Overview

iRelease has been made obsolete. If you’re interested in the capabilities, we suggest looking at our Deck Topside

iRelease is a rugged, handheld unit that’s used as part of a Lightweight Command Unit (LCU) setup on the back deck to test, load and release our legacy range of ORT and DORT acoustic release transponders.

At a glance

- Use it to test and control legacy ORT and DORT acoustic releases

- Compatible with legacy LCU dunking systems (replaces obsolete Psion unit)

- Handheld design, battery powered, rechargeable

- Splash-proof and rugged; designed for the back deck

- Easy-to-use five-button interface

Specifications table

| Feature | Type 8315 | |

|---|---|---|

| Case | Rugged polypropylene copolymer case with styrenic over mould shock protection | |

| Keypad | Sealed 5 key navigation pad | |

| Display | 320 x 240 sunlight readable LED display | |

| Connections | USB | Splash-proof mini-USB Type B |

| Serial | 9-way D-type (male) | |

| Charging | USB to PC or USB to wall adaptor | |

| Internal flash memory | 1 GB | |

| Battery | Li-ion 3.7 V 1,300 mAh (typical) | |

| Battery life | Normal (screen on) | >5 hours (screen automatically turns off after a selectable period) |

| Idle (screen off) | >12 hours (press a key or ‘shake to wake’ to turn screen back on) | |

| Off | >3 months (press a key to wake) | |

| Off for shipping | >1 year (requires USB connection to wake-up) | |

| Operating temperature | -10 to 55°C | |

| Storage temperature | -10 to 55°C | |

| Dimensions (length x width x depth) | 194 x 84 x 40 mm | |

| weight | 0.8 kg |

Datasheets

Manuals and quick start guides

Using a hammer to crack a nut? Try using a USV instead

USVs are no longer new. They’ve been used in defence for some time now, for a range of tasks from surveillance to mine counter measures. USVs are being used to survey coastal and offshore waters in hydrographic surveys, for ocean science and in oil and gas

The challenge

Crewed vessels used in offshore construction projects are costly and can even hinder progress. But it doesn’t have to be that way. Other sectors that operate in the marine space are now finding new, smaller, smarter, cleaner tools. They’ve been using uncrewed surface vessels (USVs), so the big, crewed vessels can stick to the jobs they’re good at.

So why are we not using them heavily in offshore construction?

One reason may be because offshore construction was in fact an early adopter. But, at the time, there were only a handful of commercial USV operators whose vehicles were just too big for what was needed, making them unwieldy to deploy from an offshore vessel, defeating the point of the exercise.

Another may be the worry of the complexity involved in offshore construction. Creating complex structures on shore is one thing. Creating them under metres of salt water is entirely another.

Then there is the issue of communication and control over the construction process. Making sure each step is taken exactly as planned is fundamental to the overall success of a construction project.

