reduces the cost of repeated ocean bottom seismic campaigns, as the node handling vessel is removed from the operations. It also reduces the impact on the environment and marine ecosystems.

The activation of the nodes, verification of subsidence event alarms, calibration of internal clocks and harvesting of seismic data will be performed using an autonomous underwater vehicle (AUV) called Flatfish developed, in a closely interlinked ANP project, by partners Shell Brasil, Petrobras, SENAI CIMATEC and Saipem.

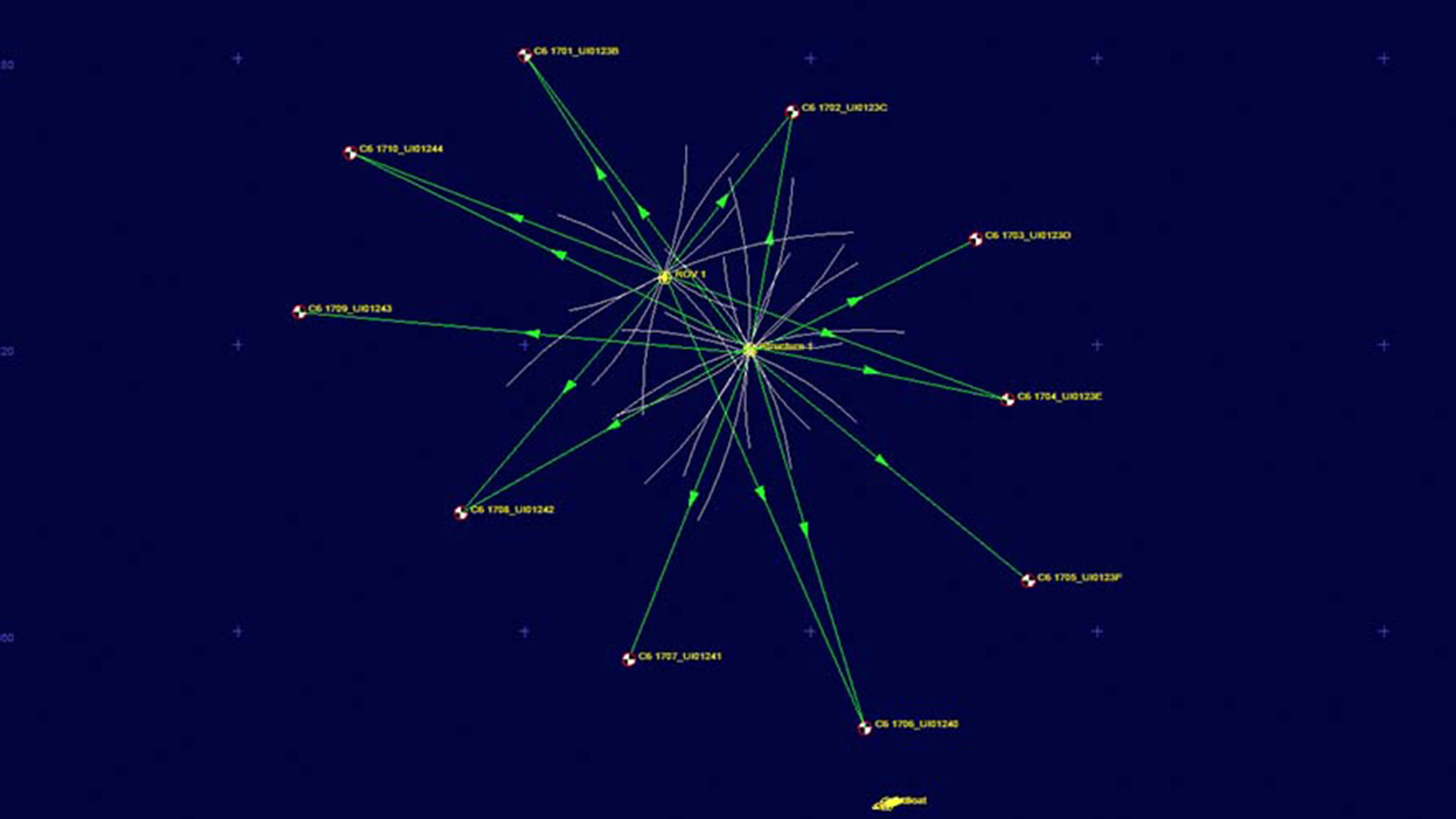

Flatfish will find each node using Sonardyne’s 6th generation (6G) of acoustic positioning systems. Our acoustics will also support data telemetry with the nodes, for health checks, configuration and acoustic time synchronization. The Flatfish will then hover above each node, in turn. Using an extremely high bandwidth and energy efficient laser-based variant of Sonardyne´s BlueComm optical communications device, it will wirelessly harvest many gigabytes of seismic data in just a few minutes.

This variant uses two rapidly modulated lasers to produce simultaneous bi-directional communications over more than five meters range. It is optimised for peak data transfer performance, with speeds of over 600 megabits per second demonstrated. This makes it excellent for harvesting large amounts of data from seabed nodes.

“Using OD OBN in combination with Flatfish, a 4D seismic campaign in the pre-salt may be executed in a simpler manner, with lower operational cost, lower risk of human exposure and lower environmental impact,” says Jorge Lopez, Manager of Subsurface Technology at Shell Brasil. “On top of this, the nodes also measure seafloor deformation and can continuously monitor for possible subsidence events that may occur during the production of the field.”

The results

In the first phase of the OD OBN project, eight fully functional prototype nodes were built. These comprised of two different concept types and were designed and built by SENAI CIMATEC in Salvador, Bahia together with Sonardyne Brasil.

In 2021, initial tests of seismic data recording were conducted at the Sapinhoá pre-salt field offshore Brazil and interoperability tests between the nodes and the Flatfish AUV were performed in shallow water in Trieste, Italy.

A very intensive laboratory and offshore testing and demonstration program is being conducted over the next 18 months to ensure the OD OBN system meets its operational requirements. This program will increase the maturity of the solution, with tests in pre-salt fields for recording seismic data with the OD OBN prototypes and the communication and data harvesting AUV missions.

In the next phase of the project, starting later in 2022, Shell and Petrobras will sign a new agreement to manufacture 600 nodes and deploy them for three years of reservoir monitoring in a Brazilian pre-salt field.

Maior eficiência, baixo custo de operação, para sísmica em águas profundas através de autonomia submarina

A Shell Brasil, em parceria com a Petrobras, a Sonardyne e o instituto de pesquisa brasileiro SENAI CIMATEC estão trabalhando juntos para trazer uma mudança radical na coleta de dados sísmicos 4D na região do pré-sal em águas profundas do Brasil.

Descubra como estamos colaborando para desenvolver tecnologia autônoma inovadora que tornará o monitoramento desses desafiadores campos em águas profundas mais eficiente, com menos pessoas e menor impacto ambiental.

O desafio

Os dados sísmicos são uma parte essencial da atividade de desenvolvimento de campos offshore, especialmente para apoiar o gerenciamento proativo de reservatórios e a otimização da produção. As técnicas para coletar esses dados evoluíram dramaticamente ao longo das décadas; desde o uso de streamers marinhos para grandes campanhas sísmicas de exploração até o uso rotineiro de veículos operados remotamente (ROV) para implantar nós de fundo oceânico (OBN) para imagens de alta resolução de reservatórios do pré-sal.

No entanto, a coleta de dados sísmicos para imagens de reservatórios do pré-sal continua sendo um trabalho intensivo. Envolve embarcações tripuladas grandes, caras e emissoras de carbono para implantação e recuperação de, normalmente, milhares de nós. Como exemplo, para uma campanha de 10 meses em um dos campos gigantes do pré-sal brasileiro, uma embarcação de manuseio de nós pode emitir cerca de 10.000 toneladas de CO₂. Operações caras e complexas podem reduzir a frequência de levantamentos, inclusive daqueles feitos para coletar o lapso temporal que é chamado de dados sísmicos 4D, necessários para monitorar os reservatórios do pré-sal.

A Shell e a Petrobras nos procuraram acreditando que poderia haver uma forma mais barata e sustentável de adquirir dados sísmicos 4D, além de outros parâmetros, como subsidência do fundo do mar, para ajudar a monitorar melhor os reservatórios. Eles também viram que isso poderia ser feito com um impacto ambiental menor e mantendo mais pessoas seguras.

A solução

Juntos, Shell Brasil, Petrobras e Sonardyne uniram forças com o SENAI CIMATEC para desenvolver um sistema avançado de aquisição de dados sísmicos em um projeto de pesquisa e desenvolvimento promovido pela Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP).

Em seu núcleo está um On-Demand Ocean Bottom Node, ou OD OBN. Este sistema semipermanente do fundo do mar é usado para a aquisição de dados sísmicos de alta resolução e subsidência do fundo do mar.

Assim como os nós convencionais do fundo do mar (OBN), cada OD OBN contém três geofones e um hidrofone, um sistema de gravação de dados, baterias e um relógio de alta precisão. Os sensores detectam ondas de pressão emitidas por uma fonte do tipo airgun, rebocada por um navio, à medida que são refletidas para cima em direção ao fundo do mar a partir das camadas subjacentes de rocha ao redor do reservatório.

Ao contrário dos nós convencionais, os OD OBNs permanecem no fundo do mar, até 3.000 m, coletando dados sísmicos por até cinco anos. Isso reduz significativamente o custo de repetidas campanhas sísmicas no fundo do oceano, uma vez que a embarcação de manuseio de nós é removida das operações. Também reduz o impacto no meio ambiente e nos ecossistemas marinhos.

A ativação dos nós, a verificação dos alarmes dos eventos de subsidência, a calibração dos relógios internos e a coleta dos dados sísmicos serão realizados por meio de um veículo submarino autônomo (AUV) denominado Flatfish, desenvolvido em um projeto ANP estreitamente interligado, pelos parceiros Shell Brasil, Petrobras, SENAI CIMATEC e Saipem.

O Flatfish encontrará cada nó usando a 6ª geração (6G) de sistemas de posicionamento acústico da Sonardyne. Nossa acústica também suportará telemetria de dados com os nós, para verificações de integridade, configuração e sincronização de tempo acústico. O Flatfish irá então pairar acima de cada nó, por sua vez. Usando uma largura de banda extremamente alta e uma variante baseada em laser com eficiência energética do dispositivo de comunicação óptica BlueComm da Sonardyne, ele coletará sem fio muitos gigabytes de dados sísmicos em apenas alguns minutos.

Esta variante usa dois lasers modulados rapidamente para produzir comunicações bidirecionais simultâneas em um alcance de mais de cinco metros. Ele é otimizado para desempenho de transferência de dados de pico, com velocidades demonstradas de mais de 600 megabits por segundo. Isso o torna excelente para coletar grandes quantidades de dados de nós do fundo do mar.

“Usando OD OBN em combinação com o Flatfish, uma campanha sísmica 4D no pré-sal pode ser executada de forma mais simples, com menor custo operacional, menor risco de exposição humana e menor impacto ambiental”, afirma Jorge Lopez, Gerente de Tecnologia de Subsuperfície da Shell Brasil. “Além disso, os nós também medem a deformação do fundo do mar e podem monitorar continuamente possíveis eventos de subsidência que podem ocorrer durante a produção do campo”.

Os resultados

Na primeira fase do projeto OD OBN, doze nós protótipos totalmente funcionais foram construídos. Estes são compostos por dois tipos de conceito diferentes e foram projetados e construídos pelo SENAI CIMATEC em Salvador, Bahia em conjunto com a Sonardyne Brasil.

Em 2021, os testes iniciais de registro de dados sísmicos foram realizados no campo do pré-sal de Sapinhoá no litoral brasileiro e os testes de interoperabilidade entre os nós e o Flatfish AUV foram realizados em águas rasas em Trieste, Itália.

Um intenso trabalho em laboratório e um programa de demonstração e testes offshore estará sendo realizado nos próximos 18 meses para garantir que o sistema OD OBN atenda aos seus requisitos operacionais. Este programa aumentará a maturidade da solução, com testes em campos do pré-sal para registro de dados sísmicos com os protótipos OD OBN e as missões AUV de comunicação e coleta de dados.

Na próxima fase do projeto, a partir do final de 2022, a Shell e a Petrobras assinarão um novo acordo para fabricar 600 nós e implantá-los para três anos de monitoramento de reservatórios num campo do pré-sal brasileiro.

Mini-Ranger 2 for the next-level USV operations

Fugro is expanding the possibilities of remote marine operations with its growing fleet of SEA-KIT X-class uncrewed surface vessels (USVs) and eROVs. Read on to learn how our Mini-Ranger 2 Ultra-Short BaseLine (USBL) positioning system supports their remote capability.

The challenge

Leading geo-data specialist Fugro has a clear goal – to achieve safer, faster and more sustainable operations. One of the ways it’s doing that is by using uncrewed surface vessels (USV) to carry out subsea inspection, construction support and hydrographic and geophysical surveys operations.

Fugro’s fleet is initially being built with several 12 m-long SEA-KIT X class USVs, named Blue Essence™ by Fugro, with larger SEA-KIT designs planned. These vehicles are operated over-the-horizon from one of Fugro’s onshore global onshore remote operations centres (ROCs).

The Blue Essence™, Fugro Maali 12 m USV can be remotely launched and recovered by personnel at the ROC.

