The solution

L3Harris had already used our Mini-Ranger 2 for USBL aiding an iXblue Phins INS, via one of our AvTrak 6 OEM Nanos, on one of its Iver3s on a separate customer project. Read more here.

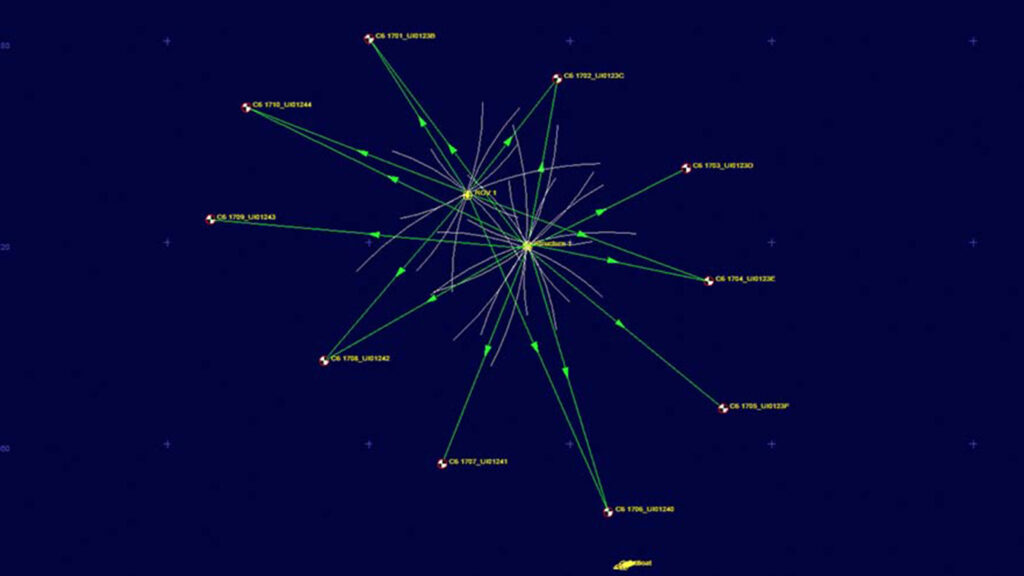

