Delivering subsea synergy in ORE inspections

There are numerous challenges associated with offshore wind visual inspections, including currents, turbidity, time and cost. Sonardyne, EIVA and Voyis, all part of the Covelya Group, are working together to bring a complete imaging, navigation and autonomy solution to overcome these obstacles and enhance the inspection data product.

With almost a century of combined subsea expertise between them, the companies are ideally placed to offer a solution to the offshore renewable energy (ORE) market that is even greater than the sum of its parts.

Combining great experience to create even greater things.

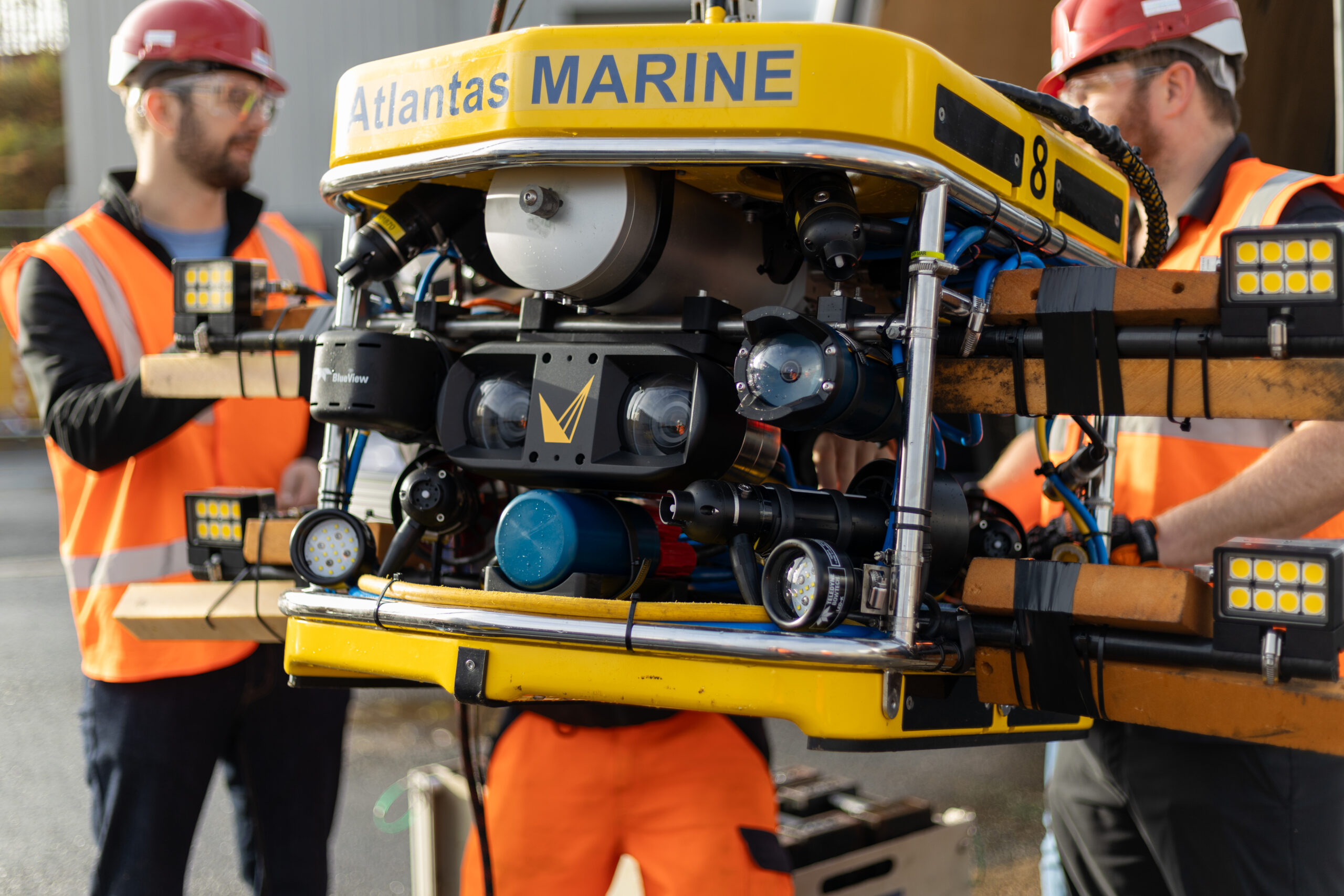

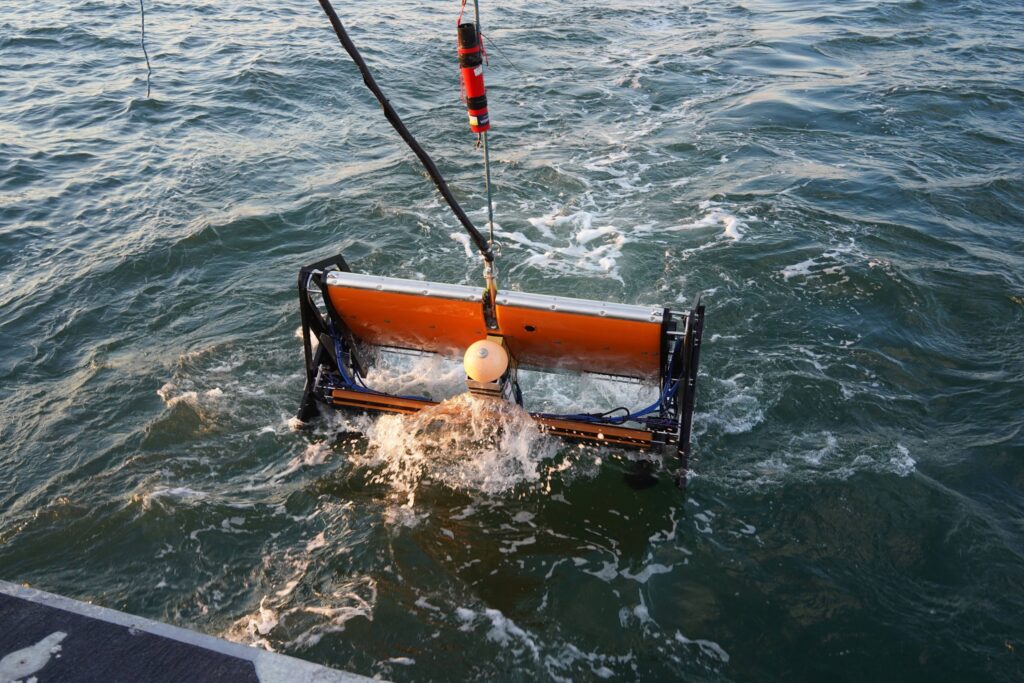

Bringing together their combined expertise at a technology accelerator event at the ORE Catapult Subsea and Marine testing facility in Blyth, Northumberland, UK, Sonardyne, EIVA and Voyis were able to demonstrate the potential of their ORE inspection solution to industry users, vehicle manufacturers and end clients recently.

Each company brought its own existing technologies which were integrated, on remotely operated vehicles (ROVs) provided by Atlantas Marine , to demonstrate an even more effective solution for underwater surveying.

During the demonstration, NaviSuite VSLAM leveraged the Discovery Stereo system to enable augmented piloting through real-time 3D point cloud images for quality control, while NaviSuite Mobula provided an end-to-end software solution for acquisition, processing and delivery of data.

Sonardyne SPRINT-Nav Mini

Sonardyne’s SPRINT-Nav Mini provides robust, reliable, navigation for piloting and surveying. It is the world’s smallest hybrid acoustic-inertial navigation system and can be used as an all-in-one vessel and marine robot navigation instrument with performance beyond its size. The SPRINT-Nav Mini eliminates the need for separate sensors, such as AHRS, DVL, INS, and depth sensors. This results in no further calibration requirements, fewer cables and connectors to manage and it is more cost-effective than the four sensors it replaces.

It will work in the most challenging environments and remains unaffected by steel structures such as wind turbine foundations and provides a continuous stream of positions, orientation, velocities, depth and altitude at up to 200 updates per second.

Voyis Discovery Stereo camera

Voyis’ Discovery Stereo camera provides a powerful platform for a vehicle’s subsea vision needs, delivering stills images, video, IMU data and 3D data with a data-centric DDS architecture. Through edge computing, it integrates with EIVA’s visual simultaneous localisation and mapping (VSLAM) software technology to provide real-time 3D reconstruction, ensuring area coverage mapping and augmented piloting. Mounted on the front of the ROV, the Discovery Stereo provided 4K video stream and high-resolution images for both navigation and inspection throughout the demonstration.

EIVA NaviSuite Mobula

EIVA’s NaviSuite Mobula software package provides a complete topside software solution for the ROV, enabling efficient acquisition of data with the Voyis Discovery Stereo and Sonardyne SPRINT-Nav Mini. This software offers unique capabilities for automating remotely operated subsea inspection and surveying operations – using tools for a wide variety of tasks, leveraging the software toolbox of NaviSuite.

Demonstrating the difference.

The technology accelerator event at Catapult provided the perfect opportunity to showcase the possibilities in developing this combined subsea inspection solution. The test dock contains a turbine foundation and various other structures, perfect for subsea navigational and photogrammetry demonstrations.

The ROV was fitted with a SPRINT-Nav Mini at the rear, Discovery Stereo camera at the front and utilised the NaviSuite Mobula and VSLAM software packages to control the ROV movements, represent the operation in a real-time 3D visualisation and pilot view, along with monitoring coverage and inspection data quality.

Once the ROV was launched, focus shifted to the control room where the assembled delegates watched the live 4K video stream from the Discovery Stereo camera as the vehicle navigated the dock.

Whilst its primary navigation and positioning was provided by the SPRINT-Nav Mini, as the ROV navigated and surveyed the subsea structures the Discovery Stereo camera and NaviSuite software combined their capabilities to provide millimetric positioning precision and 3D point cloud detail which was fed back to the control room. A video from the demonstration, giving more information about the technology, can be viewed here.

In real-life operations, these actionable insights could then be used to make immediate decisions about state of the asset, the quality of the data and subsequent actions required from the ROV. Having the capability to make real-time operational decisions greatly reduces the risk of collecting inaccurate data and helps to avoid the associated wasted time and cost.

For Sonardyne, EIVA, Voyis and the wider Covelya Group, this demonstration of synergetic working is just the beginning of our ‘Better Together’ approach. The opportunities for delivering smarter, faster, cleaner and more effective subsea technology solutions from within the group of companies are almost endless.

Mapping the future for seagrass beds in Plymouth Sound

Seagrass beds are incredibly important ecosystems that offer a range of ecological benefits. Not only do they provide crucial habitats for a diverse array of marine wildlife, especially in coastal areas like Plymouth Sound, they can also store carbon, helping to mitigate the effects of climate change. These underwater meadows serve as nurseries for many species of fish in the early stages of their life, offering them protection and abundant food sources. Additionally, seagrass beds help to stabilise the seabed with their root systems, preventing coastal erosion and maintaining water quality by trapping sediments and nutrients.

However, despite their importance, locating and monitoring seagrass beds using traditional methods, such as survey boats, presents significant challenges. Seagrass typically grows in shallow waters, which can make it difficult for boats to navigate close enough to the shore to obtain accurate data. Traditional survey boats are often large and cumbersome, making them hard to manoeuvre in shallow or rocky areas. This limitation can result in incomplete or inaccurate assessments of seagrass distribution and health.

Furthermore, the process of using boats for surveying can be time-consuming and labour-intensive. It often requires multiple trips and extensive manual labour to map out the seagrass beds accurately. The visibility in shallow waters can also be poor due to water turbidity, further complicating the survey efforts and leading to potential underestimation of seagrass coverage.

