The solution

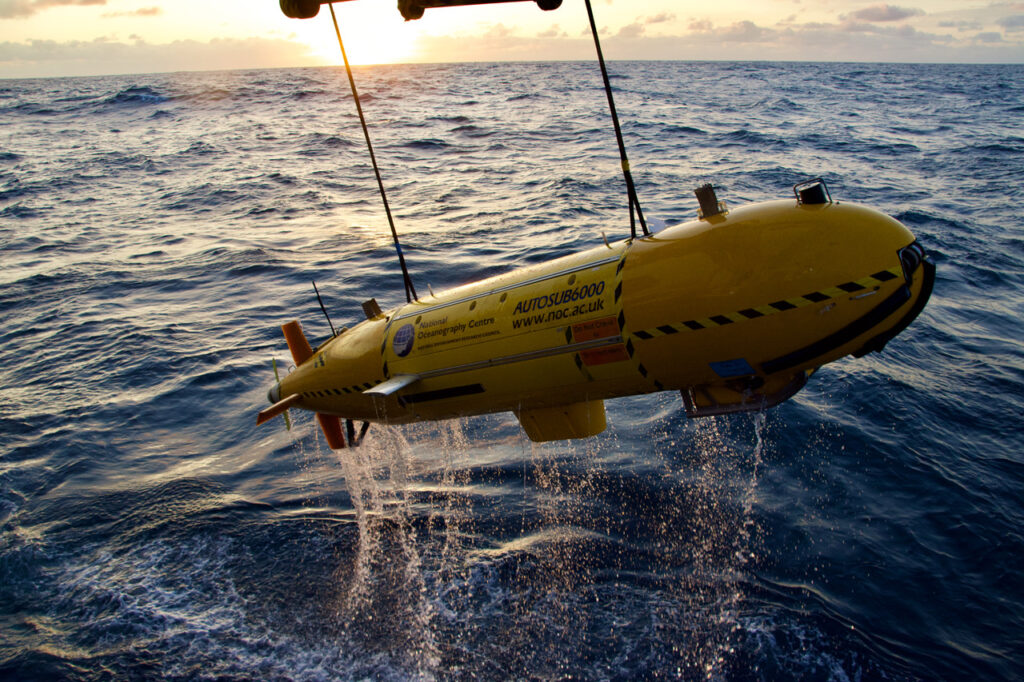

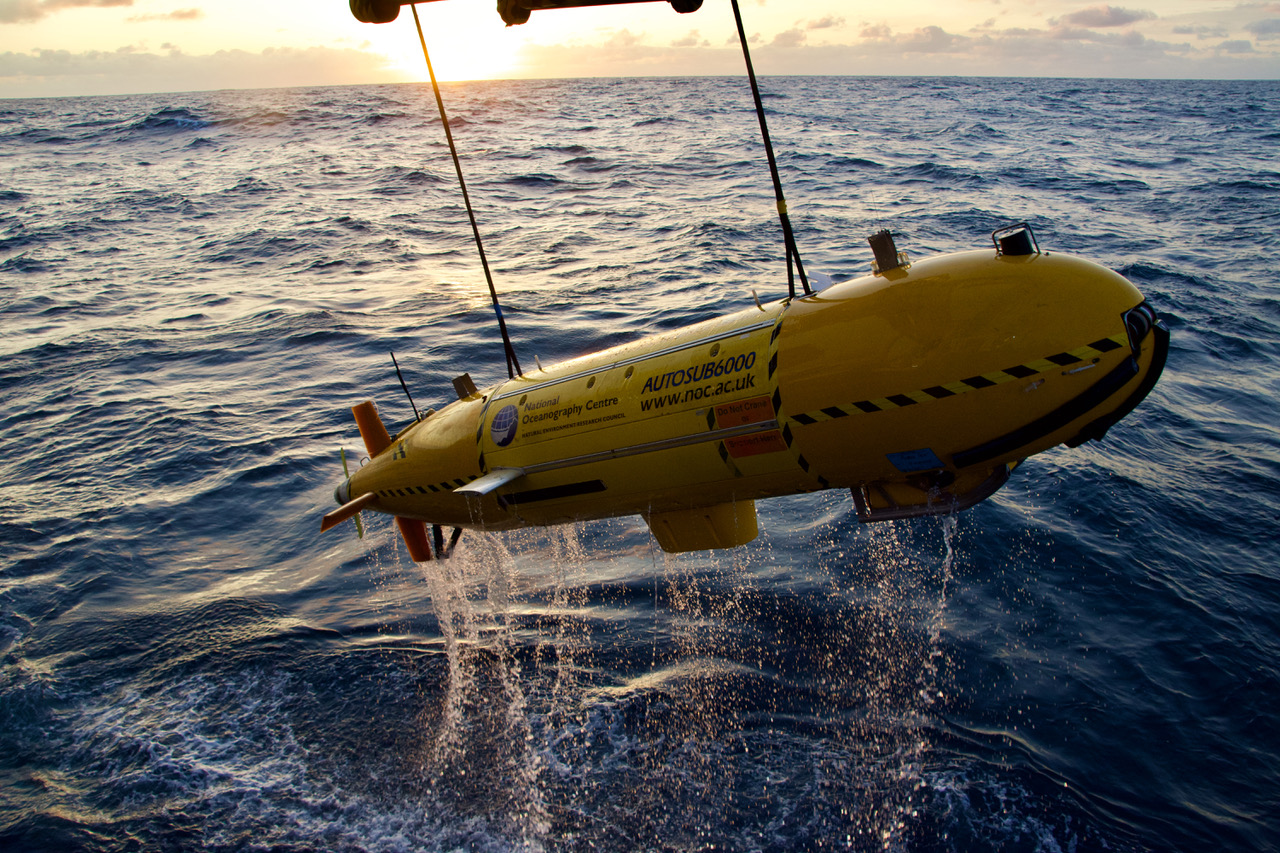

We’re leading a two year, £1.4 million project, with partners the National Oceanography Centre (NOC) and L3Harris ASV, to change all that. We aim to develop new positioning technologies that will extend the limits of AUVs and UUVs.