To ensure accurate control and high quality data gathering during its operations using the ROV, Fugro needed a suitable underwater Ultra-Short BaseLine (USBL) positioning system. In particular, Fugro was focused on shallow water inspection operations in 5 – 150 m water depth, that would involve long layback tracking.

The solution

Fugro selected our Mini-Ranger 2 Ultra-Short BaseLine (USBL) underwater positioning system and a Wideband Sub Mini 6+ (WSM 6+) transponder/responder for tracking the ROV.

Mini-Ranger 2 provides a high level of performance without the complexity of a deep water USBL system. It’s compact and easy to install, yet supports tracking, telemetry and control with an operating range of 995 m, extendable to 4,000 m.

At its heart is our HPT 3000 transceiver. It’s low weight (9.5 kg in water) and power draw, so it has minimal impact on any USV’s key performance budgets. It’s optimized for use in shallow water, high elevation and long lay back operating scenarios, making it ideal for Fugro’s shallow water operations, as well as much deeper water work.

HPT 3000 is compatible with all our 6G transponder options, supporting a wide range of functionality, including tracking, telemetry and control. That can be with up to 10 targets simultaneously, whether that’s ROVs, AUVs or divers. It’s also popular for use in ocean data gathering, thanks to its high data rate data collection capability from underwater.

The results

Fugro’s first SEA-KIT Blue Essence™, called Fugro Maali, was delivered to its base in Perth, Australia, in early 2021. Mini-Ranger 2 was configured with an external AHRS and SVP, as well as Fugro’s Starfix® GNSS, to ensure the best possible results from the system.

The vehicle was put to work straight away on an entirely remote nearshore inspection of three gas trunklines off Australia for the Woodside-operated North West Shelf Project – an industry first.

The inspection covered 1,300 km and included a multibeam survey, visual inspection using the ROV and a cathodic protection assessment of the gas trunklines to comply with Woodside and regulatory requirements, with operations controlled from Woodside’s King Bay Supply Facility and Fugro’s ROC in Perth.

Since then, Fugro Maali has carried out further campaigns through 2021 and into 2022, including subsea asset inspection, benthic habitat mapping and high resolution pipeline surveys.

“We couldn’t be happier with how the Mini-Ranger 2 has performed to date onboard the Fugro Maali USV,” says Matt Lussu, Principal Hydrographic Surveyor, Fugro. “We’ve seen reliable USBL positioning even in moderate sea states. We’ve also had good results with shallow water tracking, even when then ROV is several orders of water depth away from the transceiver.”

Fugro took delivery of its second Blue Essence™ USV in 2021. A third USV is about to be operational in the Middle East. A fourth is in sea trials and a the fifth in build, all with Mini-Ranger 2 onboard. In 2023, the company is also expected to take delivery of its next range USV, the Blue Eclipse™, an 18 m vessel, built by SEA-KIT and based on its XL-class design.

For the USV delivery, we worked closely with Fugro and SEA-KIT to deliver this integrated remote USV operations capability, ahead of the X-Class USV’s first operations offshore Australia.

Rapid leak detection for subsea production and storage sites

The ocean is a critical habitat that needs protecting. With decades of experience in sonar detection systems, our technologies provide an essential early subsea leak detection and warning system, across your oil and gas assets, CO₂ storage and offshore hydrogen transport and storage sites.

The challenge

A supermajor international energy company, with production infrastructure in more than 2,000 m (6,500 ft) of water depth, wanted a single subsea leak detection system that could be permanently installed to detect and localise, within seconds, oil or gas leaks across a wide area of its subsea infrastructure.

Existing sonar-based solutions are mostly based on sensors attached to subsea assets to detect leaks at specific or very localised locations, i.e. within a few metres. Alternative, non-acoustic, systems rely on anomalies in production data rates, which can be challenging should the leak occur upstream of the monitoring device.

At worst, leak detection relies on viewing the leak at the sea surface in the form of an oil-based sheen – when it’s already too late. This option is also limited when it comes to detecting leaks at gas producing fields and offshore carbon capture and storage (CCS) sites.

With a globally significant installed and aging asset base, as well as new infrastructure in the form of offshore CO₂ and hydrogen transport and storage, there’s increasing interest in alternative leak detection technologies that can operate autonomously and sustainably over wide areas in all water depths.

The solution

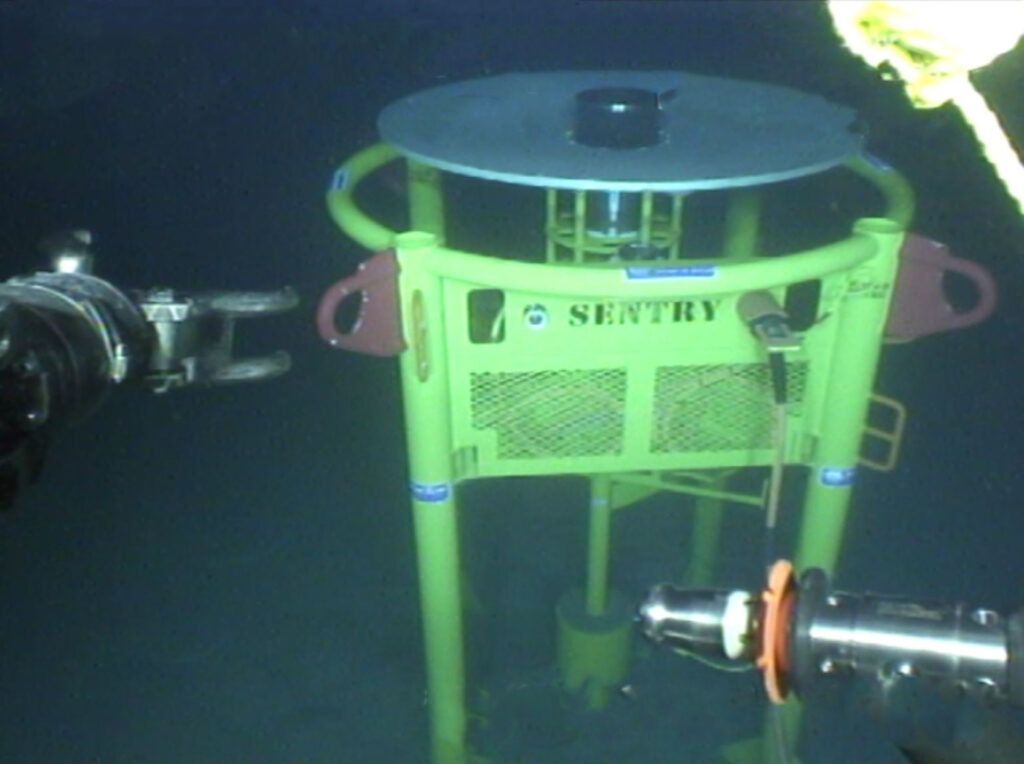

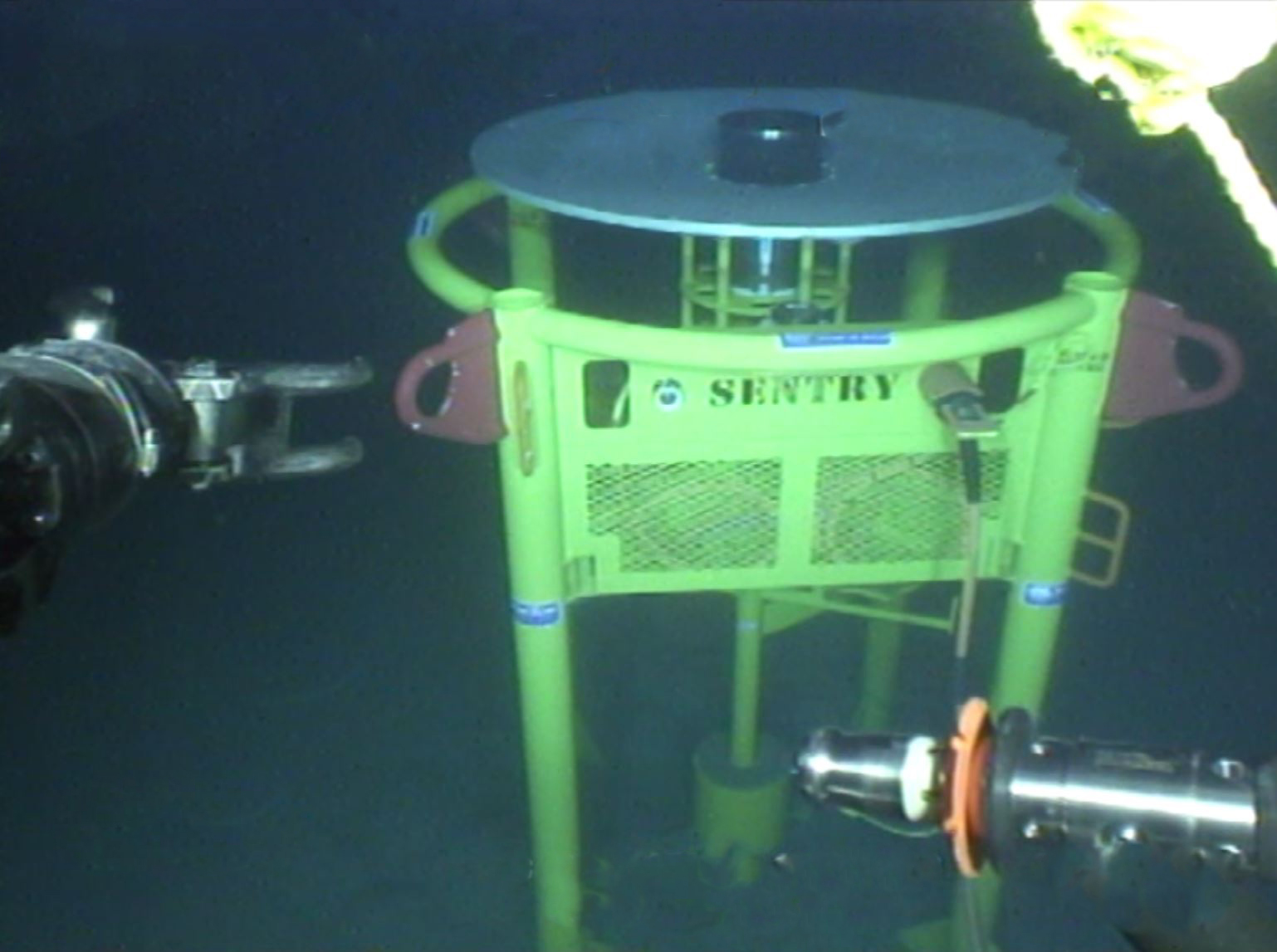

Developed by Wavefront Systems and manufactured and commercialised by Sonardyne, our Sentry Integrity Monitoring Sonar (IMS) is the only commercially available wide-area subsea leak detection system. A single Sentry head can provide 360-degree coverage of a 1,200 m diameter area, or more than one billion cubic feet of seawater, automatically alerting the operator as soon as an oil or gas leak is detected.

Detection rates are very impressive, with Sentry being able to detect monophase gas down to 0.1 litre per minute (equivalent to around 1 barrel of oil per day) or monophase oil to 1 litre per minute (equivalent to 9 barrels of oil per day). That means operators can react quickly to an infrastructure integrity breach before it becomes a bigger environmental and financial problem.

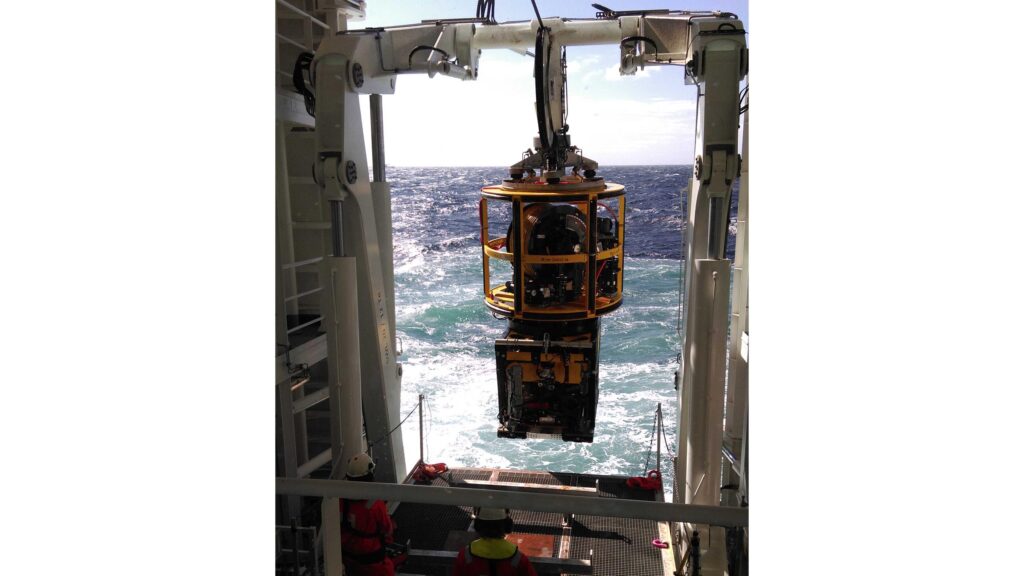

Sentry is an active acoustic-based solution that is based on a remotely operated vehicle (ROV) deployable low-power sonar proven for long-term monitoring. It’s available as a wired solution, that can be connected via existing subsea infrastructure directly into a surface asset. There, a Sentry workstation with graphical user interface (GUI) is able to provide users with clear real-time and automatic alerts of any oil or gas leaks.