Finding a solution…

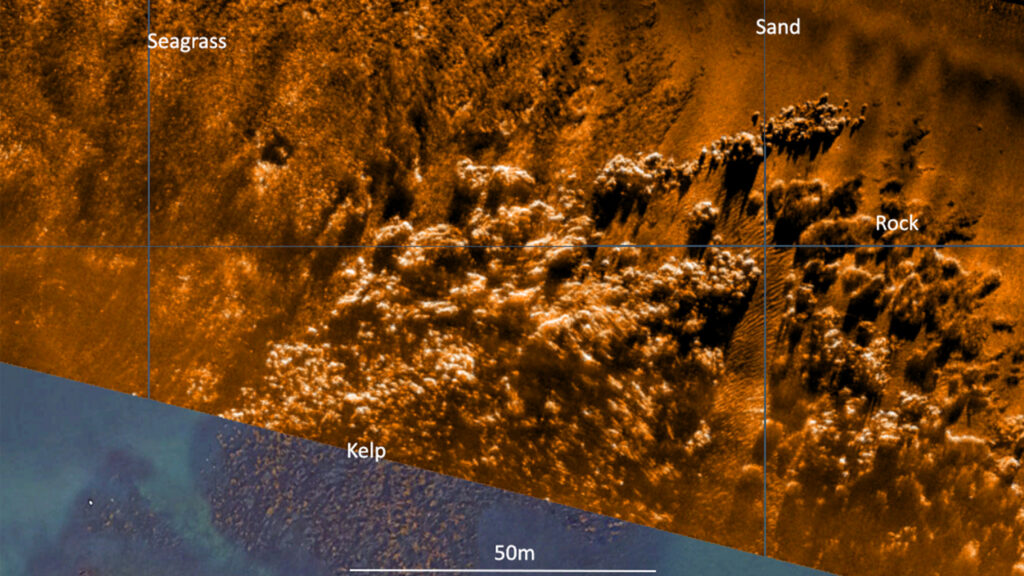

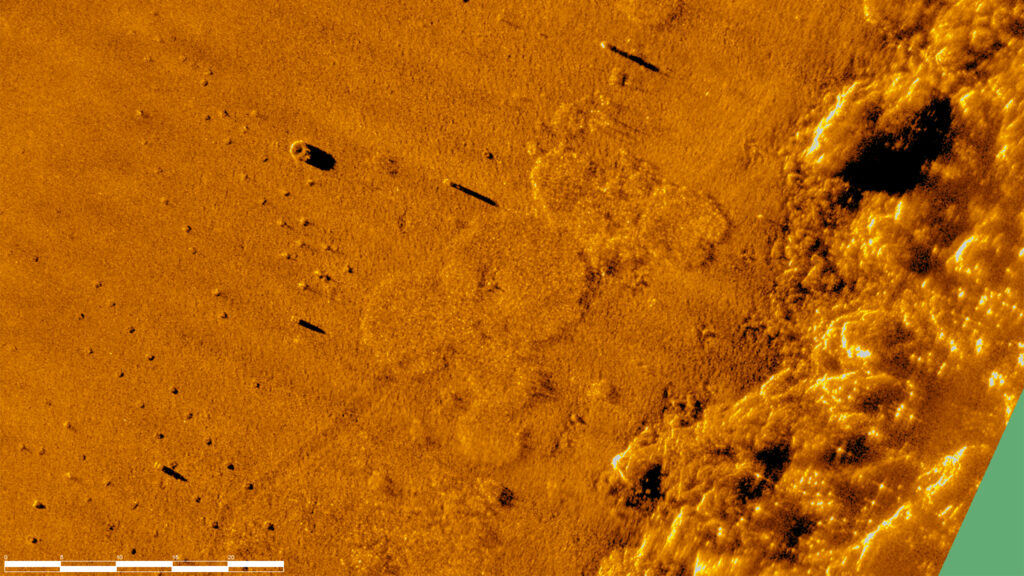

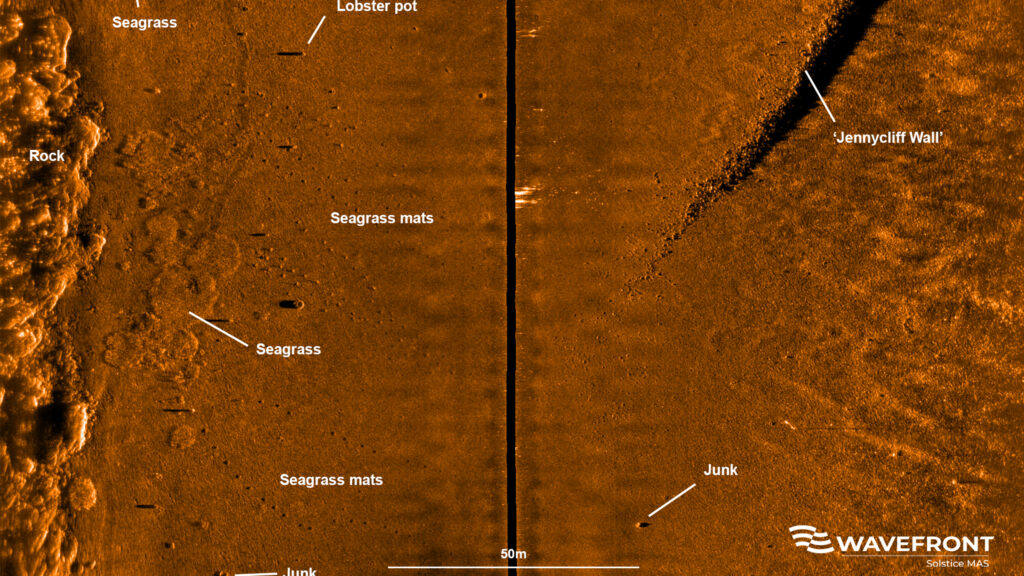

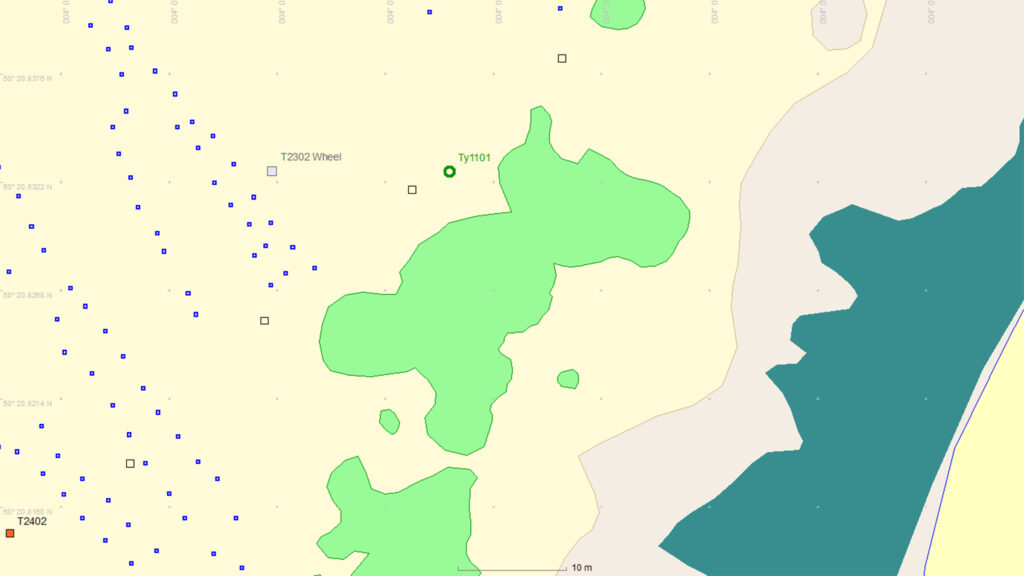

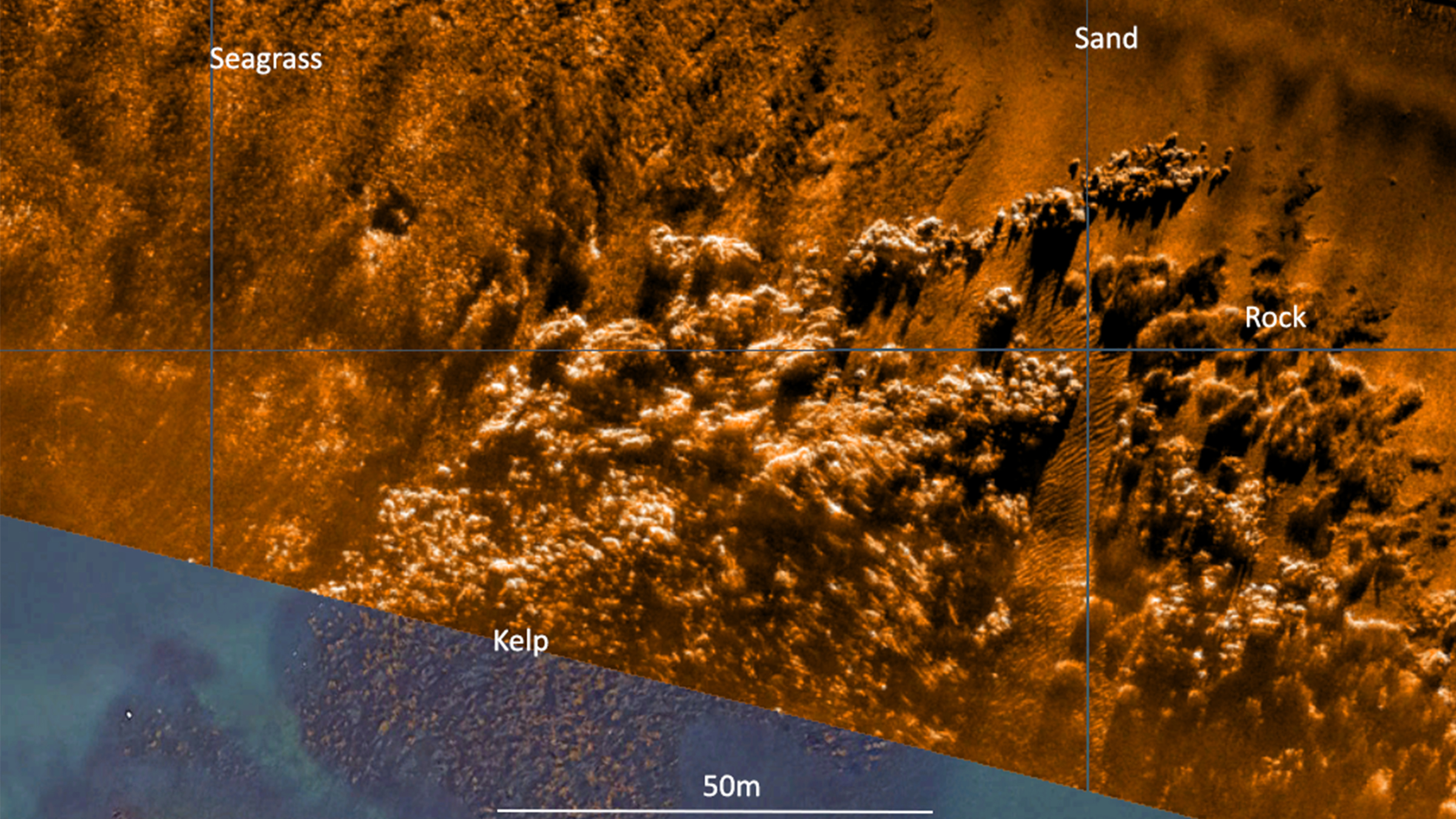

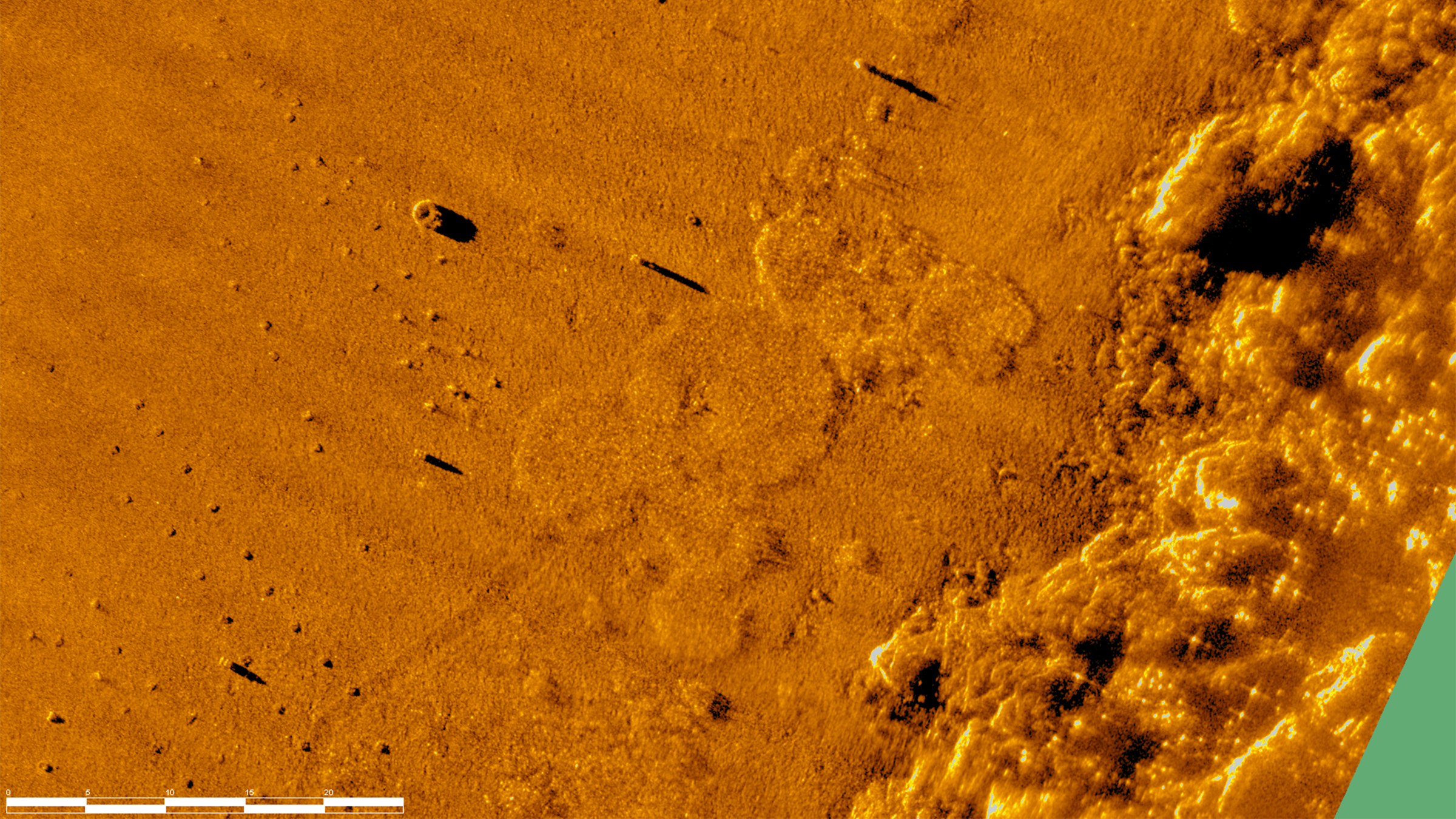

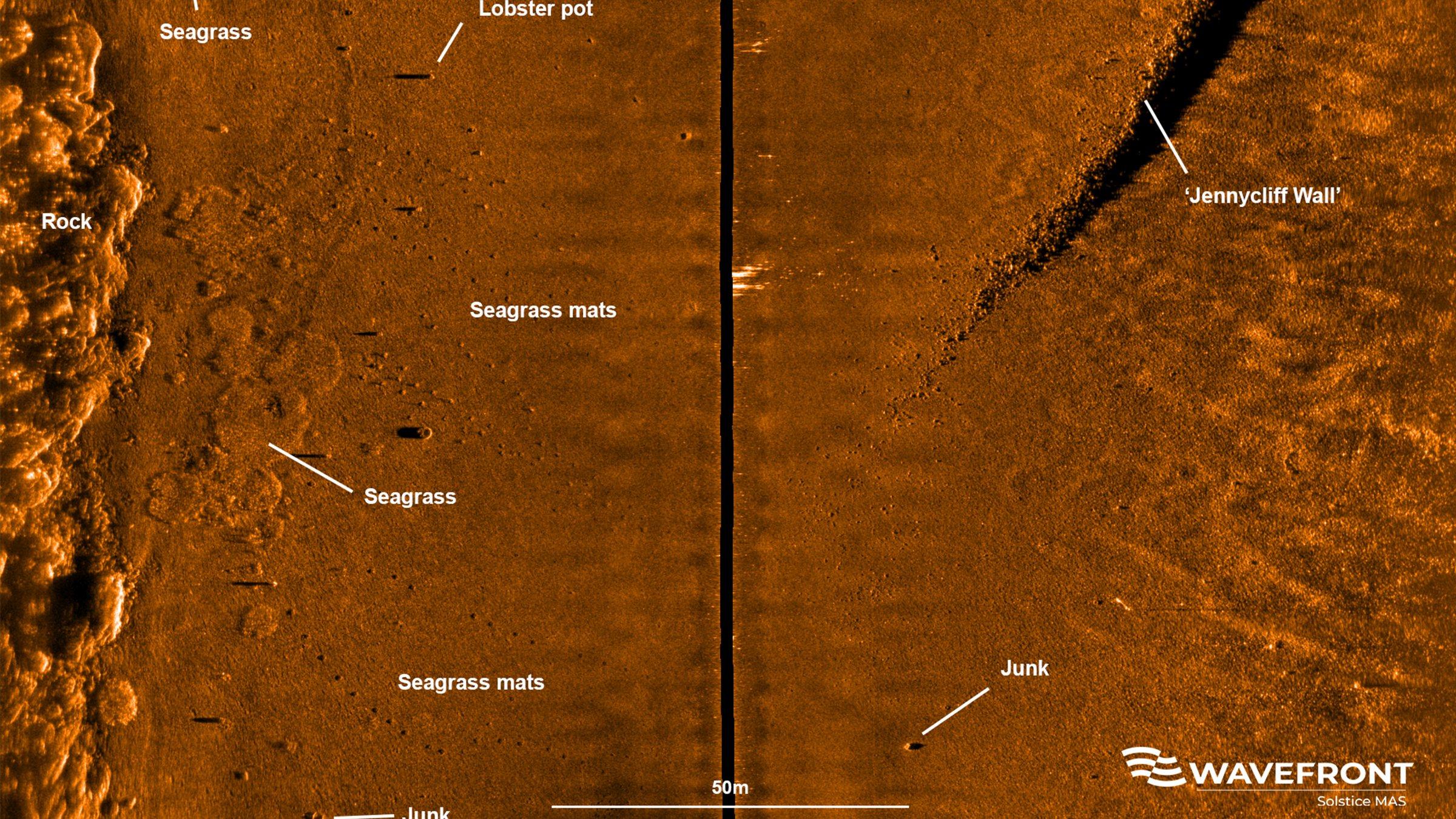

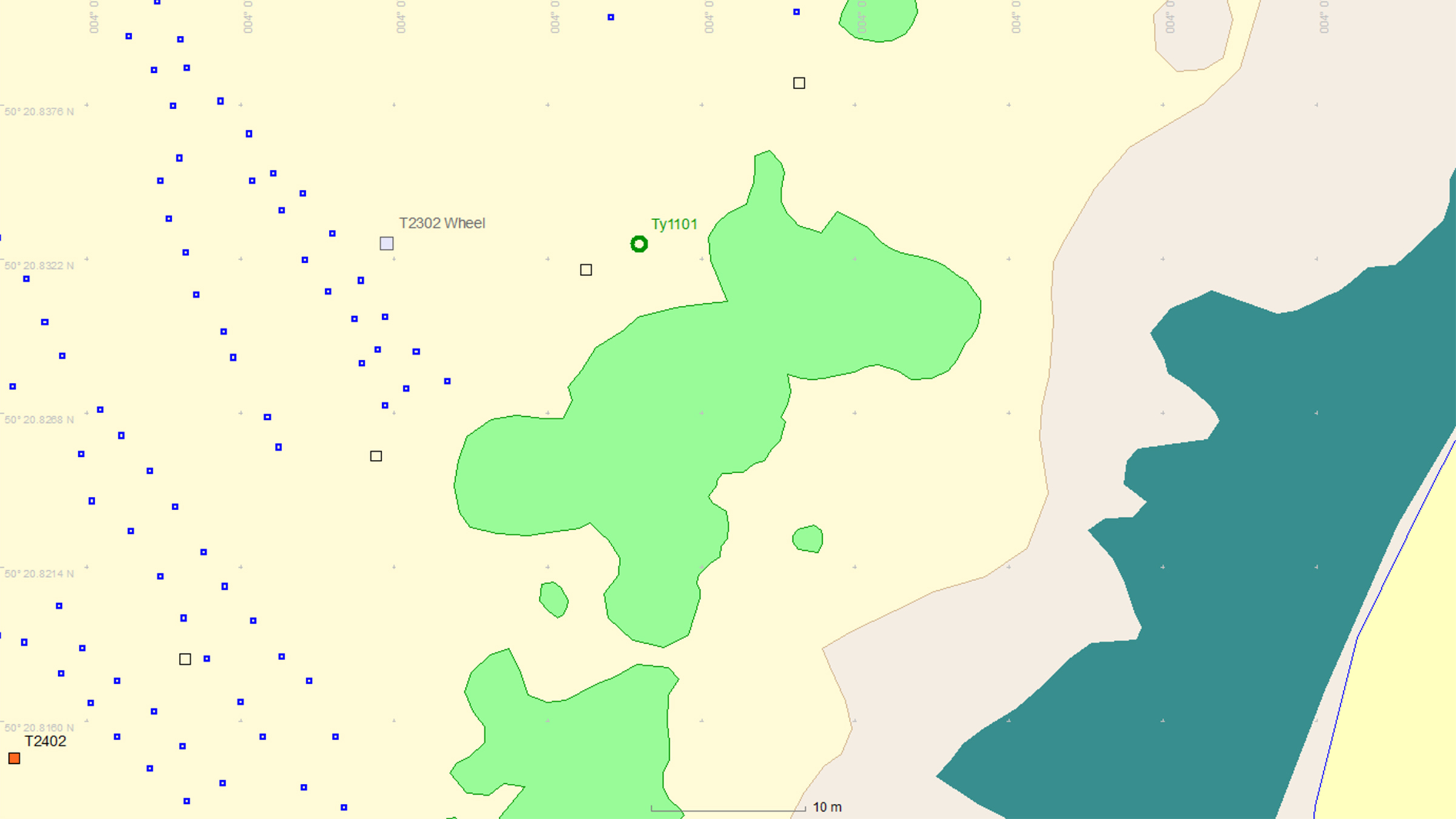

This is where Sonardyne and Wavefront Systems come in. The solution, which combines Sonardyne and Wavefront technology, is a survey boat carrying Solstice MAS™ (Multi-Aperture Sonar) as well as a SPRINT-Nav Mini mounted to a pole, deployed over the side of the boat; this maps the chosen area in 200 m wide strips. Once this survey has been completed, the sonar data that has been captured is then processed to create a map of the seagrass in a GIS. A Remotely Operated Vehicle (ROV) is then sent to the same area to ground truth features on the seabed to check that they are how they have been interpreted by Solstice MAS. The ROV is fitted with SPRINT-Nav Mini, allowing us to track its position underwater and guide it, using the map, to the features identified by Solstice; the ROV is also fitted with a camera and the recorded video can be used to create 3D models of the seabed.

Wavefront Systems’ Solstice MAS uses sound signals to produce high-quality images of the seabed, capable of creating images 200 metres wide at high resolution even in shallow water environments, all while consuming very little power. The Solstice family of sonars are built on unique MAS technology and are designed to fill the gap between standard side scan sonars, which are typically simple in design but give low image resolution, and Synthetic Aperture Sonars (SAS), which are expensive, more susceptible to complete data loss due to platform movement and also produce vast amounts of data. In order to execute more detailed mapping, Solstice MAS requires a high quality navigation sensor, which in this case is SPRINT-Nav Mini.

