Our Acoustic Data Logger has a track record of more than 30 years of successful installations. The current generation includes our 6G and Wideband 2 acoustic technology, allowing large volumes of logged data to be rapidly and accurately retrieved at the surface.

At a glance

Perfect for well appraisal campaigns

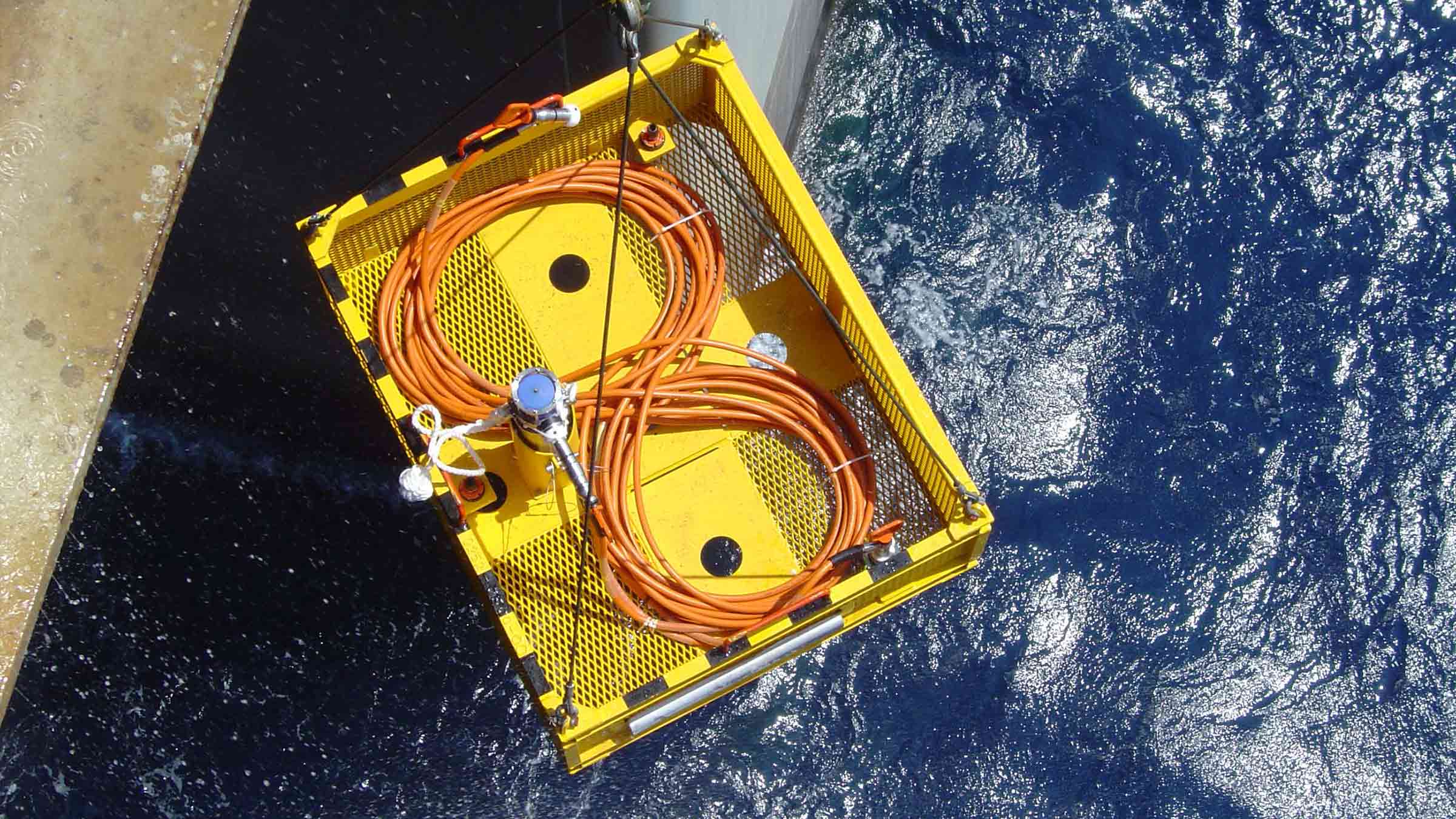

ROV-deployable, easy to move between wells

Can be interfaced to wide range of down hole gauges

Depth rated to 3,000 m (10,000 feet)

Harvest data using vessel, rig or Waveglider

Suitable for

Insight for your subsea asset monitoring campaigns

Want to find out more?