The project – Precise Positioning for Persistent AUVs, or P3AUV for short – is supported by funding through Innovate UK’s research and development competition for robotics and artificial intelligence in extreme and challenging environments.

So, what’s involved? In short, we’re developing ways to provide greater positioning accuracy for long-endurance operations in deep water. At the same time, we’re reducing power requirements for AUVs and UUV. We’ll also be increasing the use of autonomy to make Long BaseLine (LBL) positioning transponder box-in faster and easier, with onboard data processing and calibration.

This is all being done through work in three key and complementary areas: improved lower power navigational accuracy over long distances for AUV/UUVs; autonomous transponder box-in with an unmanned vessel; and improved positioning accuracy during vehicle descent/ascent in the water column.

Central to this work is the vehicle’s acoustic and inertial navigation system (INS). This is because low power sensors have much lower navigation accuracy meaning they often have to surface to correct positioning error with a GPS fix. However, by integrating low and high-power sensors to work together, the best of both worlds – high performance and much lower power consumption – can be achieved.

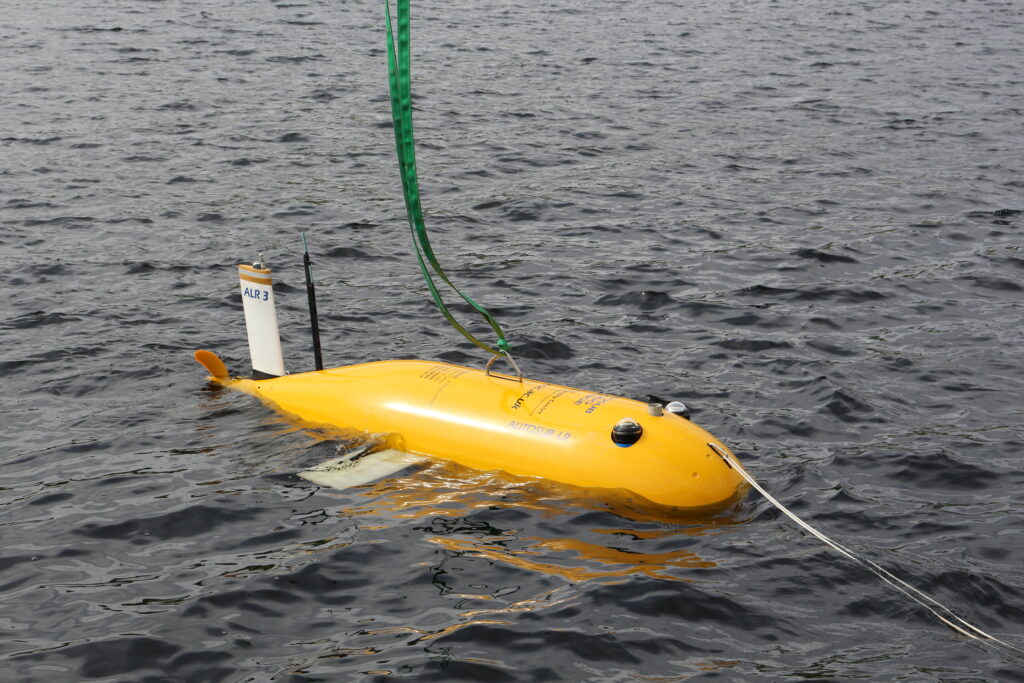

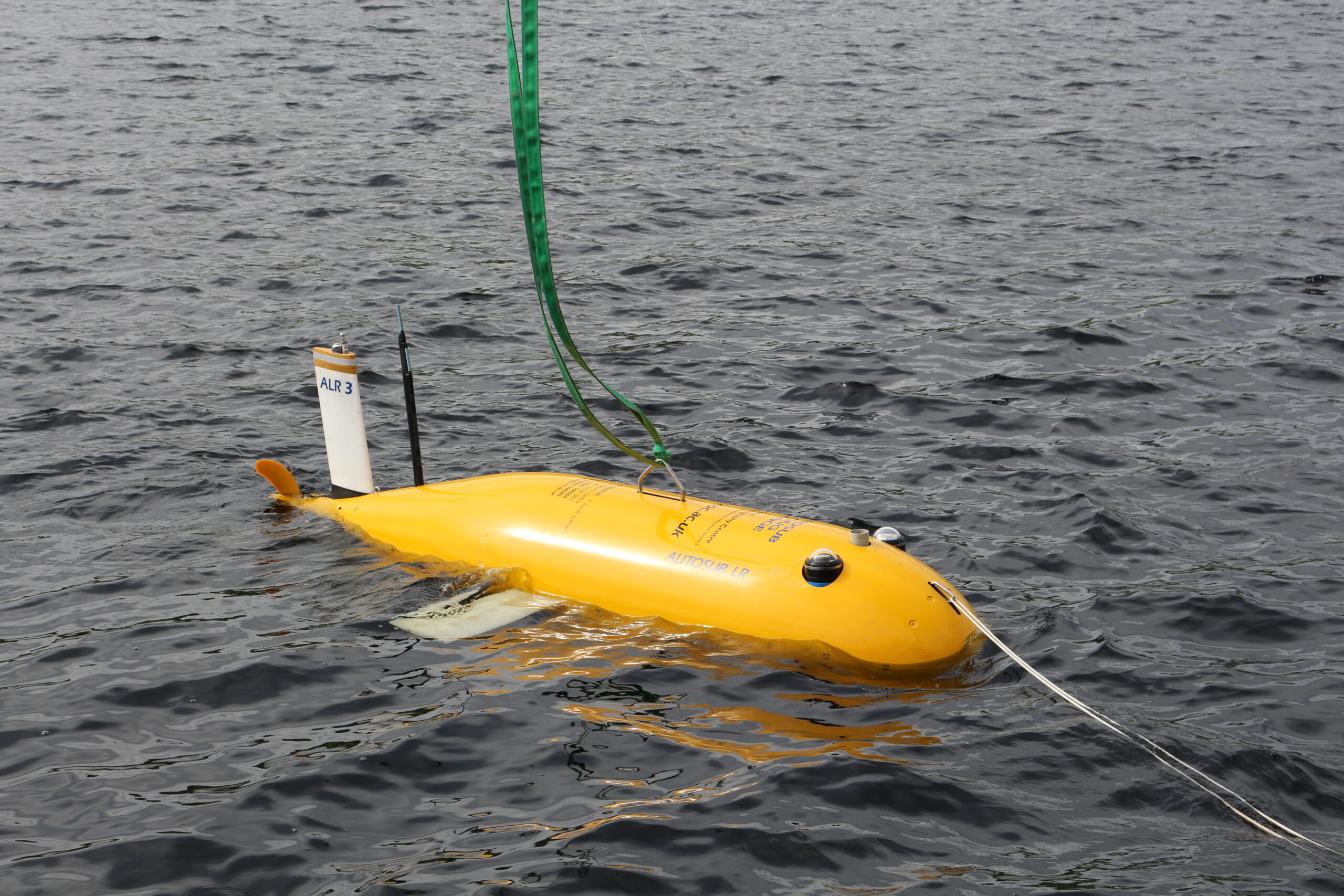

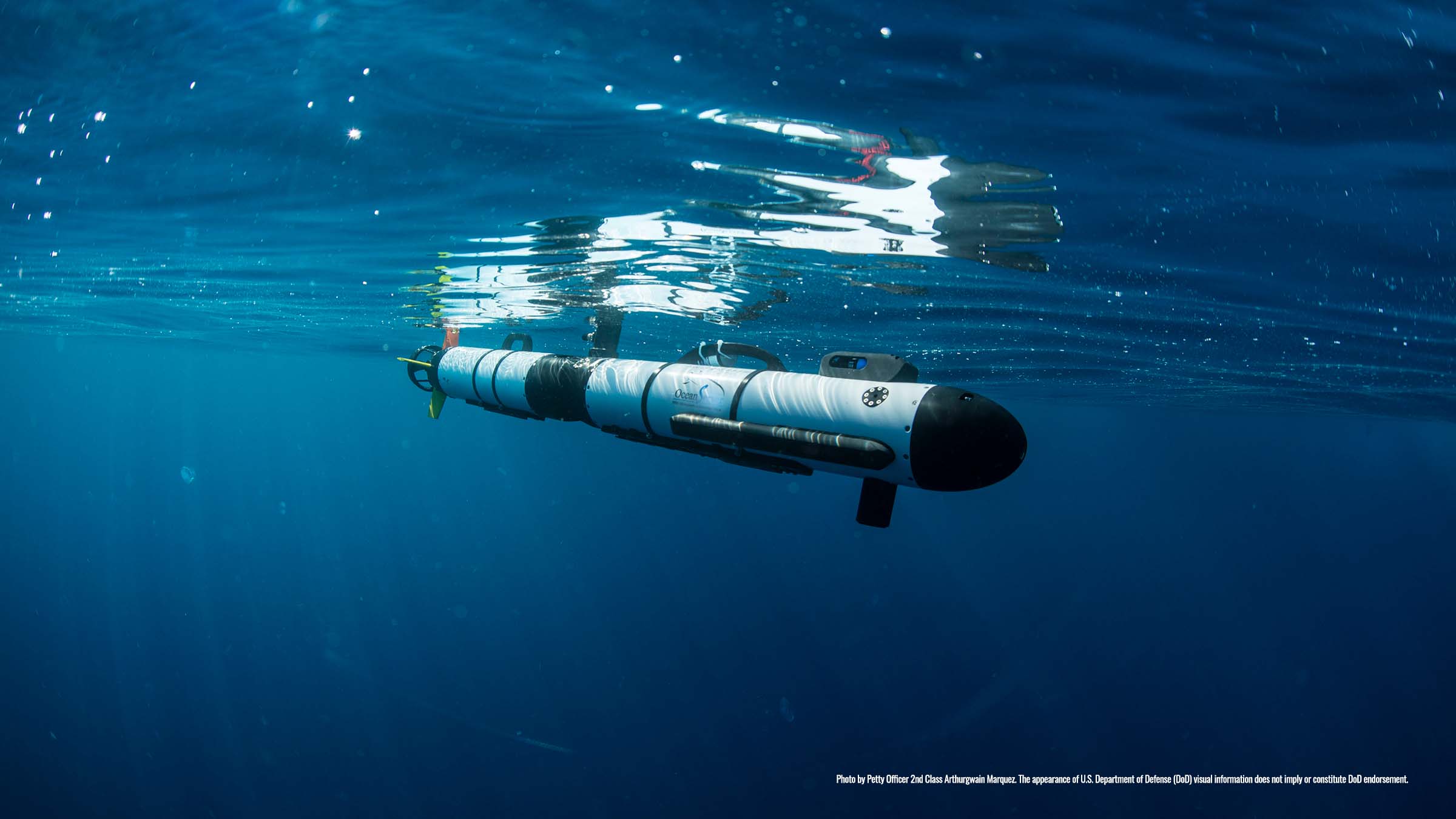

As an example, the NOC’s Autosub Long Range (ALR) currently uses a low-power microelectronic mechanical system (MEMS) supported by separate Doppler velocity log (DVL) and ADCP input to calculate how far it has travelled on missions. These missions can be several months long. To increase the ALR’s positioning accuracy over longer distances, we’re using our SPRINT-Nav, alongside MEMS technology to work towards high-precision solutions that save space and power.