SPRINT-Nav Mini is an all-in-one vehicle guidance and navigation instrument, which combines AHRS data, Doppler Velocity Logger (DVL), Inertial Navigation System (INS) and depth sensor into a single housing. Having SPRINT-Nav Mini fitted onto the ROV provides positioning input, as well as attitude and heading data.

Creates images

0

m

at high resolution

ROV fitted with

0

D

camera

Solstice creates images

0

m

each side of the vessel

Adopting these technologies on such small versatile platforms opens the possibility of high-grade survey data in shallow waters. As a result of the cross Covelya Group collaboration between Sonardyne and Wavefront Systems, a high-definition map of seagrass beds can be created with a greater degree of accuracy than was previously possible with more traditional methods.

A seagrass restoration project conducted by the Ocean Conservation Trust (OCT) in Plymouth Sound, which involves monitoring, conserving and expanding the existing seagrass beds can be enhanced with the use of an ROV which has SPRINT-Nav Mini fitted to it. To help grow the existing seagrass beds, the OCT are placing seagrass mats on the seabed in Plymouth Sound. A survey boat fitted with Solstice and SPRINT-Nav Mini followed by an ROV fitted with SPRINT-Nav Mini can then be used to monitor and create a map of where these mats have been placed so that they have a better understanding of the success of the restoration and expansion project.

Repeatable, configurable, long-term surveillance

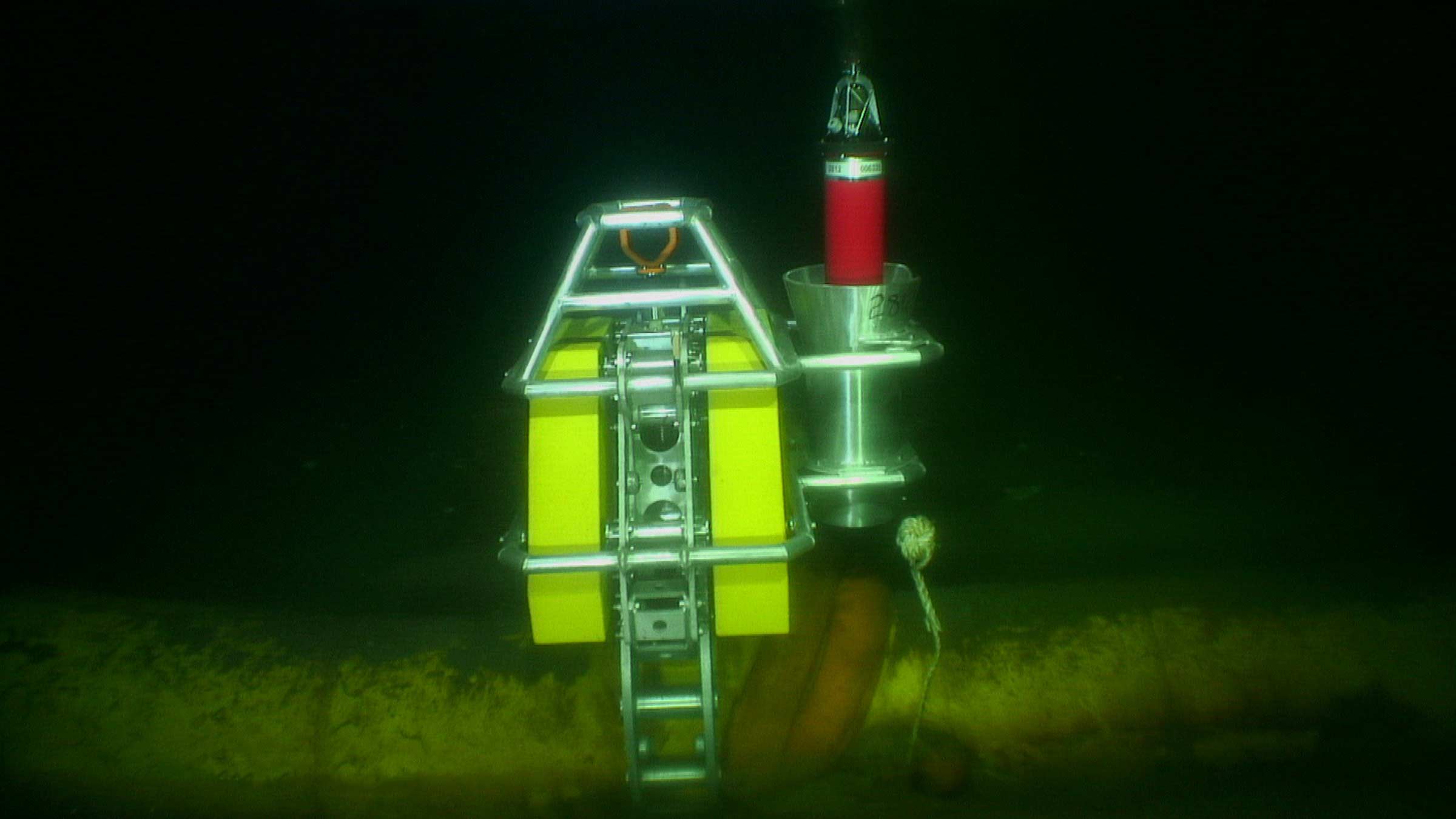

The Autonomous Monitoring Transponder (AMT) is a long-endurance transponder engineered for your long term subsea survey tasks and is capable of autonomously acquiring acoustic ranges and sensor data without surface control.