The solution

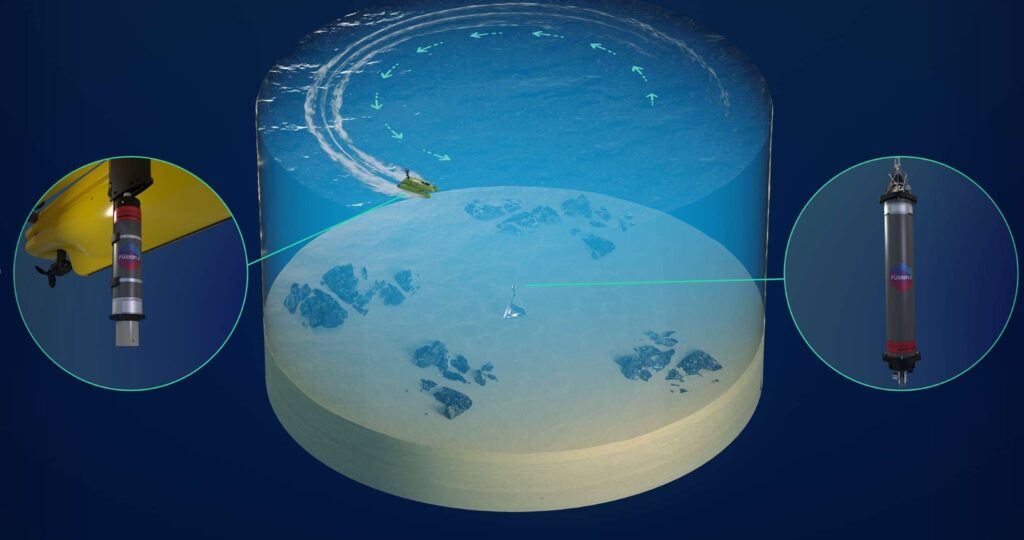

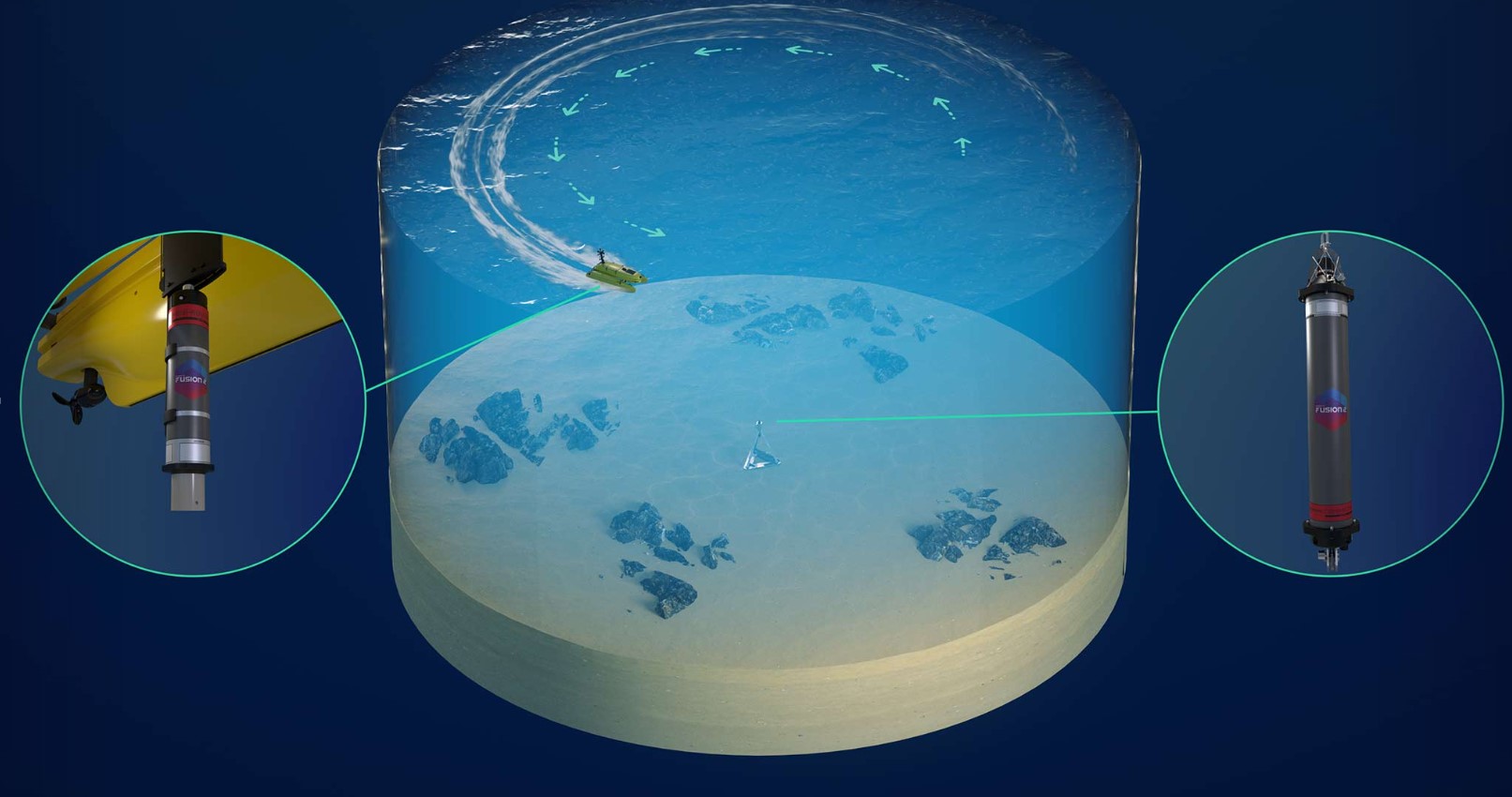

USV technology has come a long way since their inception. They’ve been used in defence for some time now, for a range of tasks from surveillance to mine countermeasures. USVs are being used to survey coastal and offshore waters in hydrographic surveys, for ocean science and in oil and gas. They’re being used to go out and gather data, either as a platform for oceanographic instruments or by carrying acoustic communications systems to harvest data from sensors deployed at the seabed. You could think of them being like a remote-controlled Dunker.

USVs are now part of the toolbox across a number of sectors and the levels of sophistication and capability are increasing. Worries about lack of control, the complexity of operations or large clunky kit that isn’t up to the delicate tasks required in offshore construction are today unfounded.

In offshore renewables and oil and gas USVs are being used as part of site and seismic surveys, and then through field life, for inspection operations. They’re also being used for maintenance and repair, by acting as deployment platforms for autonomous underwater vehicles (AUVs), remotely operated vehicles (ROVs) and even aerial drones (UAVs).

The results

Today there’s a wide choice of USVs to choose from. From one-man portable USVs to full sized vessels, and on to fully electric coastal systems and hybrid long-range ocean-going vehicles that can operate for weeks on end. The range of commercial models has also grown. You can buy them outright or purchase a data service where you just order the end result – be it data or an inspection campaign.

USVs can now play a central role in construction operations. They can streamline operations and reduce risk for manned offshore construction teams. When deployed they reduce reliance on heavier, costlier tools and free-up crewed assets to be used on elements of a project where they’ll bring more value.

Optimising shallow water positioning for combined magnetometer and hydrographic surveys

Seabed surveys are now on the critical path towards meeting global renewable energy generation targets. That’s why Ocean Floor Geophysics are working on ways to improve how pipelines and cables are detected and monitored. Our positioning and navigation technologies were used to support a demonstration of their Hypermag gradiometer with Covelya Group company EIVA.

The Challenge

Detecting cables or pipelines on the seabed and checking or monitoring cable depth are essential requirements in the development and management of most offshore energy projects. With a global target of 80 GW of offshore wind to be built annually by 2030, these tasks are also now on the critical path.