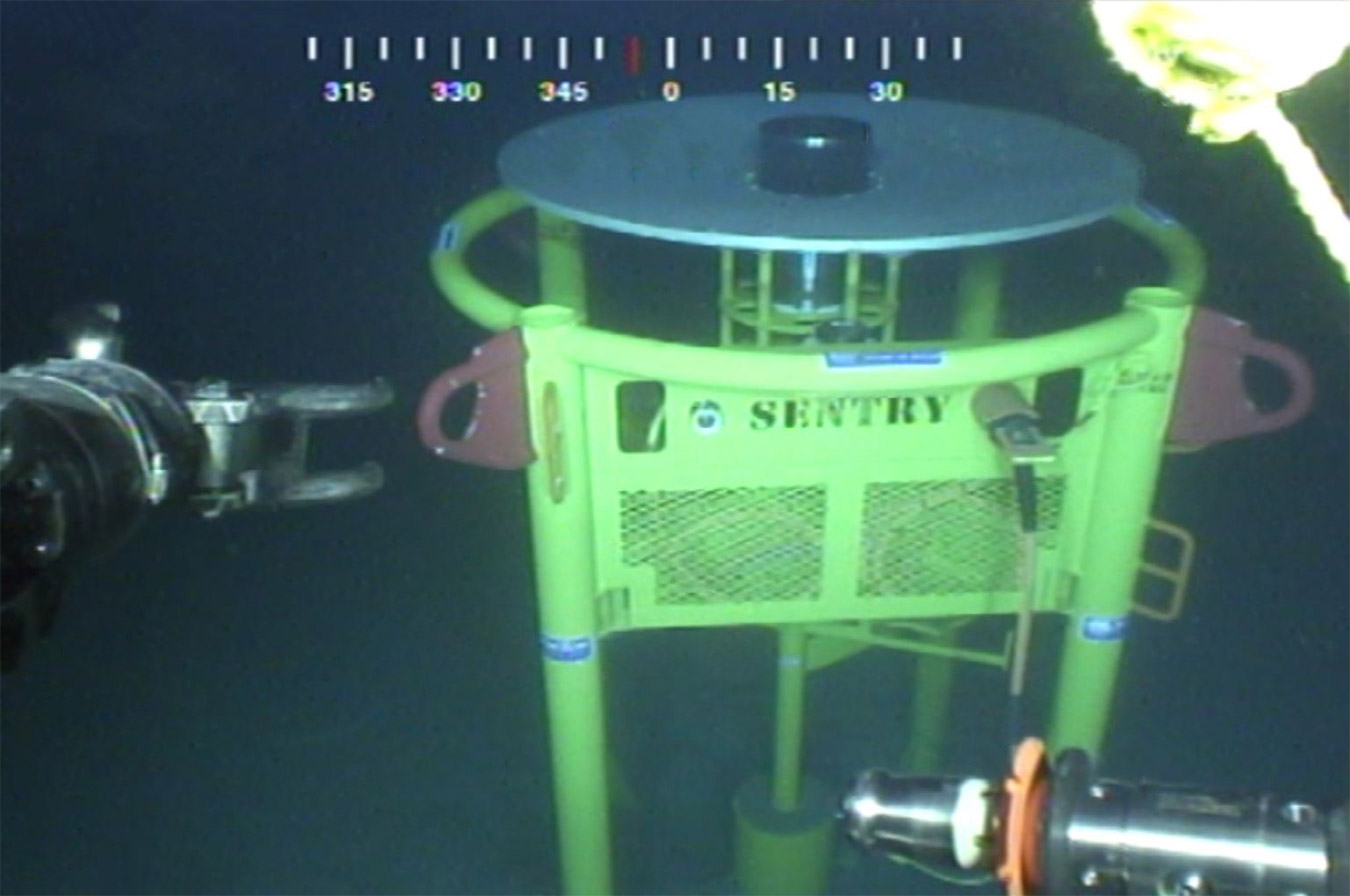

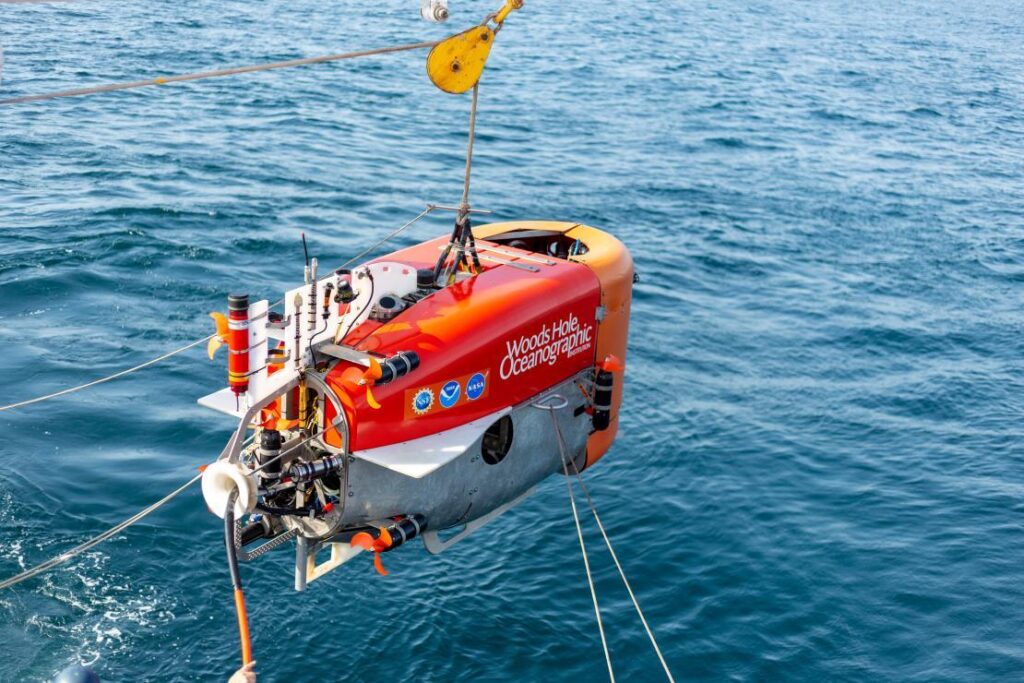

The project also involves improving positioning accuracy when subsea vehicles transition through the water column. This is a notoriously difficult area for AUV deployments, because it relies on the Doppler velocity log (DVL) being able to ‘lock’ on to the seafloor (bottom lock), so that vehicle XYZ velocities can be calculated, supported by pressure data.

However, DVLs are range limited, so there is often a period where the DVL is out of range. When there are thousands of metres of water between the surface and the seabed, this can introduce significant positioning uncertainty. This problem is solved by using the acoustic Doppler current profiler (ADCP) capability in our SPRINT-Nav INS instrument (looking down) and a second Syrinx DVL (looking up). We can then build up a layer by layer profile of the water column velocities that can be used as tracking layers.

The objective is to reduce positioning errors significantly during both the dive and surfacing phases of an operation. This does depend on the variability of the current regime in any given area, but we’re putting this to the test throughout the P3AUV project.

The data collected during the descent and surfacing phases can be processed to provide a full ocean depth current profile – collection of which is required for many offshore energy projects. It can also be valuable for ocean research.

At the heart of this capability is our class-leading SPRINT-Nav instrument, which combines our SPRINT INS, Syrinx DVL and a high-accuracy pressure sensor in a single housing. These instruments are tightly integrated, enabling the SPRINT-Nav to use individual beam level measurements from our Syrinx DVL. This makes it a much more robust and reliable system than a separate DVL, which calculates velocity from all the beams.