AMTs can detect subtle movement often not picked up by traditional ROV surveys so it’s ideal for monitoring slow movements, like creeping or buckling pipelines. Using structure and seafloor transponder buckets, they can be ROV-deployed, removed and re-installed to provide insight over time. Your AMTs can be configured to take measurements at specific intervals and be adjusted on-demand by you as your campaign progresses. Data can even be collected in real time using a USV should your operation need it.

As it’s collected, data is time-stamped and logged internally for recovery via the integrated high-speed acoustic telemetry modem. This autonomy allows measurements to be made over a long period of time without requiring a surface vessel or ROV to command the process. This enables new applications that save vessel and survey time so reducing cost and risk.

At a glance

- Recommended for long endurance site surveys

- Leave it deployed for six years or more

- Extensive choice of monitoring sensors

- Depth rated to 3,000 m

- Harvest data using a ship, buoy, AUV or USV

AMT has many of the same acoustic functions as Compatt 6, our most popular navigation transponder. It operates in the Medium Frequency (MF) band and is fully Sonardyne Wideband 2 compatible.

Precision pressure, temperature, sound velocity and dual-axis inclinometer sensors are integrated and are intelligently powered up at the requested time and sampling period, providing an ultra-low power platform for up to three years deployment. Sampling regimes can be re-programmed, and recovery of all data can be achieved via the acoustic modem.

The instrument is available with a range of omni and directional transducers, depth ratings and pressure housings dependent on deployment duration and application. Additional external sensors can be easily integrated via the power and communications port.

Acoustics

• Sonardyne Wideband 2 MF band (18 – 36 kHz)

• Over 500 unique addresses, ideal for large array deployments

• Data transfer rates of 100 to 9,000 bps – user selectable

• Omni-directional and directional transducers to suit environmental conditions

• Ranging precision: Better than 15mm

Sensing

• Standard onboard: Temperature, tilt, strain gauge

• Optional onboard: high precision stain gauge, DigiQuartz pressure sensor, high accuracy inclinometer, sound velocity

• Sampling rate: user configurable

• Vessel, USV or AUV data harvesting options

• Optional external: current meters, turbidity sensors

Design

• 3,000 m depth rating

• Aluminium or aluminium-bronze housing depending on environmental conditions and duration of deployment

• Can be deployed for over 5 years without recovery (maxi housing)

• ROV-friendly design: integrated acoustic release mechanism as standard

Ownership

• Warranty: 1 year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export Licence: Not required

• A typical system: multiple seafloor and structure mounted AMTs (typically 6), vessel-based Modem 6 or Dunker 6 or HPT 5000 / 7000, SIU, Monitor software

Specifications

| Feature | Type 8305-3411 | Type 8305-3111 | Type 8305-3113 | |

|---|---|---|---|---|

| Depth rating | 3,000 m | 3,000 m | 3,000 m | |

| Operating frequency | MF (20–34 kHz) | MF (20–34 kHz) | MF (20–34 kHz) | |

| Transducer beam shape | Omni-directional | Omni-directional | Directional | |

| Transmit source level (dB re 1 µPa @ 1 m) | 187–196 dB (4 levels) |

187–196 dB (4 levels) |

190–202 dB (4 levels) |

|

| Tone Equivalent Energy (TEE) | 193–202 dB | 193–202 dB | 196–208 dB | |

| Receive sensitivity (dB re 1 µPa) | 90–120 dB (7 levels) |

90–120 dB (7 levels) |

80–120 dB (7 levels) |

|

| Ranging precision | Better than 15 mm | Better than 15 mm | Better than 15 mm | |

| Number of unique addresses Wideband 1 & 2 | >500 | >500 | >500 | |

| Battery life (listening, disabled) | Alkaline | 833 days | 833 days | 833 days |

| Safe working load (4:1) | n/a | 250 kg | 250 kg | |

| Mechanical construction | Aluminium-bronze | Aluminium | Aluminium | |

| Dimensions (length x diameter) | 1007 x 130 mm | 1034 x 134 mm | 1018 x 134 mm | |

| Weight in air/water | 35/24 kg | 24/12 kg | 24/12 kg | |

| Endcap sensors and options | ||||

| Temperature (±0.1°C) | Standard | Standard | Standard | |

| Tilt switch (±30-45°) | Standard | Standard | Standard | |

| Strain gauge pressure sensor (±0.1%) | Standard | Standard | Standard | |

| High precision strain gauge (±0.01%) Presens or Keller | Optional | Optional | Optional | |

| Paroscientific digiQuartz pressure sensor 1350 m, 2000 m, 4130 m, 6800 m (±0.01%) |

Optional | Optional | Optional | |

| High accuracy inclinometer range: ±90°, Accuracy: ±0.05° over 0 – ±15°; ±0.2° over 0 – ±45° | Optional | Optional | Optional | |

| Sound velocity sensor ±0.02 m/s accuracy under calibration conditions | Optional | Optional | Optional | |

| Release mechanism | n/a | Standard | Standard |

Frequently asked questions

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

What's possible

You need transponders to be tough, reliable and easy to work with. RT 6-3000 meets these requirements.

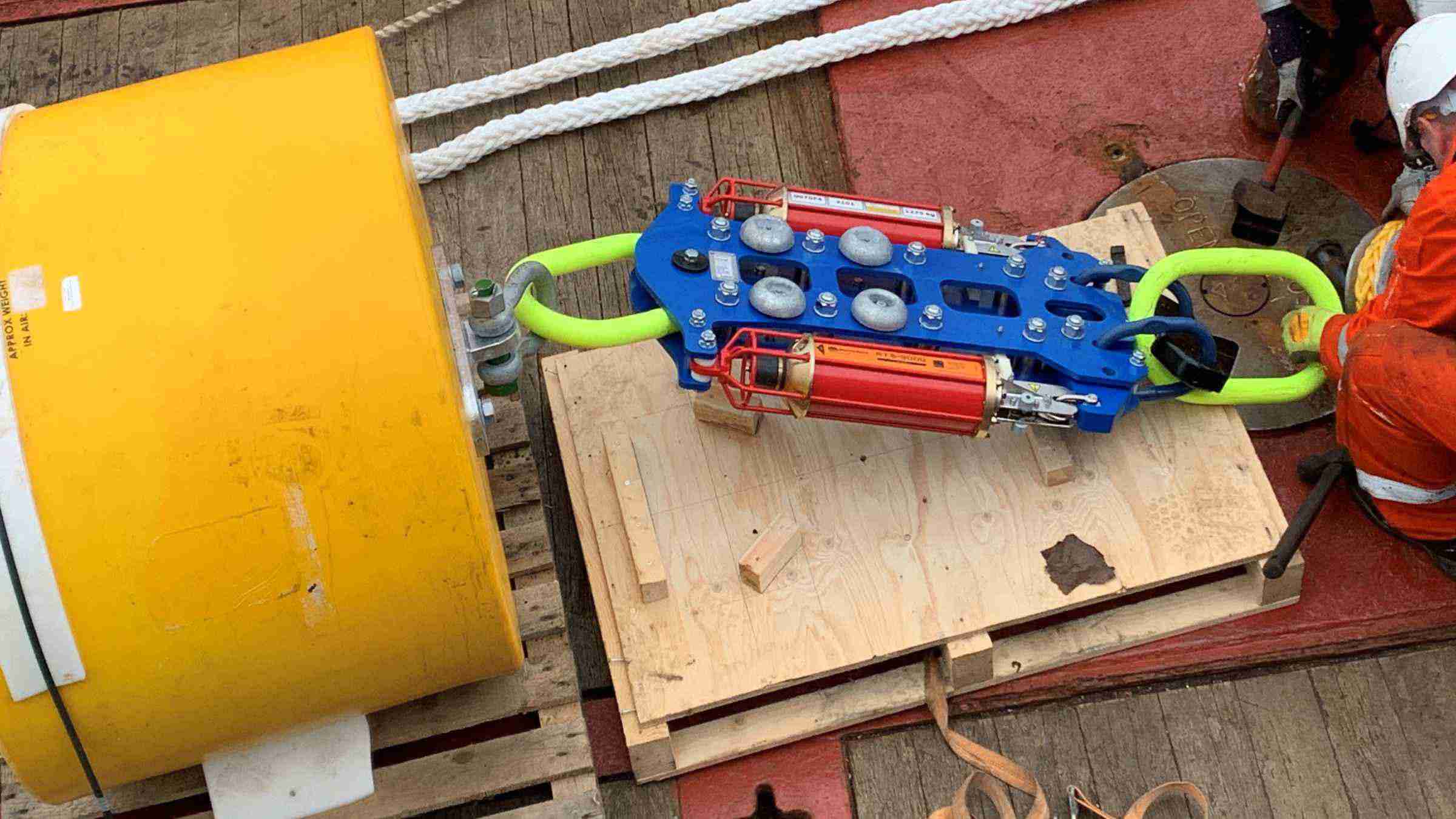

Part of our range of acoustic releases, RT 6-3000 combines our extensive mechanical design track record and many years of subsea mooring experience with the flexibility of our 6G platform. The result is an enhanced battery life and, perhaps most significantly, compatibility with our Ranger 2 USBL family.

Deploy. Track. Locate. Recover.

With RT 6-3000, you can use your Ranger 2 USBL to deploy, track, locate and command the instrument – removing the need for a separate topside unit.

If you don’t have access to a Ranger 2 USBL, our rugged and lightweight Deck Topside with an over-the-side dunker is all you need to configure and command your RT 6-3000s.

RT 6-3000s are used to anchor oceanographic moorings to the seabed. However, their compact size and compatibility with Ranger 2 makes them ideal for incorporation into instrument frames or lowered platforms to enable deployment of sub-system packages. Depth rated to 3,000 m, the maximum slant range for operation is dependent on the noise environment and topside used, but ranges to 4,500 m are achievable.

A battery disconnect fob is located on the transducer and uses an internal magnetic switch to electronically disconnect the battery when not in use. This means you don’t have to open the unit to manually disconnect the battery, saving time and reducing the risk of incorrect re-assembly.

Standard features include a Working Load Limit (WLL) of 1,275 kg (at 4:1) and the same trusted spring-assisted release mechanism used on thousands of Sonardyne transponders globally for many years. RT 6-3000 is compatible with our standard tandem and high-load release frames for scenarios requiring a higher WLL.

Speak to us about your requirements as custom frames are also an option.

Acoustics

• Medium Frequency (19-34kHz) band, Wideband 2

• Omni-directional transducer. Track it all the way to the surface

• Sonardyne Wideband 2 signal architecture supporting over 300 unique addresses

• Compatible with any Ranger 2 USBL system and Deck Topside

Design

• 700 x 142 mm, 15 kg weight in water

• Aluminium bronze, duplex stainless steel construction. ROHS compliant

• Configured with iWand hand-held acoustic transponder test and configuration device

• Compatible with our standard tandem and high-load release frame

Performance

• 3,000 m depth rated

• 4,500 m working range

• >32 months battery life; alkaline battery

• 1,275 kg Working Load Limit

• Secure and robust two-way acoustic communications. Only release what you want to release

Ownership

• What’s in the box: RT 6-3000, shackles, manual on USB

• Warranty: 1 year return to Sonardyne service centre

• ITAR Controlled: no

• UK Export Licence: not required

Specifications

| Feature | Type 8320-3411 |

|---|---|

| Depth Rating | 3,000 m* |

| Maximum Slant Range | 4,500 m |

| Operating Frequency | MF (20–34 kHz) |

| Transducer Beam Shape | Hemispherical |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 186 dB |

| Tone Equivalent Energy (TEE) | 192 dB |

| Receive Threshold (dB re 1 µPa) | <90 dB |

| Working Load Limit (4:1) | 1,275 kg |

| Proof Load | 2,550 kg |

| Breaking Load | 5,100 kg |

| Maximum Safe Release Load | 1,700 kg |

| Battery Life (Alkaline) | >32 months active |

| Inclinometer Accuracy | ±5° |

| Surface Unit | Deck Topside, Ranger 2 USBL |

| Mechanical Construction | Aluminium bronze and duplex stainless steel |

| Operating Temperature | -5 to 40°C |

| Storage Temperature | -20 to 55°C |

| Dimensions (Length x Diameter) | 700 x 142 mm (27.5 x 5.6”) |

| Weight in Air/Water | 20/15 kg |

| Standards | CE Marked to EN-60945, EN-61010 |

| Options | Shallow Water Deck Kit (Deck Topside) – 602-0175 |

| Mid Water Deck Kit (Deck Topside) – 602-0179 | |

| Heavy Duty Release Frames (7.5 T, 15 T and 25 T) | |

| *RT 6-3000 is pressure rated to 4,000 m; however, due to operating range constraints of MF, its use at depths greater than 3,000 m is not recommended. |

Frequently asked questions

What is an Acoustic Release and how does it work?