Built using secure Wideband communications

ROV-friendly connectors

Standard or long-battery life housing configurations

Designed to be deployed and recovered using ROV

Why Acoustic Data Logger is perfect for your operations

Long life

It can remain deployed for several years without intervention.

Compatibility

It can be interfaced with all industry-standard downhole gauges.

Configurable

Data logging regimes are fully adjustable to suit your needs.

Overview

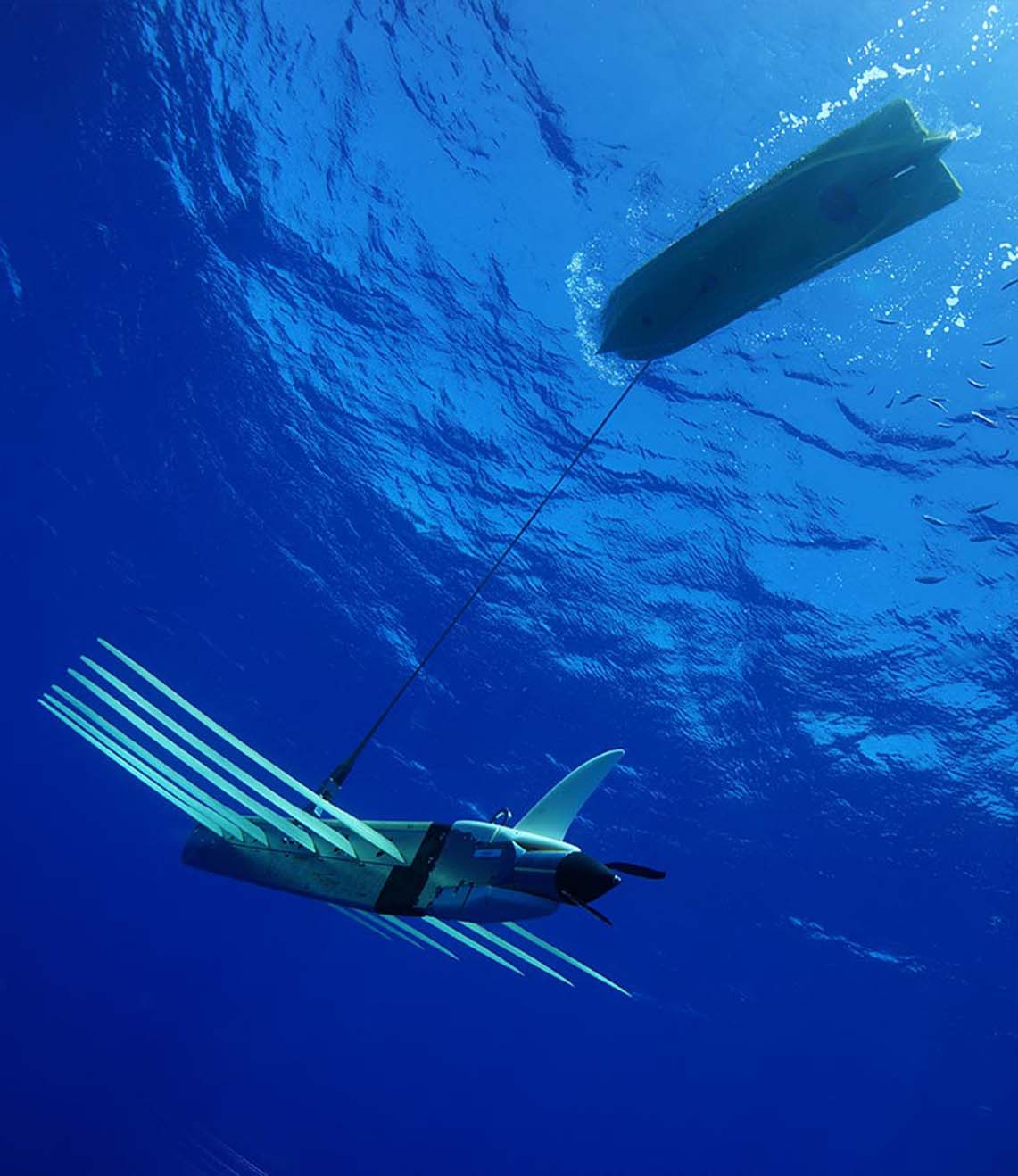

Our long-life acoustic Data Loggers can provide power to read multiple gauges at predefined intervals, securely store the received information within the unit, then transmit it acoustically through the water column to the surface on-demand.

