Combined excellence

Overview

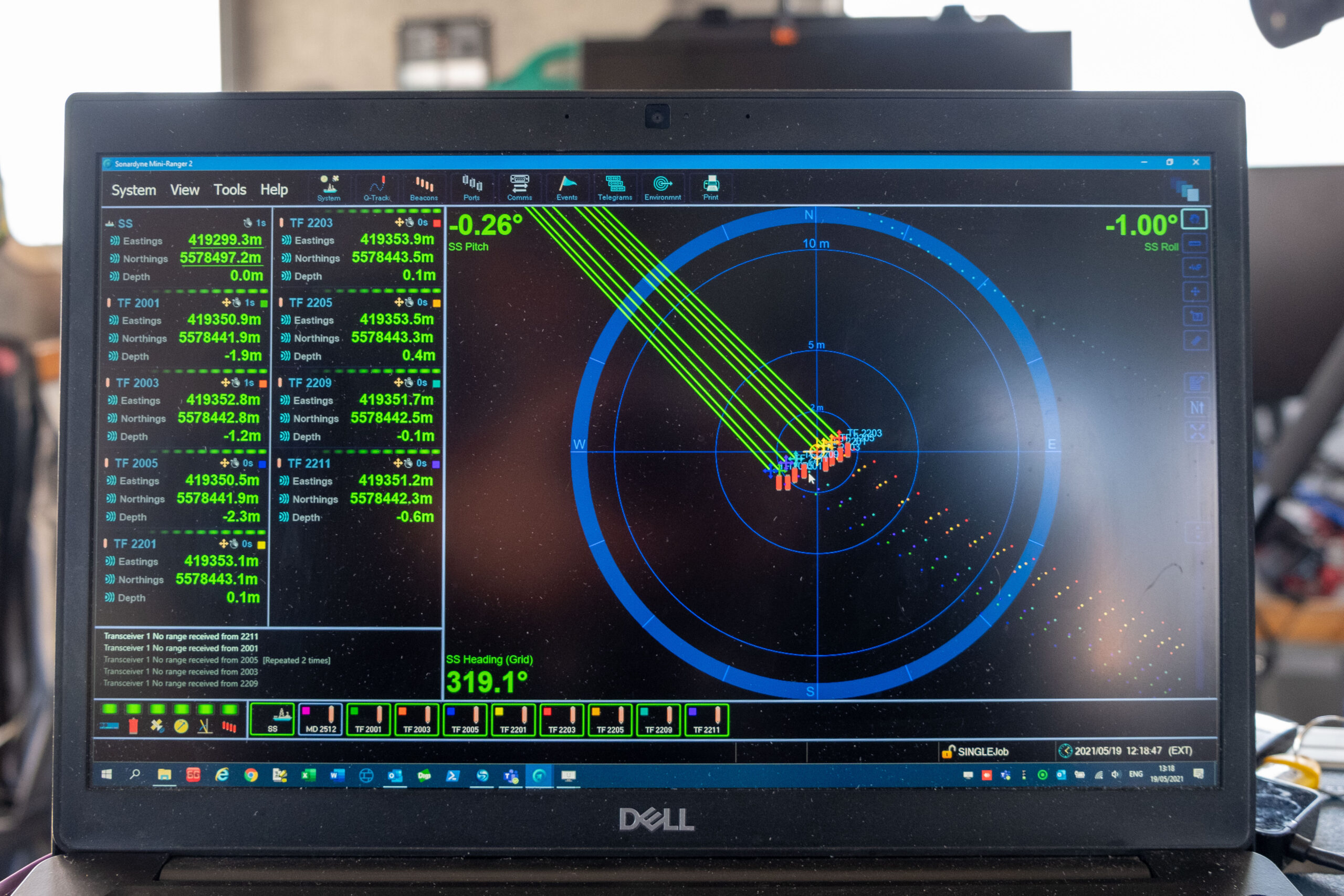

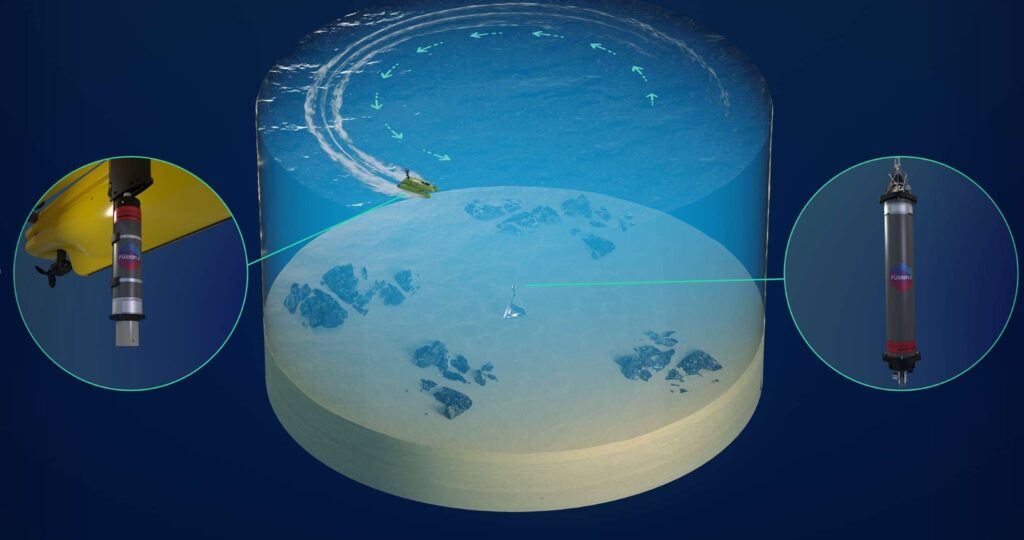

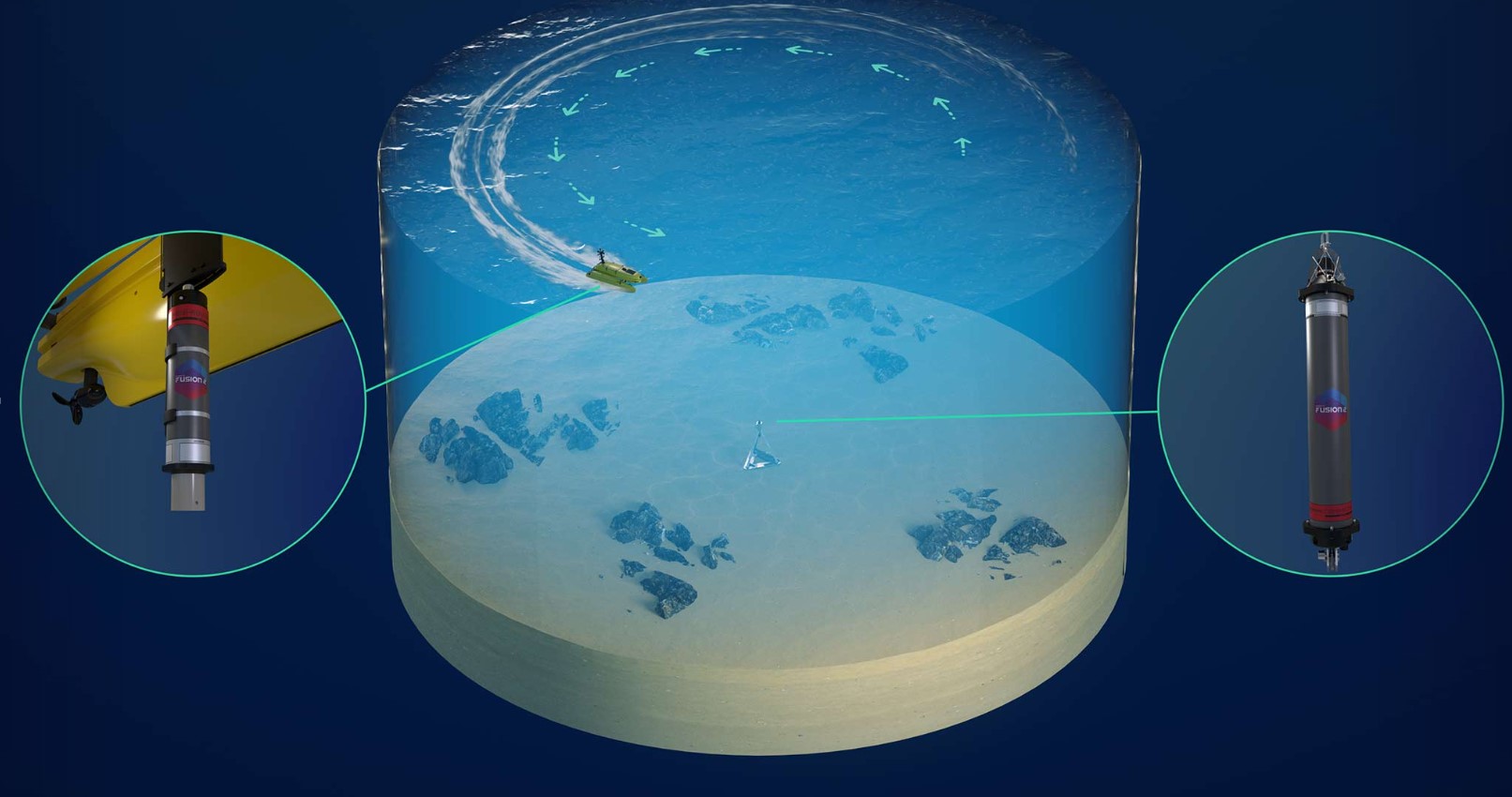

Equinox is a true example of how Covelya Group technologies combine to provide ground-breaking products. Designed around the Solstice MAS from Wavefront Systems, it is commercialised by Sonardyne and features our state-of-the-art SPRINT INS and Mini-Ranger 2 USBL for state-of-the-art navigation and positioning.