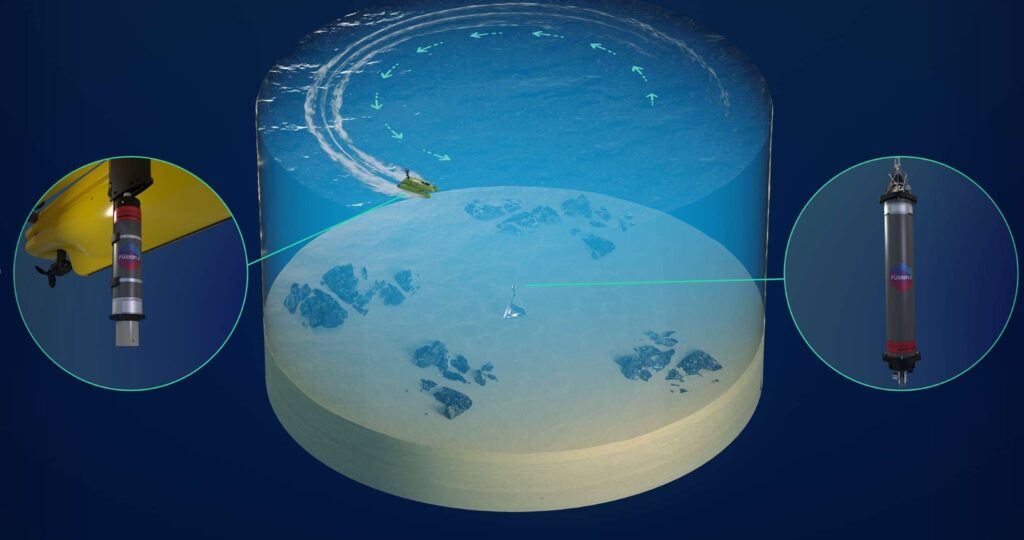

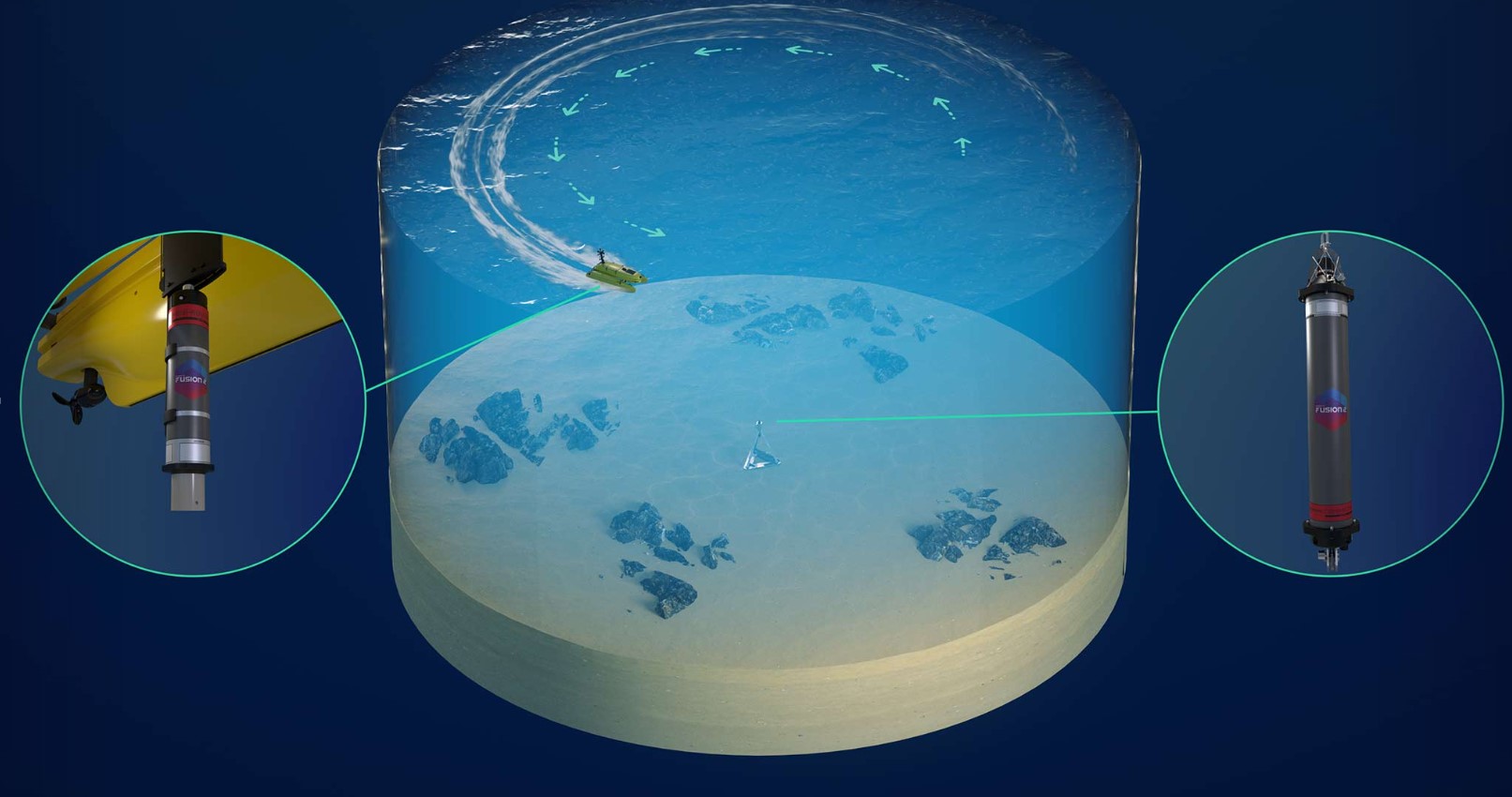

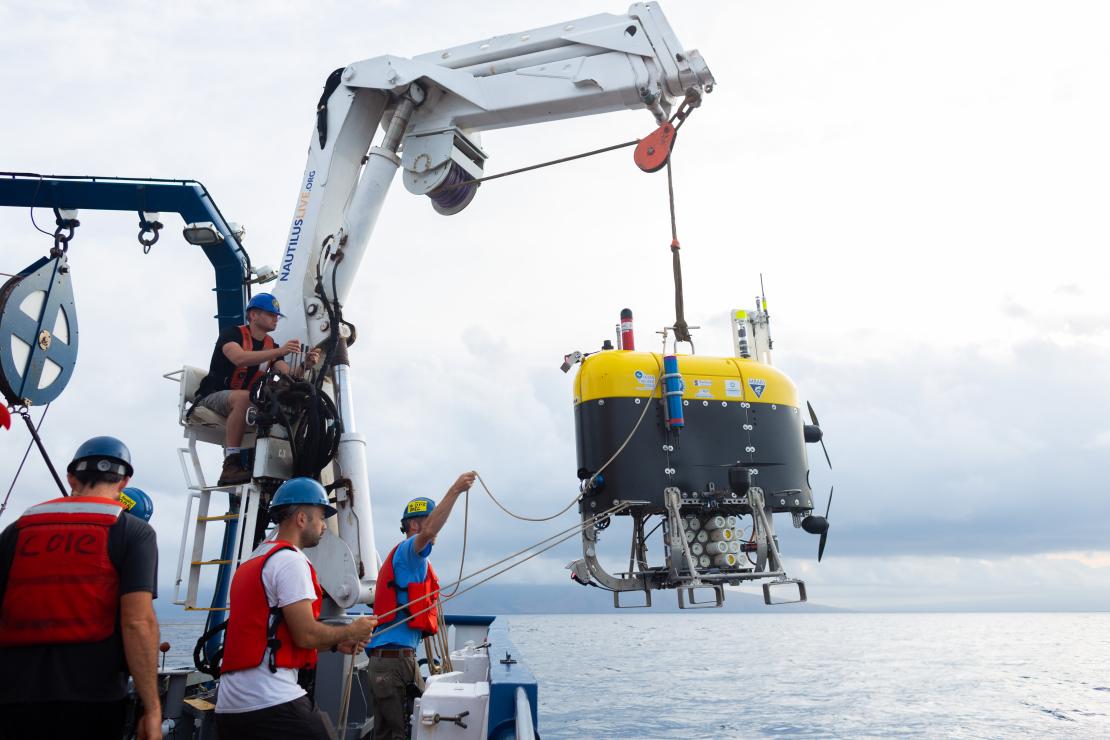

Additionally, we’re implementing systems to box-in our trusted Compatt seafloor positioning transponders with a USV to make LBL operations faster and easier.