Why isn’t serial communication available using the iWand in RT 6 Dunker Mode?

6G Terminal Lite Range Test

What is the safe working load for different RT 6 products?

What should I use instead of an ORT and DORT?

How to change the battery on an RT 6-3000 or RT 6000

How to load the release on an RT 6-3000 and RT 6-6000

Which RT 6 is correct for my operations?

How to release an RT 6 acoustic release transponder using Ranger 2

How long can an RT 6-3000 and RT-6 6000 be deployed for?

Deployment

STP files

Software and control hardware

Manuals and quick start guides

Did you know?

RT 6-3000 can be used with our Ranger 2 USBL family or Deck Topside

Entry level – next level

What's possible

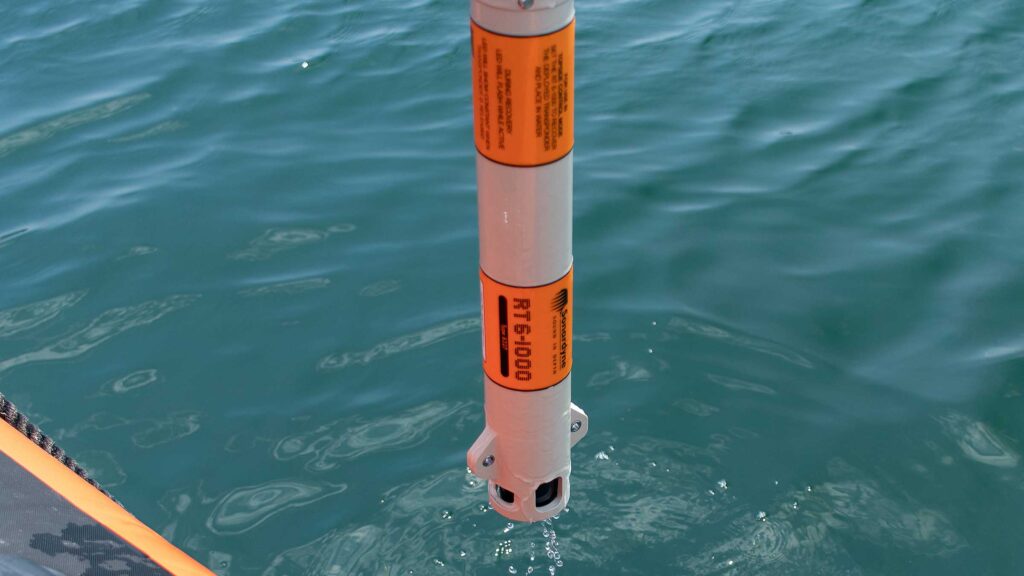

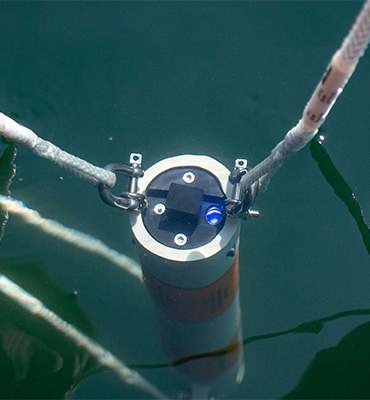

The RT 6-1000 is the versatile acoustic release transponder for your subsea operations. It can be commanded from multiple sources, including the Deck Topside, an Android app, or any Ranger 2 USBL system. This flexibility allows you to easily deploy, track, locate and retrieve your seabed equipment and ocean sensors.

One of the key advantages of the RT 6-1000 is its depth rating of 1,000 metres and weight load limit of 150 kg. This depth and payload capacity make it an ideal choice for scientists, surveyors, and military personnel who require a reliable and enduring solution for their underwater applications.

The RT 6-1000 is compatible with Sonardyne’s Ranger 2 USBL tracking systems, which are widely used on survey vessels around the world. This integration allows for seamless deployment, tracking, and retrieval of your equipment. No access to Ranger 2? No problem, the RT 6-1000’s NFC capability enables setup and control via its Android app or a dedicated Deck Topside unit.

Deploy. Track. Locate. Recover

At a glance

- The reliable choice to deploy, leave and recover seafloor equipment and sensors

- 1,000 metre depth rating; twice that of similar low-cost acoustic release transponders

- Tested, loaded, commanded and released using Deck Topside

- Also works with any Ranger 2 USBL to track it and activate it

- >13-month battery life means less time servicing it and more time using it

- 150 kg Working Load Limit to support your sensors and instruments

- Optional rope canister for heavy lifting

The RT 6-1000 offers impressive endurance, with a battery life of up to 13 months, making it well-suited for long-term deployments and year-long surveys. Its screw-off release mechanism ensures reliable recovery of the transponder and your equipment.

An optional rope canister attachment allows you to quickly and easily raise items left on the seabed, such as tools, cables and salvage. The canister deploys a high-strength rope as the transponder ascends, providing a convenient means of retrieval.

Acoustic

• Medium Frequency (20-34 kHz) band.

• Omni-directional transducer. Track it all the way to the surface

• Sonardyne Wideband 2 signal architecture supporting over 300 unique addresses. Perfect for very large surveys involving multiple moorings close to each other

Performance

• 1,000 m depth rated

• >13 months battery life; alkaline battery

• 150 kg Working Load Limit

• Compatible with Ranger 2 USBL systems

• Secure and robust two-way acoustic Communications. Only release what you want to release

Design

• 450 mm x 65 mm (max dia. 100 mm), 500 grams weight in water

• Field proven screw-off release mechanism

• NFC for setup using Android app

• Optional rope canister for lifting heavy items

• Plastic, super duplex stainless steel and anodised aluminium construction. ROHS compliant

Ownership

• Warranty: one year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export Licence: Not required

• What’s in the box: RT 6-1000, shackles, release nuts (x10), manual on USB

Specifications table

| Feature | Type 8327 | |

|---|---|---|

| Depth rating | 1,000 m | |

| Operating frequency | MF (20–34 kHz) | |

| Transducer beam shape | Hemispherical | |

| Transmit source level (dB re 1 µPa @ 1 m) | 187 dB | |

| Tone Equivalent Energy (TEE) | 193 dB | |

| Receive threshold (dB re 1 µPa) | <100 dB | |

| Working load limit (4:1) | 150 kg | |

| Proof load | 300 kg | |

| Breaking load | 600 kg | |

| Maximum safe release load | 150 kg | |

| Battery life (alkaline) | >13 months | |

| Inclinometer accuracy | ±5° | |

| Mechanical construction | Anodised aluminium alloy, plastic and super duplex stainless steel | |

| Operating temperature | -5 to 40ºC | |

| Storage temperature | -20 to 55ºC | |

| Maximum dimensions (length x diameter) | 450 x 65 mm | |

| Weight in air/water | 2.0/0.5 kg | |

| Standards | CE Marked to EN-60945, EN-61010 | |

| Options | Part number | |

| Shallow Water Deck Kit (Deck Topside) | 602-0175 | |

| Rope Canister | 70 m (250 kg WLL) | 641-0673 |

| 120 m (250 kg WLL) | 641-3265 | |

| 160 m (150 kg WLL) | 641-0080 | |

| Release Nut | 830-0073 (note: 10 nuts supplied with each new RT 6-1000) |

|

| Shackle (bridle) | 231-0140 | |

| Deployment rope (bridle) | 231-0351 |

Frequently asked questions

What is an Acoustic Release and how does it work?

Why isn’t serial communication available using the iWand in RT 6 Dunker Mode?

RT 6-1000 NFC connection and operating information

6G Terminal Lite Range Test

How long can an RT 6-1000 be deployed for?

What is the safe working load for different RT 6 products?

What should i use instead of an LRT

How do I mark where my RT 6-1000 is deployed?

No NFC device is available to connect the battery

Why can’t my NFC device contact the transponder?

How to change the battery in an RT 6-1000

Which RT 6 is correct for my operations?

Why should I use a rope canister and what is it?

Where can I find the RT6 release app

How to release an RT 6 acoustic release transponder using Ranger 2

How to use a rope canister

How to recover an RT 6-1000

Deployment

STP files

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

Did you know?

RT 6-1000 can be used with our Ranger 2 USBL family or Deck Topside

Unlocking subsea secrets with PIES

Imagine the possibilities

Boost your operations: Make informed decisions with a deeper understanding of ocean currents and seismic activity.

Save time and money: Deploy PIES for up to five years, reduce personnel costs and environmental impact through unmanned data retrieval.

Uncover hidden insights: Combine PIES data with other geophysical measurements for a comprehensive view of the ocean floor.

How PIES works for you

PIES is designed to seamlessly integrate into your system:

- Easy to use: Simple setup and configuration, with flexible ping rates to match your needs.

- Reliable data: Consistent, accurate measurements for months or even years.

- Versatile retrieval: Access data when you want it, remotely, mid-operation, via unmanned vehicles or by traditional end of mission retrieval methods.

- Comprehensive insights: Developed for marine seismic and ocean science applications.

Why invest in PIES

- Suitable for environmental surveys / ocean currents monitoring / site survey and characterisation

- Harvest data using ROV, AUV, USV or surface vessel

- Integrated acoustic release for easy recovery

- Depth ratings to 6,000 m

- Choice of form factor to suit your operations

PIES in action

Unlocking the Gulf Loop Current

Read moreTransponders provide reliable releases for Allton offshore Norway

Read moreLong endurance monitoring of tectonic motion

Read morePerformance

• 3,000 or 6,000 m depth rated

• Up to five-year deployment life

• Monitor for months or years – PIES is engineered for sustained observation campaigns

• PIES helps oceanographers and geophysicists to better understand the physical processes that occur deep in the ocean

Design

• Anti-trawl frame option available

• Customisable sensor payload options

• Glass sphere or hard anodised aluminium housing options

• Easy to set up with configuration and sampling period programmable via modem

Acoustic

• 80–120 dB (7 levels) receive sensitivity

• 190–202 dB (4 Levels) transmit source level

• LMF (14–19 kHz) operating frequency

• Integrated modem with data rates ranging from 100 to 9000 bps

Ownership

• Warranty: 1 year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export License: not required

Specifications

| Feature | Type 8302-3116 | Type 8306-3816 | |

|---|---|---|---|

| Depth Rating | 3,000 or 6,000 m | 3,000 or 6,000 m | |

| Operating Frequency | LMF (14–19 kHz) | LMF (14–19 kHz) | |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 190–202 dB (4 levels) | 190–202 dB (4 levels) | |

| Receive Sensitivity (dB re 1 µPa) | 80–120 dB (7 levels) | 80–120 dB (7 levels) | |

| Battery Life (Capacity) | Multi-years life, dependent on sensors and sampling interval (100 Ahr) |

5 years life (dependent on sensors and sampling interval (180 Ah) | |

| Mechanical Construction | Hard anodised aluminium housing, duplex stainless steel guards | Glass sphere, galvanised stand, duplex stainless steel guards and connectors | |

| Weight in Air/Water | Fetch | 30.6/16.1 kg | 43/-10 kg (upthrust buoyancy) |

| Stand | n/a | 60/52 kg | |

| Sensors and Options | |||

| Temperature (±0.1°C) | Standard | Optional | |

| Tilt Switch (±30–45°) | Standard | Standard | |

| High Precision Strain Gauge (±0.01%) Keller or Presens |

Optional | Optional | |

| Paroscientific DigiQuartz Pressure Sensor (±0.01%) 1,350 m, 2,000 m, 4,130 m, 6,800 m |

Standard | Standard | |

| High Accuracy Inclinometer Range: ±90° Accuracy: ±0.05° over 0–±15°; ±0.2° over 0–±45° |

Optional | Optional | |

| Sound Velocity Sensor ±0.02 m/s Accuracy Under Calibration Conditions |

Optional | Optional | |

| External Sensor Options Turbidity, Conductivity, ADCP | n/a | Optional | |

| Release Mechanism (Screw-off) | Standard | Standard | |

| Connector Type | Subconn MCIL8M | Impulse MCIL-8-MP | |

| Note: See Compatt 6 and AMT datasheets for more information |

Frequently asked questions

Software and firmware

Datasheets

Manuals and quick start guides

Navigating new waters: How real-time current monitoring can transform port operations

Port of Aberdeen, Scotland's largest berthage port – previously known as Aberdeen Harbour, was established in 1136 by King David I of Scotland. It is the oldest existing business in Britain, with a history spanning almost 900 years.