It’s also available as a wireless, battery-powered solution for semi-permanent deployment, with data transmitted acoustically to a topside transceiver system. The transceiver can be deployed from a platform, buoy, vessel of opportunity or, now more commonly, via uncrewed surface vehicles (USVs).

The results

To make sure Sentry was fit for the oil major’s needs, the operator oversaw a trial deployment of a hardwired Sentry IMS. This included using a simulated monophase oil target, in this case nitrile-rubber strands, equivalent to a nominal oil leak rate of around 150 barrels per day.

The trials provided fast and accurate results. Detection and classification of the equivalent release of 100 barrels of oil per day out to 245 m (820 ft) was achieved, a distance constrained only by limitations of the trial set up. Leak detection was alerted within seconds of the simulated leak skid being deployed.

Sentry’s capability, however, covers 100 barrels per day mono-phase oil leaks at distances of up to 740 m (2,427 ft). It is even more sensitive to mono-phase gas leaks, with the system being capable of detecting down to the equivalent of just 1 barrel per day at 500 m (1,640 feet) or 100 barrels per day (as measured at depth) at 1,000 m (3,280 ft).

Following the extensive and successful trials, the operator purchased the Sentry IMS system for installation at its deep-water field development.

0

degree

coverage

0

m

diameter area

0.1 litre

per minute gas detection

Supporting the energy transition

As we transition from fossil fuels to new energies, many are looking to offshore as potential sites for CCS, as well as for hydrogen production.

Sentry helps to de-risk these projects. It ensures that, should carbon sequestration and offshore hydrogen transport and storage sites develop a leak, their operators will be alerted quickly, enabling a swift response, preventing larger environmental and financial problems.

Read about how we proved subsea leak detection capability for carbon capture and storage sites (CCS) through an Energy Technologies Institute research project, with partners Fugro, National Oceanography Centre, British Geological Survey and Plymouth Marine Laboratory here.

A new world of multi-robot ocean exploration

The OECI’s Technology Integration Challenge made major strides in multi-robot operations, on the surface and underwater, unlocking ways to explore our ocean – and far more efficiently. Find out how and the role our acoustics played.

The challenge

Ocean exploration is costly. Operations involving single underwater platforms, such as remotely operated vehicles (ROVs) or autonomous underwater vehicles (AUVs), often take up an entire cruise. Even when multiple underwater robots can be accommodated on a vessel, only one tends to be deployed at any one time, due to the complexity involved in its deployment, operations and recovery. It makes ocean exploration expensive and limits how much science can be conducted on any one cruise. But what if uncrewed surface vessels (USVs) could be used, not just as force multipliers for mapping operations, but as a remote shepherd, coordinating multiple underwater vehicles, they would be able to operate entirely freely from a mother ship.

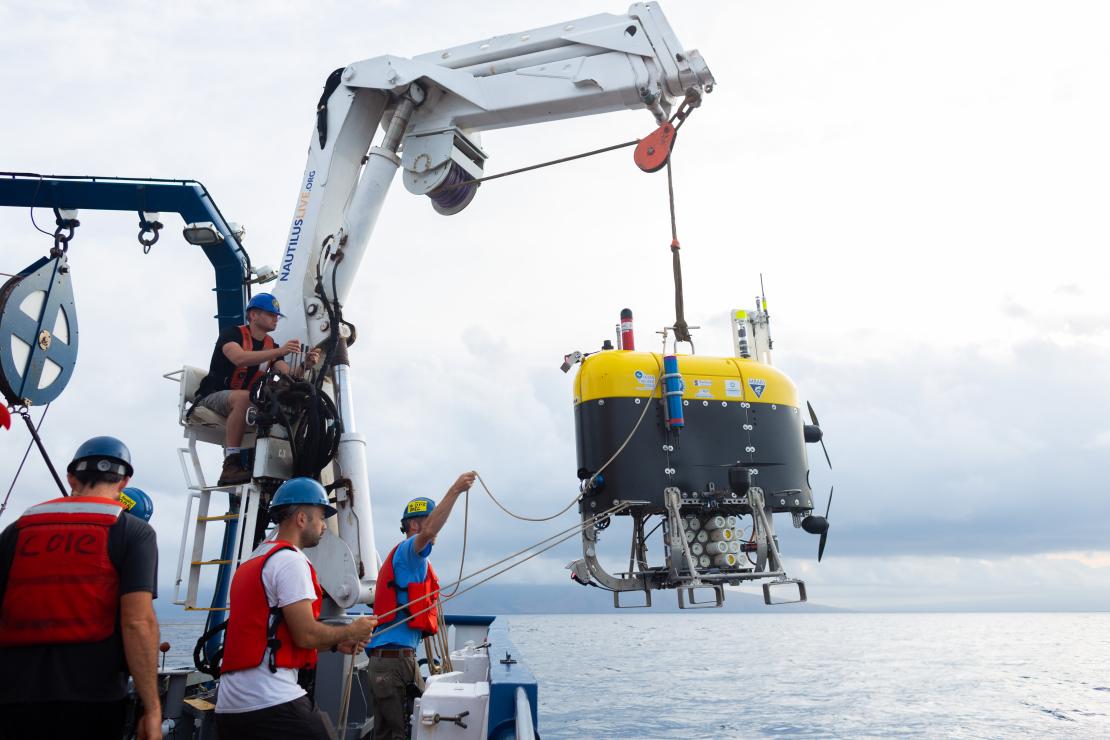

This was a key objective of the US’ Ocean Exploration Cooperative Institute (OECI) 2022 Technology Integration expedition NA139 on the Exploration Vessel (EV) Nautilus.

Enhancing ocean exploration through the use of remote and autonomous operations is a key objective of the OECI, a partnership between The University of Rhode Island, The Ocean Exploration Trust (OET), The University of Southern Mississippi, the University of New Hampshire (UNH), Woods Hole Oceanographic Institution (WHOI) and primary funding partner National Oceanic and Atmospheric Administration (NOAA) Ocean Exploration.

The expedition brought together OECI partner robots together with OET’s EV Nautilus for a ground-breaking technology demonstration in the Pacific Ocean during May 2022. These were:

Mesbot – WHOI’s mid-water robot that is designed to image and sample plankton layers.

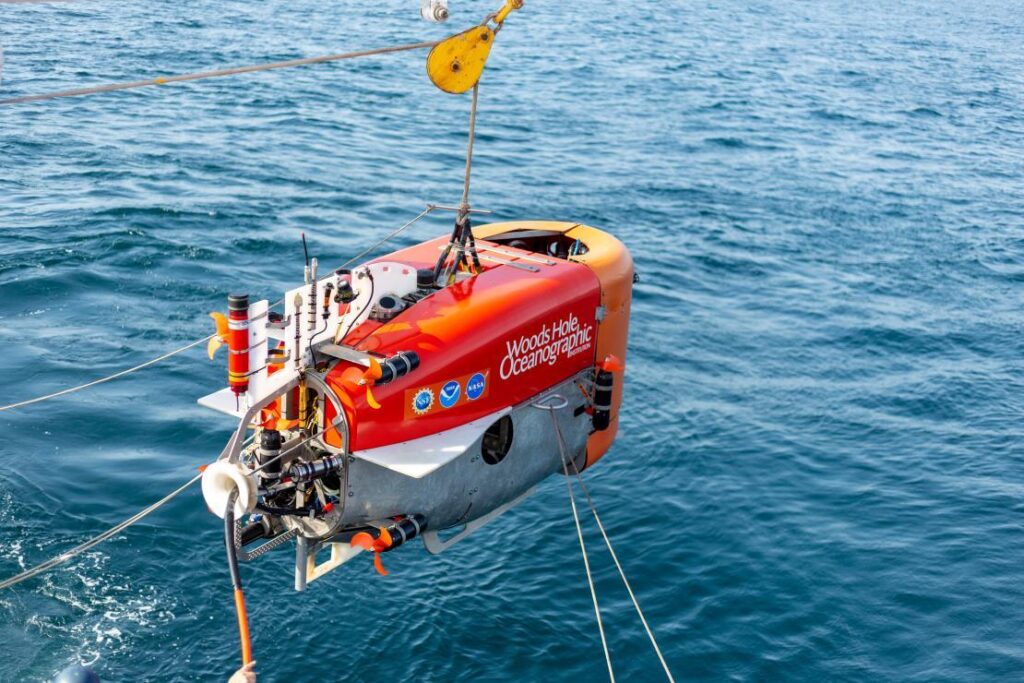

NUI – WHOI’s hybrid ROV-AUV, designed initially to work under ice, that can operate out to about 20km on a fibre optic cable for high data rate data, but can also continue to operate without the fibre link.

DriX – UNH’s 7 m-long USV capable of supporting a variety of payloads such as multibeam echo sounders, acoustic communications and tracking and surface communications.

Their goal was to have all three platforms operating together, sharing information and situational awareness and relaying their information, via the DriX, back to the EV Nautilus, enabling scientists onboard to remotely control subsurface operations up to 20 km away from the ship.

Key to meeting their goal was inter-vehicle communications, tracking and positioning.

The solution

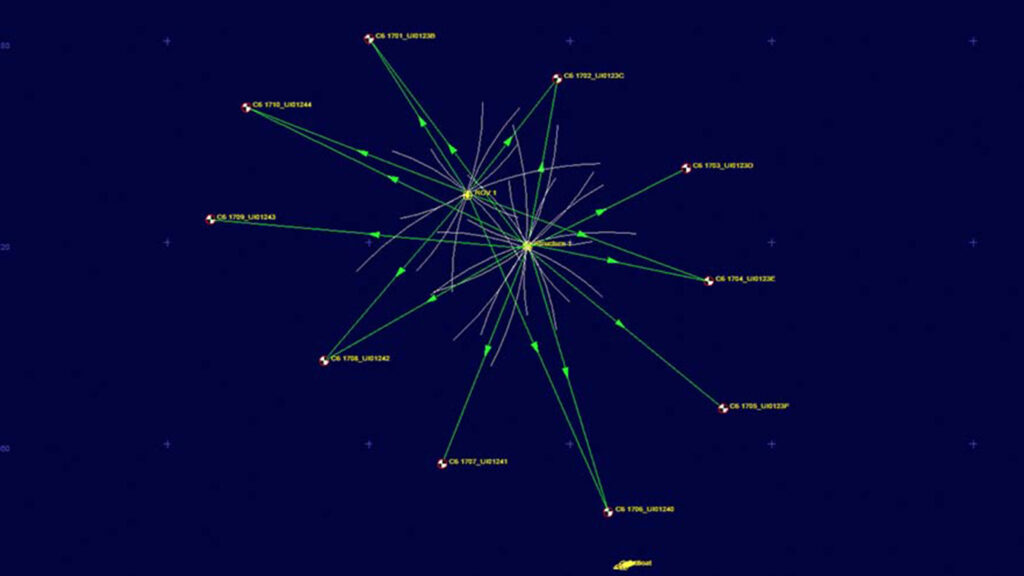

The DriX used a marine broadband radio link to communicate with the RV Nautilus (and our HPT 3000) to track, position and communicate with (including providing navigation data) the Mesobot and NUI as part of our Mini-Ranger 2 Ultra-Short BaseLine USBL system.

The underwater vehicles Mesobot and NUI were fitted with our AvTrak 6 combined tracking, telemetry and control transponders. The EV Nautilus was also fitted with our Ranger 2 Gyro USBL system, which would have also be able to track, position and communicate with the Mesobot and NUI, if this had been required.

Mini-Ranger 2 is our mid-level USBL tracking system that’s also able to support communications with underwater vehicles. It can track up to 10 targets at a time, at ranges of up to 4,000 m (with an extended range option) and, with our Robotics Pack, enables command and control untethered underwater vehicles.

For the OECI team, it was this combination of communications and positioning – acomms and USBL – that offered the broadest possibilities to the mission, from a single system.

AvTrak 6 is our tracking, communications and relocation transceiver. It allows USBL aiding for your AUV from a surface vessel and robust telemetry for AUV to vessel and AUV-to-AUV communications.

Ranger 2’s Gyro USBL comes pre-calibrated, thanks to its perfectly aligned acoustic transceiver and built-in attitude and heading reference sensor (AHRS), so you don’t need to take the measurements otherwise needed to determine the alignment of the ship’s motion sensors to the acoustic transceiver.

This makes it a very a portable system that the OET can use on vessels of opportunity. On the EV Nautilus, it was fitted through the vessel’s moon pool.

0

robots

0

dives

Communications

0

km

range

The results

“This was a real first for us,” – Professor Larry Mayer, Director of the Center for Coastal and Ocean Mapping, University of New Hampshire.

Over the course of the 16-day expedition near the island of Oahu, off Hawaii, the team tested and demonstrated operational capabilities. Over 30 dives were performed, totaling 210 hours in the water.

The team established a common control system, based on the robot operating system (ROS) for the vehicles and then set out, each time proving out more and more capabilities.

First, they had DriX track and communicate with Mesobot, using Mini-Ranger 2. Because the DriX has GNSS data at the surface, this meant it could position the Mesobot in the real-world and relay this data back to the RV Nautilus.