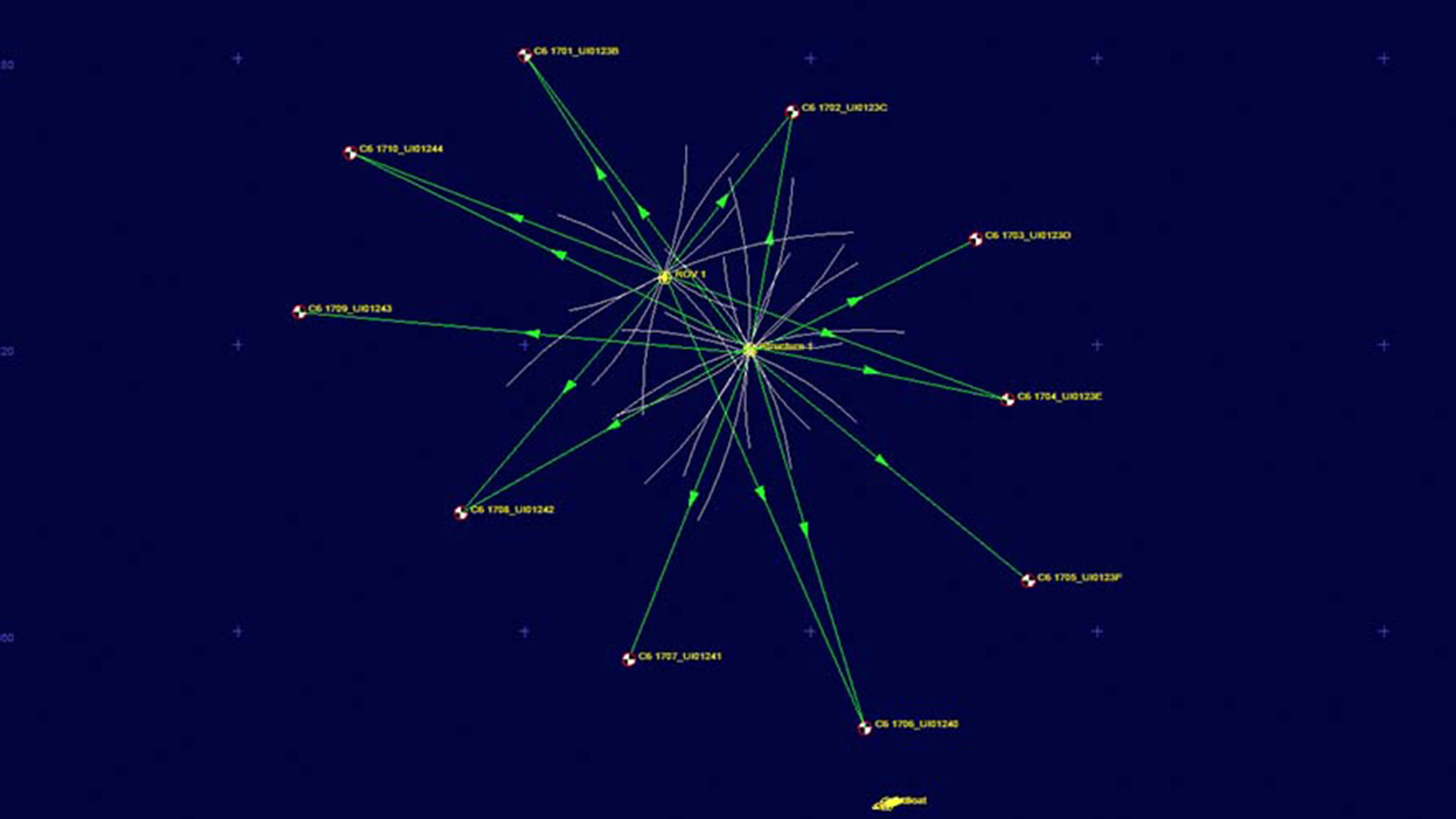

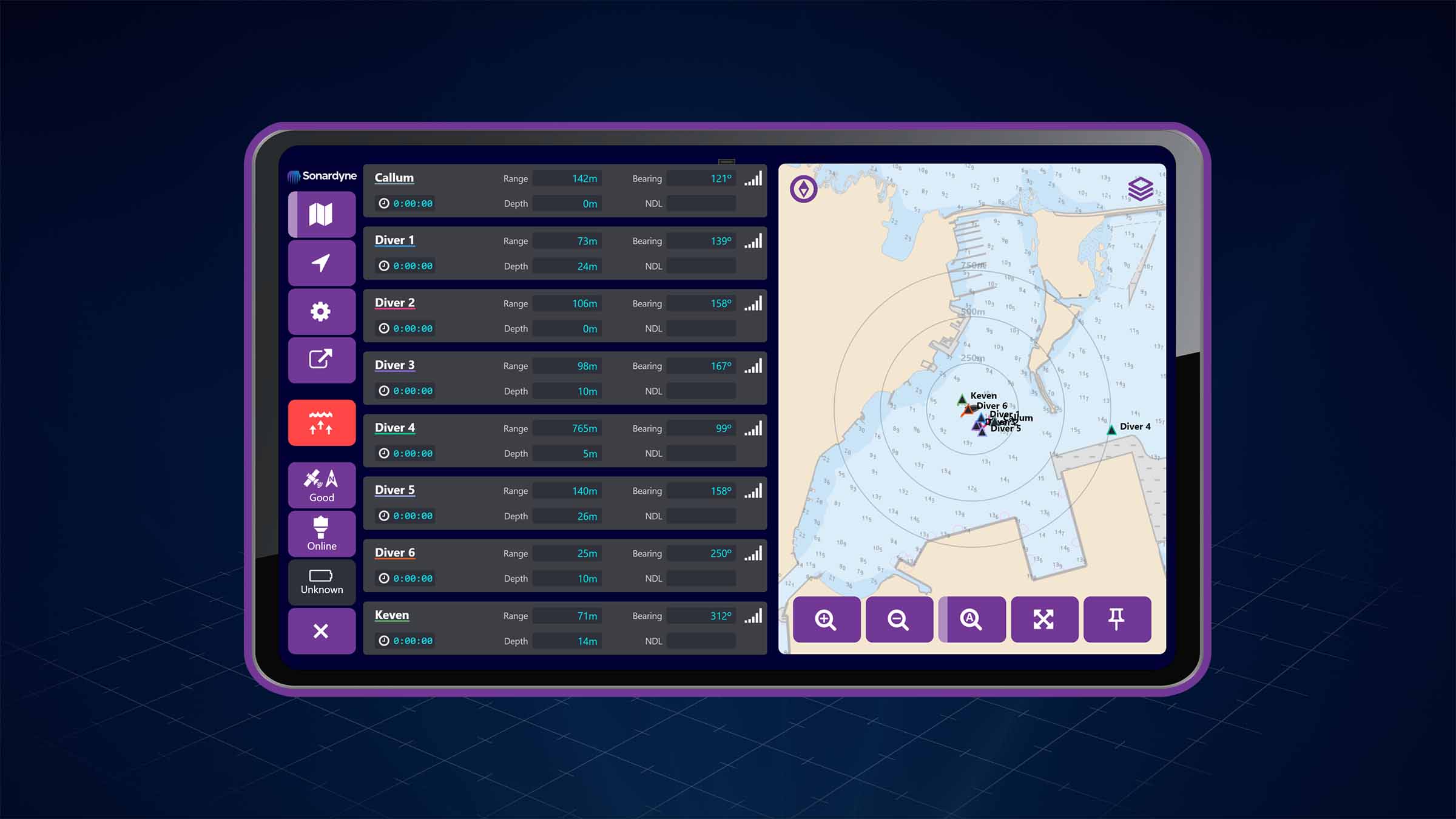

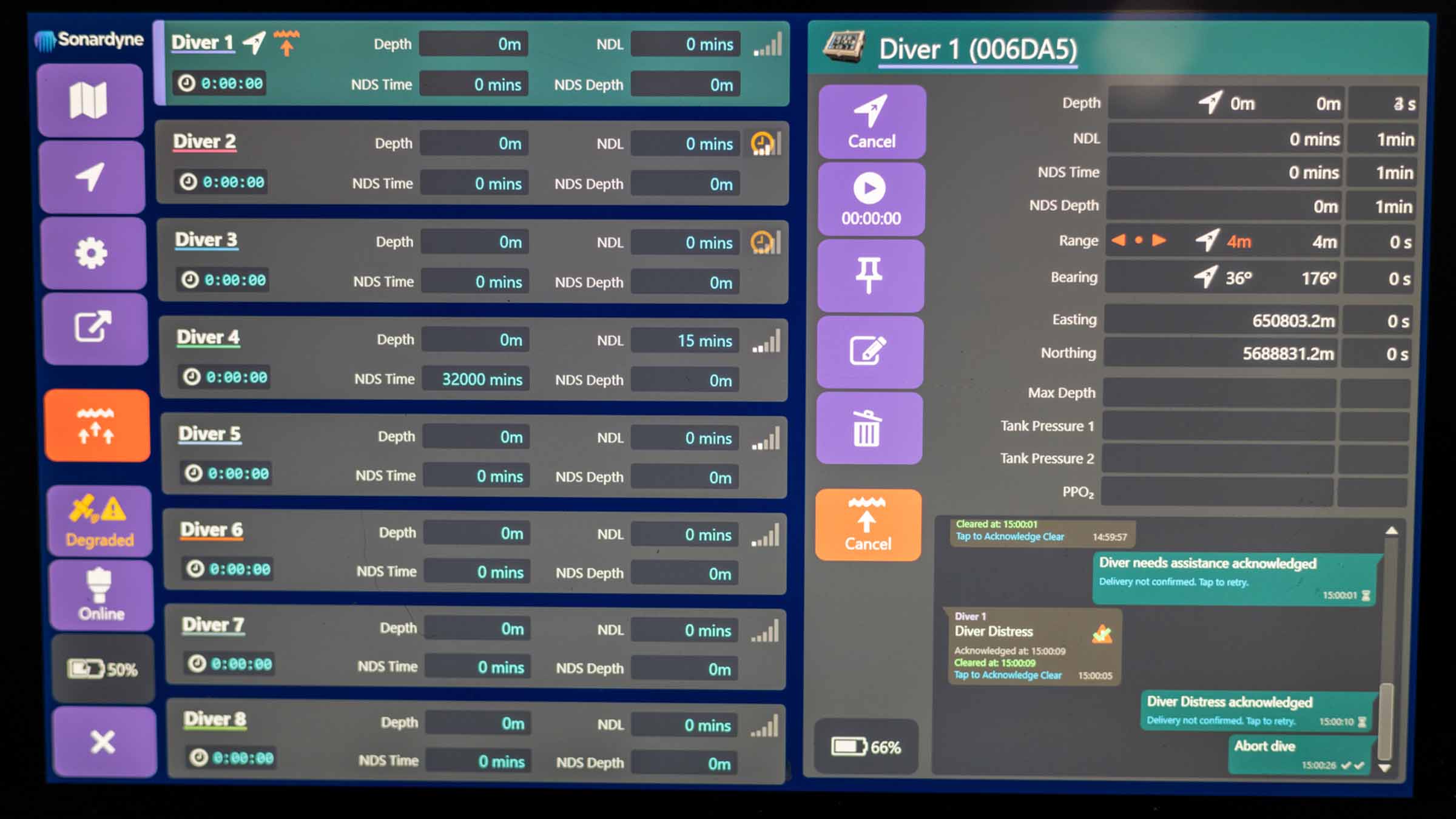

Mini-Ranger 2 is the ideal USBL system for coastal operations, supporting high-elevation tracking of up to 10 targets simultaneously down to 995 m water depth (extendable to 4,000 m), as well as data harvesting. It offers performance without the cost and complexity of a larger deep water USBL system.