Magnetometers or gradiometers (comprising an in-line array of magnetometers) are a key tool for these operations. Accurately knowing the position of these instruments in the water throughout a survey ensures that target detection resolution is as high as possible. So, Canada-based Ocean Floor Geophysics’ (OFG) has developed the Hypermag gradiometer.

Rather than towing a magnetometer or gradiometer from a vessel or ROV, OFG’s Hypermag has been designed with multiple vector magnetometers installed in a scalable array that can be integrated directly onto a remotely operated towed vehicle (ROTV), such as EIVA’s ScanFish. This removes any positional uncertainties seen when using a layback offset when towing a magnetic sensor. The multi-vector gradiometer could then acquire compensated magnetic data in real-time

OFG possesses advanced multiphysics capability, particularly in fusing acoustic data with magnetic and electromagnetic field data, in this case magnetic field interpretation across multiple three-vector sensors. The team, therefore, required optimum shallow water positioning of the ROTV to demonstrate the gradiometer at its highest capability. “A high-quality, accurate navigation solution is a key component in achieving the full potential from our next generation of magnetic vector gradiometer sensors,” says OFG CEO Matthew Kowalczyk. “In shallow water environments, such as near-shore windfarms and UXO survey sites, it can also be one of the most difficult datasets to produce.”

The solution

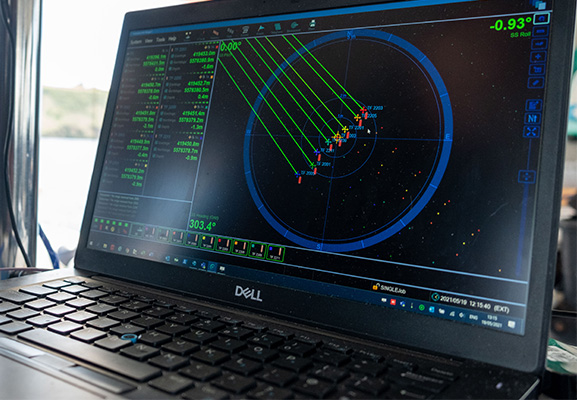

Covelya Group companies EIVA and Sonardyne supported a demonstration of the Hypermag in the vicinity of a wind farm in the North Sea. EIVA provided ScanFish support, including integration of the Hypermag configuration, a Norbit multibeam and a NaviPac software solution. Sonardyne provided a SPRINT-Nav Mini INS system alongside Ranger 2 equipped with a Gyro USBL transceiver, providing OFG with comprehensive position and behaviour accuracy of the ScanFish platform and it’s offset Hypermag sensors.

The SPRINT-Nav Mini Navigator is our smallest form factor hybrid navigation instrument, combining an INS, AHRS, Doppler velocity log (DVL) and pressure sensor.

By using this integrated INS system, updated by the Ranger 2 Gyro USBL, positioning errors or any erroneous USBL pings or dropouts could be mitigated. The INS can, in real-time, reject outliers in the data and output AHRS data, velocity, depth and altitude, as well as outputting real-world positional data in real-time, mitigating the need for post-processing. In addition, the SPRINT-Nav Mini could support multibeam data acquisition when a combined multibeam and magnetic gradiometer solution is used.

To put the approach to the test, a vessel of opportunity, the 22 m Marshall Art survey vessel, was mobilised. We used our Ranger 2 Gyro USBL system, which comes pre-calibrated, for easy mobilisation, with a Norbit iWBMSh multibeam echosounder (MBES) on Marshall Art providing RTK GNSS into the Gyro USBL.