Next, they sent commands, via the DriX to Mesobot, from EV Nautilus to open and close its samplers, as well as to move up or down or to the right or left as well as change speed through the water column.

But then the most exciting thing happened, explains Professor Mayer:

“Mesobot is designed to sample layers in the water column. But it doesn’t know where they are. DriX has a sonar (EK-80) that could see those layers. So we could get DriX sonar data back on the ship and in real-time see what’s called the scattering layer of plankton and command the Mesobot to go to that layer to sample it.

“Because Drix is circling above, it can actually see the Mesobot in the layer. This was a whole new world. Normally, Mesobot is sampling blindly. We could now direct it into the layer, know it’s in the layer and see if its entrance causes the layer to scatter. All these were unknowns before.”

The team were then able to repeat these activities with NUI, including using DriX to map the seafloor east of Maui and then relay a mission to NUI for further investigation. In addition, CTD data, as well as snippets of imagery and bathymetry were transmitted acoustically up to the DriX, using Mini-Ranger 2, and then via the radio link back to the Nautilus.

“By the end of the cruise we were able to have both vehicles in the water with the DriX circulating above, communicating with each of the vehicles, giving each other situational awareness, and the mothership, it was off do its own thing. I couldn’t have asked for a more successful cruise,” says Larry.

“We are really opening up a new world of multi-vehicle operations. In the old days, we would schedule a cruise and just use the Mesobot or schedule a cruise and just the NUI or an ROV. Even if they would all fit on one ship at the same time, you only use one at a time, so the $60,000 a day would be clicking away and you’re only doing a single science operation.

“Now we can do 2-3 science operations, the efficiencies are tremendous and it allows us to explore the seafloor, water column and surface all at once.

“The Mini-Ranger 2 system gave us the broadest base of possibilities with having both the acoustic communications and the positioning, USBL and acoustic communications, from the same system and that combined set of capabilities was so important to us.

“The standardization and ease at which we were able to send messages across from our programmers made it easy to use. The cooperativeness and responsiveness of the team at Sonardyne was also really helpful. They didn’t see it as disruption, they saw the possibilities.”

The expedition was funded by NOAA Ocean Exploration via the Ocean Exploration Cooperative Institute.

For more information and to watch other videos from Nautilus, click here.

Bringing special order accuracy to small diameter AUVs

L3Harris has armed its Iver3 AUV with Special Order survey navigation capability – thanks to our Mini-Ranger 2 Ultra-Short BaseLine (USBL) system and AvTrak 6. Find out how – and how it will help cut offshore wind farm survey costs.

The challenge

Demand for underwater surveys in coastal waters as part of the offshore wind life cycle is at an all-time high. There’s little sign of that demand falling, thanks to a global shift to renewable energy. But surveys come at a cost.

To keep costs down, surveyors are looking at innovative ways to survey more seabed more efficiently using smaller AUVs that reduce operational costs by requiring smaller vessels and fewer people and reducing their overall carbon footprint.

This includes International Hydrographic Organization (IHO) classified Special Order standard surveys, which are often specified for pre- and post-surveys underwater power cables and UXO surveys.

To meet navigation requirements, Special Order surveys in shallower waters tend to require ship-mounted sensors, to achieve the absolute positional accuracy required (using the vessel’s RTK/GNSS position).

In deeper waters, heavier, larger diameter AUVs are used. Because they rely on a DVL and an inertial navigation system (INS) for their navigation, they also must be supported by large vessels.

But what if you could perform Special Order surveys in shallower coastal waters with smaller low-cost AUVs, reducing your reliance on large vessels, reducing logistics, emissions and operational costs?

This was the challenge set by customers of L3Harris who were keen to find ways to use their Iver3 AUV for Special Order surveys.

Specifically, they set out to test if USBL-aiding at high enough accuracy for Special Order surveys could be achieved within the size, weight and power limitations of a smaller, light weight AUV platform, such as the 5.8 in-diameter Iver3.

If it could, it would allow underwater run-times of more than eight hours, and a new paradigm in lower operational cost coastal surveys.

The solution

L3Harris had already used our Mini-Ranger 2 for USBL aiding an iXblue Phins INS, via one of our AvTrak 6 OEM Nanos, on one of its Iver3s on a separate customer project. Read more here.

Mini-Ranger 2 is the ideal USBL system for coastal operations, supporting high-elevation tracking of up to 10 targets simultaneously down to 995 m water depth (extendable to 4,000 m), as well as data harvesting. It offers performance without the cost and complexity of a larger deep water USBL system.

At the heart of the system our HPT 3000, a highly capable surface deployed USBL transceiver which is optimized for performance in shallow water, high elevation and long lay back operating scenarios, as well data telemetry.

To provide INS aiding, L3Harris’ customer chose to integrate our AvTrak 6 OEM Nano, with a remote transducer, into their Iver3.

AvTrak 6 OEM Nano is the smallest variant of our AvTrak transceiver, designed for ease of integration on smaller underwater vehicles. It combines the functions of a transponder, transceiver and telemetry link, enabling communications, tracking and USBL aiding for subsea robotics. It’s also based on our 6G hardware platform, which means it’s interoperable with all our USBL, LBL and INS systems. This provides flexibility, but also performance enhancement, for example when combined with a Sonardyne INS.

As in the earlier project, the AvTrak 6 was programmed to speak the right language to the third-party IXBLUE Phins INS, by sending out an APOS PSIM SSB telegram, instead of our proprietary SPOS. The AvTrak 6 transducer was also supplied on a special Iver3 mounting post design, to make it easy to plug and play into the AUV – and any other Iver3, for that matter.

Mini Ranger 2 was pole-mounted to the support vessel with hemisphere GPS for topside absolute positioning.

The results

L3Harris ran a <5 km-long survey, with six 800 m legs, in challenging <20 m water depth in Narraganset Bay on the north side of Rhode Island Sound.

Real-time USBL-aiding improved the survey accuracy by upwards of 7 m on far end of survey legs through the turns. During the survey, real-time survey performance ranges up to 800m were tested with USBL position standard deviations ranging from 1 – 3 m.

In addition, using Mini-Ranger 2’s robotics pack, the L3Harris team were able to provide the vehicle with information of the acoustic environment, so its autonomy could make decisions to adjust the AvTrak 6 OEM Nano’s power and gain settings to improve acoustics without a human in the loop.

“The standard deviation on the USBL position fixes were accurate allowing real-time position updates to the INS. The ease of operation using the Mini-Ranger 2 topside to track and monitor environmental influences throughout the survey also added a layer of safety for monitoring the UUV.”

“This set up allows surveyors to meet Special Order navigation standards, which is a big deal for small unmanned underwater vehicles (UUVs),” says John Sloat, Application Engineering Lead, L3Harris. “The problem before has been that there’s not a lot of real estate inside smaller UUVs to house the onboard technology required for Special Order navigation capability in. But now they can.

“This capability adds a high level of survey efficiency by reducing the need to frequently surface for a position fix which increases the vehicles endurance, reduces the risk of vehicle entanglement or loss, and allows for larger areas to be surveyed. It also means they have real-time data vehicle positioning, which, when post-processed, could be improved even more. That’s really valuable to survey customers and we do see this as the cusp of a new UUV survey era,” adds John.

What was also hugely valuable to the L3Harris team was the support from Sonardyne’s experts.

“The level of support and service from Sonardyne has been exceptional,” says John. “We are very pleased. It’s been a fantastic experience at every phase of the integration we have done and that’s a big de-risk for us, having a partnership like this.”

A 'custom-off-the-shelf' product provides a timely solution for Dana Petroleum

Our experience and expertise allowed us to rapidly adapt our off-the-shelf technology for Dana Petroleum. This delivered a cost-efficient, low environmental impact, and timely solution for them to monitor their suspended wells in the North Sea.

The challenge

As they reach the end of their productive life, oil and gas well heads still need to be monitored whilst suspended – for up to five years, before they become fully abandoned / decommissioned. A regime must be in place to monitor the assets ‘in perpetuity’ to meet government regulations. As this is ‘abandonment expenditure’, rather than capital expenditure, any monitoring schedule must be conducted as cost effectively as possible.