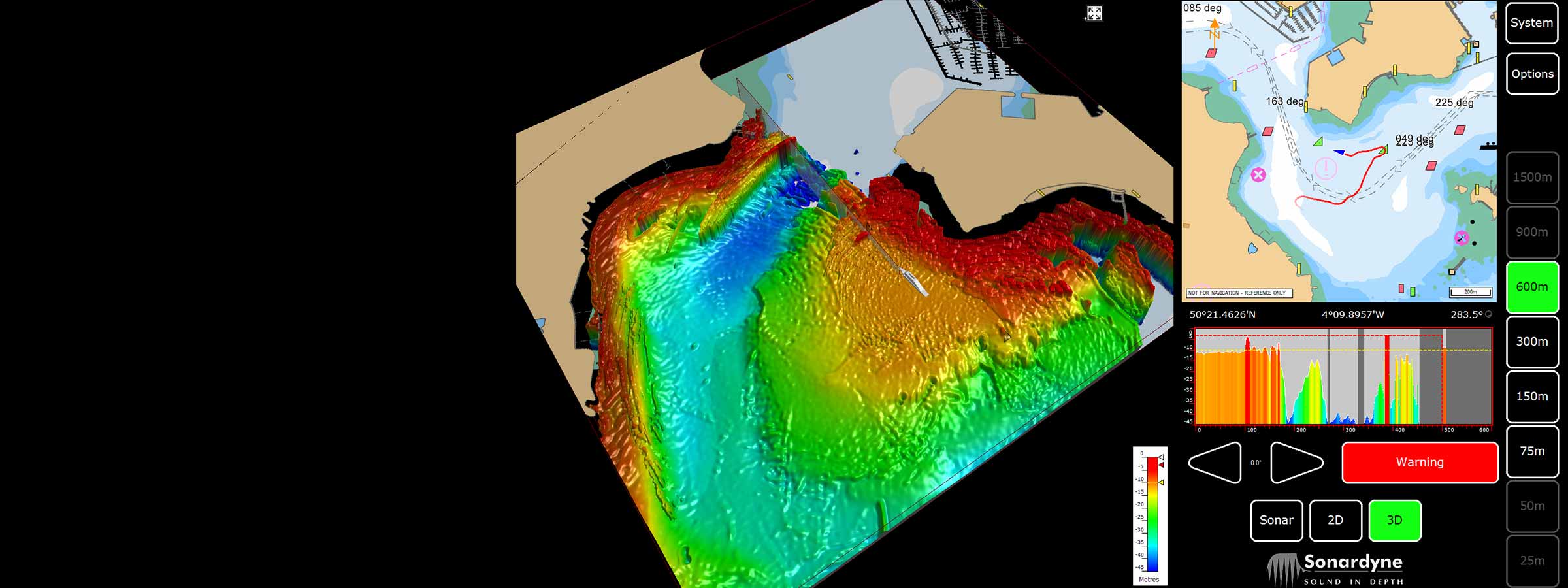

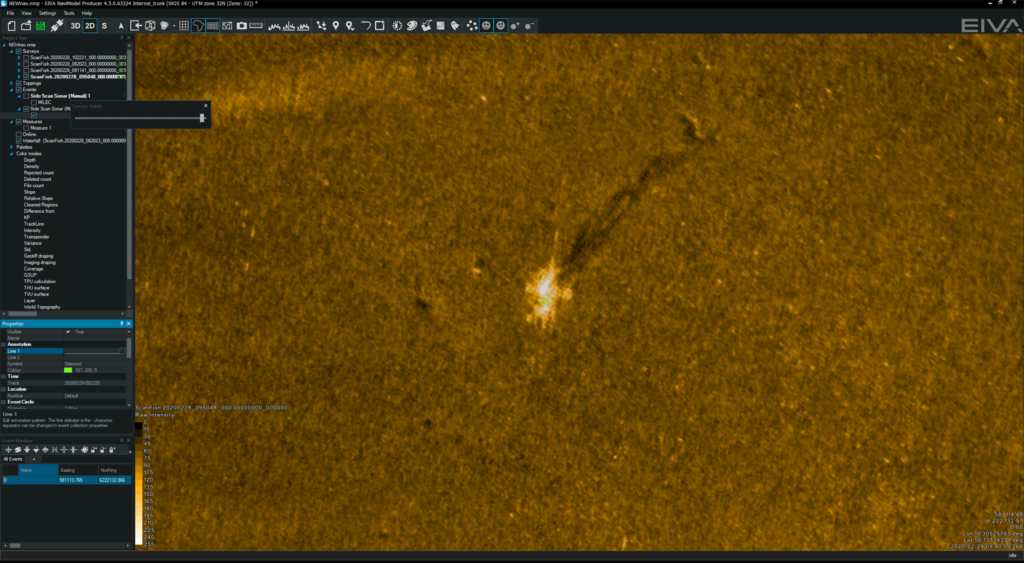

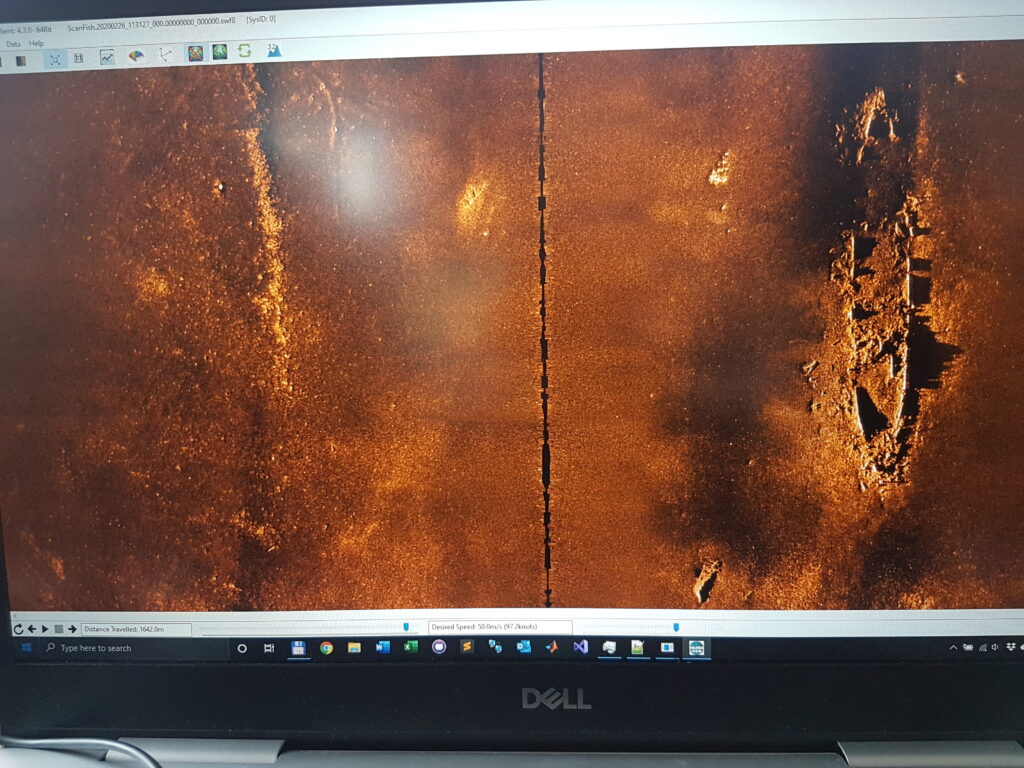

The Sonardyne and Wavefront Systems payloads are all mounted on EIVA’s renowned ScanFish 3D, a steerable remotely operated towed vehicle (ROTV). EIVA’s NaviSuite Kuda user interface is used to plan, autopilot and display the gathered data in real-time.