Construction of the port’s South Harbour started in 2017 after years of planning. Completed in August 2023, the £420 million expanded port was the largest marine infrastructure project in Trust Port history. It offers 2,800 metres of deep-water berths to a maximum depth of 14.8 metres (MWHS).

The harbour extension is aimed at attracting vessels and project activity – such as cruise ships and offshore renewable energy (ORE) operations – which would have previously gone to European ports capable of handling their requirements. This increased activity will support local jobs, attract local supply chain spend and investment.

A key feature of South Harbour is its ability to berth large ships. To ensure safe passage for these vessels, it’s important to have accurate and detailed data within the harbour. With its long history, Port of Aberdeen has this information for the North Harbour and is continuing to build a comprehensive understanding of the water movements within South Harbour. This data can then be used to enhance navigational safety and operability within the port.

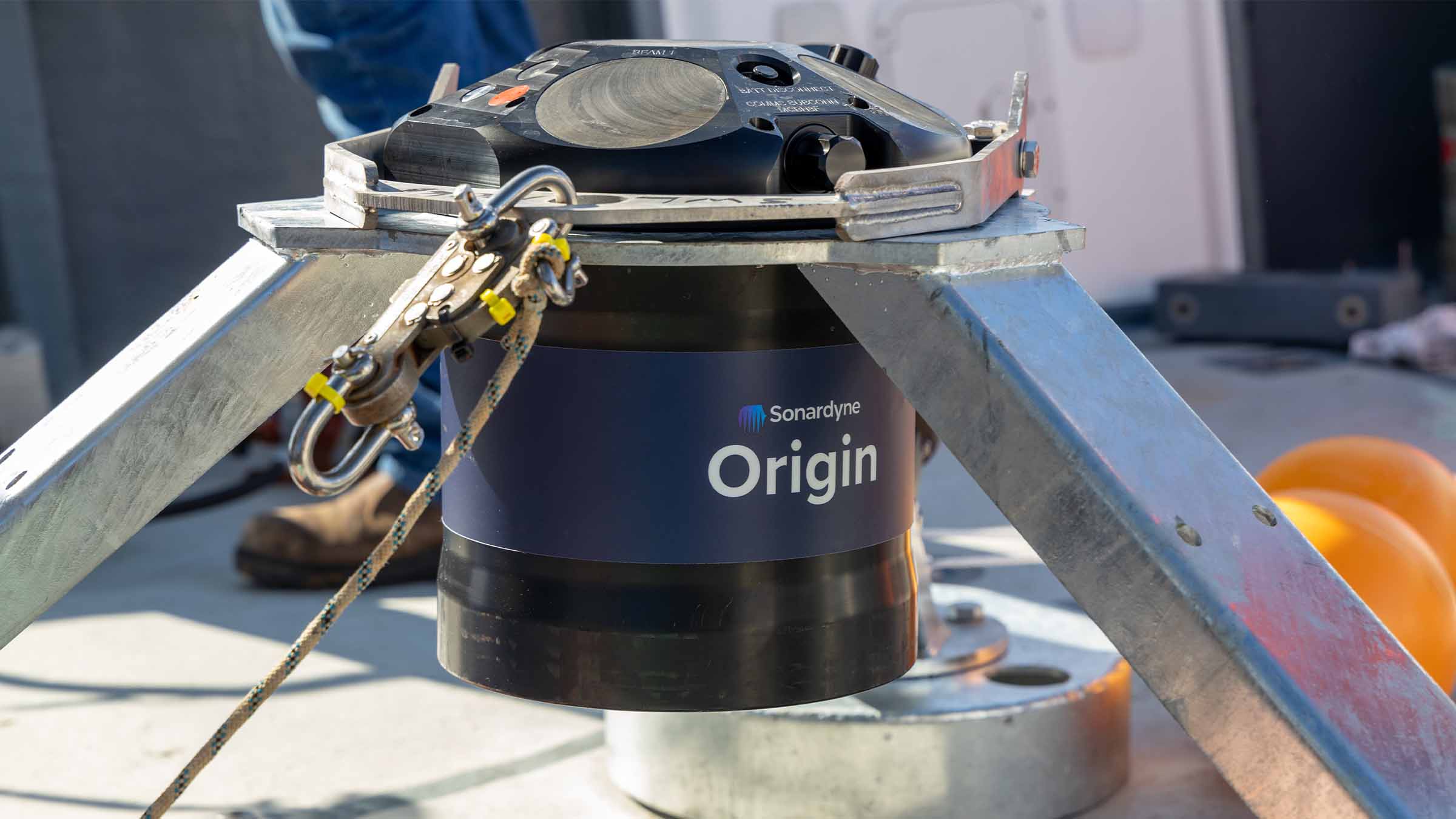

Sonardyne’s Origin® 600 Acoustic Doppler Current Profiler (ADCP) enables users to monitor waves, currents and turbulence. Its built-in acoustic modem enables remote access while it’s deployed. This allows battery and storage checks, the opportunity to inspect and upload data, reconfigure schedules and run quality control, all whilst the ADCP is on the seabed. Enabling users to make time-critical decisions with near real-time data delivery.

Realising the potential for gathering valuable, high quality data to support their operations, Port of Aberdeen approached Sonardyne’s Aberdeen office to hire an Origin 600 for an initial six month period.

“We’re delighted that Port of Aberdeen chose to hire an Origin 600 to monitor the water movement within South Harbour. The knowledge they will gain from the data is vital to help them provide the best possible service for their customers and operators within the port. We look forward to working with them on this project and beyond.” Thomas Blair, Operations Manager, Sonardyne, Aberdeen.

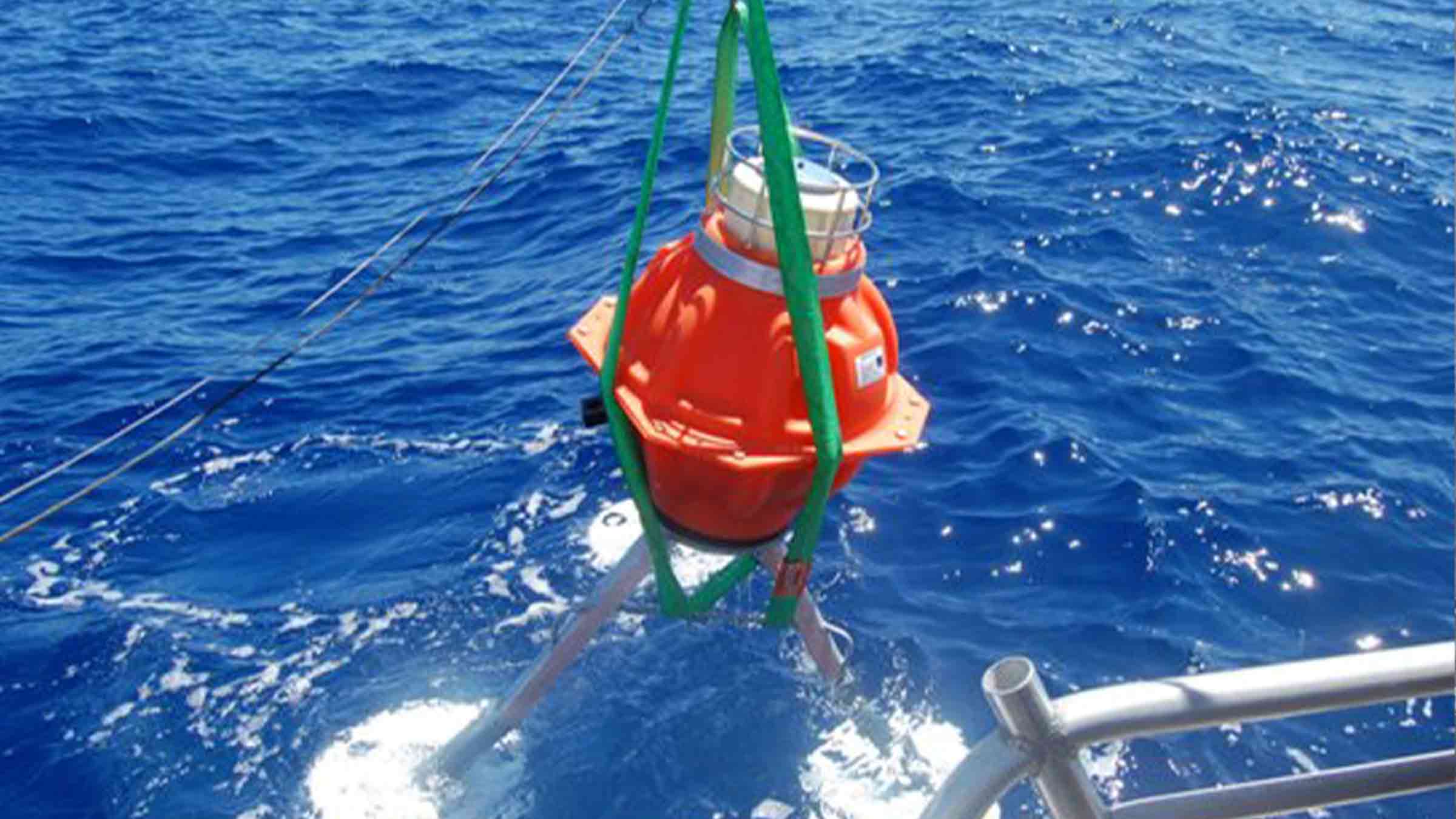

The Origin 600 was deployed, using Sonardyne RT 6 1000 and 3000 release transponders, in the port district on 20th March 2025. Its onboard data processing via implementation of Edge ‘apps’ enable it to deliver information on the wave environment, together with the speed and direction of water column currents, and the timing of tides – fundamentally slack tides. All the data is processed and stored on the unit until Port of Aberdeen are ready to harvest it. This can be done without retrieving the ADCP via its onboard acoustic modem.

In June 2025 the unit was temporarily retrieved to recharge the battery and will be redeployed for a further three months in an alternative, suitable location.

“Origin 600’s ability to monitor and report on the behaviour of currents throughout the water column whilst remaining on the seabed makes it an ideal choice for projects where actionable information is critical for operational safety, just as we have seen with Port of Aberdeen’s South Harbour. What’s more, Origin 600’s real-time reporting capability can be used to support and inform dredging activities, opening up a further avenue where this instrument can help Port of Aberdeen. I’m truly excited to see the full extent of the outputs from this project and how the Origin ADCP data will be applied moving forward.” Michelle Barnett, Business Development Manager – Ocean Science, Sonardyne.

As more current and tidal data is gathered, Port of Aberdeen will be able to use it to enhance operability within the port.

“Port of Aberdeen relies on accurate, reliable data to drive informed decision-making. Having a company with this technology right on our doorstep is a significant advantage – not only in helping us achieve our own objectives, but also in supporting our customers, stakeholders, and port users in delivering their work scopes and projects efficiently and effectively.” Benji Morrison, Harbour Master, Port of Aberdeen

Origin 600 being deployed in Port of Aberdeen South Harbour

If you have a similar project or challenge, talk to us about how Origin ADCPs or other Sonardyne technology can help.

The Gulf of Mexico is home to the highly energetic ocean circulation feature known as the Gulf Loop Current System (LCS). This current system influences all ocean processes in the Gulf, characterised by highly disruptive Loop Current Eddy (LCE) events. LCEs are rings of warm water which rotate at speeds of up to four knots in a clockwise direction, measuring approximately 100-200 km in diameter, reaching down to depths of 500–1000 m, and breaking away from the extended Loop Current around every 8-9 months. Loop Current Eddy events have serious implications for a great range of natural and human activities, from ecosystem dynamics and hurricane intensification to fishing operations and oil and gas exploration.

The challenge

The behaviour of the LCS remains difficult to forecast with sufficient accuracy to guide operations beyond a few days, yet its significance for processes and operations in the Gulf of Mexico drives a need to improve and extend forecasts of the LCS and LCEs. The difficulty has arisen partly because interactions of the upper currents with deep eddies have not been detectable in real time to guide numerical models.

Unlocking the Gulf current – a continuance

Sonardyne were introduced to this challenge back in 2018 when the University of Rhode Island launched a multi-year scientific study that included deployment of five Sonardyne Current Pressure Inverted Echo Sounders (CPIES) at depths down to 3500 m in the area of the extended LCS.

The Sonardyne solution

Sonardyne’s modem-enabled CPIES were a key element in the initial two-year project. These instruments were part of a mass deployment to measure two-way travel time (or tau) over an extended area in order to map the local horizontal velocity and density fields in the extended LCS, as can be read at https://www.sonardyne.com/case-study/unlocking-the-gulf-loop-current/.

Soon after the 2018 deployment, Sonardyne began the development of Origin 65, a combined PIES and ADCP with acoustic modem to enable adaptive data harvesting. The benefit of Origin 65 over CPIES is that it not only supports but augments density/current mapping projects.

Where CPIES use a separate single point current meter to provide a deep reference velocity for calculated geostrophic currents, Origin 65 measures a whole profile of currents over a greater range. Being an all-in-one instrument, Origin 65 also removes the risk and expense of combining separate devices for a single application.

What’s more, by utilising Origin 65’s onboard Edge data processing capability, PIES data is time-synchronised and fused with the ADCP measurements for simpler analysis. After extensive trials, Origin 65 was launched in 2023.