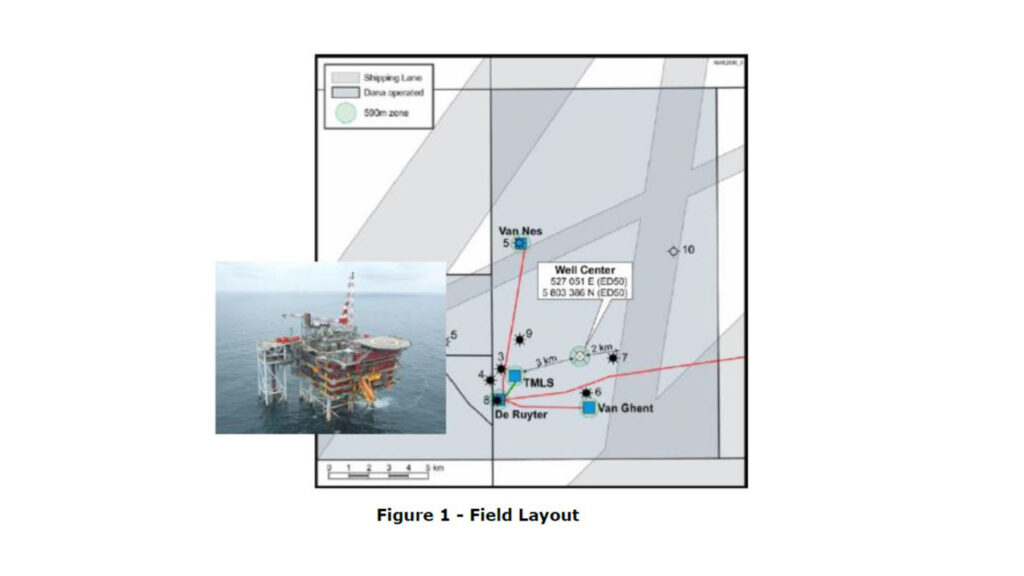

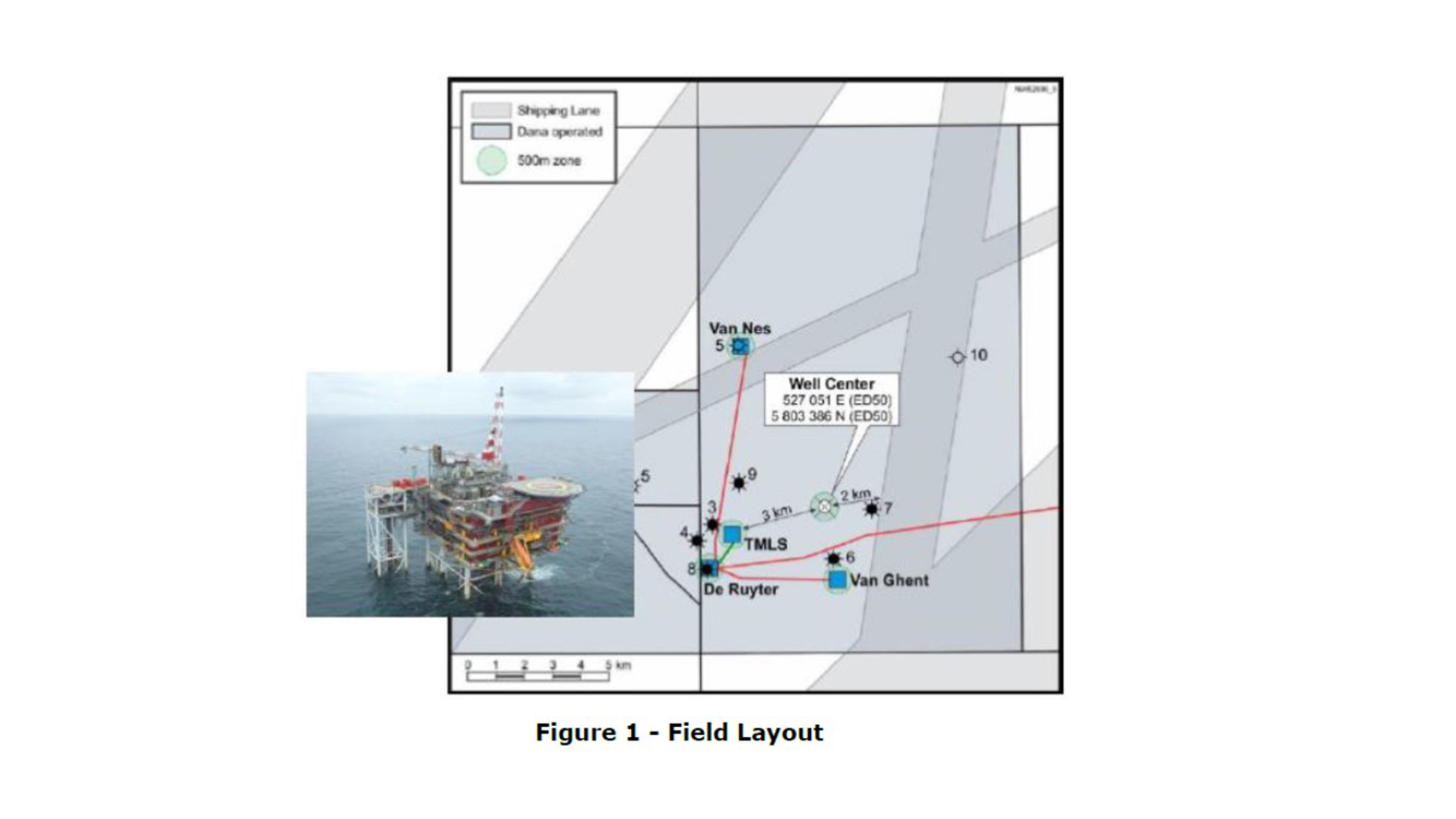

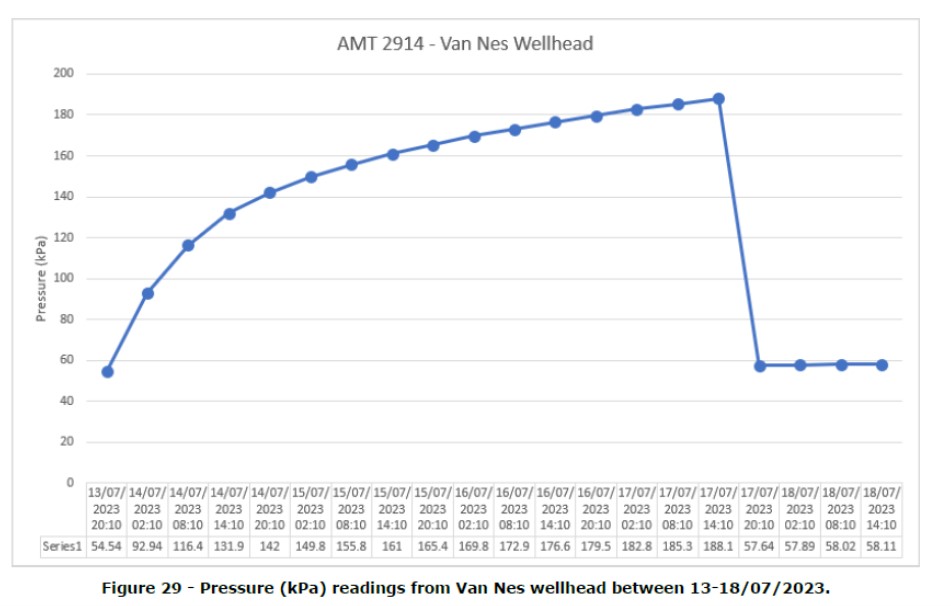

Dana Petroleum (Netherlands) was faced with one such challenge in early 2023 when they needed to plan and implement a well annulus monitoring schedule for suspended wells at their Van Ghent and Van Nes subsea wells, situated in the North Sea approximately 60km West of The Hague. The wells were situated alongside others still in operation and although the topside platform remained, communication links with the sensors on the suspended subsea wells had been lost. There was an additional challenge of the system needing to be in place within 12 weeks.

The solution

The ’simple’ solution would have been to lay new communication cables from the suspended well heads to the topside platform to enable the monitoring. But this would have been lengthy, expensive and carbon intensive, involving bringing in large vessels to lay long stretches of subsea cables. A quicker, cost effective and lower carbon solution was needed. Having heard about Sonardyne’s experience and expertise in long-term subsea asset monitoring, Dana Petroleum approached us for a solution.

We have many years’ experience in providing subsea pressure and temperature data directly from well downhole gauges, mostly during the appraisal phase in a field development, providing essential data to the reservoir engineers before connection is made to the offshore or onshore facility.

Although Dana Petroleum’s requirement was well within our capabilities, there were some initial unknowns such as; field layout, pressure gauge model and manufacturer and how the equipment would be mounted to the subsea manifold. Also, which topside would be most suitable for data harvest? Something which is typically dictated by the vessel size, noise profile and water depth. The timeframe was also very challenging.

In the following weeks, Dana Petroleum provided information on the field layout, drawings of the subsea infrastructure and a strong specification for a system capable of monitoring the annulus pressures at both locations. Having received this, we were able to provide illustrations of previously designed bracketry, 3D CAD images of our potential offering and expert advice to work out the optimum placement to enable best line of site for data harvesting. With a firm specification and known time constraints we looked to our off-the-shelf products with a view to creating a semi-custom solution with our projects team.

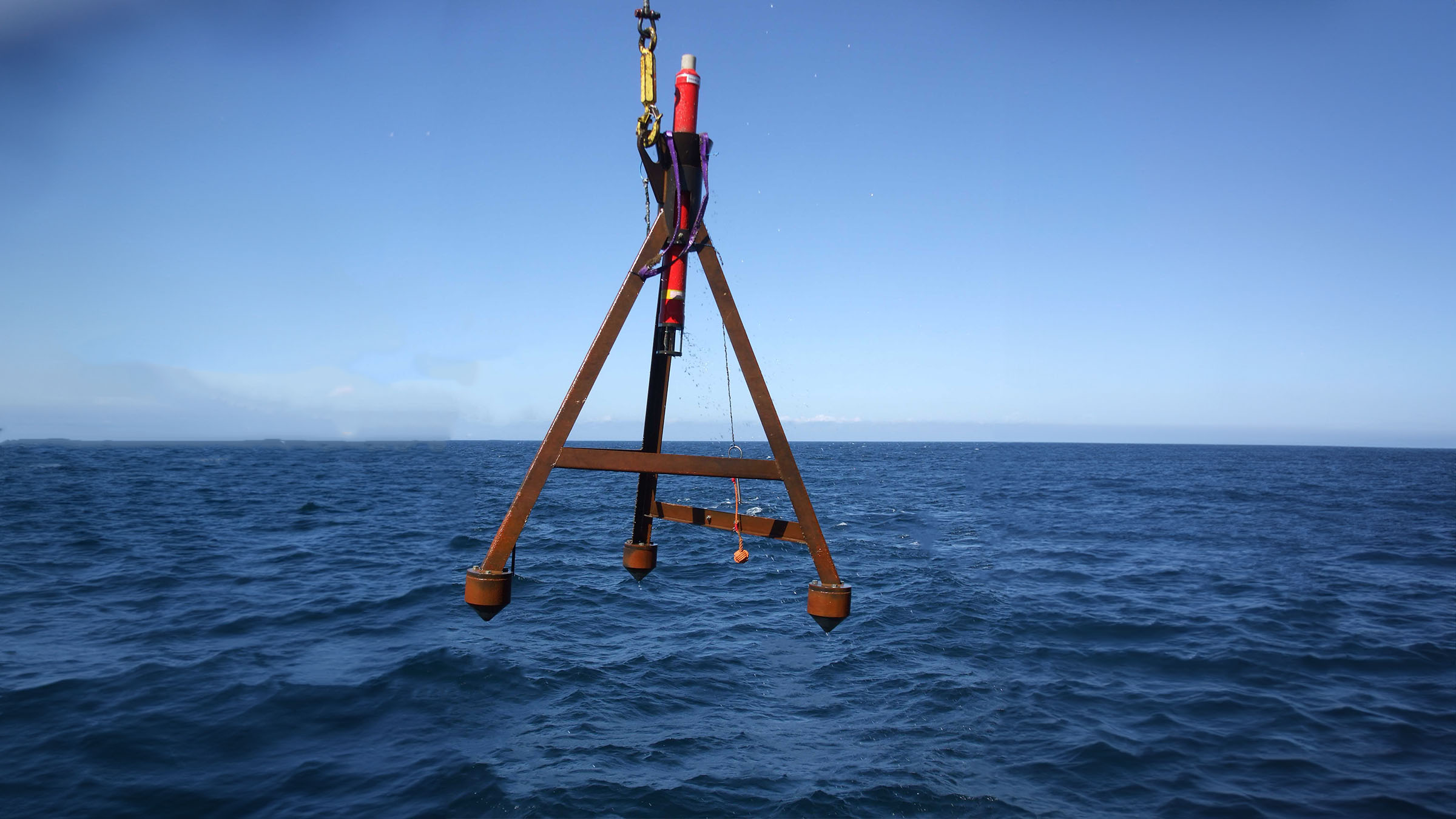

The obvious choice was to make custom alterations to our Autonomous monitoring transponder (AMT). The AMT has been used in a wide variety of different applications including overburden monitoring and pipeline movement monitoring, all utilising and autonomously logging pressure sensor data. These solutions can operate autonomously over long periods of time, over five years – depending on deployment – logging data and making it accessible for wireless upload.

The topside platform of choice was a Nano topside equipped with a ruggedised laptop running Sonardyne’s Monitor software fitted to a small crew transfer vessel that would pass by the wells at regular intervals, delivering workers to the platforms. The size of the vessel dictated a small portable solution but other options are available for all sizes of vessels.

Once the seabed and topside products were selected, custom modifications were made by the projects team to the AMT, allowing the pressure sensor to be connected to the annulus via a flange – rather than inside the AMT –to give flexibility in the location of the AMT and achieve best line of communication with the Nano transceiver when it passed overhead.

A factory acceptance test was witnessed by Dana Petroleum where our projects team provided documentation and coordinated the testing. Following this the equipment was shipped and ready for installation – all within a few months!

Over the horizon robotic data harvest aids Shell's net zero ambition

Sonardyne, working with XOCEAN’s Uncrewed Surface Vehicles (USV), deliver a lower cost, lower risk and lower carbon, remote acoustic data harvesting service to Shell from their Ormen Lange gas field in the Norwegian Sea.

Shell’s Ormen Lange gas field is a deep-sea site 120 km / 75 miles off the coast of Norway. As Norway’s second largest gas producer, it plays a key role delivering stable gas supplies to Europe. Built on the site close to Storegga, a major landslide which occurred some 8000 years ago, about 5 million tonnes of rock was used to prepare the seabed for subsea equipment back in 2005. The field has been operational since 2007. Ormen Lange is distinctive in that it doesn’t have conventional surface operation platforms.

Close monitoring of any seabed movement is key to prevent any potential impact to the pipe system. Monitoring of the ocean floor around the well heads is conducted by seabed sensors. The first monitoring array at the site saw 203 Acoustic Monitoring Transponders (AMTs) installed in 2011. These sensors enabled monitoring of changes in pressure and tilt to provide an understanding of seabed movement.

This array was recovered in 2016 due to battery limitations and uncertainty in drift. Today the monitoring is undertaken by an array of 75 Sonardyne seabed Pressure Monitoring Transponders (PMTs). Shell took the decision to install 30 PMTs in 2019 with a further 45 installed in 2020.

The challenge

Without surface platforms, acoustic data from the subsea sensors had to be harvested by crewed vessels in the early years of the field’s operation. This was costly, carbon heavy and posed a risk to personnel in often challenging sea conditions.

With a company ‘Powering Progress’ strategy to achieve net-zero emissions by 2050, Shell was looking for an alternative data harvest method that would reduce cost and risk as well as its carbon footprint.

The solution

Marine robotic platforms provide the opportunity to remove carbon and personnel risk. Working with the customer and XOCEAN as a sub-contractor we developed a solution that would save time, costs. and carbon, while also eliminating the human risk element, using a USV to conduct the data harvest.

The proposal was to use our HPT 3000 transceiver mounted to an XOCEAN USV to remotely harvest data from the 75 seabed PMTs. The HPT 3000 is perfect in terms of size, weight and power for deployment from a USV and can communicate with seabed transponders at depths up to 995 m (or 4000 m with an extended range version).

XOCEAN USVs are perfect for the data harvesting mission at Ormen Lange. They enable full over-the-horizon 24/7 operations. This means that operators and data analysts can remain safely onshore whilst the operation takes place and data can be sent ashore and verified in near real-time using the USV’s satellite communications.

This satisfied Shell’s commitment to accelerate the transition of their business to net-zero emissions and to integrate sustainability within their business strategy. Following the successful PMT installation in 2019, a five year project was agreed where Sonardyne are responsible for the data delivery to Shell and XOCEAN are responsible for delivering the transceiver to the field for data collection via their USV.

The results

The project began in January 2020 and this was the first time a remote USV data harvest was completed offshore in Norwegian waters by any operator.

Whilst the USV and HPT 3000 were in Norwegian waters surveying the Ormen Lange site, the Sonardyne and XOCEAN personnel never left their bases in England and Ireland.

The data harvest was monitored in real time, 24/7 and the two teams were in contact with each other as well as the remote equipment. This mean that data was being monitored by our team as it was collected and there was no risk of the USV returning with missing or irrelevant data. Had there been any missed or partially collected data the Sonardyne team could ask the XOCEAN team to return to recollect from a particular PMT whilst still in the field, rather than waiting until the vessel returned and having to send it out again.

Successful data harvests have been conducted yearly since 2020 and continue to be a cost effective, low impact operation. This year we collected data from the Ormen Lange site twice, in Spring and Autumn.

If you think you have a similar challenge for us, contact us today.

Autonomous robots prepare to storm the ocean depths

Sonardyne were delighted to be part of the trials of a fleet of marine robots able to tackle complex offshore tasks as part of a ground-breaking project funded by Innovate UK, which is poised to change approaches to ocean exploration. Autonomous marine systems are being developed and deployed in increasing numbers. However, as maritime operations become ever more complex and expensive, and installed energy infrastructure increases in scale and distance from shore, there is a rapidly emerging need for more sophisticated multi-platform capabilities in the offshore renewable energy (ORE) market.