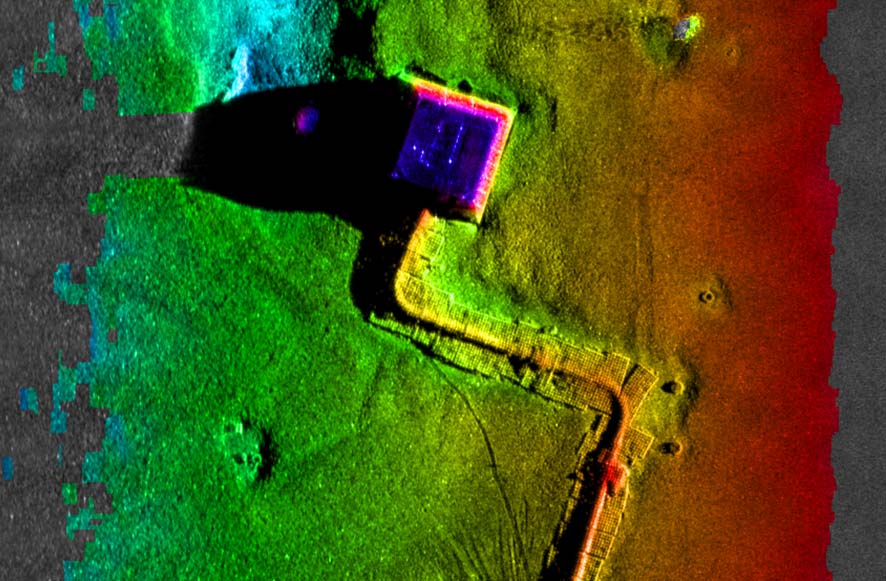

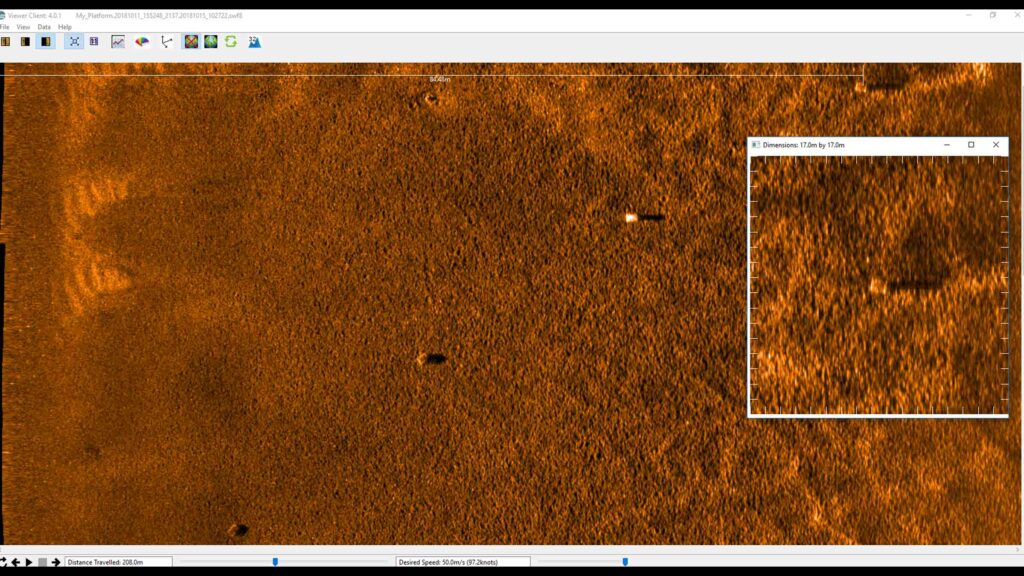

Producing stunningly accurate pictures, it’s ideal for vessels of opportunity or unmanned surface vessels delivering hydrographic, archaeological, search, salvage, unexploded ordnance, and mine countermeasure missions.

At a glance

- Mission ready; designed to support search, classify and map (SCM) and hydrographic operations

- Survey more ground in a single pass; effective area coverage rate (ACR) of up to 1.6 km2/hr

- Along track resolution of 0.15°; best in class delivering maximum detection rates

- Co-located side-scan image and bathy improves your situational awareness

- Real-time motion compensation and positioning accuracies better than 1 m DRMS

- Automatically follows terrain and avoids obstacles

- Suitable for site survey and characterisation and high tempo MCM missions

Why Equinox is perfect for your operations

The ScanFish 3D is a trusted ROTV and, thanks to its inherent stability, the ideal platform to operate Solstice from. At a total weight of 220 kg in air, Equinox can be easily mobilised.

Unlike towed Synthetic Aperture Sonar (SAS) systems, Equinox offers you an affordable, lower-logistics alternative still capable of providing high area coverage rates. By combining leading navigation and positioning from Mini-Ranger 2 USBL and SPRINT INS, imaging data is geo-referenced with an accuracy that’s unrivalled for these types of applications at this price.

Planning a mission is easy. Using NaviSuite Kuda software, you can define your sailing route and run-lines by simply selecting the area you would like to cover. During the mission, NaviSuite Kuda continuously updates the vessel and ScanFish 3D position in real-time.

Equinox also provides real-time geo-rectified waterfall, mosaics and DTM maps and the user interface tools that enable an operator to mark and process objects, including automatic target recognition using AI.

That’s not all; ScanFish 3D can carry heavier payloads and there is room in the fibre cable to include additional payload sensors such as gap fillers. Equinox users can count on improved probability of detection and decreased probability of false alarms, improving the efficiency of your mine countermeasures, archaeological, search and salvage missions.

Equinox case studies

General

• All-in-one, rapidly mobilised solution for MCM, SCM and hydrography

• High stability platform with automatic terrain following

• NaviSuite Kuda software reduces planning times and improves processing times

• Everything supplied, including winch and 1Gbps cable

Performance

• Depth rated to 300 m

• Across track resolution 37.5 mm

• Along-track resolution 0.15°

• Geo-rectified waterfall display

• Image resolution 30 mm x 30 mm

• Co-located 200m swath side-scan and bathy

• Real-time CAD/CAC option

Design (SCANFISH)

• 1210 mm x 1858 mm x 1049 mm, 220 kg in air (73 kg in water)

• Survey speeds 3 to 6 knots

• Pitch and roll stabilised

• Automatic altitude following

Ownership

• What’s in the box: ScanFish 3D, NaviSuite Kuda software, cable and winch, Solstice MAS, Mini-Ranger 2 USBL, WSM 6+, SPRINT 500 INS, DVL

• Warranty: 1 year return to Sonardyne/EIVA service centre

• ITAR Controlled: No

• UK Export License: TBD

Datasheets

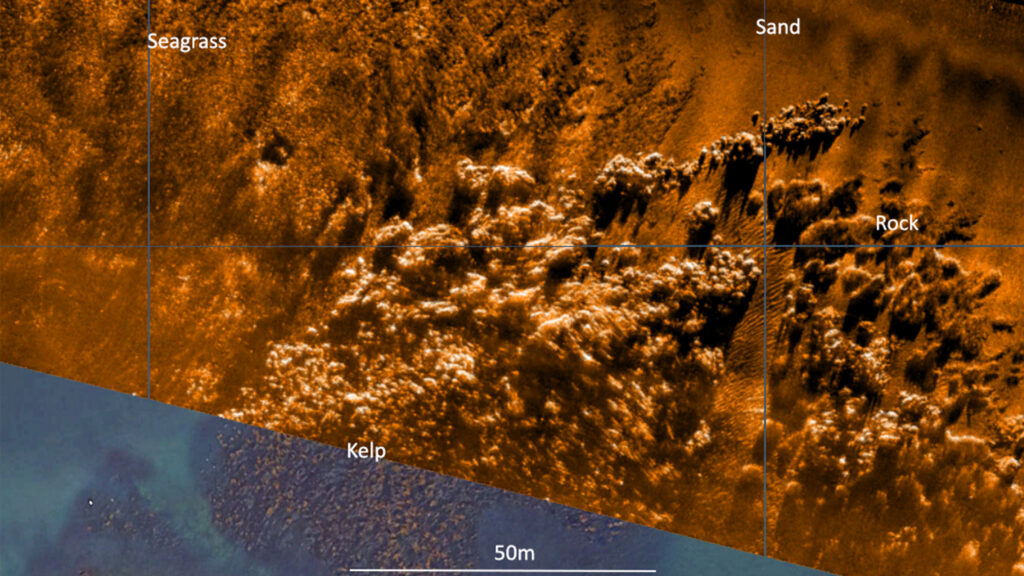

Capture every feature and every detail in ultra-high resolution.

Key benefits

- Mission ready; designed to support search, classify and map (SCM) and hydrographic operations

- Small and compact arrays; optimised for low-logistic AUVs and towed bodies

- Survey more ground in a single pass; 200 m-wide swath ensures high coverage rates

- Along track resolution of 0.15°; best in class delivering maximum detection rates

- Collocated side scan image and bathy improves your situational awareness

- Consumes only 18 W power: budget friendly and increases your AUV’s endurance

- Depth rated to 300 or 600 m

Solstice offers enhanced underwater detection capabilities for various missions, including mine countermeasures, archaeological, search, and salvage operations. The system provides high-performance coverage with large 200m swaths on each side, enabling efficient site characterisation without sacrificing detail. Its class-leading imagery allows you to make confident classification decisions more quickly, with the added versatility of deployment on both autonomous underwater vehicles (AUVs) and towfish platforms. By improving probability of detection and decreasing false alarms, Solstice significantly increases the overall efficiency and reliability of underwater exploration and survey missions. It is suitable for:

- Autonomous underwater vehicles (AUV)

- Site survey and characterisation

- Mine countermeasures (MCM)

- Remotely operated vehicles (ROV)

- Delivering pixel perfect imaging

Exceptional high-contrast seafloor imagery across diverse water depths

How it works

Solstice, designed by Wavefront Systems and commercialised by Sonardyne, is a world-leading side scan sonar for autonomous underwater vehicles (AUVs) and towed bodies. Its advanced technology delivers exceptional seafloor imagery through multiple aperture arrays with 32 multibeam elements, enabling superior signal-to-noise ratio performance and stunning imagery at extended ranges. The sonar’s unique back-projection beam-forming technique ensures focused imaging for every pixel, eliminating distortions caused by platform motion and guaranteeing 100% ground coverage across diverse water depths.

Designed for a wide range of marine missions including hydrographic, archaeological, search, salvage, and mine countermeasure operations, Solstice stands out through its innovative features. Its real-time array calibration dynamically recalibrates hydrophone elements multiple times per second, compensating for dynamic strains and maintaining linear element alignment. The system produces high-contrast imagery in environments ranging from 600-metre depths to very shallow littoral waters, utilising a specialised array technology that provides wide swath coverage with exceptional shadow contrast.

Solstice case studies

Using a hammer to crack a nut? Try using a USV instead

USVs are no longer new. They’ve been used in defence for some time now, for a range of tasks from surveillance to mine counter measures. USVs are being used to survey coastal and offshore waters in hydrographic surveys, for ocean science and in oil and gas

The challenge

Crewed vessels used in offshore construction projects are costly and can even hinder progress. But it doesn’t have to be that way. Other sectors that operate in the marine space are now finding new, smaller, smarter, cleaner tools. They’ve been using uncrewed surface vessels (USVs), so the big, crewed vessels can stick to the jobs they’re good at.

So why are we not using them heavily in offshore construction?

One reason may be because offshore construction was in fact an early adopter. But, at the time, there were only a handful of commercial USV operators whose vehicles were just too big for what was needed, making them unwieldy to deploy from an offshore vessel, defeating the point of the exercise.

Another may be the worry of the complexity involved in offshore construction. Creating complex structures on shore is one thing. Creating them under metres of salt water is entirely another.

Then there is the issue of communication and control over the construction process. Making sure each step is taken exactly as planned is fundamental to the overall success of a construction project.