On the ScanFish there were two OFG Hypermag panels, comprising a total of eight magnetometers, our SPRINT-Nav Mini Navigator, an omnidirectional Wideband Sub Mini 6+ transponder and a Norbit multibeam. An OceanEnviro fibreoptic winch system was installed on the vessel to tow the ScanFish. Orientation and position data was provided by the SPRINT-Nav Mini.

The results

“This was a great collaboration,” says Matthew Kowalczyk. “The combination of Sonardyne’s Ranger 2 Gyro USBL system and SPRINT-Nav Mini allowed us to quickly produce a navigation solution for the Hypermag system that exceeded our expectations.

“A high-quality navigation solution is necessary for achieving the full potential from our next generation of marine magnetic vector gradiometer sensors. Sonardyne’s support contributed to the trial’s overwhelming success.”

Another benefit of using SPRINT-Nav Mini on the ScanFish is that it can support its 3D steer algorithm, which can make surveying more efficient, reducing overall survey costs.

Pipelines and cables are often surveyed using a zig-zag pattern to decrease survey time. However, the most efficient way to survey a pipe would be to run parallel to the pipe, which EIVA 3D Steering allows with a suitable navigation solution because the position of the data measurement can be known with higher certainty.

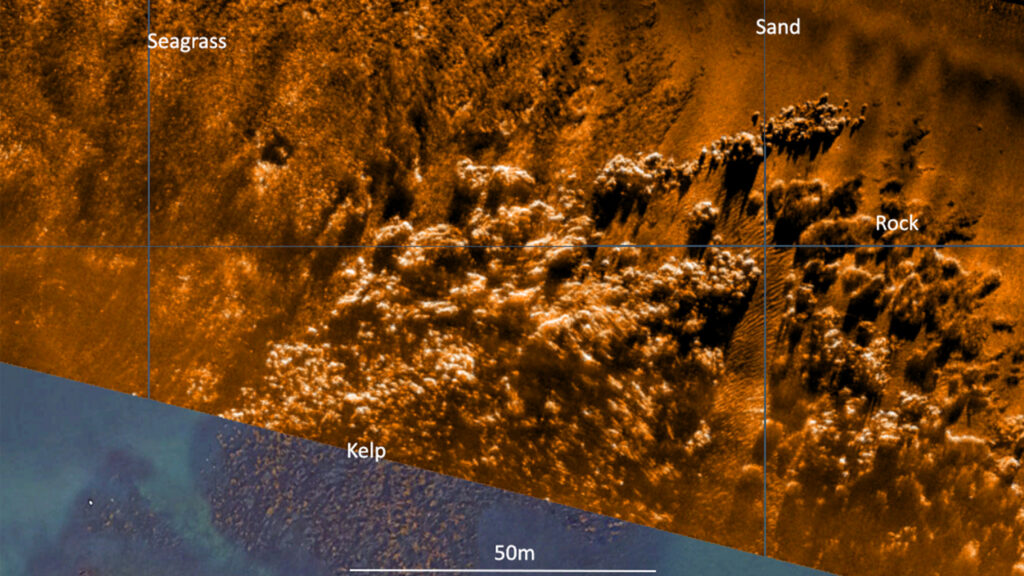

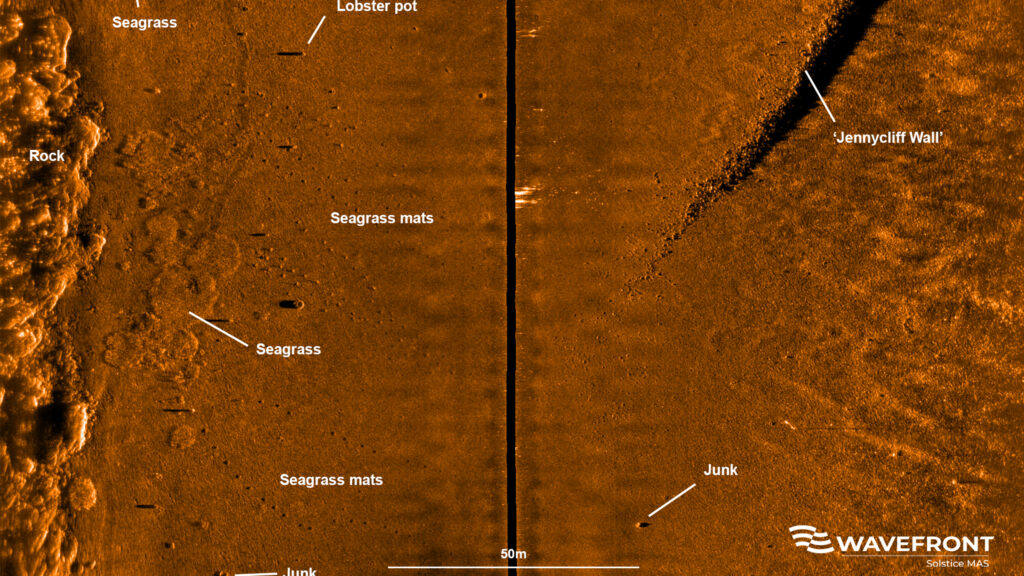

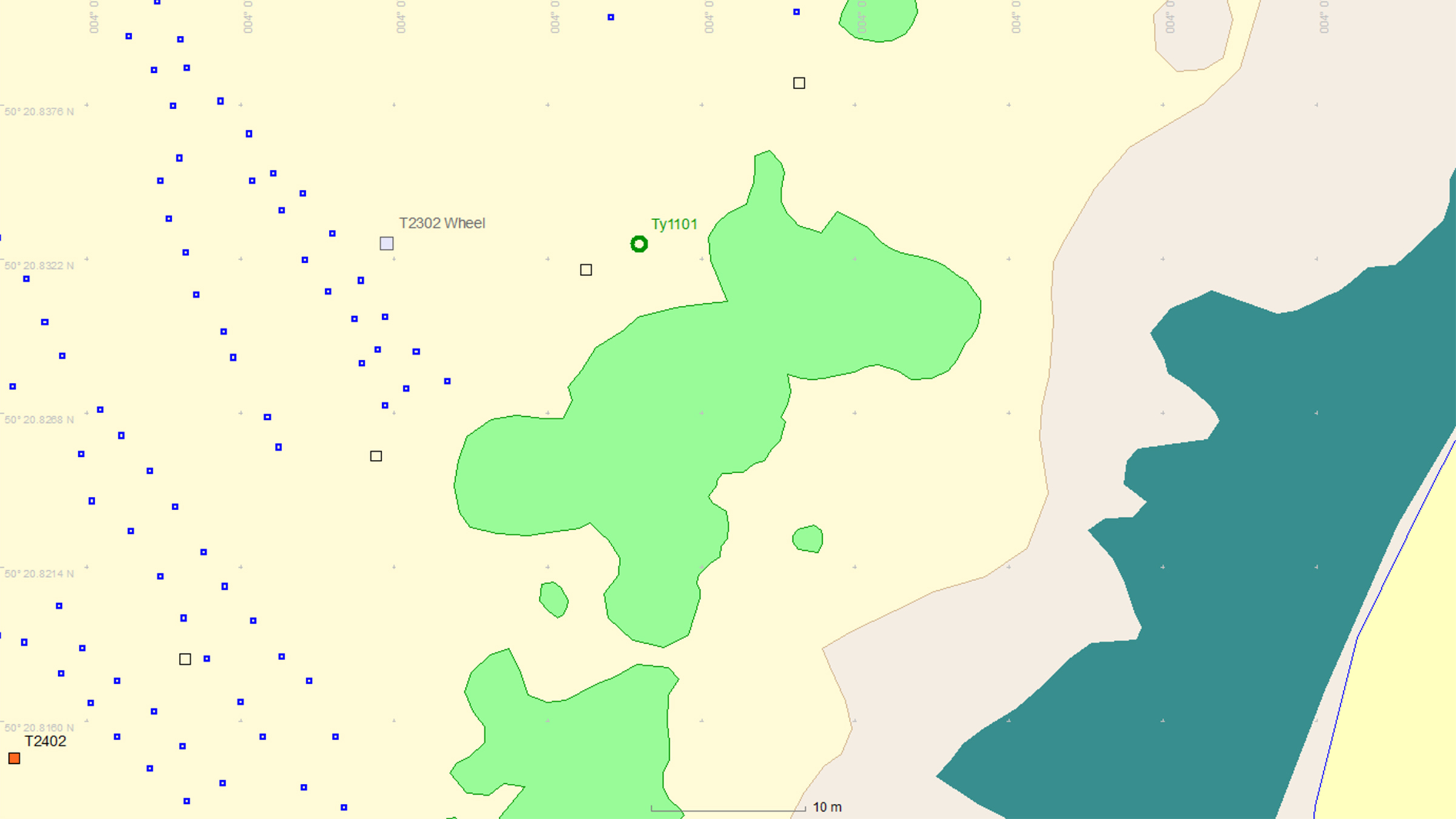

Mapping the future for seagrass beds in Plymouth Sound

Seagrass beds are incredibly important ecosystems that offer a range of ecological benefits. Not only do they provide crucial habitats for a diverse array of marine wildlife, especially in coastal areas like Plymouth Sound, they can also store carbon, helping to mitigate the effects of climate change. These underwater meadows serve as nurseries for many species of fish in the early stages of their life, offering them protection and abundant food sources. Additionally, seagrass beds help to stabilise the seabed with their root systems, preventing coastal erosion and maintaining water quality by trapping sediments and nutrients.

However, despite their importance, locating and monitoring seagrass beds using traditional methods, such as survey boats, presents significant challenges. Seagrass typically grows in shallow waters, which can make it difficult for boats to navigate close enough to the shore to obtain accurate data. Traditional survey boats are often large and cumbersome, making them hard to manoeuvre in shallow or rocky areas. This limitation can result in incomplete or inaccurate assessments of seagrass distribution and health.

Furthermore, the process of using boats for surveying can be time-consuming and labour-intensive. It often requires multiple trips and extensive manual labour to map out the seagrass beds accurately. The visibility in shallow waters can also be poor due to water turbidity, further complicating the survey efforts and leading to potential underestimation of seagrass coverage.