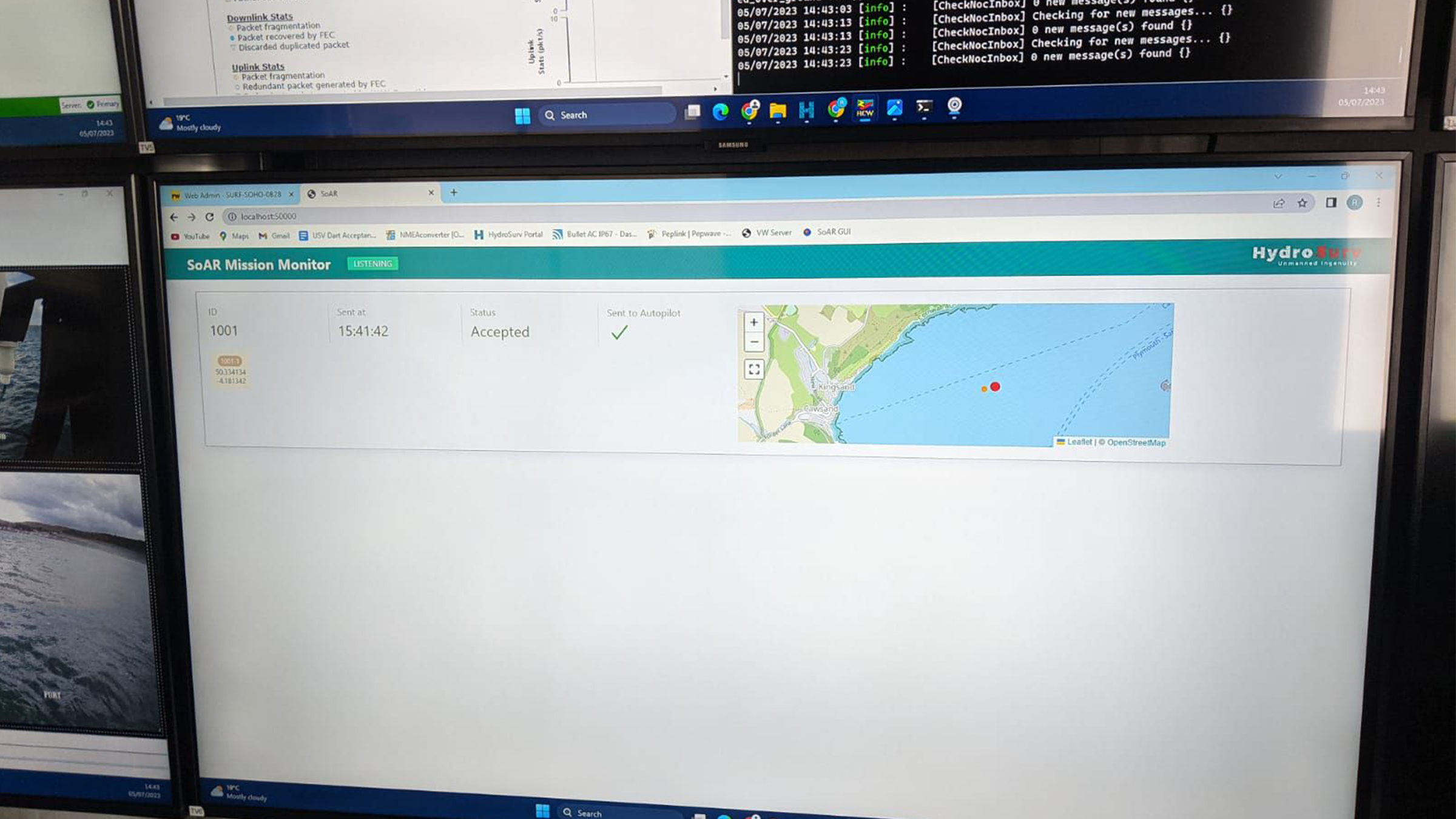

Squads of Adaptive Robots (SoAR) is a two-year collaborative research project, led by the developer of ecoSUB autonomous underwater vehicles (AUVs), Planet Ocean. The project kicked off in September 2021 and culminated this summer with full system testing at Smart Sound Plymouth on England’s south coast.

The SoAR team’s aim was to demonstrate how large-scale survey and exploration missions can be achieved by going beyond the limitations of individual AUVs. We worked alongside industry and academic partners; Planet Ocean, HydroSurv, the National Oceanography Centre (NOC), Royal Holloway University and the Offshore Renewable Energy (ORE) Catapult to develop advanced AI-driven mission planning, communications protocols for fleet coordination and significant improvements in underwater navigation and communications technology.

The trials simulated an offshore windfarm concession survey mission informed by a comprehensive business case analysis by the team at ORE Catapult.

The technology

The fleet-level autonomy engine developed by Royal Holloway, University of London served as the mission’s central nervous system, making real-time decisions and replanning when necessary due to factors such as inaccurate mission execution, vehicle faults, changes in the operating environment or the addition and removal of stations. The division of labour enabled by this approach showed significant promise in productivity gains made possible by robotics and AI.

The SoAR Communications Backbone, developed and released by the team at the NOC, acted as a central messaging system which enabled interoperability between the fleet-level autonomy engine, each vehicle-specific command and control system and any other sub-system requiring bi-directional communication. This was key to allowing the seamless introduction of different platforms and sub-systems in diverse combinations to suit a wide range of mission objectives.

We provided inter-medium communications via our AvTrak 6 Nano acoustic transceivers fitted to each AUV. This enabled simultaneous USBL tracking via a surface vessel and robust telemetry for AUV-to-vessel and AUV-to-AUV communications.

A small swarm of four ecoSUB AUVs, each fitted with an AvTrak 6 Nano acoustic transceiver, played a crucial role in rapidly assessing the underwater environment and conducting preliminary evaluations to identify targets of interest.

An Auto-Hover 1 (AH1) AUV, owned and operated by NOC, capable of exceptional precision in maintaining station and navigating vertically within the water column, and fitted with an AvTrak transceiver, was dedicated to close inspection tasks, enabling intricate and comprehensive examination of identified targets.

Our HydroSurv REAV-60 uncrewed surface vessel ‘Decibel’ assumed a pivotal role, serving as a crucial communications gateway to and from the AUV swarm. It was fitted with an HPT 3000 transceiver and ran our well-established Ranger-2 software on its topside, facilitating inter-medium communication and providing navigation support to the AUVs. Decibel was also equipped with various communications devices including 4G/LTE and Iridium satellite communication systems to enable communications between subsea, surface and the Autonomy Engine.

The deployed SoAR fleet was managed and controlled from HydroSurv’s shore-based Remote Operations Centre in Exeter, using 4G/LTE and Iridium communications.

The results

The open-water trials successfully showcased co-ordinated missions designed, monitored and adapted in real-time by an intelligent “Autonomy Engine”. The trials involved several surface and underwater autonomous systems, with mission management conducted from a remote shore-based command and control facility.

SoAR has led to the introduction of several technological innovations, including advanced AI-driven mission planning, open-source communications protocols for heterogenous fleet coordination and a range of new and enhanced platform capabilities for both surface and sub-surface systems. The variety of small form factor robotic platforms involved in the project represented some of the best innovation in UK ocean robotics to date.

The SoAR concept is adaptable to various applications but strategically tailored to address the specific needs of the offshore wind sector, developing an approach that will offer new operating paradigms and substantial long term cost savings for offshore asset construction and maintenance compared to conventional methods.

SoAR received funding from the ‘Next Generation Subsea Technologies’ competition, a joint initiative supported by Innovate UK, the Net Zero Technology Centre and the Royal Navy.

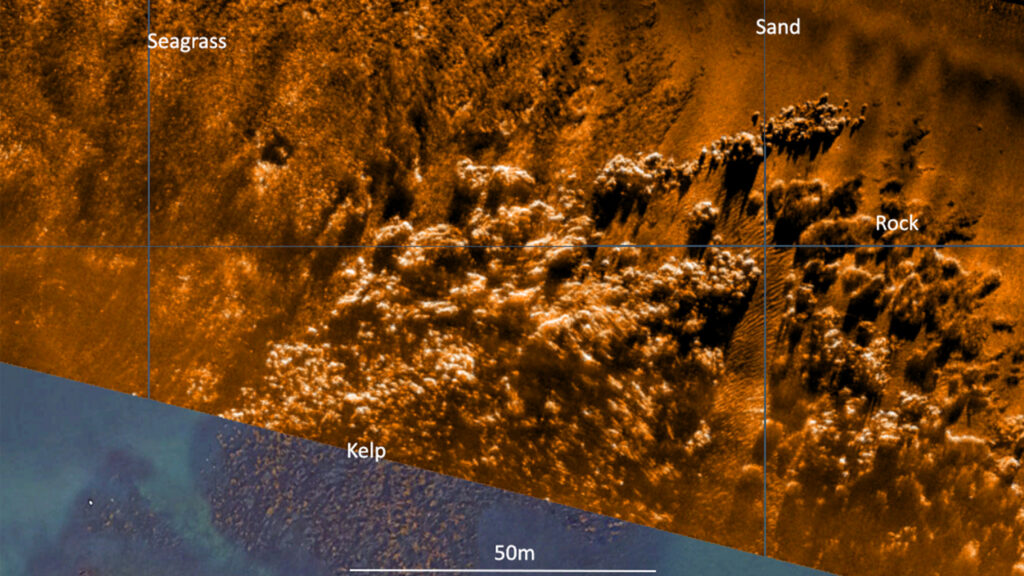

Mapping the future for seagrass beds in Plymouth Sound

Seagrass beds are incredibly important ecosystems that offer a range of ecological benefits. Not only do they provide crucial habitats for a diverse array of marine wildlife, especially in coastal areas like Plymouth Sound, they can also store carbon, helping to mitigate the effects of climate change. These underwater meadows serve as nurseries for many species of fish in the early stages of their life, offering them protection and abundant food sources. Additionally, seagrass beds help to stabilise the seabed with their root systems, preventing coastal erosion and maintaining water quality by trapping sediments and nutrients.

However, despite their importance, locating and monitoring seagrass beds using traditional methods, such as survey boats, presents significant challenges. Seagrass typically grows in shallow waters, which can make it difficult for boats to navigate close enough to the shore to obtain accurate data. Traditional survey boats are often large and cumbersome, making them hard to manoeuvre in shallow or rocky areas. This limitation can result in incomplete or inaccurate assessments of seagrass distribution and health.

Furthermore, the process of using boats for surveying can be time-consuming and labour-intensive. It often requires multiple trips and extensive manual labour to map out the seagrass beds accurately. The visibility in shallow waters can also be poor due to water turbidity, further complicating the survey efforts and leading to potential underestimation of seagrass coverage.