The solution

USV technology has come a long way since their inception. They’ve been used in defence for some time now, for a range of tasks from surveillance to mine countermeasures. USVs are being used to survey coastal and offshore waters in hydrographic surveys, for ocean science and in oil and gas. They’re being used to go out and gather data, either as a platform for oceanographic instruments or by carrying acoustic communications systems to harvest data from sensors deployed at the seabed. You could think of them being like a remote-controlled Dunker.

USVs are now part of the toolbox across a number of sectors and the levels of sophistication and capability are increasing. Worries about lack of control, the complexity of operations or large clunky kit that isn’t up to the delicate tasks required in offshore construction are today unfounded.

In offshore renewables and oil and gas USVs are being used as part of site and seismic surveys, and then through field life, for inspection operations. They’re also being used for maintenance and repair, by acting as deployment platforms for autonomous underwater vehicles (AUVs), remotely operated vehicles (ROVs) and even aerial drones (UAVs).

The results

Today there’s a wide choice of USVs to choose from. From one-man portable USVs to full sized vessels, and on to fully electric coastal systems and hybrid long-range ocean-going vehicles that can operate for weeks on end. The range of commercial models has also grown. You can buy them outright or purchase a data service where you just order the end result – be it data or an inspection campaign.

USVs can now play a central role in construction operations. They can streamline operations and reduce risk for manned offshore construction teams. When deployed they reduce reliance on heavier, costlier tools and free-up crewed assets to be used on elements of a project where they’ll bring more value.

How to optimise carbon storage monitoring with marine robotics

For a long time, while carbon capture and storage (CCS) in offshore underground reservoirs had been widely regarded as a major way to reduce carbon emissions, it failed to attract the up-front investment needed to make it work. That’s now changing.

The challenge

In today’s far more climate conscious world, sentiment and interest in CCS has very much changed. Significant projects are now being planned. Projects are moving forward in Norway, Netherlands and the UK. Carbon storage licenses are being awarded and wells are being drilled specifically for carbon capture and storage.

Since 1996, CCS projects have been relatively small, yet their potential is vast. On the UK Continental Shelf alone there’s at least 78 gigatonnes of CO2 potential storage capacity – some 200 times the UK’s 2016 emissions*.

From capture to transport by pipeline and injection into a suitable geological formation offshore, there’s a lot to process. But the challenges do not end there. What happens to the CO2 once injected? How will we know if it finds a leak path to the surface?

To answer these challenges and achieve the visions that operators from Equinor in Norway to BP in the UK are promoting, increased capability for marine robotics is required.

The solution

Thanks to the Energy Technologies Institute (ETI) funded three-year research programme back in 2014, this challenge for increased capability of marine robotics has been attained. The project was delivered by a consortium of experienced companies including Fugro, National Oceanography Centre (NOC), British Geological Survey (BGS), Plymouth Marine Laboratory (PML) and ourselves, Sonardyne.

Along with increasing the capability of marine robotics for successful CO2 storage, four key technology elements for large carbon storage and monitoring projects were identified.

The first is a low-power and hence long-endurance autonomous underwater vehicle (AUV). This is required for cost-effective wide-area coverage surveys during baseline and repeat environmental surveys. We found using a combination of our Solstice side scan sonar and chemical sensing worked extremely well.

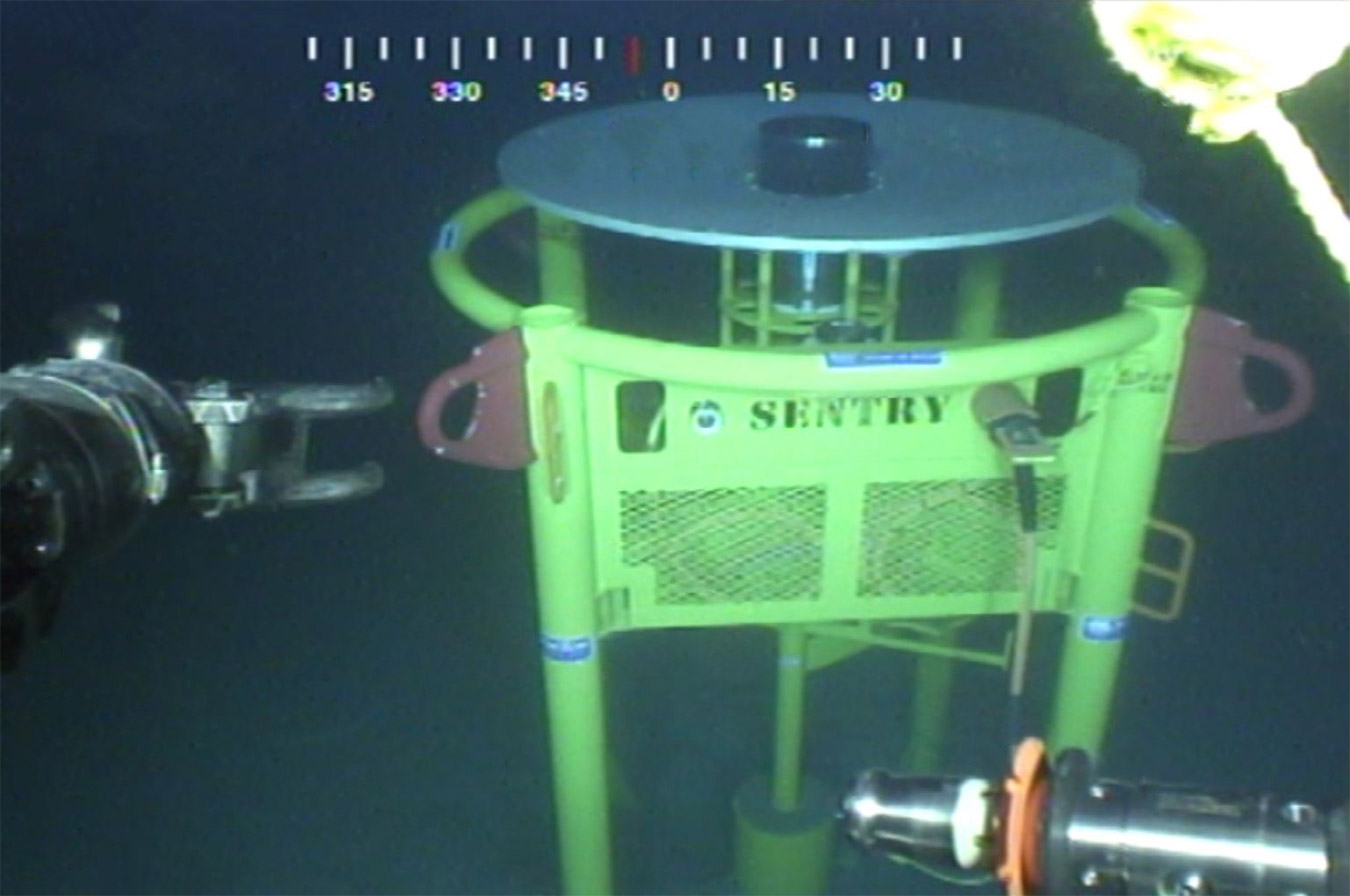

Second and third elements are seabed landers capable of detecting and monitoring any leakage at high-risk locations. These consist of two different landers, one using an active sonar and the second combining passive sonar and chemical sensing.

The active sonar lander, based on our Sentry integrity monitoring system (IMS), gives sensitive and reliable automated leak detection capability across a wide area. For instance, around an injection well, Sentry can monitor an area of over 2.3 million square metres, to help visualise that’s equivalent to around 325 football pitches. The passive sonar and chemical lander, uses the smarts from our underwater acoustics capabilities. It’s capable of both detection of leaks, but offers improved verification and has the potential to estimate leak rates at shorter ranges.

The fourth and final element is a surface gateway to enable communication between a shore-based monitoring office and the underwater systems. Such a gateway can be deployed from a fixed platform, from a moored buoy or from an uncrewed surface vessel (USV), many variants of which are now readily available in the market for over-the-horizon data harvesting missions.

We have a range of payloads suited specifically for use on operator’s USVs for their requirements. We also offer our own end-to-end data-harvesting service, when you just want the data without the worry about the interfaces involved in getting it.

Our system of systems approach to CCS was tested on the ETI project. Wideband acoustic communications between the underwater landers and a buoy on the surface was used to forward all data via satellite communications to a server. This type of set-up is well-proven and used globally on tsunami monitoring systems. Display and interpretation of the monitoring data can be simply integrated into a third-party system to allow non-expert users access via a web portal. From here they can see data visualizations and run reports.