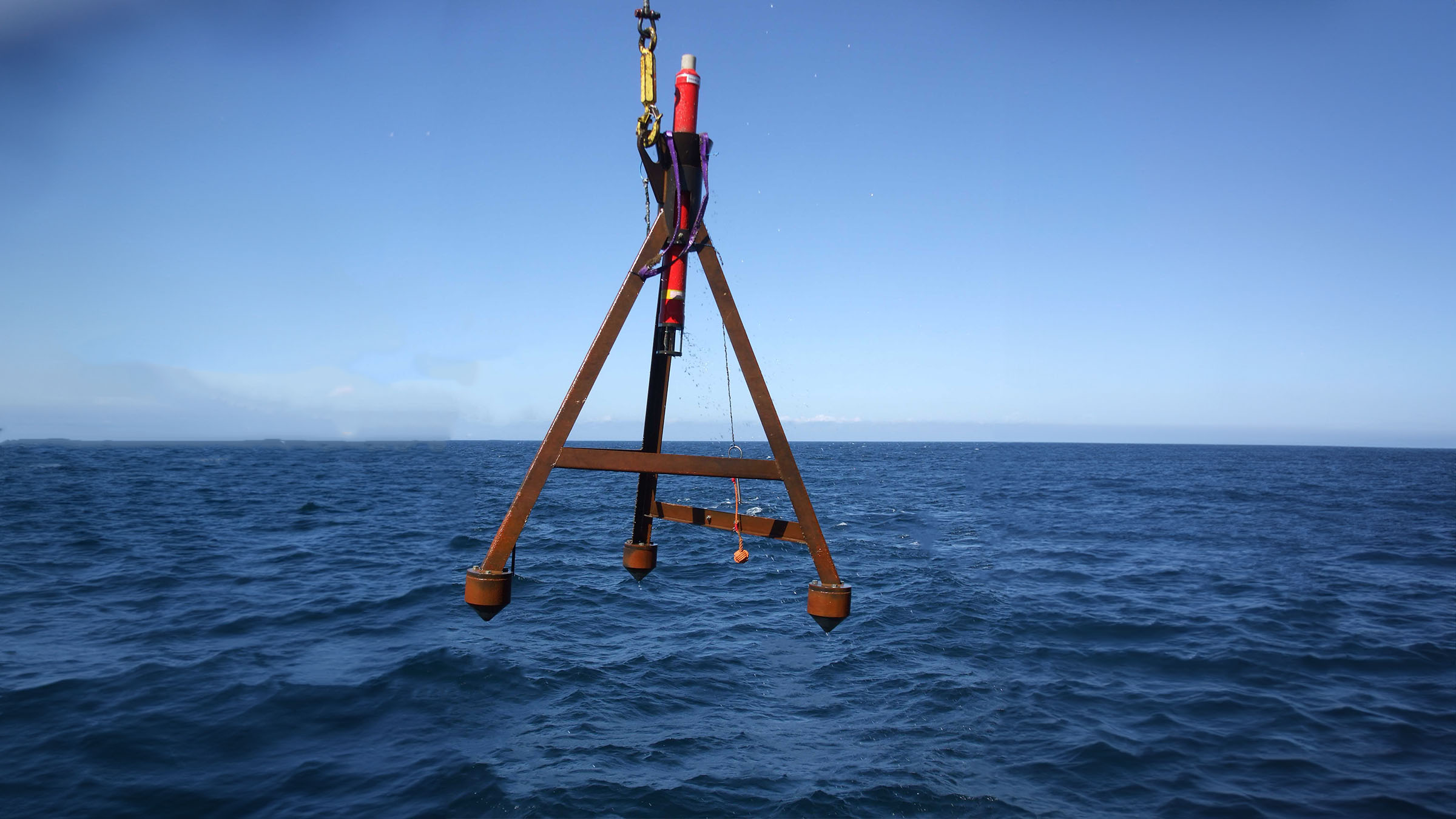

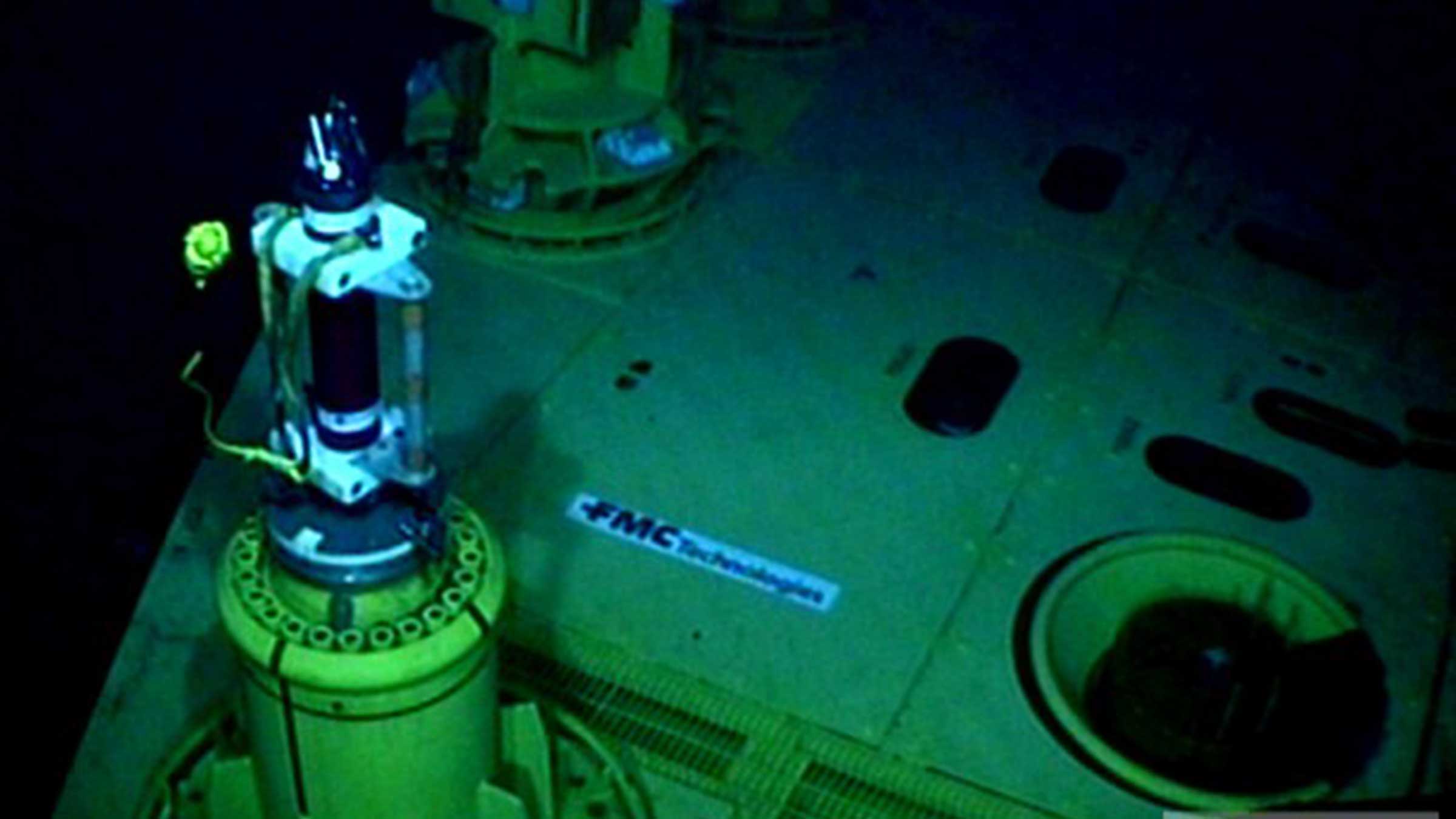

At the heart of the system our HPT 3000, a highly capable surface deployed USBL transceiver which is optimized for performance in shallow water, high elevation and long lay back operating scenarios, as well data telemetry.