Finding a solution…

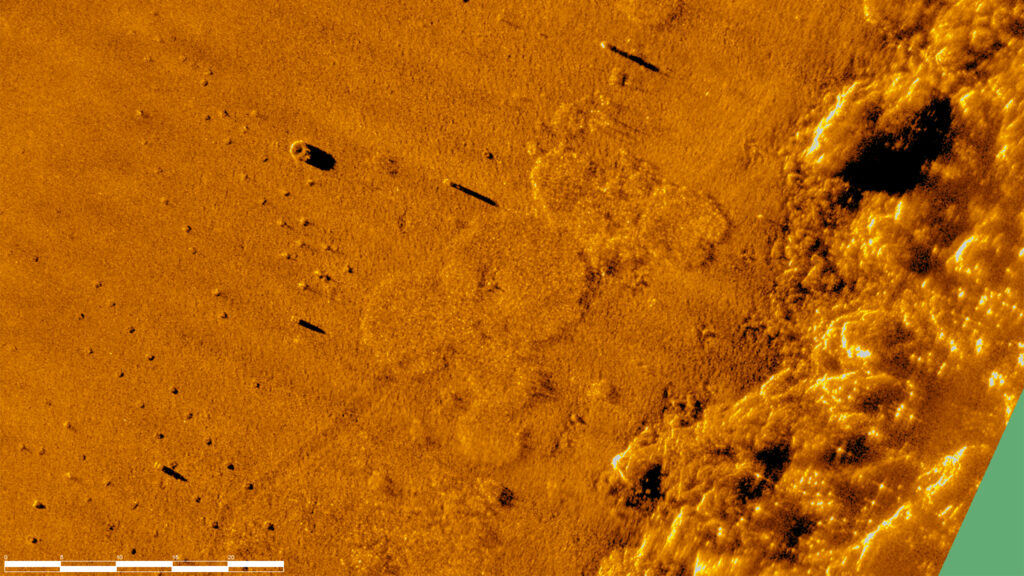

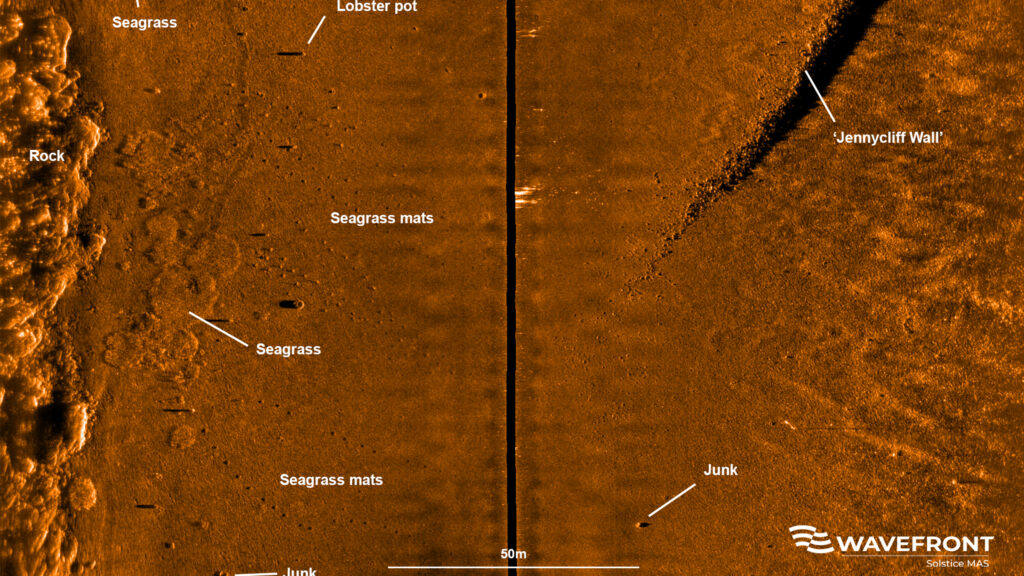

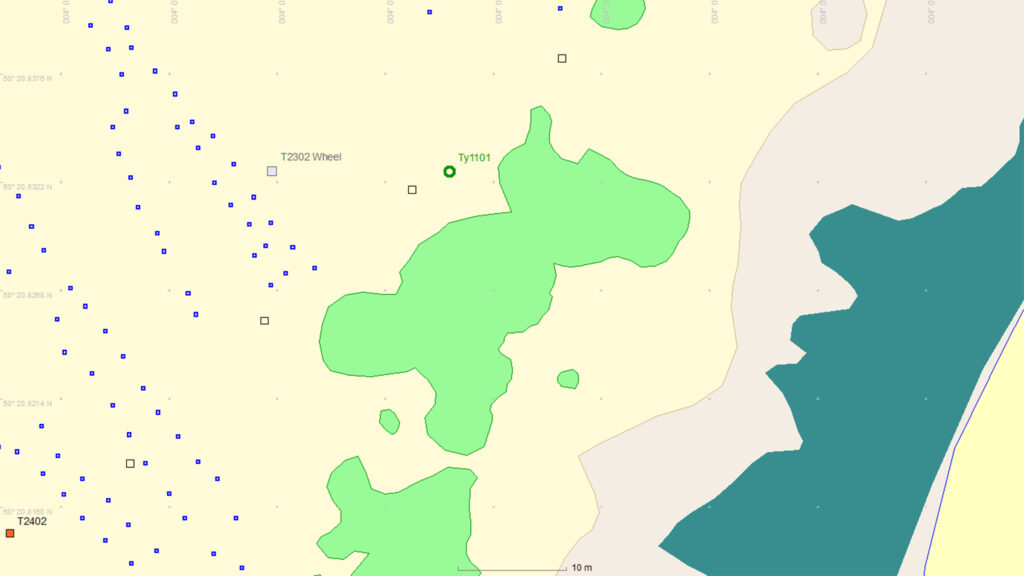

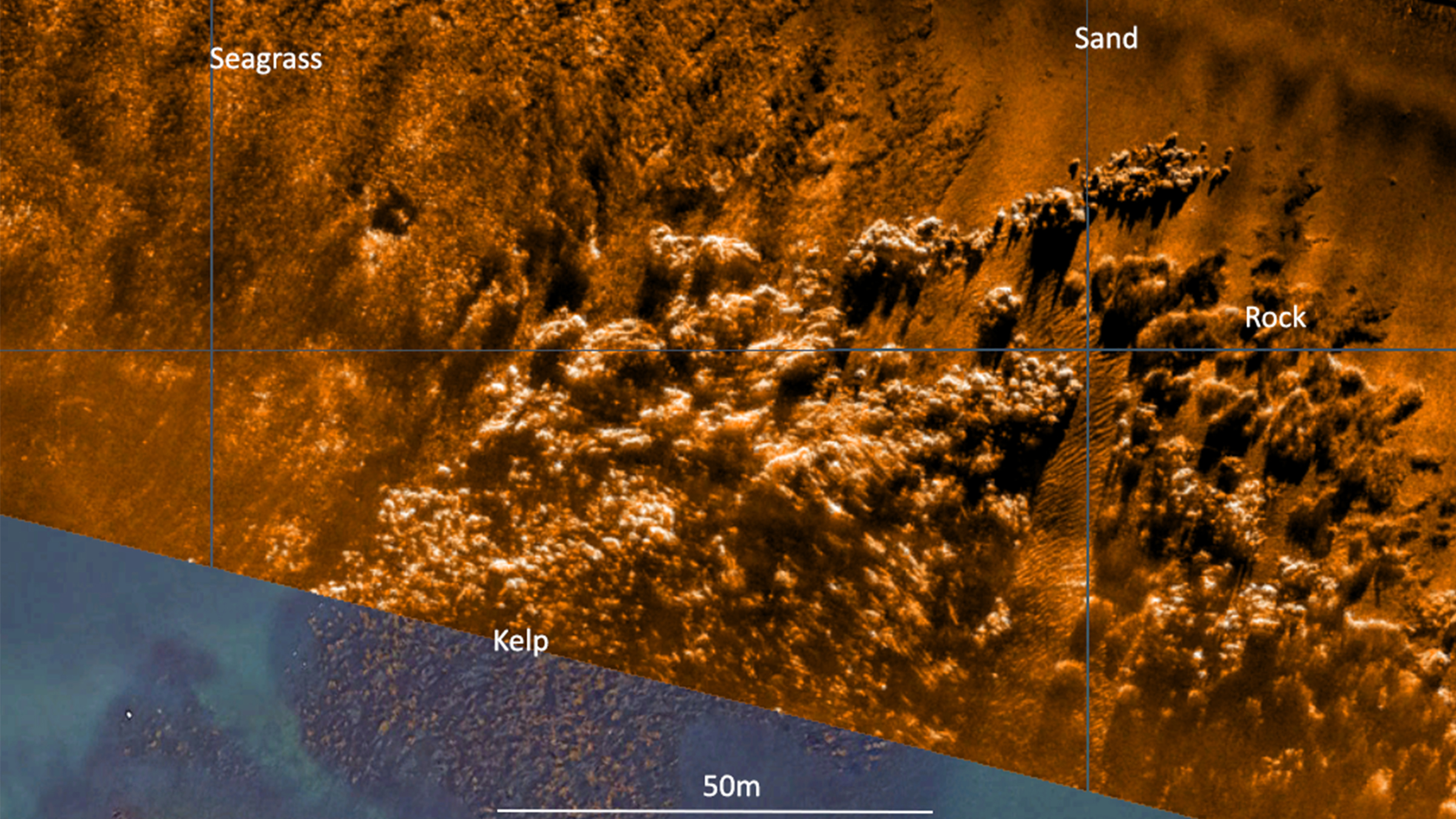

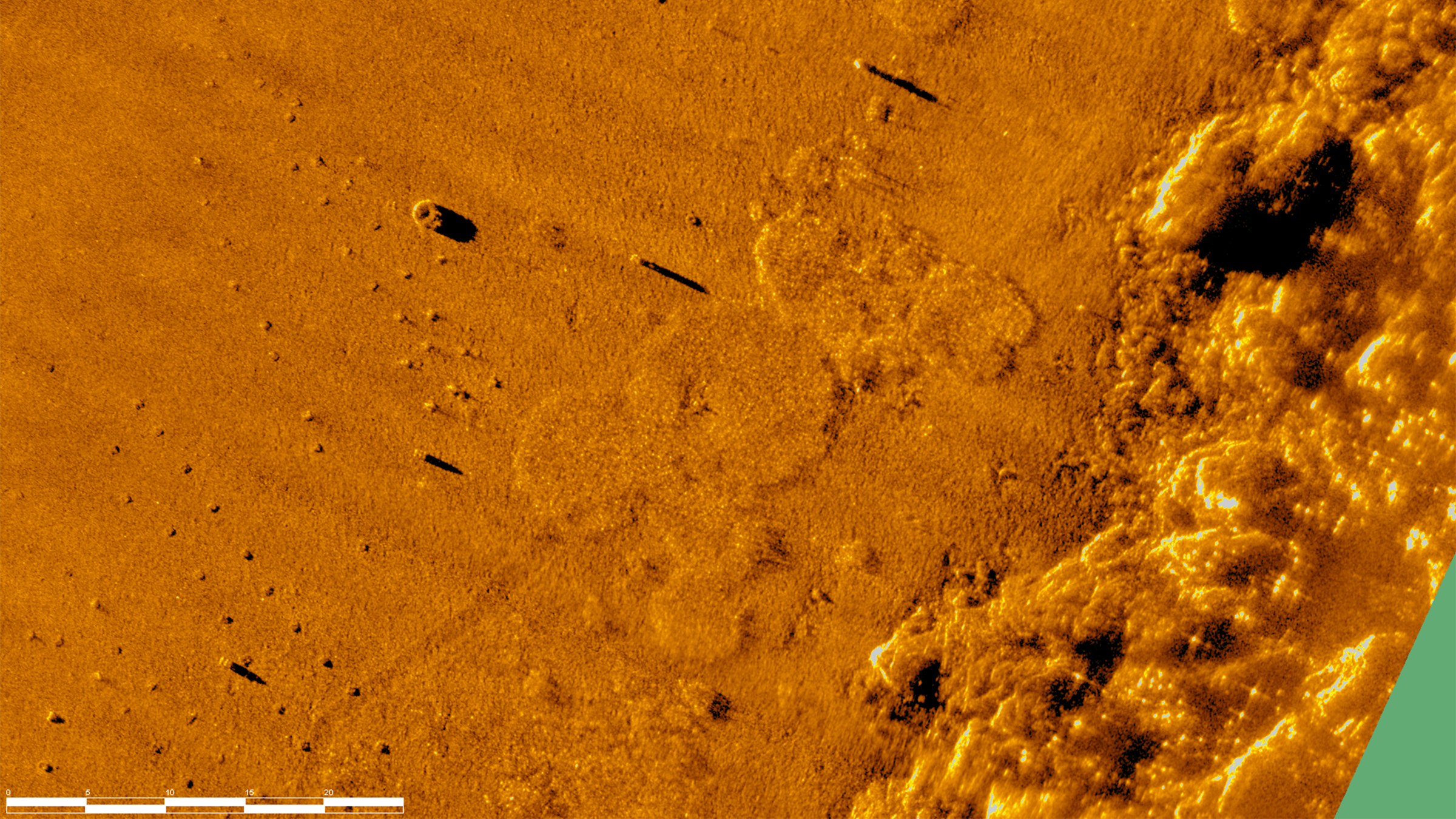

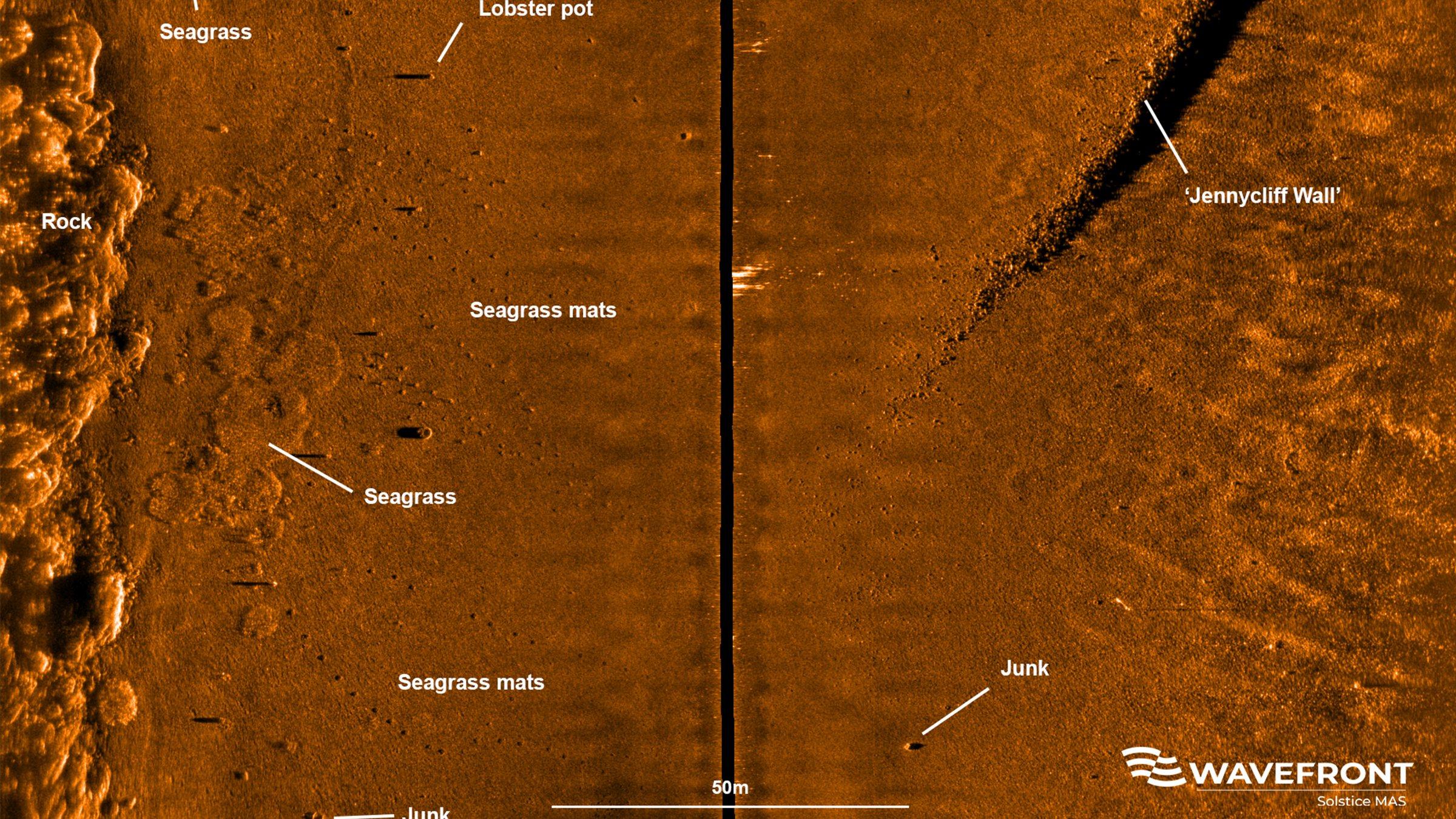

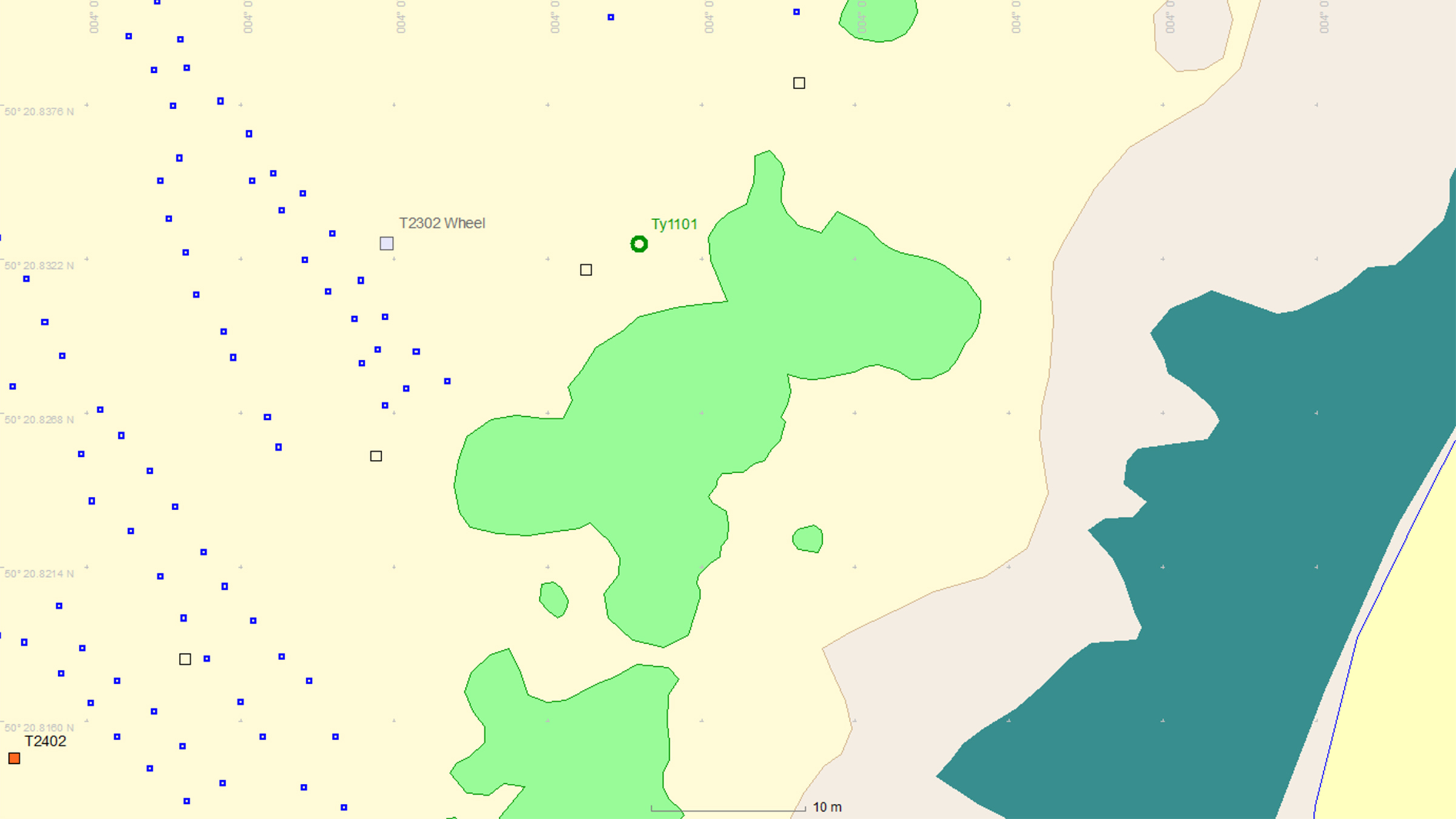

This is where Sonardyne and Wavefront Systems come in. The solution, which combines Sonardyne and Wavefront technology, is a survey boat carrying Solstice MAS™ (Multi-Aperture Sonar) as well as a SPRINT-Nav Mini mounted to a pole, deployed over the side of the boat; this maps the chosen area in 200 m wide strips. Once this survey has been completed, the sonar data that has been captured is then processed to create a map of the seagrass in a GIS. A Remotely Operated Vehicle (ROV) is then sent to the same area to ground truth features on the seabed to check that they are how they have been interpreted by Solstice MAS. The ROV is fitted with SPRINT-Nav Mini, allowing us to track its position underwater and guide it, using the map, to the features identified by Solstice; the ROV is also fitted with a camera and the recorded video can be used to create 3D models of the seabed.

Wavefront Systems’ Solstice MAS uses sound signals to produce high-quality images of the seabed, capable of creating images 200 metres wide at high resolution even in shallow water environments, all while consuming very little power. The Solstice family of sonars are built on unique MAS technology and are designed to fill the gap between standard side scan sonars, which are typically simple in design but give low image resolution, and Synthetic Aperture Sonars (SAS), which are expensive, more susceptible to complete data loss due to platform movement and also produce vast amounts of data. In order to execute more detailed mapping, Solstice MAS requires a high quality navigation sensor, which in this case is SPRINT-Nav Mini.

SPRINT-Nav Mini is an all-in-one vehicle guidance and navigation instrument, which combines AHRS data, Doppler Velocity Logger (DVL), Inertial Navigation System (INS) and depth sensor into a single housing. Having SPRINT-Nav Mini fitted onto the ROV provides positioning input, as well as attitude and heading data.

Creates images

0

m

at high resolution

ROV fitted with

0

D

camera

Solstice creates images

0

m

each side of the vessel

Adopting these technologies on such small versatile platforms opens the possibility of high-grade survey data in shallow waters. As a result of the cross Covelya Group collaboration between Sonardyne and Wavefront Systems, a high-definition map of seagrass beds can be created with a greater degree of accuracy than was previously possible with more traditional methods.

A seagrass restoration project conducted by the Ocean Conservation Trust (OCT) in Plymouth Sound, which involves monitoring, conserving and expanding the existing seagrass beds can be enhanced with the use of an ROV which has SPRINT-Nav Mini fitted to it. To help grow the existing seagrass beds, the OCT are placing seagrass mats on the seabed in Plymouth Sound. A survey boat fitted with Solstice and SPRINT-Nav Mini followed by an ROV fitted with SPRINT-Nav Mini can then be used to monitor and create a map of where these mats have been placed so that they have a better understanding of the success of the restoration and expansion project.

Unite your navigation and positioning for seamless efficiency

Fuse your workflow and control all your Long BaseLine (LBL), Sparse LBL, and SPRINT Inertial Navigation System (INS) projects from one intuitive interface. No more juggling multiple programmes – Fusion 2 simplifies your operations.

From subsea structure installation, metrology, pipeline and spool piece monitoring to pipeline positioning and more, Fusion 2 streamlines your subsea navigation and positioning. It connects LBL, Sparse LBL, and SPRINT INS for smooth workflows, real-time calibration and efficient deployments. This future-proof technology unlocks the potential of 6G+ and Wideband 3 instruments.

Real-Time Calibration: For faster, more efficient Sparse LBL operations, Fusion 2 allows real-time calibration of seabed transponders using Simultaneous Localisation and Mapping (SLAM). Eliminating delays and ensuring you collect accurate data from the start.

Enhanced efficiency through optimising hardware mobilisation. By consolidating control under one program, you require less equipment offshore, reducing costs and simplifying logistics, as well as saving you valuable setup time.

Built for our latest 6G+ instruments, Fusion 2 unlocks the full potential of Wideband 3 signal technology, ensuring your operations are at the forefront of subsea navigation.