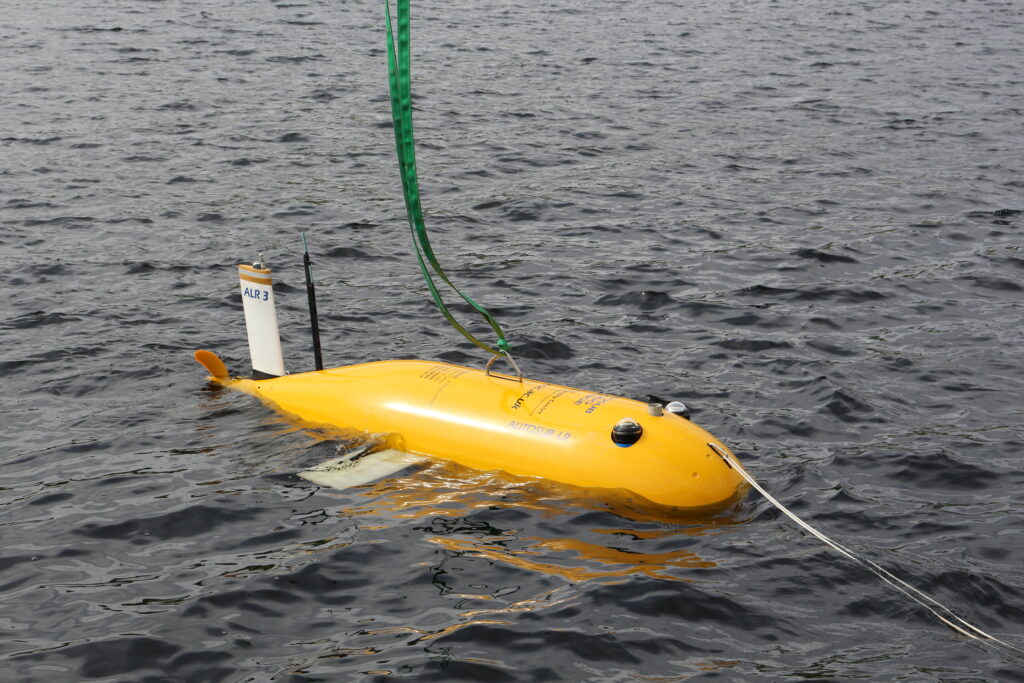

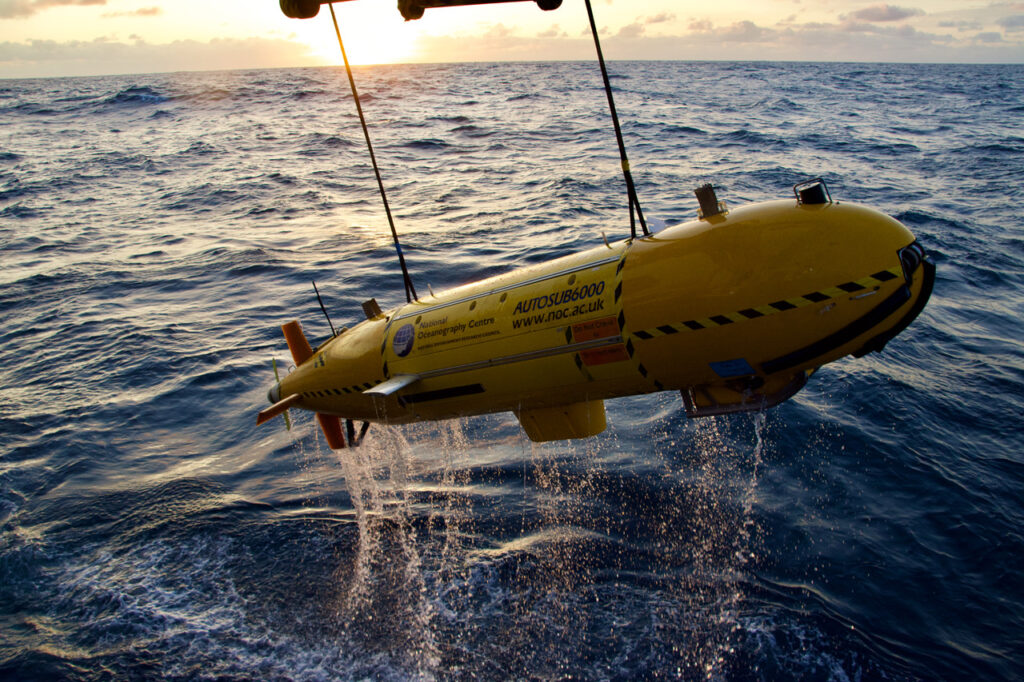

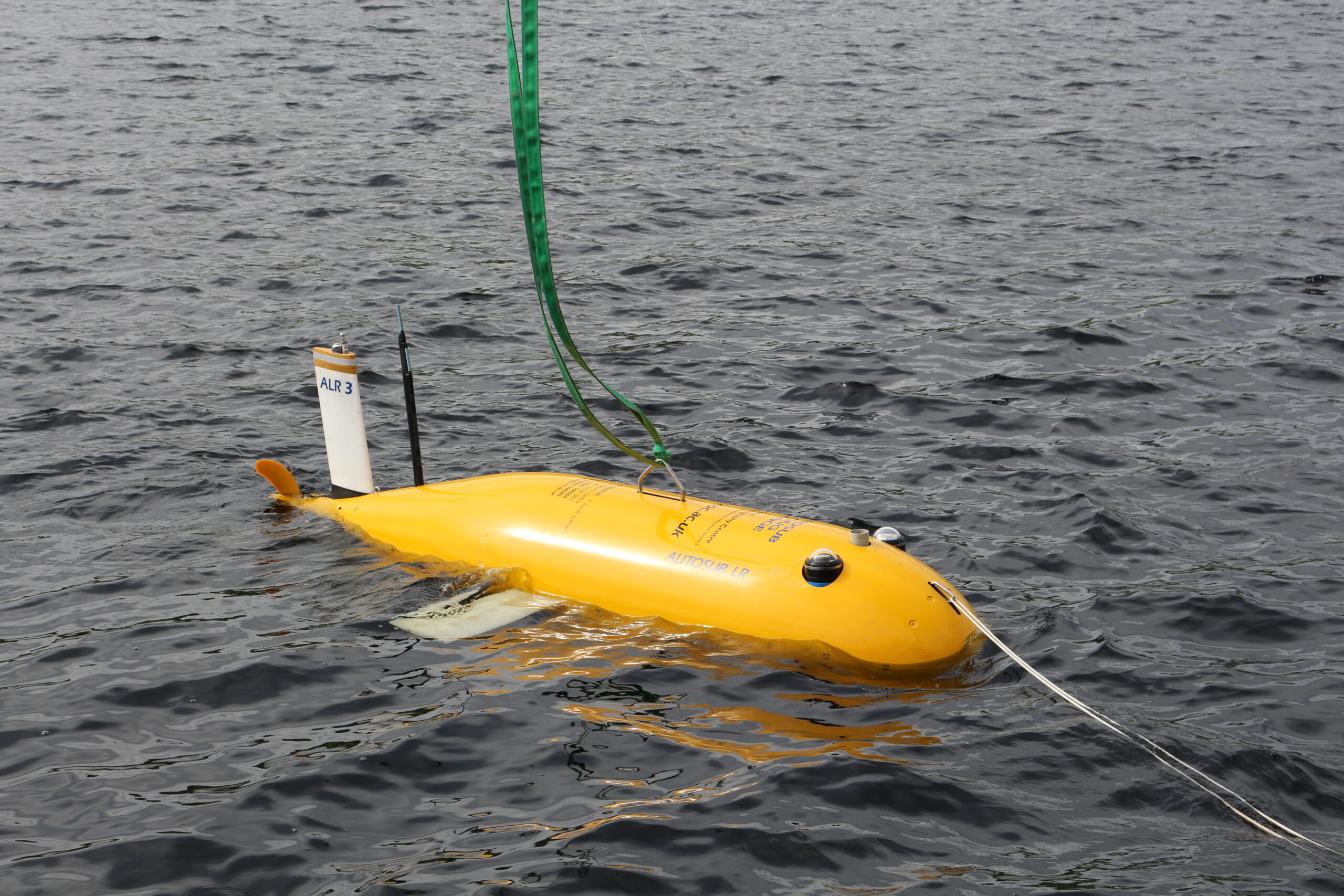

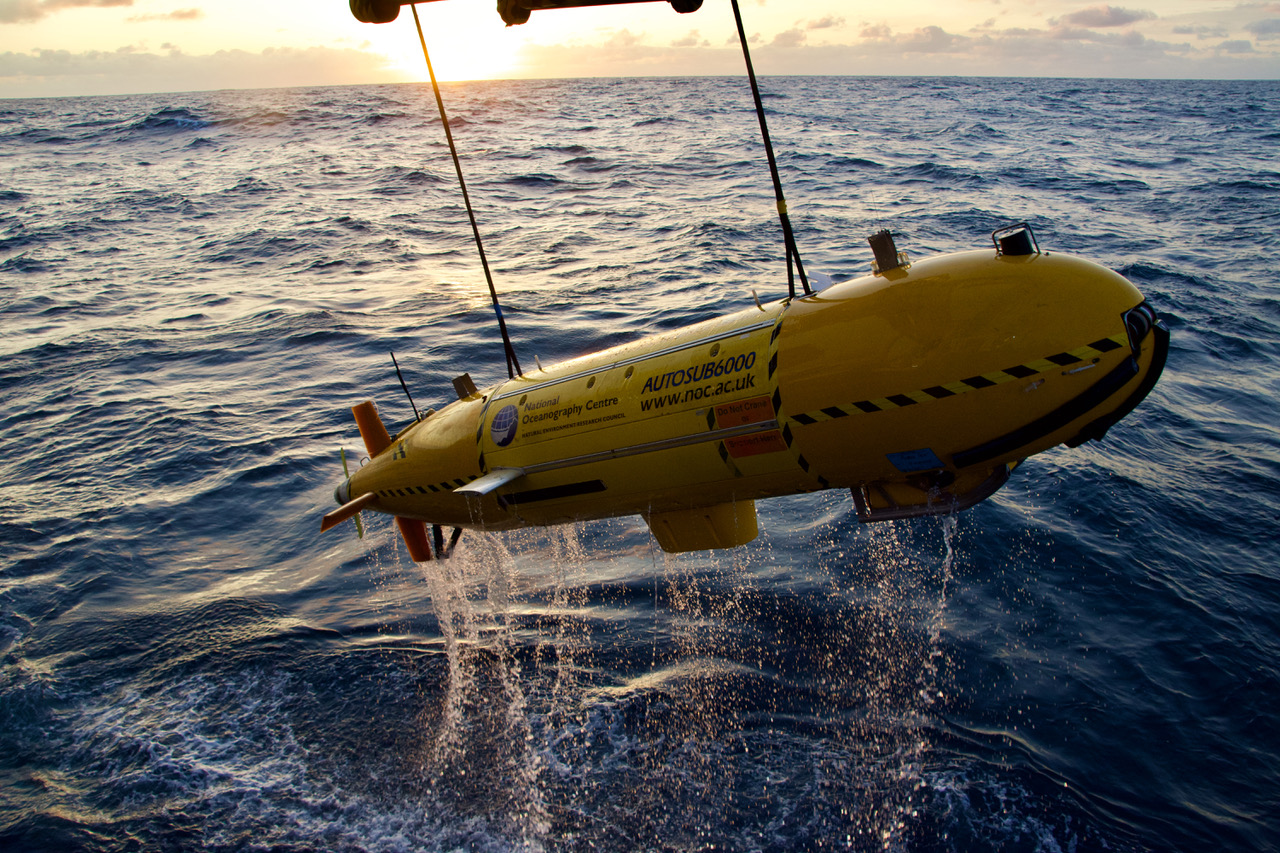

The leak target was deployed in the North Sea, east of Bridlington. The NOC’s Autosub Long Range (ALR) was deployed from the small port at Bridlington and towed a short distance off the coast. After the ALR performed a series of tests to demonstrate safe navigation, the leak – a small CO2 leak – was turned ‘on’ with a flow rate of between 16 and 20 litres per minute of gas at depth, depending on the state of the tide.