“Pulses of strong currents pose a hazard to industry along steep escarpments in the deep Gulf. Moreover, their unexpected arrival compounds the hazard: satellite and near-surface observations and numerical models do not predict them reliably. We needed a forecast tool grounded in observations with adaptive reporting capability. We had a tall order for the observations: We needed to profile currents from the bottom through hundreds of meters above the bottom and we required fast acoustic telemetry capability. Sonardyne committed the engineering capability to develop a combined PIES and upward-looking low frequency ADCP with a vertical range of 800m. It was an outstanding match to our needs, and Sonardyne’s fast acoustic telemetry capability was key to being able to harvest the data and report it ashore in near-real time.”

Professor D. Randolph (Randy) Watts, Professor of Oceanography, University of Rhode Island

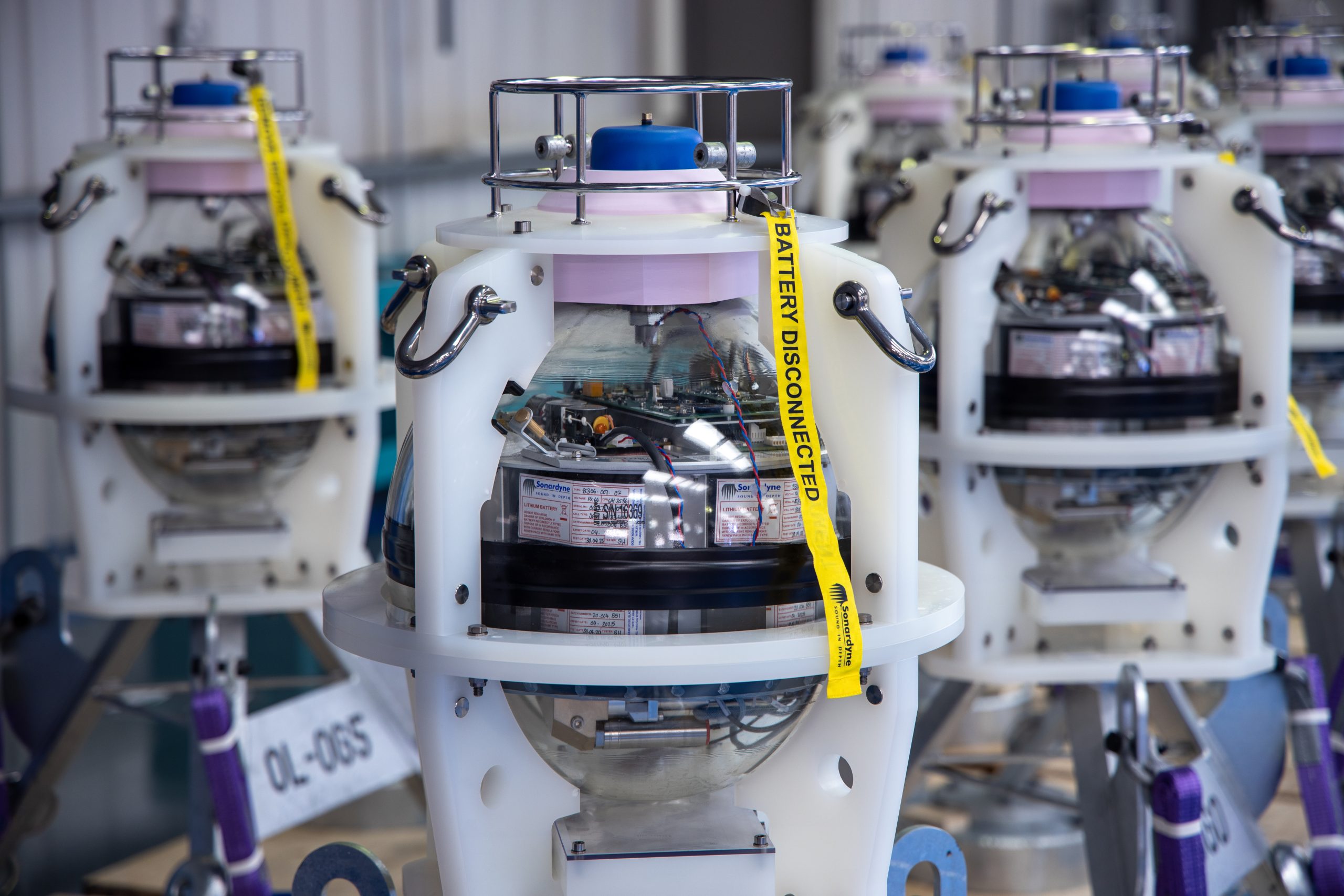

The 2024 deployment

In 2024, funded by the US National Academies of Science, Engineering, and Medicine Gulf Research Programme and led by a team of scientists from the University of Rhode Island, five Sonardyne Origin 65 units were deployed alongside the original Sonardyne CPIES in the Gulf of Mexico (depth range of 1800 – 3200 m) for an initial 18-month measurement campaign.

Both the Origin 65s and CPIES have integrated acoustic modems enabling high-speed (up to 9000 bps) acoustic telemetry to support wireless retrieval of data by an uncrewed surface vessel (USV) in addition to remote control of the instruments.

Despite similar telemetry capability, the volume of data generated by Origin 65 compared to CPIES is much greater, and therefore limited acoustic bandwidth presents a challenge when looking to transfer this substantial data via acoustic telemetry.

This is where Origin 65’s Edge onboard data processing capability comes into play to condense the bulky raw data into small packets of actionable information, easily exportable via the acoustic modem.

The five Origin 65 units were deployed with an Edge application (app) installed to perform combined onboard processing of the ADCP and PIES data. More specifically, the Edge app implemented a custom algorithm that produced an hourly compact (24 bytes) binary output containing a timestamp, the mean current speed and bearing in six depth-bins above the bottom, plus the mean of the PIES results.

The beauty of the onboard data processing was apparent during planned USV visits, where it took less than 20 minutes to acoustically harvest more than 2 months’ worth of data

An assessment was conducted whereby the integrated acoustic release on one of the Origin 65 instruments was triggered after 66 days of deployment to allow recovery (Figure 1) of the device and complete data download for a thorough evaluation. This instrument was located in a water depth of 2142 m.

Figure 1: Retrieval of the Origin 65 aboard the R/V Pelican.

Pies

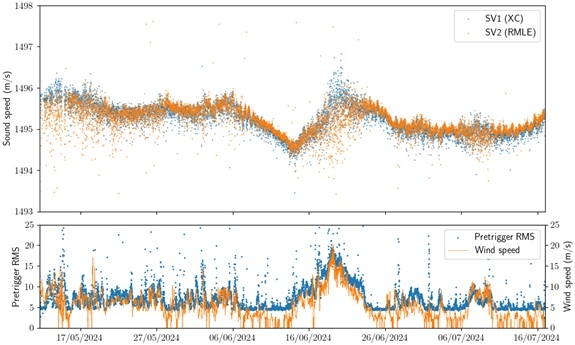

The PIES portion of the Origin 65 performed consistently (Figure 2). Periods of increased scatter in the sound speed measurements are observable, but these are a result of higher ambient noise levels (pretrigger RMS), which correspond to higher sea states (local wave activity is a dominant source of acoustic noise given that in higher sea states the surface return from the PIES chirp is more spread out).

Figure 2: PIES sound speed and ambient noise (pretrigger RMS) measurements for the deployment. The bottom plot compares ambient noise (pretrigger RMS) to the level of local wave activity using wind speed (as recorded by station Green Canyon 338, 124 km to the WNW of the deployment site) as a proxy for sea state.

ADCP

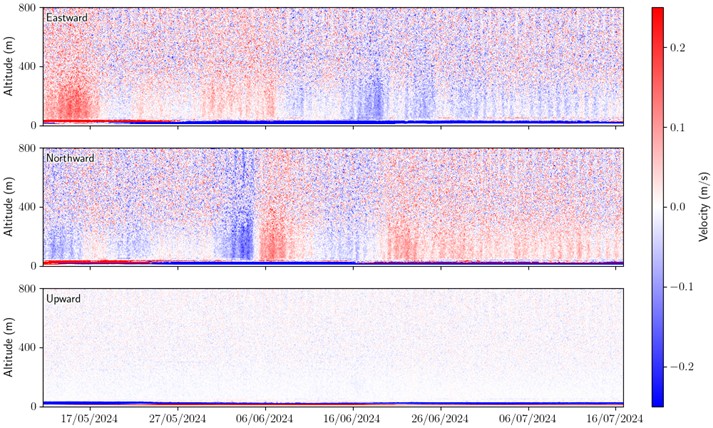

Velocity data demonstrates expected current behaviour (Figure 3), with velocities much larger in the Eastward and Northward directions than in the upward direction. The lack of significant apparent velocity in the vertical direction indicates that there is no systematic bias in the beam-frame Doppler velocities.

In addition, the observed velocity signals (large blue and red patches) vary on timescales between days and weeks, which is expected.

Of particular interest, it can be seen around 6th June, the prevailing current changed from South-Easterly to North-Westerly over the course of around two days.

This corresponded with a sudden increase in scatter density, thought to be an indication that the seabed was disturbed by the changing current.

Figure 3: Components of the Earth-frame velocities for the 66-day deployment (60-ping ensembles).

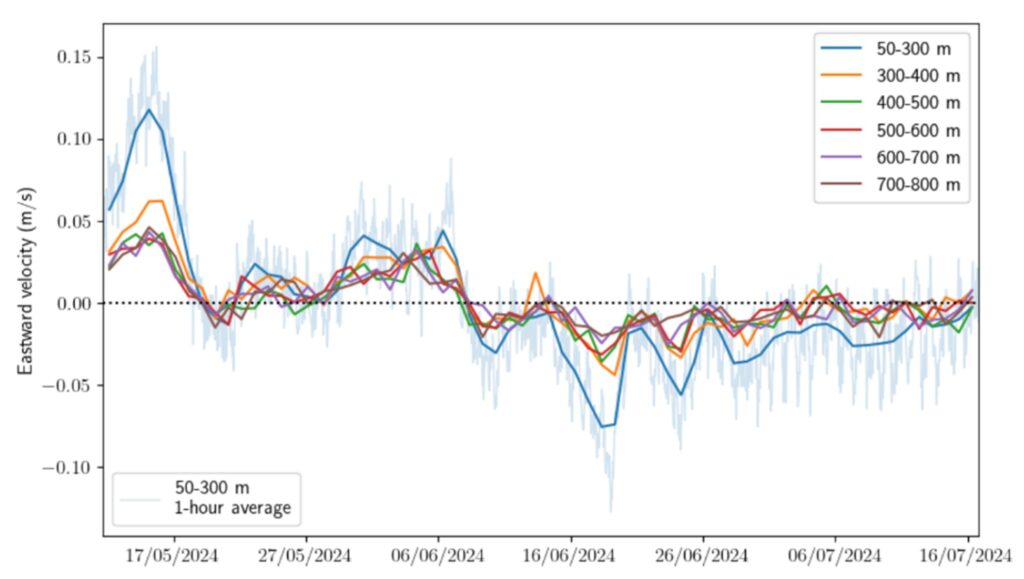

Low scatterer concentration in the deep waters (>2000 m) of the Gulf of Mexico reduced the effective profiling range of the Origin 65 from its achieved maximum range of > 800 m. However, with a sufficiently long averaging period it can been seen that the current velocity signal is present for the entire 800 m range of the Origin 65 (Figure 4).

Figure 4: Comparison of 24-hour averages of Eastward current velocity for different altitude bins. Performing increased averaging shows that a consistent current velocity signal is exhibited across the 800 m range of Origin 65.

“Our collaboration with the University of Rhode Island has been instrumental in augmenting our PIES technology in the form of Origin 65, a combined ADCP and PIES, for oceanographic study of geostrophic currents fields like that found in the Gulf of Mexico. We’re delighted to see Origin 65 being applied in this vital study, and by extension, to be able to support research efforts to improve and extend forecasting of the LCS and LCE behaviour with the accuracy desired. We look forward to continuing our relationship with the University of Rhode Island, and to seeing further successful USV data harvests from the Origin 65 units over their deployment period in the Gulf of Mexico.”