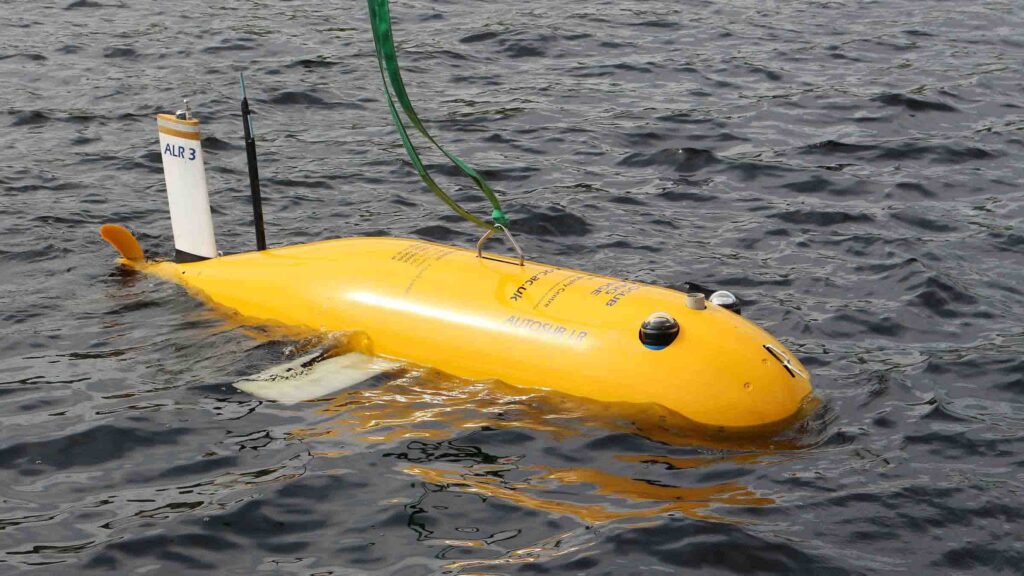

To provide INS aiding, L3Harris’ customer chose to integrate our AvTrak 6 OEM Nano, with a remote transducer, into their Iver3.

AvTrak 6 OEM Nano is the smallest variant of our AvTrak transceiver, designed for ease of integration on smaller underwater vehicles. It combines the functions of a transponder, transceiver and telemetry link, enabling communications, tracking and USBL aiding for subsea robotics. It’s also based on our 6G hardware platform, which means it’s interoperable with all our USBL, LBL and INS systems. This provides flexibility, but also performance enhancement, for example when combined with a Sonardyne INS.

As in the earlier project, the AvTrak 6 was programmed to speak the right language to the third-party IXBLUE Phins INS, by sending out an APOS PSIM SSB telegram, instead of our proprietary SPOS. The AvTrak 6 transducer was also supplied on a special Iver3 mounting post design, to make it easy to plug and play into the AUV – and any other Iver3, for that matter.