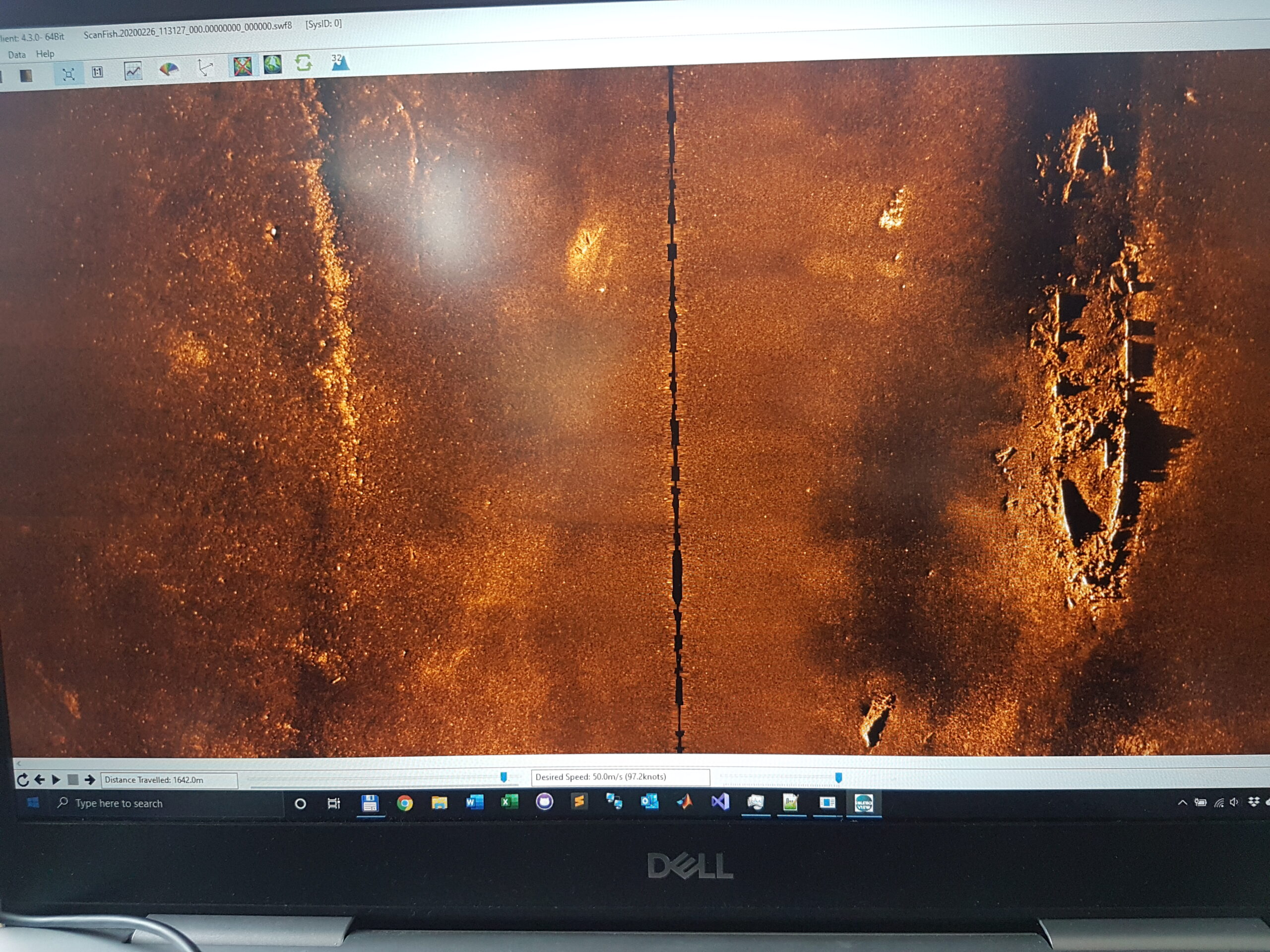

With the leak “on”, ALR performed a series of different wide-area and fine-area search patterns over five days to seek out the leak. The sensor hub on the vehicle processed in real-time a complex set of Solstice sonar, physical and chemical sensor data, into useful information.

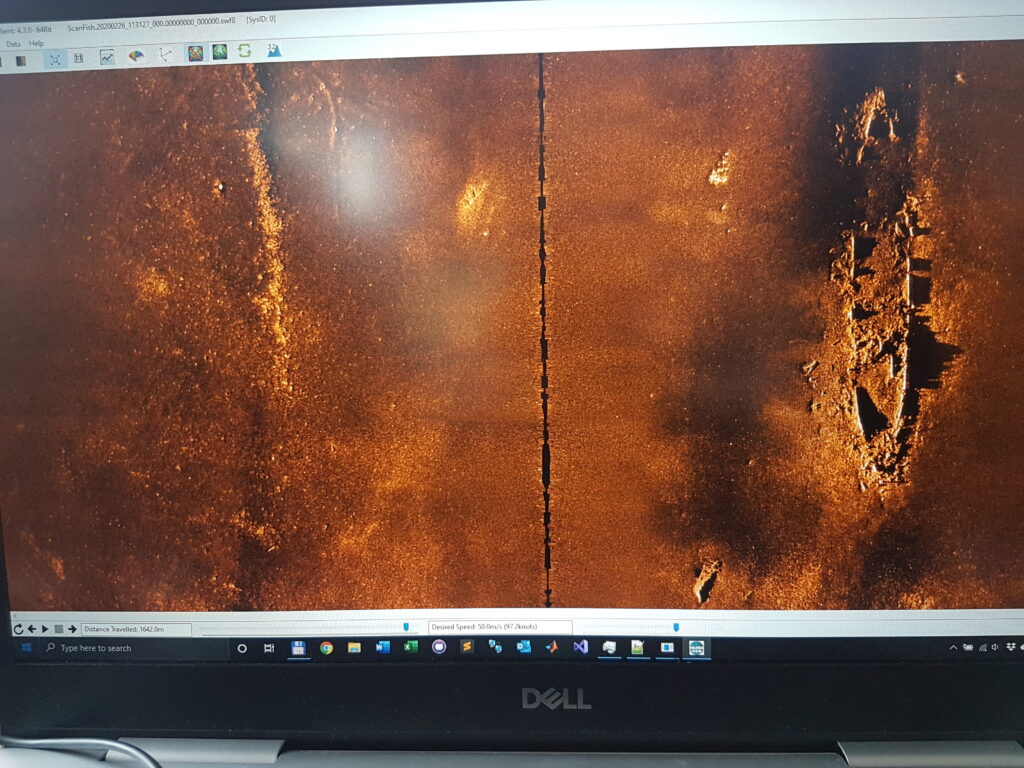

Automatic target recognition algorithms were used to identify any leaks or regions of interest. The system then scored these regions of interest and saved a small “snippet” of the sonar image data. At regular intervals throughout the survey, ALR would surface and send back data via satellite, including navigation data, chemical and physical sensor data and details of snippets of sonar data from detected leaks – an example of which can be seen below.

All of the uploaded data was simultaneously transferred to an internet server which allowed for presentation and interpretation using Fugro’s Metis software. This is an intuitive data delivery platform that allows metocean, vehicle navigation, chemical and sonar snippet data to be combined and displayed. This allowed data sharing across a wide team and supported operational decision making.

During the five days of testing, the ALR travelled a total of 270 km and could have surveyed 54 sq km of seabed in normal operation. However, for the purposes of the demonstration, a total of 16.1 sq km was actually surveyed. Throughout its mission, the ALR was remotely controlled from the shore, mostly from the NOC’s control room in Southampton.

The results

The ETI project consortium demonstrated a functional “system of systems” which can provide operators of offshore CO2 storage sites with a high level of confidence in their safe operation and assist in the provision of regulatory compliance.

We’ve proven it is possible to conduct shore-to-field-to-shore environmental survey operations using a long-endurance AUV. We’ve also shown it’s more than possible to operate well in excess of normal AUV deployments.

This method of working makes it possible to rely on a small local deployment team for CCS projects. The small team can then be supported by remote shore-based operations and a data interpretation team. This cuts both the time and cost of CCS operations considerably.

It is also entirely possible, and has been demonstrated elsewhere, that a further reduction of human decision making can be achieved to reduce operator intervention.

The ETI project demonstrated that it is possible to build highly cost-effective and autonomous sensing systems with on-board intelligence. These systems are both simple to deploy and operate and are very cost competitive with vessel-based or vessel supported AUV survey operations.

The project members have also developed two flexible seabed lander packages capable of extended duration deployments of six months to a year. These can provide localised and still also wide-area monitoring, automated processing of data subsea and communication of that information to surface.

Looking beyond carbon capture, the potential applications of such integrated marine robotic and intelligent remote sensing technologies are many and varied across ocean science, renewables, security and naval domains.