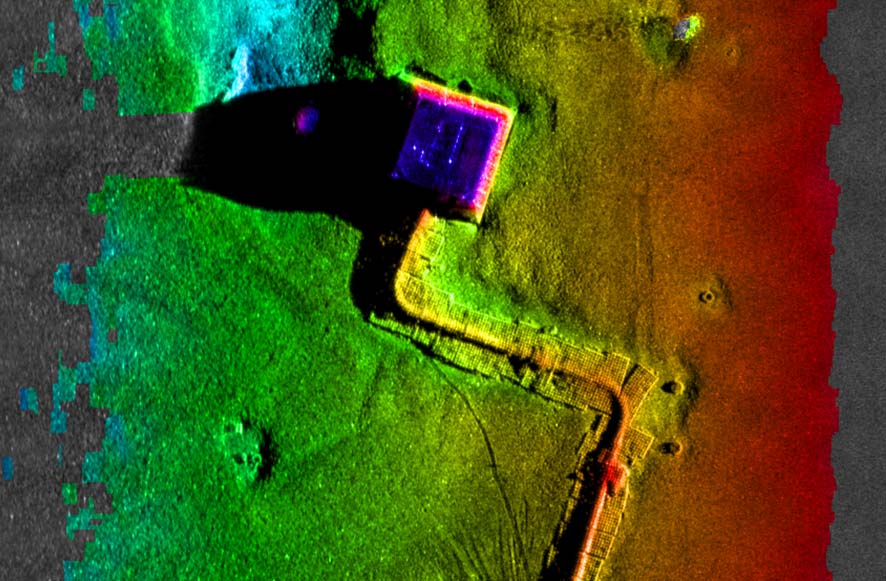

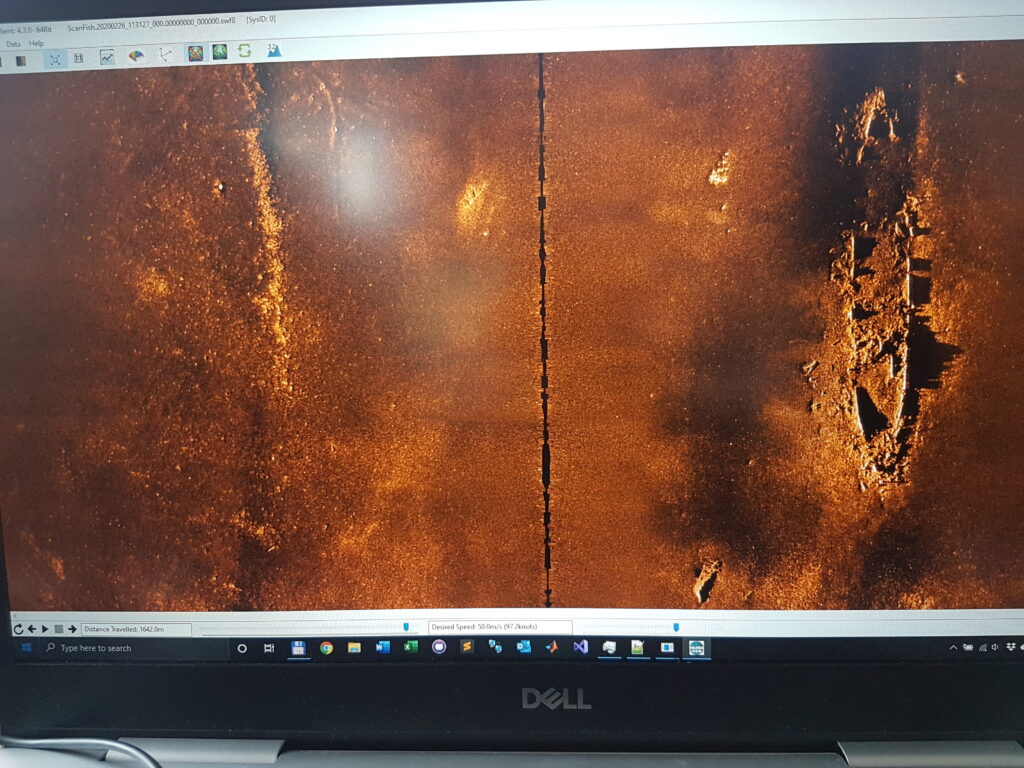

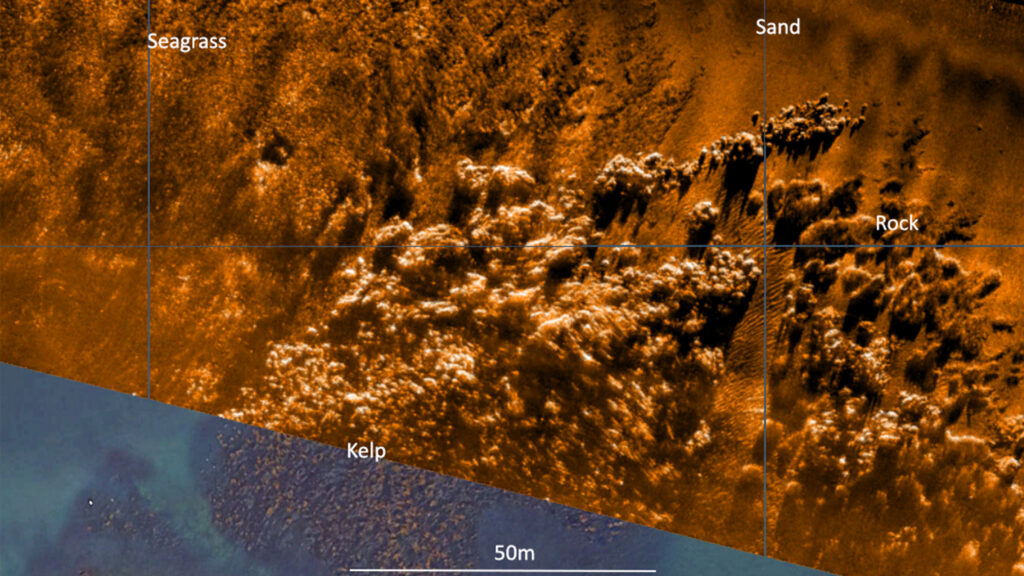

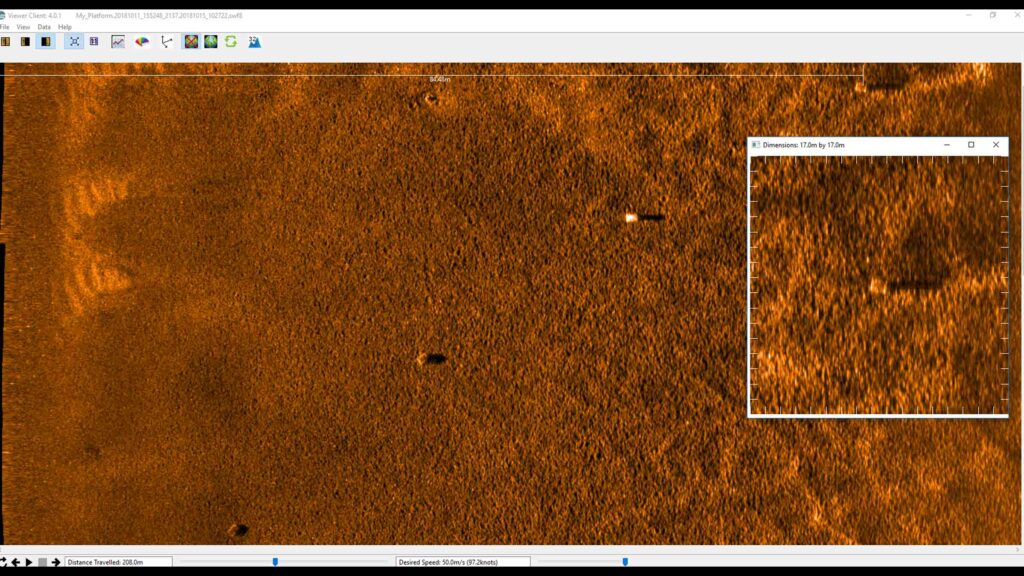

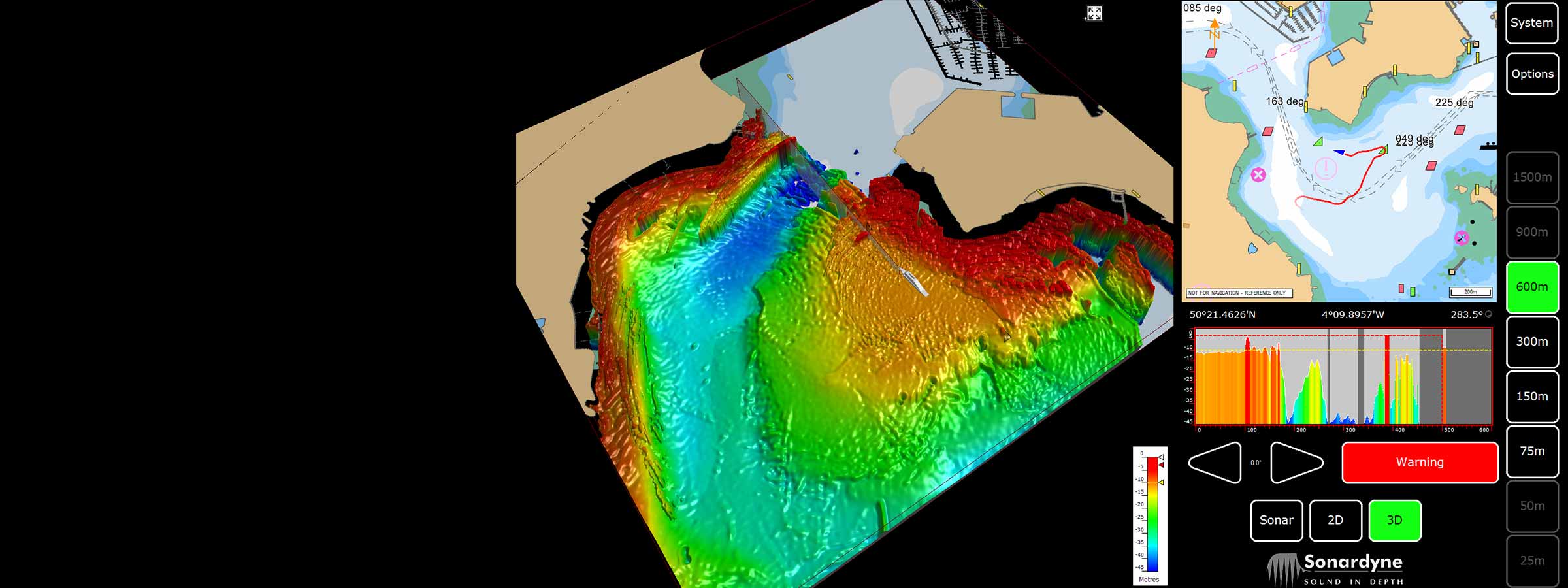

The goal is to enable full ocean depth, 1 m accuracy wide-area seabed mapping, using the L3Harris ASV’s C-Worker USV, to precisely position them (box them in). These Compatts could then be used in combination with SPRINT-Nav to calculate a Sparse Long BaseLine (Sparse LBL) solution.

Using autonomous calibration techniques will remove the need for a manned vessel to do this, providing a dramatic cost saving over current ‘state-of-the-art’ AUV operations, as well as any other operations where an LBL positioning system is needed.

To put this into perspective, an offshore support or research vessel will typically burn some 3,000 tonnes of fuel annually and generate about 10,000 tonnes (equivalent) of greenhouse gases. The environmental footprint of an independent ASV or AUV is, by comparison, negligible.

The reduction of manned vessel operations, as well as reducing deployment/recovery of vehicles over-the-side of such vessels, will reduce risk in offshore survey operations. Furthermore, the ability to mobilise this capability at short notice, without the high cost of mobilising a ship, could generate a new service industry model.