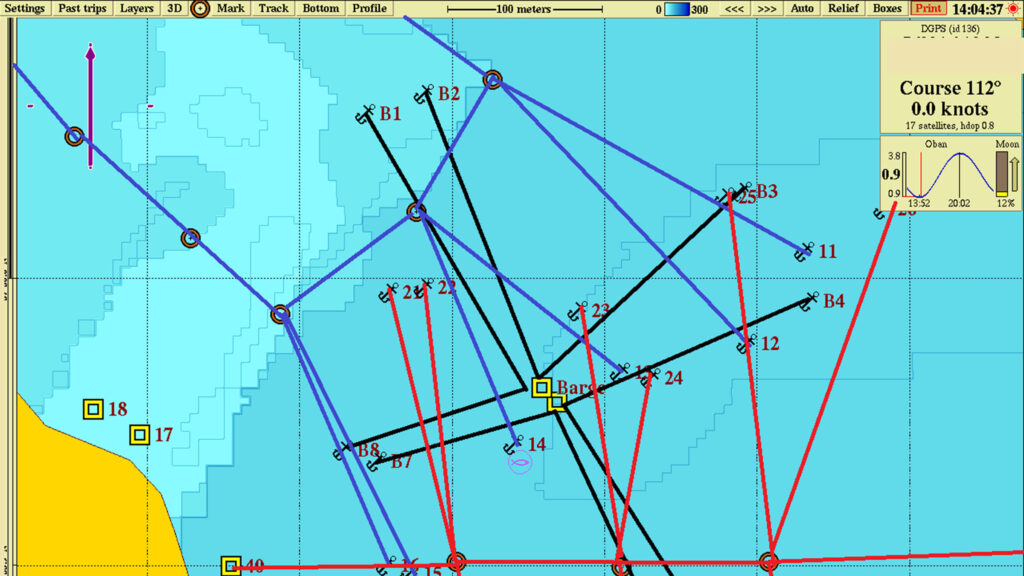

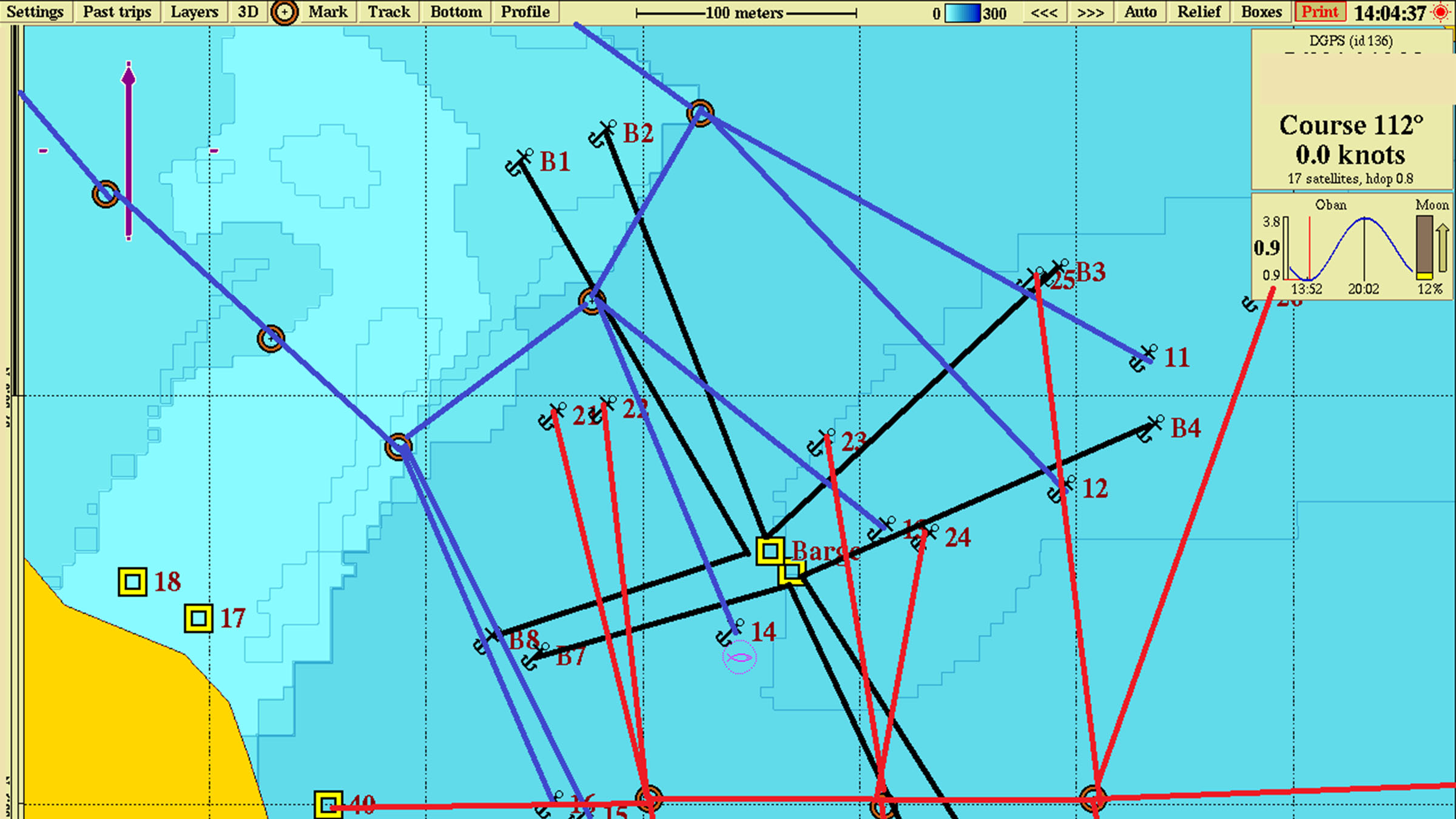

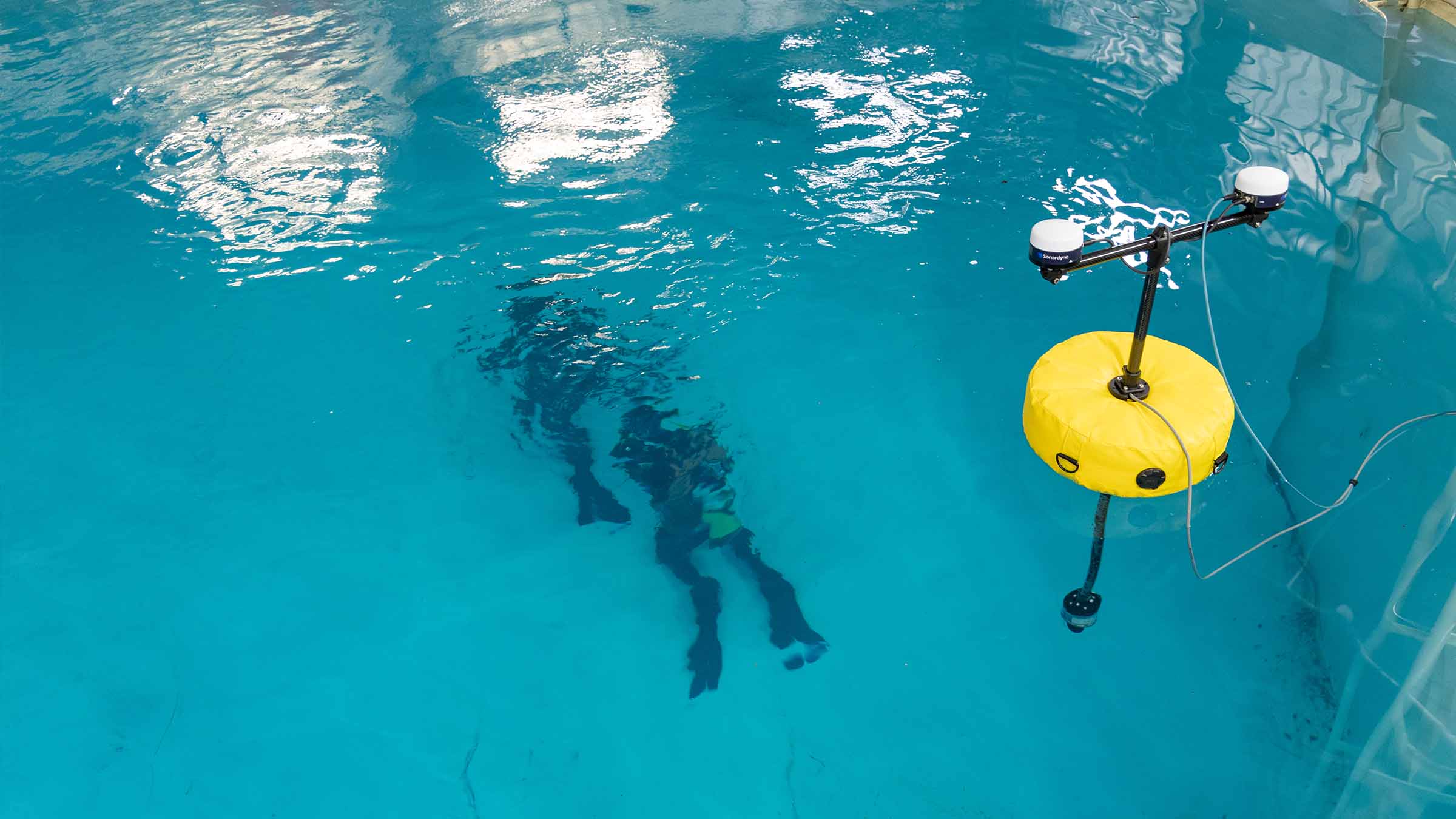

Mini Ranger 2 was pole-mounted to the support vessel with hemisphere GPS for topside absolute positioning.