Michelle Barnett, Business Development Manager – Ocean Science, Sonardyne

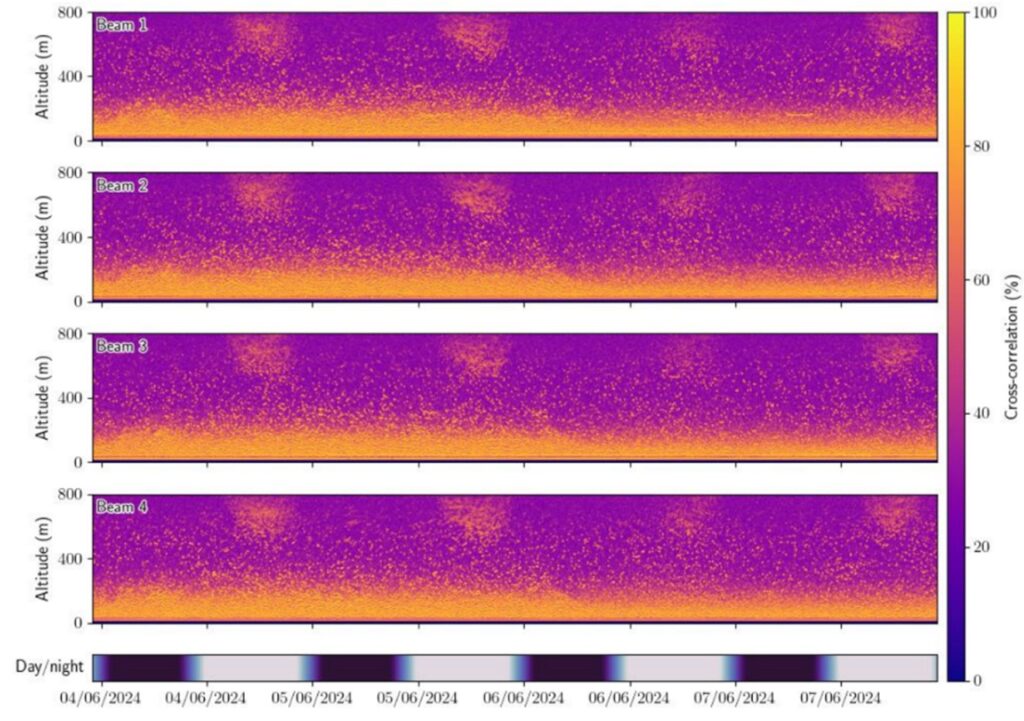

What’s more, evidence of diel plankton migration is apparent with the repeated appearance and disappearance of a scattering layer between 500 m and 800 m height above the bottom. This pattern has a period of roughly 24 hours with the scattering layer clearly visible in daylight hours, as is consistent with the cycle of diel vertical migration observed ubiquitously in aquatic systems throughout the world.

This is nicely demonstrated in cross-correlation data, where values increased to around 80% on a daily cycle in response to the plankton migration (Figure 5). This cross-correlation data helps to indicate the effective maximum range of the system of around 800 m.

Figure 5: An excerpt (4 – 7th June) of unaveraged cross-correlation data for each of the four beams of the Origin 65 demonstrating a clearly observable diel vertical migration pattern. The lower plot represents the local time, with the colour being a function of the local solar altitude.

“This suite of instrumentation and platforms will help refine predictive tools for future applications in the Gulf. Looking ahead, the combination of Sonardyne Origin 65 current profilers and adaptive data-harvesting technology opens the door for long-term deployments in deep water – anywhere in the world. This is very exciting: we could access remote and critically important regions supporting sustained observations and advancing science.”

Professor Kathleen (Kathy) Donohue, Professor of Oceanography, University of Rhode Island

What’s next?

Two successful data harvests by a SeaTrac SP-48 USV equipped with a Sonardyne HPT 7000 L transceiver head have already been conducted. A third data harvest is scheduled for the end of July and the instruments will be recovered in September 2025. Keep an eye on our website and social media for further information about this and the data captured.

If you have an operational challenge for Origin 65, or any other Sonardyne product, please contact us.

The drive towards greener offshore energy generation begins well before the first wind turbine blade turns. Geophysical marine survey company Sulmara are innovating the way they work with the offshore energy sector, leveraging technology wherever possible to help offshore wind projects be developed in the most efficient and environmentally sound ways possible. Founded in 2019, they are an international services provider specialising in site investigation, construction support, subsea survey and inspection across the offshore energy and utilities sectors.

The challenge

With a focus on unexploded ordnance (UXO), boulder and linear infrastructure mapping, Sulmara are pushing the boundaries of technologies to deliver depth of burial surveys and identify obstacles in and around potential offshore development sites across the energy sector.

By integrating an ROTV with an Edgetech Buried Object Sonar System (eBOSS) and Micro-Fabricated Atomic Magnetometers (MFAMs) from Geometrics and then layering custom software and delivery packages on top, Sulmara have developed a technology stack capable of enhancing site investigation and asset inspection campaigns. To deliver high quality data with the system that is deployable from a range of vessels and subsea vehicles, Sulmara required very high accuracy positioning and navigation inputs. They were also looking for a way to lighten the payload for towed operations. Sulmara approached Sonardyne as a world-leading supplier of acoustic positioning and hybrid inertial-acoustic navigation technologies to help them rise to this challenge.

The solution

In February 2025, as part of their continuing commitment to pre-commercialisation development, Sulmara mobilised a vessel and survey setup in Norfolk, Virginia USA to perform various trials and data acquisition tasks with a range of sensor equipment. The integrated eBOSS, MFAMs, and ROTV were mobilised and extensively trialled over a range of seabed conditions. For a positioning solution to support the towed platform, Sulmara selected Sonardyne’s Mini Ranger 2 USBL system.

For navigation, Sulmara had opted for an integrated Sonardyne SPRINT-Nav Mini hybrid inertial-acoustic navigator, and they were happy with the navigation performance provided. However, in their drive to make their technologies more compact, any savings on size, weight and power were considered, and Sonardyne sent out members of their engineering team with a prototype of the SPRINT-Nav U hybrid inertial-acoustic navigator to work with Sulmara and utilise this new smaller, lighter and lower powered navigator to the test on the towed platform.

Small, light, precise

Measuring just 134 mm in height, 114 mm in diameter and weighing a mere 600 grams in water, SPRINT-Nav U is the world’s smallest hybrid acoustic-inertial navigator.

Its small form factor packs the full, trusted, SPRINT-Nav capability into a space traditionally filled by just a DVL on a small robotic platform to deliver USBL aided performance up to 4x better than standard, with just 8W of power consumption. SPRINT-Nav U is simple to integrate into any marine vehicle along with other payload sensors and uses same field-proven web user interface found on the SPRINT-Nav Mini. Pre-calibration in the factory also means it’s incredibly quick to set up and deploy on site. An alignment time of as little as five minutes, compared to the standard 15-20 minutes of other gyro compassing inertial navigation systems, also makes it the world’s fastest aligning hybrid navigator.

“The all-in-one and compact nature of SPRINT-Nav Mini and SPRINT-Nav U make them ideal for integration into towfish platforms. Towfish are currently positioned either using magnetic heading sensors or course made good, which may lead to large positioning and heading errors. Affecting both data at nadir and at the edge of a sonar swath. The combination of high-grade fibre optic gyro based IMU and DVL means that our small SPRINT-Nav products provide class leading navigation inputs into the wider towfish system, ensuring reliable data outputs and eliminating any need to re-run lines because of poor navigation.” John Houlder, Senior Product Manager, Sonardyne.

When paired with a Sonardyne Ranger 2 USBL system, in Sulmara’s case the Mini-Ranger 2, the combination of precision navigation and positioning, is second to none.

As our mainstay USBL system for nearshore operations, Mini-Ranger 2 is a tracking, positioning, and communications system with robotic capability that tracks up to 995m out of the box, expandable to 4,000m with an extension pack. It’s suitable for AUVs, divers, ROVs, towfish, USVs, and vessels in shallow to mid-depth waters and features a large array with excellent rear noise blocking, making it ideal for quick vessel mobilisations and long layback tracking in towed surveys.

The results

The combination of Sonardyne Mini Ranger 2 USBL with the new SPRINT-Nav U hybrid inertial-acoustic navigator gave the towed platform a heading accuracy of 0.15°. This was well within the required performance for the geophysical survey specifications that Sulmara are looking to achieve for their clients. Due to the need for location of ferrous materials, such as UXO, having the fibre optic gyrocompass (FOG) inertial measurement unit (IMU) within the SPRINT-Nav U meant that the navigation performance was not compromised in the same way that it would be if the ROTV was using a magnetic heading sensor or course made good for navigation.

“The introduction of the SPRINT-Nav U as a navigation solution for our towed platform provides us with a solution that is not only accurate and reliable in all environments, it also ensured high quality geophysical datasets. It’s low power, size and weight meets our requirement to provide increased manoeuvrability on the ROTV. Pairing the navigation capabilities of SPRINT-Nav U with the Mini-Ranger 2 gives us a great option, as having this one vendor solution means that integration is simplified. The use of a fibre optic gyro is also key; this stops our heading being impacted by any nearby magnetic fields.” Dennis Wilson, Development Scientist, Sulmara.

“Having integrated SPRINT-Nav Mini and SPRINT-Nav U, we’ve been really impressed with the performance of both navigators. The performance of SPRINT-Nav U is really striking for equipment with such a small form factor. This is something we value at Sulmara, as we’re always seeking efficient hardware options to support our innovative survey efforts. We’re increasing the adoption of uncrewed and remote technologies, and it is essential that we do not compromise on the quality of the data we collect when reducing the size of the payload. Having the power of Sonardyne’s SPRINT-Nav products paired with their Mini-Ranger 2 USBL available to deliver guidance for our ROTV operations gives us the reliability needed.” Dennis Wilson, Development Scientist, Sulmara.

If you have a similar challenge in your small robotic platform operations, talk to us about how we might help you to find the solution. Click on the link below and let’s start a conversation…

Overview

Acoustic release transponders are a vital piece of ocean equipment – relied upon by energy, defence and science users to moor valuable equipment strings for years at a time, and when commanded to do so, reliably return equipment and logged data to the surface.

Transponders need to be tough, reliable and easy to work with. RT 6-6000 meets these requirements.

Part of our new range of acoustic releases, RT 6-6000 combines the extensive mechanical design track record of our renowned ORTs and DORTs with the flexibility of our 6G platform, resulting in enhanced battery life and perhaps most significantly, compatibility with our Ranger 2 USBL family

With RT 6-6000, you can use your vessel’s Ranger 2 USBL to deploy, track, locate and command the instrument – removing the need for a separate topside unit. If you don’t have access to a Ranger 2 USBL, our rugged and lightweight Deck Topside with an over-the-side dunker is all you need to both configure and command RT 6-6000s.

At a glance

- Tested, loaded, deployed and released using Deck Topside

- Also works with Sonardyne Ranger 2 USBL to deploy, track and command in very deep water

- Highly reliable release mechanism design and thousands are in service globally

- Working Load Limit 1,275 kg (4:1)

- Depth rated to 6,000 m

- External battery disconnect to maximise battery life with no need to open unit

- Compact and rugged design

RT 6-6000s are most commonly used to anchor oceanographic moorings to the seabed. However, their compact size and compatibility with Ranger 2 makes them ideal for incorporation into instrument frames or lowered platforms to enable deployment of sub-system packages.

Standard features include a Working Load Limit of 1,275 kg (at 4:1) and a spring-assisted release mechanism. RT 6-6000 is compatible with our standard tandem and high-load release frames for scenarios requiring a higher WLL. Speak to us about your requirements as custom frames are also an option.

A battery disconnect fob is located on the transducer and uses an internal magnetic switch to electronically disconnect the battery when not in use. This means you do not have to open the unit to manually disconnect the battery, saving time and reducing the risk of incorrect re-assembly.

RT 6-6000s use the same trusted spring-assisted release mechanism that has been in service for many years and used on thousands of Sonardyne transponders globally.

Choice of topsides

You can use our rugged Deck Topside, or if you’ve got access to a Ranger 2 USBL system on your survey or research vessel, then you have everything you need to control your RT 6-6000.

Versatile

RT 6-6000 is more than just an acoustic release. It can be tracked with our Ranger 2 USBL making relocating and recovering it fast and simple.

High WLL

Use it with our Heavy-Duty Release Frames and significantly increase your Working Load Limit when deploying seabed structures.

Support

You can find a wide range of support articles for our family of acoustic release transponders on our knowledge base.

Specifications table

| Feature | Type 8321-6250 |

|---|---|

| Depth Rating | 6,000 m |

| Operating Frequency | LMF (14–19 kHz) |

| Transducer Beam Shape | Hemispherical |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 188 dB |

| Tone Equivalent Energy (TEE) | 192 dB |

| Receive Threshold (dB re 1 µPa) | <90 dB |

| Working Load Limit (4:1) | 1,275 kg |

| Proof Load | 2,550 kg |

| Breaking Load | 5,100 kg |

| Maximum Safe Release Load | 1,700 kg |

| Battery Life (Alkaline) | >32 months |

| Inclinometer Accuracy | ±5° |

| Surface Unit | Deck Topside, Ranger 2 USBL |

| Mechanical Construction | Aluminium bronze and duplex stainless steel |

| Operating Temperature | -5 to 40°C |

| Storage Temperature | -20 to 55°C |

| Dimensions (Length x Diameter | 700 x 142 mm (27.5 x 5.6”) |

| Weight in Air/Water | 20/15 kg |

| Standards | CE Marked to EN-60945, EN-61010 |

| Options | Deep Water Deck Kit (Deck Topside) – 602-0180 |

| Heavy Duty Release Frames (7.5 T, 15 T and 25 T) |

Frequently asked questions

What is an Acoustic Release and how does it work?

Why isn’t serial communication available using the iWand in RT 6 Dunker Mode?

6G Terminal Lite Range Test

What is the safe working load for different RT 6 products?

What should I use instead of an ORT and DORT?

How to correctly set an RT 6-6000 release mechanism

How to change the battery on an RT 6-3000 or RT 6000

How to load the release on an RT 6-3000 and RT 6-6000

Which RT 6 is correct for my operations?

How to release an RT 6 acoustic release transponder using Ranger 2

How long can an RT 6-3000 and RT-6 6000 be deployed for?

Deployment

STP files

Software and control hardware

Manuals and quick start guides

Did you know?

RT 6-6000 can be used with our Ranger 2 USBL family or Deck Topside