Fusion 2 – fuse your systems for optimal performance

Why Fusion 2 is perfect for your operations

Do more with less – no need to operate two independent software and hardware systems to control your 6G LBL and SPRINT INS – Fusion 2 does it all in a single interface.

Fusion 2 LBL allows you to run calibrations in real time. Meaning you spend less time calibrating and more time collecting the right data, first time.

Lower your start-up costs: for practical, reliable LBL INS, Fusion 2 supports use of our SPRINT 300 with fewer transponders.

Backed by over 40 years of LBL system experience, Fusion 2 is the obvious choice for your offshore installation projects. Its 6G+ technology allows centimetric subsea positioning in all water depths. Highly robust and accurate instruments, professionally supported by our in-house engineers and surveyors, have made it the system of choice for subsea structure installations for decades.

Used with products such as GyroCompatt 6+, it provides you with centimetric positioning along with class leading Lodestar gyroscopes for heading, pitch and roll measurements all in a single, easy to deploy instrument.

If your underwater operations require precise measurements, an acoustic metrology system using several Compatt 6+ transponders can be placed in a network on the seabed / structures / hubs. The depths of the Compatts can then be accurately measured and 6G+ Wideband acoustic ranges collected between them.

Fusion 2 enables your seabed transponders to be SLAM calibrated in real-time for easier and faster Sparse LBL operations. And by embedding sensor data with high-update navigation ranging data, there’s no more interruptions to positioning updates at critical moments.

You’ll begin to see the benefits even before your project teams head offshore. Acoustic and INS projects can be configured and checked onshore prior to vessel mobilisation – saving you time, streamlining procedures and helping you to further de-risk operations.

If you need to tailor your operations, Fusion 2 enables multiple computations, comparing different set-ups, allowing you to pick the one you want. Sparse LBL might suit one operation more than LBL and vice versa. Now it’s easy to check, on-site, which works best for you.

For optimal performance, Fusion 2 can be used with a number of our products – including Gyro Compatt 6+, Compatt 6+, SPRINT-Nav, ROVNav 6+ / mini ROVNav.

To further increase operational efficiency, digital signal processing protocol, Fusion 2 is best paired with Wideband 3, which you’ll find inside our trusted 6G platforms, Compatt 6+ and ROVNav 6+.

Wideband 3 gives you sensor data alongside navigation ranging data, providing your operators with real-time positions and sensor data at the same time. This allows the acceleration of update rates by a factor of ten, eliminating latency issues.

Fusion 2 in action

Rewriting the subsea survey rules

Read moreDeepwater structure installation made easy

Read moreRemote advances; operational advantages

Read moreSupport

• Work side-by-side with our Projects Group from concept to deployment

• Systems are manufactured and tested at our world-class in-house facilities before delivery

• Talk to our experienced team about our USV data harvesting service

• 24-hour support, wherever you are in the world

Design

• Optimised for 6G+ and Wideband 3

• Combined acoustic LBL and INS navigation

• Intelligent troubleshooting built-in

• Reduced hardware requirements

• Subsea hardware options

• High precision Compatt 6+

• High power, long-range ROVNav 6+ transceiver

• Combined LBL transponder and Lodestar AHRS Gyro Compatt 6+

Specifications

| Feature | Specification |

|---|---|

| Design | The most powerful INS and LBL system on the market |

| Seamlessly combines INS and LBL positioning techniques | |

| Incorporates 50 years of subsea navigation innovation and know-how | |

| Positioning for all phases of construction survey | |

| Full range of real-time array calibration options: SLAM, Baseline and Box-In | |

| Comprehensive EPSG geodesy database | |

| Calibration and positioning calculations in scale-free reference frame | |

| Performance | Better than 4 times precision improvement over USBL with SPRINT INS |

| Up to 3 cm Range-aided positioning accuracy with SPRINT INS | |

| Up to 3 cm LBL positioning accuracy | |

| Simultaneous LBL tracking of ROVs and structures with heading computation at up to 1 Hz | |

| Acoustics | Sonardyne Wideband 3 digital acoustics for reliable performance in all environments |

| Support for Multiuser Compatt 6+ | |

| Embedded Wideband 3 sensor data retrieval from Compatt 6+ for seamless tracking and faster calibration |