Finding a solution…

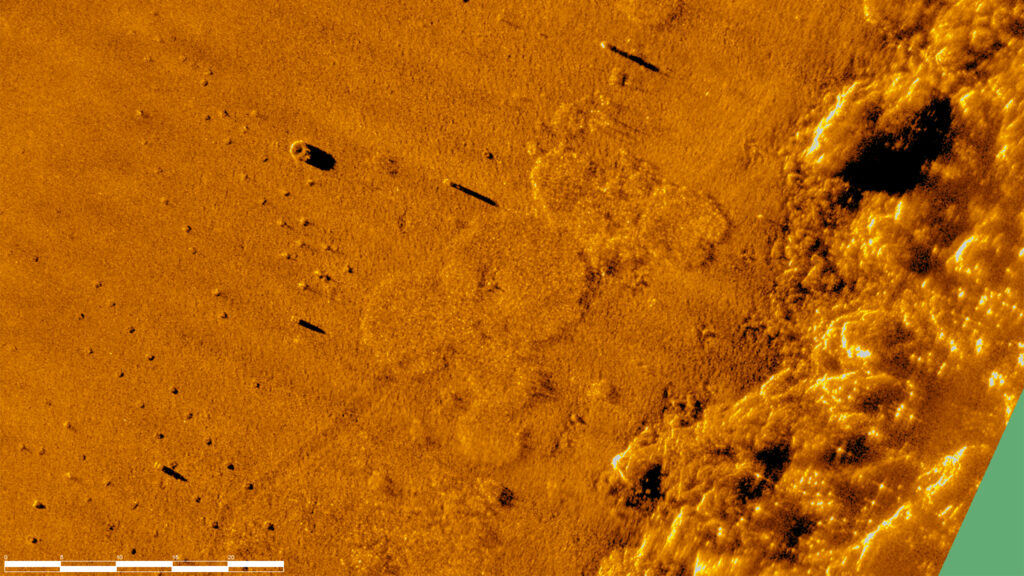

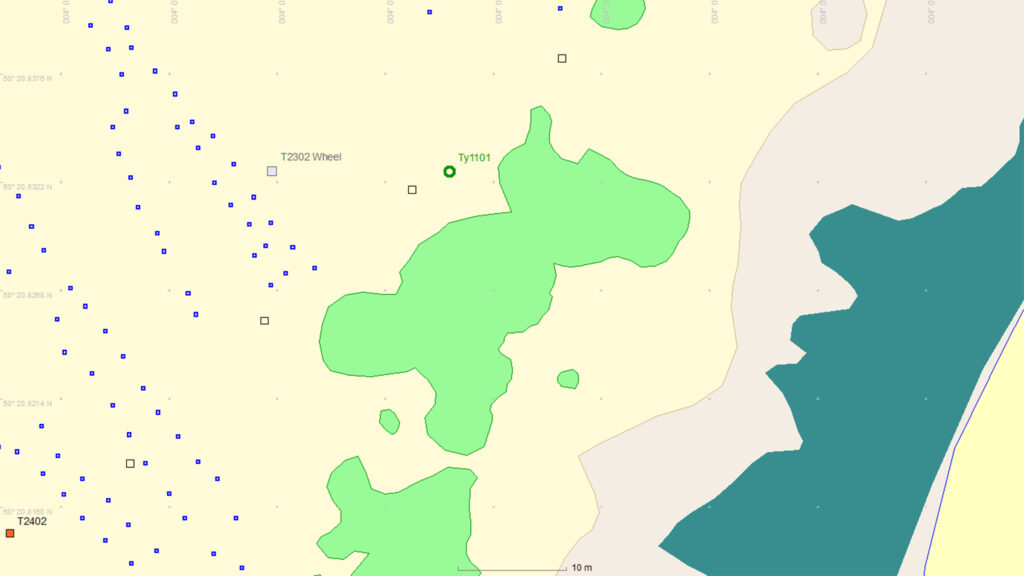

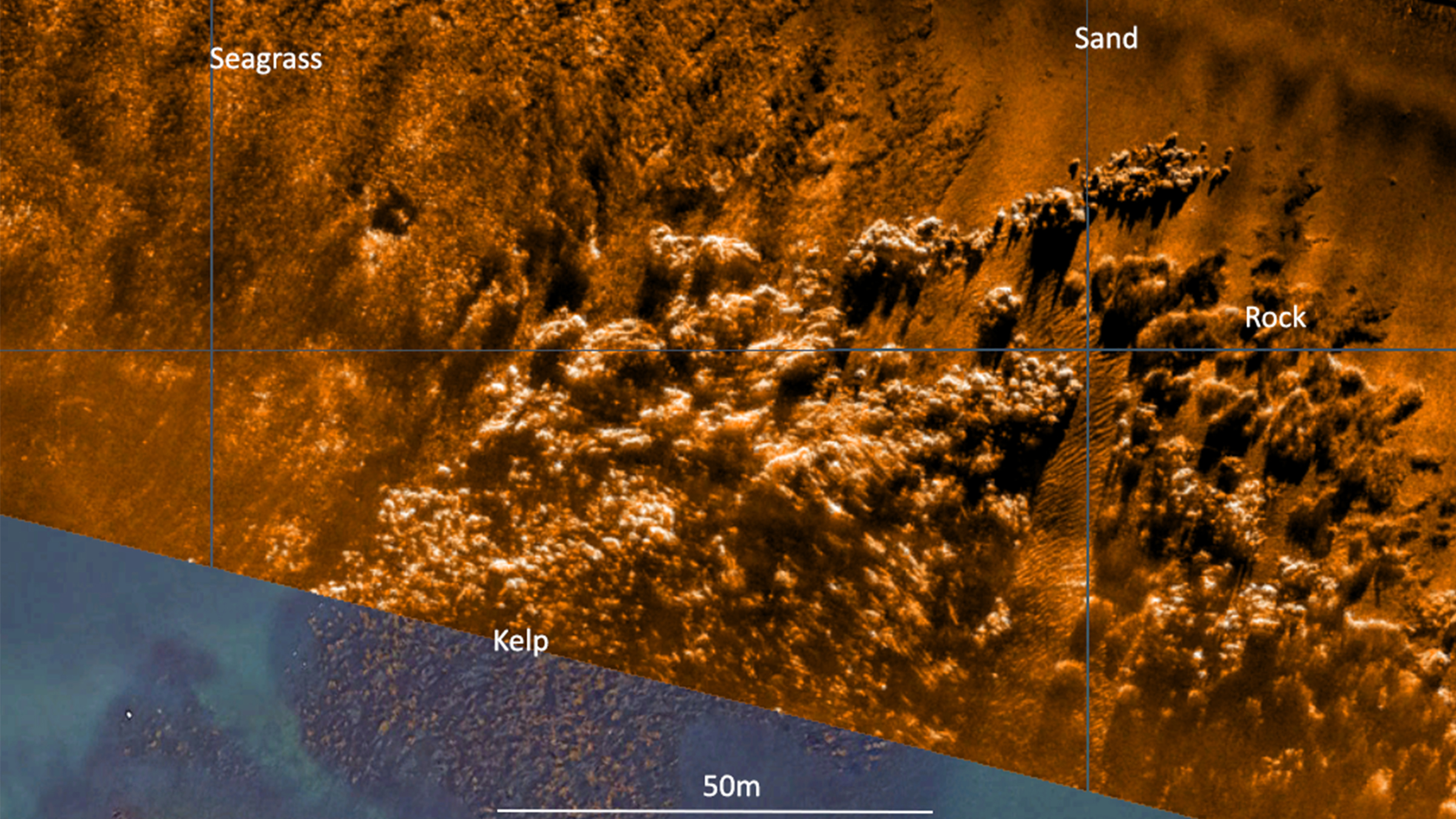

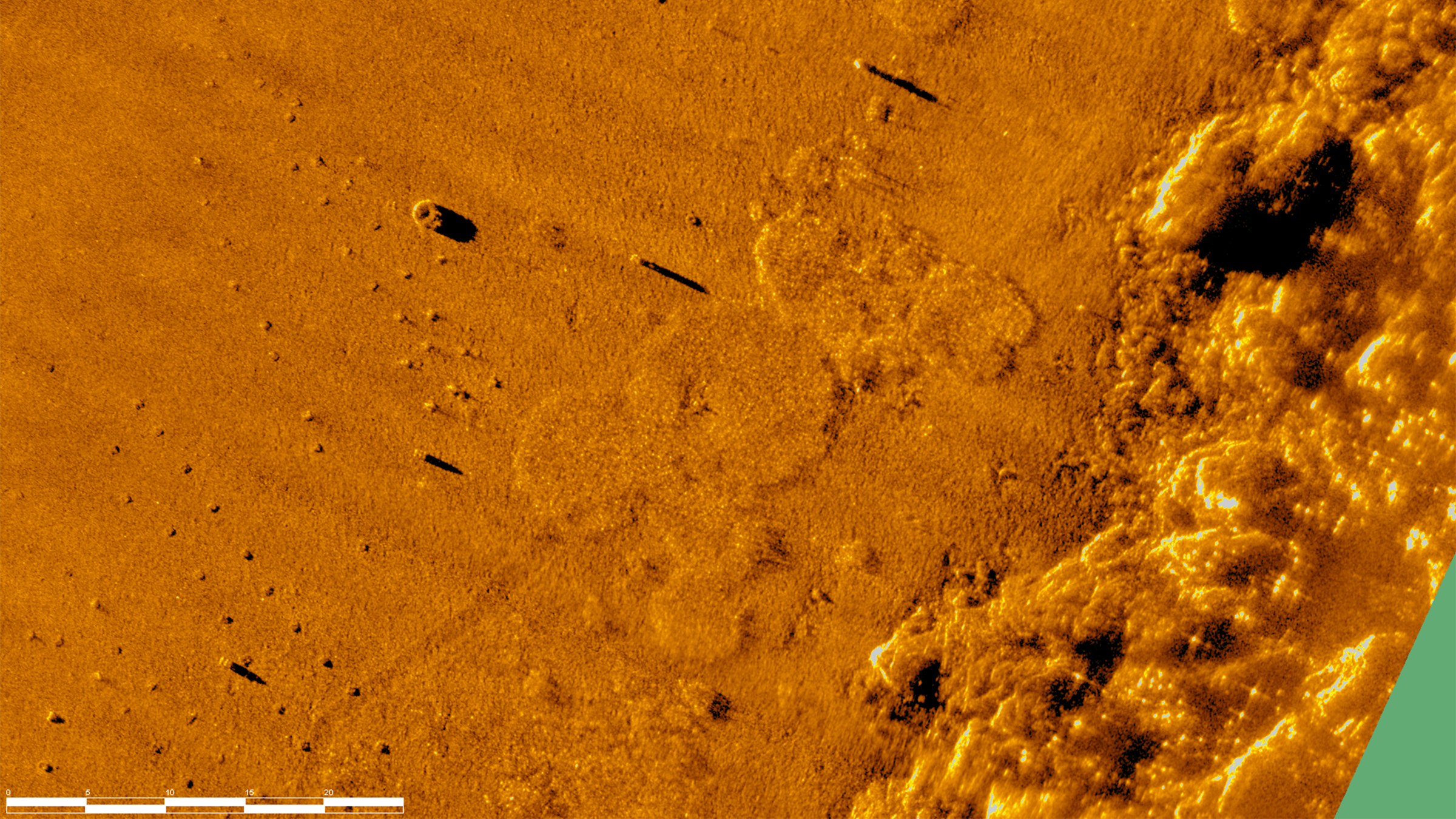

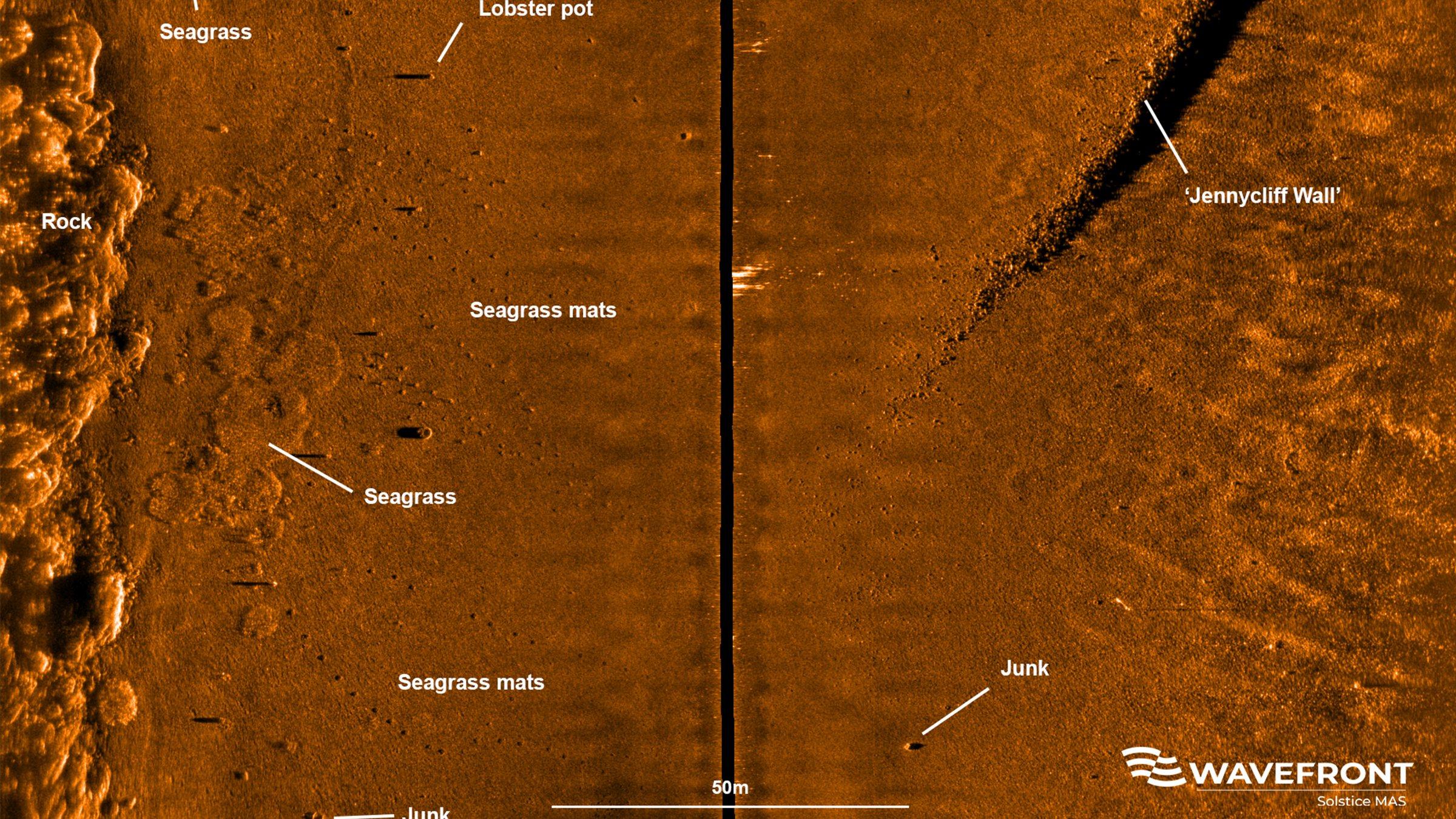

This is where Sonardyne and Wavefront Systems come in. The solution, which combines Sonardyne and Wavefront technology, is a survey boat carrying Solstice MAS™ (Multi-Aperture Sonar) as well as a SPRINT-Nav Mini mounted to a pole, deployed over the side of the boat; this maps the chosen area in 200 m wide strips. Once this survey has been completed, the sonar data that has been captured is then processed to create a map of the seagrass in a GIS. A Remotely Operated Vehicle (ROV) is then sent to the same area to ground truth features on the seabed to check that they are how they have been interpreted by Solstice MAS. The ROV is fitted with SPRINT-Nav Mini, allowing us to track its position underwater and guide it, using the map, to the features identified by Solstice; the ROV is also fitted with a camera and the recorded video can be used to create 3D models of the seabed.

Wavefront Systems’ Solstice MAS uses sound signals to produce high-quality images of the seabed, capable of creating images 200 metres wide at high resolution even in shallow water environments, all while consuming very little power. The Solstice family of sonars are built on unique MAS technology and are designed to fill the gap between standard side scan sonars, which are typically simple in design but give low image resolution, and Synthetic Aperture Sonars (SAS), which are expensive, more susceptible to complete data loss due to platform movement and also produce vast amounts of data. In order to execute more detailed mapping, Solstice MAS requires a high quality navigation sensor, which in this case is SPRINT-Nav Mini.

SPRINT-Nav Mini is an all-in-one vehicle guidance and navigation instrument, which combines AHRS data, Doppler Velocity Logger (DVL), Inertial Navigation System (INS) and depth sensor into a single housing. Having SPRINT-Nav Mini fitted onto the ROV provides positioning input, as well as attitude and heading data.

Creates images

0

m

at high resolution

ROV fitted with

0

D

camera

Solstice creates images

0

m

each side of the vessel

Adopting these technologies on such small versatile platforms opens the possibility of high-grade survey data in shallow waters. As a result of the cross Covelya Group collaboration between Sonardyne and Wavefront Systems, a high-definition map of seagrass beds can be created with a greater degree of accuracy than was previously possible with more traditional methods.