They are compatible with Intelligent Well Interface Standardisation (IWIS) and non-IWIS gauge cards from the leading wellbore downhole pressure and temperature gauge manufacturers. Data Loggers are ROV deployable (and retrievable) to a maximum depth of 3,000 m. Using normal gauge reading sample rates they can operate for up to three years. Longer deployments or higher sample rates are easily accommodated using external battery packs. All hardware is supplied in corrosion-resistant super duplex stainless steel canisters for very long deployment periods.

When combined with the feature of ROV portability, the system is the ideal solution for initial well appraisal, where frequent downhole pressure and temperature readings need to be logged over a few weeks. However, the new system is equally suitable for long-term deployments where it may remain installed on a wellhead, logging data for several years without intervention.

Suspended or abandoned well monitoring

High-availability acoustic subsea modems are designed for use with third party systems to facilitate the transfer of wellhead or wellbore data to the surface. Our modems can be designed, tested and supplied as part of a third party’s well monitoring solution, including electromagnetic, and through-casing tube technologies to the wellhead or tree-mounted modem.

Why invest

Design

-

Super Duplex Stainless Steel construction

-

Integrates into all industry-standard gauge cards

-

Fully configurable logging and reporting scheme

-

512 gb internal storage

Connectivity

-

ROV mateable connection

-

LMF (14–19kHz) acoustic link

-

High speed, spread Spectrum acoustic data link

Performance

-

Standard dept rating of 3,000 m

-

Configurable sample rates from 2 minutes to 5 days

-

Weight in water 63 kg

-

Acoustic data rate 300–9,000 bps

Support

-

Work side-by-side with our Custom Engineering Team from concept to deployment

-

Systems are manufactured and tested before delivery at our world-class in-house facilities

-

Comprehensive and flexible training for system operators

-

24-hour support, whenever and wherever you are in the world

Resources

| Feature | Type 8195 | |

|---|---|---|

| Acoustic | ||

| Operating Frequency | LMF (14–19 kHz) | |

| Transducer Beam Shape | ±30° (directional) ±70° (omni with noise shield) | |

| Transmit Source Level (dB re 1 µPa @ 1 m) | >190 dB | |

| Receiver Threshold (dB re 1 µPa) | 85–120 dB (7 levels) High speed, spread spectrum | |

| Acoustic Data | Link | High speed, spread spectrum |

| Transmission Rates | 300–9,000 baud (true payload rate variable by telemetry scheme) | |

| Power | ||

| Power | Long life lithium primary cell battery pack | |

| Battery Capacity | Single Battery Pack | 120 Ah @ 14.5 V dc |

| Dual Battery Pack | 240 Ah @ 14.5 V dc | |

| Battery Life | Dependant on interface and logging configuration | |

| Interface Card | Supply Voltage | 24 V dc ± 4 V |

| Maximum Power | 30 W | |

| Communication and Interface | ||

| Gauge Interface Card Type | 1 x IWIS DHPT Interface Card (dependant on field requirements) | |

| Interface Card Serial Communication Format | IWIS RS485 at 9,600 baud, Modbus TCP or Modbus RTU protocol | |

| Interfaces | Serial | 2x RS485/422 - 2x RS232 |

| Analogue | 6x Analogue | |

| Serial Communication | Direct serial access to data logger & Gauge Interface Card via the external serial port | |

| Logging and Data Storage | ||

| Minimum Memory Capacity | 512 Mb - Industrial SD Card (non-volatile) | |

| Sample Rates | Standard | Configurable from 2 minutes to 5 days (dependant on interface) |

| Special | High sample rate operation for user defined durations from 1 minute to 4 days with configurable rates from 5–60 seconds (dependant on interface) | |

| Mechanical | ||

| Mechanical Construction | Super duplex stainless steel - UNS32550 | |

| Mechanical Design | Sonardyne 6th Generation including inter O-ring test ports | |

| Dimensions (Length x Diameter) | MF Single Battery Configuration | 1,086 x 199 mm |

| LMF Dual Battery Configuration | 1,348 x 199 mm | |

| External Connectors | Gauge Interface | 1 x ODI or TRONIC (dependant on field requirements) |

| Serial Test Port | 1x Subconn MCBH8M 1x Subconn MCBH8F | |

| Environmental | ||

| Depth Rating | 3,000 m (dependant on connector) | |

| Operating Temperature | -10 to +55°C | |

| Storage Temperature | -25 to +70°C | |

| Design Qualification | ISO 13628-6 Level Q1 & Q2 | |

| Options | ||

| ROV Handle Type 8195-007 | ROV Handle Assembly (folding), super duplex stainless steel - UNS32550 | |

| Battery Configuration | Single (120 Ah), Dual (240 Ah) or Triple (360 Ah) |