Extending the limits of autonomous system

Sending autonomous and unmanned underwater vehicles (AUV/UUV) out on missions that will last for days or weeks, unaided by vessels or any other supporting offshore infrastructure is a major goal for the ocean science, offshore energy and defence sectors.

The challenge

Improving the endurance and navigational precision of underwater autonomous systems, while also reducing costs, could provide disruptive capability in the subsea monitoring and inspection space. All three are goals in a two-year collaborative project we are leading.

If you can do this you remove the need for a surface vessel. Risk to personnel and mission costs are reduced along with the environmental footprint generated by manned surface vessels. You are able to survey more seabed for longer and with fewer or even no people offshore.

Current constraints on AUV or UUV operations, such as limited power capacity and navigational accuracy degradation over long deployments, means that the capabilities of these systems are not quite able to meet mission requirements on their own.

The solution

We’re leading a two year, £1.4 million project, with partners the National Oceanography Centre (NOC) and L3Harris ASV, to change all that. We aim to develop new positioning technologies that will extend the limits of AUVs and UUVs.

The project – Precise Positioning for Persistent AUVs, or P3AUV for short – is supported by funding through Innovate UK’s research and development competition for robotics and artificial intelligence in extreme and challenging environments.

So, what’s involved? In short, we’re developing ways to provide greater positioning accuracy for long-endurance operations in deep water. At the same time, we’re reducing power requirements for AUVs and UUV. We’ll also be increasing the use of autonomy to make Long BaseLine (LBL) positioning transponder box-in faster and easier, with onboard data processing and calibration.

This is all being done through work in three key and complementary areas: improved lower power navigational accuracy over long distances for AUV/UUVs; autonomous transponder box-in with an unmanned vessel; and improved positioning accuracy during vehicle descent/ascent in the water column.

Central to this work is the vehicle’s acoustic and inertial navigation system (INS). This is because low power sensors have much lower navigation accuracy meaning they often have to surface to correct positioning error with a GPS fix. However, by integrating low and high-power sensors to work together, the best of both worlds – high performance and much lower power consumption – can be achieved.

As an example, the NOC’s Autosub Long Range (ALR) currently uses a low-power microelectronic mechanical system (MEMS) supported by separate Doppler velocity log (DVL) and ADCP input to calculate how far it has travelled on missions. These missions can be several months long. To increase the ALR’s positioning accuracy over longer distances, we’re using our SPRINT-Nav, alongside MEMS technology to work towards high-precision solutions that save space and power.

The project also involves improving positioning accuracy when subsea vehicles transition through the water column. This is a notoriously difficult area for AUV deployments, because it relies on the Doppler velocity log (DVL) being able to ‘lock’ on to the seafloor (bottom lock), so that vehicle XYZ velocities can be calculated, supported by pressure data.

However, DVLs are range limited, so there is often a period where the DVL is out of range. When there are thousands of metres of water between the surface and the seabed, this can introduce significant positioning uncertainty. This problem is solved by using the acoustic Doppler current profiler (ADCP) capability in our SPRINT-Nav INS instrument (looking down) and a second Syrinx DVL (looking up). We can then build up a layer by layer profile of the water column velocities that can be used as tracking layers.

The objective is to reduce positioning errors significantly during both the dive and surfacing phases of an operation. This does depend on the variability of the current regime in any given area, but we’re putting this to the test throughout the P3AUV project.

The data collected during the descent and surfacing phases can be processed to provide a full ocean depth current profile – collection of which is required for many offshore energy projects. It can also be valuable for ocean research.

At the heart of this capability is our class-leading SPRINT-Nav instrument, which combines our SPRINT INS, Syrinx DVL and a high-accuracy pressure sensor in a single housing. These instruments are tightly integrated, enabling the SPRINT-Nav to use individual beam level measurements from our Syrinx DVL. This makes it a much more robust and reliable system than a separate DVL, which calculates velocity from all the beams.

Additionally, we’re implementing systems to box-in our trusted Compatt seafloor positioning transponders with a USV to make LBL operations faster and easier.

The goal is to enable full ocean depth, 1 m accuracy wide-area seabed mapping, using the L3Harris ASV’s C-Worker USV, to precisely position them (box them in). These Compatts could then be used in combination with SPRINT-Nav to calculate a Sparse Long BaseLine (Sparse LBL) solution.

Using autonomous calibration techniques will remove the need for a manned vessel to do this, providing a dramatic cost saving over current ‘state-of-the-art’ AUV operations, as well as any other operations where an LBL positioning system is needed.

To put this into perspective, an offshore support or research vessel will typically burn some 3,000 tonnes of fuel annually and generate about 10,000 tonnes (equivalent) of greenhouse gases. The environmental footprint of an independent ASV or AUV is, by comparison, negligible.

The reduction of manned vessel operations, as well as reducing deployment/recovery of vehicles over-the-side of such vessels, will reduce risk in offshore survey operations. Furthermore, the ability to mobilise this capability at short notice, without the high cost of mobilising a ship, could generate a new service industry model.

The results

Combining all of these capabilities will bring about a step-change in AUV operations, providing a disruptive capability in the subsea monitoring and inspection space. Indeed, reducing the cost and improving the navigation precision of autonomous ocean research in remote areas could bring a disruptive capability to a wide variety of applications.

Sustained ocean observation without the need for ship support is coming under increasing focus from the research community, especially in ice-covered polar areas. Long-duration navigational capability is also a key enabler for persistent covert surveillance operations in the defence sector, as well as emerging applications, including resident seabed-based systems, deep sea mining, aquaculture and UXO surveys for renewable installations.

There are also emerging requirements to monitor decommissioned offshore infrastructure ‘in perpetuity’, all of which will generate a market for this rapid and efficient mode of seabed navigation. As the only company that produces a complete hybrid acoustic navigation solution for AUVs, we are uniquely placed to work with our partners L3Harris ASV and NOC to produce a game-changing capability through the P3AUV project.

Over-the-horizon uncrewed ocean data collection

Seabed monitoring over large areas has entered the age of autonomy, thanks to a combination of our long-endurance, wireless Fetch seabed sensors and a wide choice of uncrewed surface vessels (USVs) able to wirelessly collect their data. Read how Shell is making use of both for ocean data collection.

The challenge

A/S Norske Shell is running a long-term seabed monitoring campaign over the giant Ormen Lange gas field, 120 km offshore Norway, using an array of our Fetch pressure monitoring transponders (PMTs) in 800 – 1,100 m water depth at the field.

Fetch PMTs accurately collect pressure, temperature and inclination data at the seafloor, at pre-programmed intervals. Using this data, any vertical displacement of the seabed can be calculated. The data will help Norske Shell to proactively inform its reservoir management strategy. Each incorporates a high-speed acoustic modem, allowing stored data to be extracted at any time, wirelessly through the water, on demand.

During previous seabed monitoring campaigns, Norske Shell used a vessel of opportunity to travel out to the field to harvest the data using wireless acoustic communications. However, regularly visiting the sensors to gather the information they contain comes with costs, emissions and puts employees in potential harm’s way offshore.

The solution

We provided a full seabed to shore data collection service. Using a USV, controlled remotely, over the horizon, we visited the site and collected all the Fetch PMT data, without a single person having to travel offshore or from their home office.

The USV, an XOCEAN XO-450, was “posted” via cargo ship to Norway for the project and was launched by local marine operations service provider SafePath AS. The USV, piloted by XOCEAN staff in Ireland, then carried out the full mission, covering 300 km from Kristiansund and back, over just three days.

Throughout the mission, all those involved in the project, including Sonardyne’s remote operations specialists in the UK, XOCEAN’s pilots and Shell’s geophysicists in Norway and the US, remained working from their home offices where they were able to quality check and then receive the data, live.

0

km

offshore Norway

Up to

0

m

water depth

Meets

0

%

UK gas needs

The results

One of the largest data harvesting missions using a USV, to date, achieved safely, quickly and with significantly lower emissions and costs than could otherwise be achieved. An estimated 5.4 tonnes less CO2 per day was emitted compared with a manned vessel had been used. XOCEAN offset any remaining emissions created by its vessel.

As well as minimizing risk to personnel, reducing costs and emissions, using a USV for data collection also meant the time download the data was halved, thanks to the maneuverability and low hull and electric propulsion noise of the USV.

Planning your next ocean data collection mission? Read our white paper to find out how to move to uncrewed.

Or let us handle your next ocean data collection mission with our USV Data Harvesting Service.

Read more about why Sonardyne instruments were chosen for Ormen Lange here.

Dude, where's my ocean robot?

Autonomous naval robots are operating for longer and travelling further. Enabling them to know where they are underpins every mission so we have been investing in navigation technology that improves accuracy over time and distance.

The challenge

Any submariner will tell you that navigating underwater is no easy task. That’s because links to the global navigation satellite system (GNSS) are unreliable. Instead, submariners tend to make do with other sensors. SPRINT-Nav X, is our most accurate system yet, as the UK’s national Defence and Security Accelerator (DASA) and the Defence Science and Technology Laboratory (Dstl) would discover.

It’s a different story for autonomous craft and a lot harder to navigate without a crew. That’s why almost all uncrewed operations at sea today require access to a reliable GNSS signal. Without it, vehicles are literally lost at sea.

Our peer adversaries are investing to develop tools that block our access to GNSS, ensuring they can operate, while we’re left in the dark. It’s not just deliberate signal jamming or degradation of performance – known as spoofing – that can interrupt connections with GNSS. Loss of satellite-based timing and navigation signals needed for positioning occurs where GPS or GNSS receivers may not have a clear line of sight with the sky. This frequently affects ports and harbours situated close to tall structures or even close to cliffs and inside fjords.

We figured there had to be another way to keep track of autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs) in challenging underwater environments. So, Sonardyne entered Phase one of the Autonomy in Challenging Environments competition run by DASA on behalf of Dstl.