A seagrass restoration project conducted by the Ocean Conservation Trust (OCT) in Plymouth Sound, which involves monitoring, conserving and expanding the existing seagrass beds can be enhanced with the use of an ROV which has SPRINT-Nav Mini fitted to it. To help grow the existing seagrass beds, the OCT are placing seagrass mats on the seabed in Plymouth Sound. A survey boat fitted with Solstice and SPRINT-Nav Mini followed by an ROV fitted with SPRINT-Nav Mini can then be used to monitor and create a map of where these mats have been placed so that they have a better understanding of the success of the restoration and expansion project.

Entry level – next level

What's possible

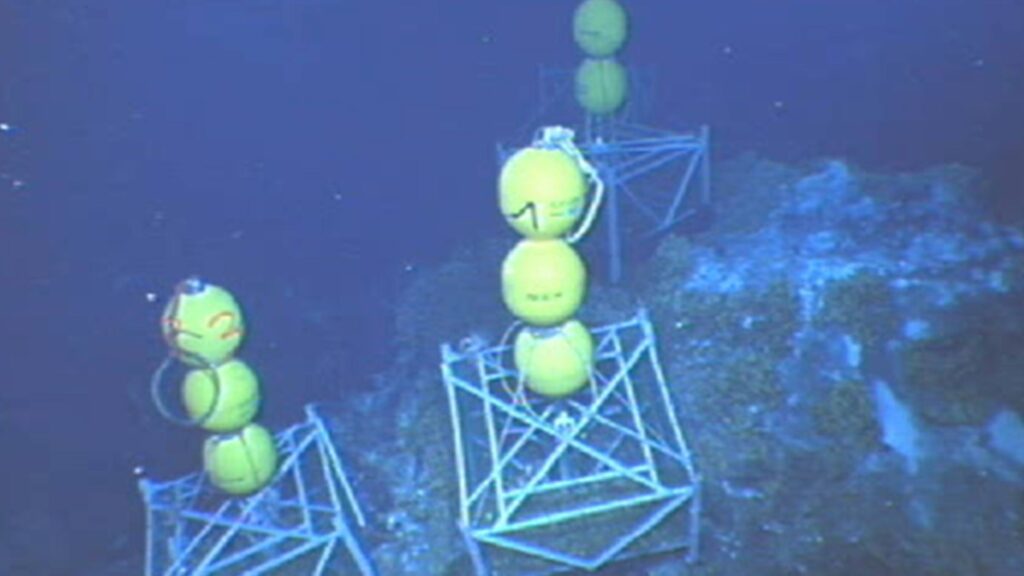

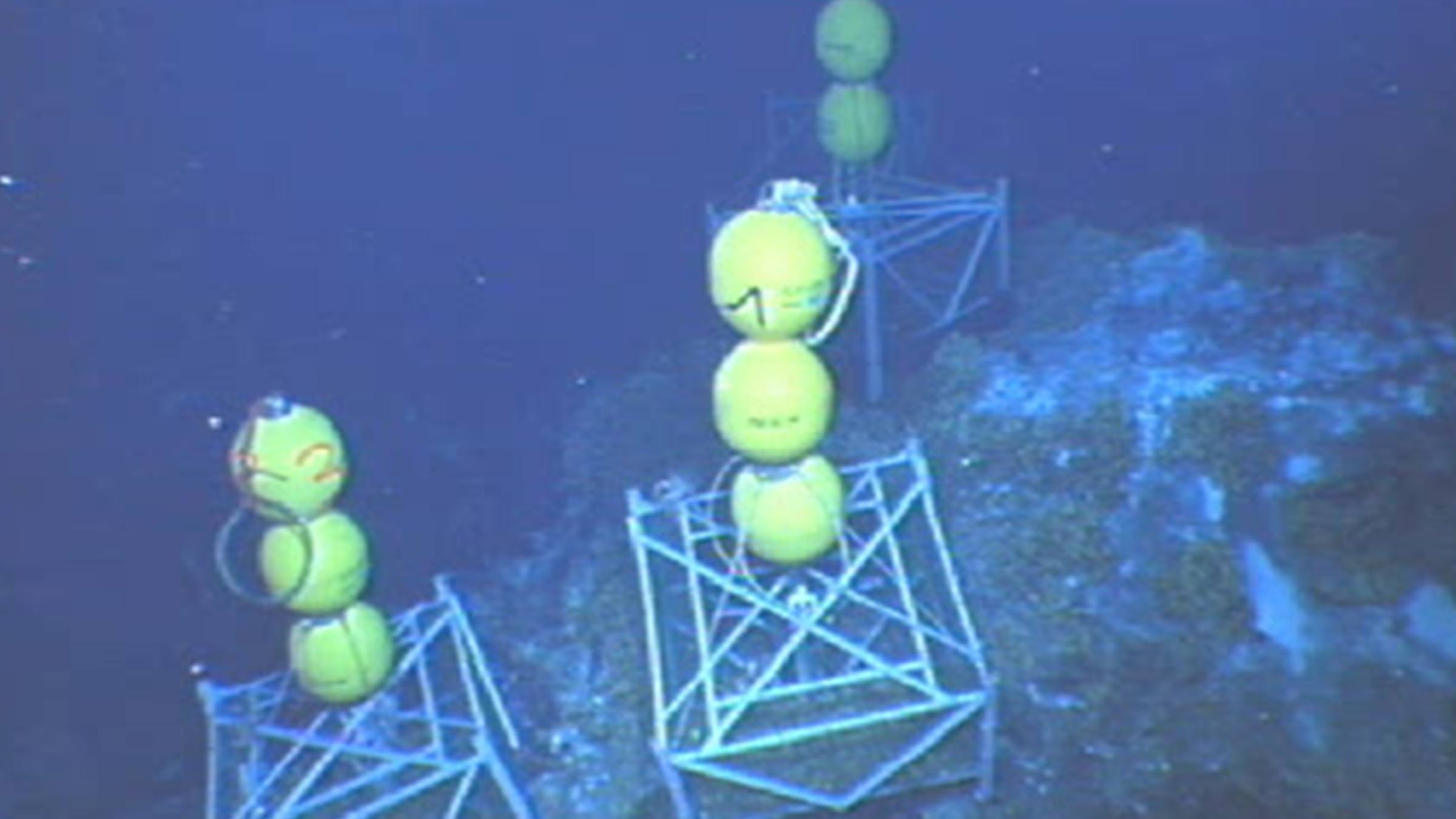

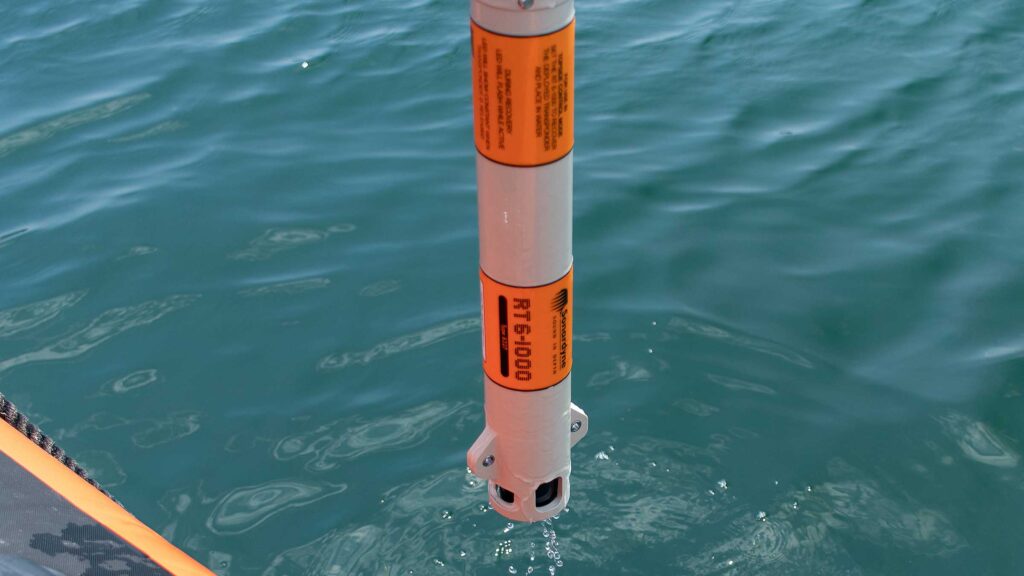

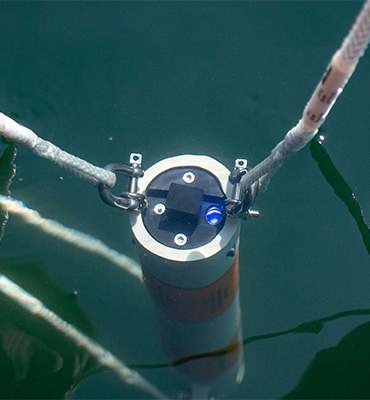

The RT 6-1000 is the versatile acoustic release transponder for your subsea operations. It can be commanded from multiple sources, including the Deck Topside, an Android app, or any Ranger 2 USBL system. This flexibility allows you to easily deploy, track, locate and retrieve your seabed equipment and ocean sensors.

One of the key advantages of the RT 6-1000 is its depth rating of 1,000 metres and weight load limit of 150 kg. This depth and payload capacity make it an ideal choice for scientists, surveyors, and military personnel who require a reliable and enduring solution for their underwater applications.

The RT 6-1000 is compatible with Sonardyne’s Ranger 2 USBL tracking systems, which are widely used on survey vessels around the world. This integration allows for seamless deployment, tracking, and retrieval of your equipment. No access to Ranger 2? No problem, the RT 6-1000’s NFC capability enables setup and control via its Android app or a dedicated Deck Topside unit.

Deploy. Track. Locate. Recover

At a glance

- The reliable choice to deploy, leave and recover seafloor equipment and sensors

- 1,000 metre depth rating; twice that of similar low-cost acoustic release transponders

- Tested, loaded, commanded and released using Deck Topside

- Also works with any Ranger 2 USBL to track it and activate it

- >13-month battery life means less time servicing it and more time using it

- 150 kg Working Load Limit to support your sensors and instruments

- Optional rope canister for heavy lifting

The RT 6-1000 offers impressive endurance, with a battery life of up to 13 months, making it well-suited for long-term deployments and year-long surveys. Its screw-off release mechanism ensures reliable recovery of the transponder and your equipment.

An optional rope canister attachment allows you to quickly and easily raise items left on the seabed, such as tools, cables and salvage. The canister deploys a high-strength rope as the transponder ascends, providing a convenient means of retrieval.

Acoustic

• Medium Frequency (20-34 kHz) band.

• Omni-directional transducer. Track it all the way to the surface

• Sonardyne Wideband 2 signal architecture supporting over 300 unique addresses. Perfect for very large surveys involving multiple moorings close to each other

Performance

• 1,000 m depth rated

• >13 months battery life; alkaline battery

• 150 kg Working Load Limit

• Compatible with Ranger 2 USBL systems

• Secure and robust two-way acoustic Communications. Only release what you want to release

Design

• 450 mm x 65 mm (max dia. 100 mm), 500 grams weight in water

• Field proven screw-off release mechanism

• NFC for setup using Android app

• Optional rope canister for lifting heavy items

• Plastic, super duplex stainless steel and anodised aluminium construction. ROHS compliant

Ownership

• Warranty: one year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export Licence: Not required

• What’s in the box: RT 6-1000, shackles, release nuts (x10), manual on USB

Specifications table

| Feature | Type 8327 | |

|---|---|---|

| Depth rating | 1,000 m | |

| Operating frequency | MF (20–34 kHz) | |

| Transducer beam shape | Hemispherical | |

| Transmit source level (dB re 1 µPa @ 1 m) | 187 dB | |

| Tone Equivalent Energy (TEE) | 193 dB | |

| Receive threshold (dB re 1 µPa) | <100 dB | |

| Working load limit (4:1) | 150 kg | |

| Proof load | 300 kg | |

| Breaking load | 600 kg | |

| Maximum safe release load | 150 kg | |

| Battery life (alkaline) | >13 months | |

| Inclinometer accuracy | ±5° | |

| Mechanical construction | Anodised aluminium alloy, plastic and super duplex stainless steel | |

| Operating temperature | -5 to 40ºC | |

| Storage temperature | -20 to 55ºC | |

| Maximum dimensions (length x diameter) | 450 x 65 mm | |

| Weight in air/water | 2.0/0.5 kg | |

| Standards | CE Marked to EN-60945, EN-61010 | |

| Options | Part number | |

| Shallow Water Deck Kit (Deck Topside) | 602-0175 | |

| Rope Canister | 70 m (250 kg WLL) | 641-0673 |

| 120 m (250 kg WLL) | 641-3265 | |

| 160 m (150 kg WLL) | 641-0080 | |

| Release Nut | 830-0073 (note: 10 nuts supplied with each new RT 6-1000) |

|

| Shackle (bridle) | 231-0140 | |

| Deployment rope (bridle) | 231-0351 |

Frequently asked questions

What is an Acoustic Release and how does it work?

Why isn’t serial communication available using the iWand in RT 6 Dunker Mode?

RT 6-1000 NFC connection and operating information

6G Terminal Lite Range Test

How long can an RT 6-1000 be deployed for?

What is the safe working load for different RT 6 products?

What should I use instead of an LRT?

How do I mark where my RT 6-1000 is deployed?

No NFC device is available to connect the battery

Why can’t my NFC device contact the transponder?

How to change the battery in an RT 6-1000

Which RT 6 is correct for my operations?

Why should I use a rope canister and what is it?

Where can I find the RT6 release app

How to release an RT 6 acoustic release transponder using Ranger 2

How to use a rope canister

How to recover an RT 6-1000

Deployment

STP files

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

Did you know?

RT 6-1000 can be used with our Ranger 2 USBL family or Deck Topside