The solution

We started out with the SPRINT-Nav, which is already the world’s highest performing all-in-one hybrid navigator for uncrewed vehicles, to create the hybrid navigation system, SPRINT-Nav X. This is our highest-grade SPRINT-Nav in the SPRINT-Nav family to date.

We innovated to combine four instruments in a single subsea pressure house: an attitude-heading and reference system (AHRS), a depth sensor, a Doppler velocity log (DVL) and an inertial navigation system (INS). All onboard sensors were optimally integrated to provide seamless operation and unprecedented levels of performance when compared with standalone instruments.

SPRINT-Nav also integrates individual DVL beam velocities thus providing sub millimetre level relative accuracy and making SPRINT-Nav robust over structures and rugged terrain.

However, SPRINT-Nav X delivers more certainty and higher accuracy while dead-reckoning and still maintaining the same form factor and weight as the other systems in the family. This level of performance opens the door to improved capabilities while still using commercial-off-the-shelf instruments.

Would this level of performance be sufficient to replace GNSS positioning?

DASA autonomy in challenging environments

Working with a 12 m-long SEA-KIT X class unmanned surface vehicle (USV), Sonardyne tested and validated SPRINT-Nav. How could we determine if it could be used instead of GNSS? We integrated with a SEA-KIT X and tested it against local GNSS for real-time kinematic (RTK) 50 mm accuracy positioning.

The SEA-KIT is a 10,000 nautical mile-range vessel able to carry up to 2.5 tonnes of payload, deploy and recover AUVs and ROVs. This capability, and flexibility, means it is well suited to support naval missions including intelligence gathering, hydrographic surveying and as a communications gateway.

We learned that SPRINT-Nav can provide a high integrity, continuously available navigation solution for a USV, like SEA-KIT X, operating in littoral zones in water depths up to 150 m.

SEA-KIT range

0

nautical miles

SEA-KIT can carry

0

tonnes of payload

0

km

mission

0

hour

long mission

The results

In 2020, during the exercise the team ran several missions, the longest of these was a 90 km mission that lasted over 13 hours. The mission was conducted in tough conditions with a swell of 2m and approximately 20 degrees of roll in places. The altitude of the USV was anywhere between 0.5 to 70 m from the seafloor with deep and shallow gradients and difficult terrain that included mud, rock, sand and shingle.

The USV moved predictably out to sea on a long straight line and then returned to conduct a traditional lawnmower survey pattern typically used in mine countermeasures (MCM). The drift between the estimated SPRINT-Nav position and the actual GNSS RTK signal never exceeded the 0.01% error relative to distance travelled within the specification, proving that AUVs and ROVs can find their way, with SPRINT-NAv technology. No other COTS system or product matches this performance.

Long-endurance AUV development with shallow water simplicity

Developing large, deepwater and long-endurance autonomous underwater vehicles (AUVs) isn’t a challenge for the feint hearted. But with the right approach to USBL-inertial systems, it’s a task that can be made simpler, without having to dive straight in at the deep end.

The challenge

That’s the approach that Anduril Industries has taken for its large displacement unmanned underwater vehicle (LD-UUV) vehicle, the DIVE-LD. It’s a rapid development programme that has included support from the Defense Advanced Research Projects Agency (DARPA) and technology partnerships with organizations including the Center for Marine Autonomy and Robotics at Virginia Tech.

Deepwater capability, shallow-water USBL-inertial test bed

The DIVE-LD is targeting littoral and deepwater survey, inspection and intelligence, surveillance, and reconnaissance (ISR). To meet these tasks, the 1.2 m-diameter, 5.8 m-long AUV has been designed to operate in down to 6,000 m water depth, traveling at 2-8 knots and covering, in a single mission, nearly 600 km.

To hone the vehicle’s systems, Anduril wanted to be able to conduct testing in its home waters. They already have one of our Ranger 2 Gyro USBL (Ultra-Short BaseLine) systems for full ocean depth positioning on vessels of opportunity. But they wanted something for positioning in just 6 – 20 m water depth that they could quickly set up on small coastal boats or even RHIBs.

The solution

The company, which recently acquired Quincy, Massachusetts-based underwater robotics innovator Dive Technologies, chose our Micro-Ranger 2 USBL system.

It’s a perfect fit. Micro-Ranger 2 is portable; everything you need comes in one, medium-sized IP67-rated ruggedised case, complete with its own 10-hour rechargable power supply. It’s also easy to set up and use from any waterside location, with Wi-Fi and ethernet connection to your laptop. It is able to track up to 10 targets out to 995 m range, including in shallow waters, thanks to our Wideband digital signal architecture. It’s also available with an integrator kit for those wanting to both track and communicate with targets, whether that’s divers, ROVs or even large displacement AUVs!

For Anduril, it ticked all the boxes for helping develop their navigation techniques and to implement USBL aiding while testing in areas with less than 20 m total water depth.

Combining USBL-inertial systems

What’s more, the DIVE-LD already has our highest grade hybrid acoustic-inertial instrument, SPRINT-Nav X, and our AvTrak 6 combined transponder, transceiver and telemetry instrument onboard. This allowed for seamless integration with Micro-Ranger 2, thanks to them all being built on our common hardware platform, 6G. All equipment with 6G hardware talks the same language. This gives the user added flexibility of working with various transponders, or in this case topsides, to get the job done.

DIVE-LD

0

kg

weight in air

Up to

0

days

endurance

0

m

depth rating

The results

Tim Raymond, founding engineer at Dive Technologies and now Chief Engineer at Anduril, says, “Micro-Ranger 2 allows us to deploy on almost any vessel while performing shallow water AUV testing. At the same time, it’s still capable of providing quality USBL positional aiding to the AUV, despite the small form factor and challenging acoustic environment.

“This system has already allowed us to develop navigation techniques and implement USBL aiding while testing in areas with less than 20 m total water depth, giving us high confidence in the capabilities of our DIVE-LD’s onboard software and aiding systems, prior to deployment in more austere environments where USBL aiding is critical for AUV navigation.

“The ability to rapidly deploy on almost any vessel and test integration and implementation of USBL aiding systems, without the overhead of a large host vessel and deployment into deep water, allowed us to develop USBL aiding capabilities for the DIVE-LD on an extremely tight schedule and with very low cost to test and validate.”

Are you developing an AUV or UUV? Get in touch to find out how we can support your development programme, no matter how shallow or deep you want to go.

Greater efficiency, lower overheads, with underwater autonomy in deepwater seismic

Shell Brasil, in partnership with Petrobras, Sonardyne and Brazilian research institute SENAI CIMATEC are working together to bring a step-change to 4D seismic data gathering in Brazil’s deepwater pre-salt region.

Discover how we’re collaborating to develop innovative autonomous technology that will make monitoring these challenging deepwater fields more efficient, with fewer people and lower environmental footprint.

Scroll down to read this case study in Portuguese.

The challenge

Seismic data is an essential part of offshore field development activity, especially to support proactive reservoir management and production optimisation. Techniques for gathering this data have evolved dramatically over the decades; from the use of marine streamers for large exploration seismic campaigns to the now routine use of remote operated vehicles (ROV) to deploy ocean bottom nodes (OBN) for high-resolution imaging of pre-salt reservoirs.

Yet, gathering seismic data for pre-salt reservoir imaging remains intensive work. It involves large, costly and carbon-emitting crewed vessels for deployment and recovery of, typically, thousands of nodes. As an example, for a 10-month campaign over one of Brazil’s giant pre-salt fields, a node handling vessel could emit close to 10,000 tons of CO₂. Costly and complex operations can mean a reduction in frequency of surveys, including of those done to gather what’s called time lapse or 4D seismic data, which is required to monitor the pre-salt reservoirs.

Shell and Petrobras came to us believing that there could be a lower-cost, more sustainable, way of acquiring 4D seismic data, as well as other parameters such as seafloor subsidence, to help better monitor reservoirs. They also saw this could be done with a lower environmental footprint and while keeping more people safe.

The solution

Together, Shell Brasil, Petrobras, and Sonardyne joined forces with SENAI CIMATEC to develop an advanced seismic data acquisition system under a Brazilian National Agency of Petroleum, Natural Gas and Biofuels (ANP) promoted research and development project.

At its core is an On-Demand Ocean Bottom Node, or OD OBN. This semi-permanent seabed system is used for the acquisition of high resolution seismic and seafloor subsidence data.

Like conventional seabed nodes (OBN), each OD OBN contains three geophones and one hydrophone, a data recording system, batteries and a highly accurate clock. The sensors detect pressure waves emitted by an airgun source, usually towed by a ship, as they are reflected upwards towards the seabed from the underlying layers of rock surrounding the reservoir.

Unlike conventional nodes, these OD OBNs remain on the seabed, down to 3,000 m, gathering seismic data for up to five years. This significantly reduces the cost of repeated ocean bottom seismic campaigns, as the node handling vessel is removed from the operations. It also reduces the impact on the environment and marine ecosystems.

The activation of the nodes, verification of subsidence event alarms, calibration of internal clocks and harvesting of seismic data will be performed using an autonomous underwater vehicle (AUV) called Flatfish developed, in a closely interlinked ANP project, by partners Shell Brasil, Petrobras, SENAI CIMATEC and Saipem.

Flatfish will find each node using Sonardyne’s 6th generation (6G) of acoustic positioning systems. Our acoustics will also support data telemetry with the nodes, for health checks, configuration and acoustic time synchronization. The Flatfish will then hover above each node, in turn. Using an extremely high bandwidth and energy efficient laser-based variant of Sonardyne´s BlueComm optical communications device, it will wirelessly harvest many gigabytes of seismic data in just a few minutes.

This variant uses two rapidly modulated lasers to produce simultaneous bi-directional communications over more than five meters range. It is optimised for peak data transfer performance, with speeds of over 600 megabits per second demonstrated. This makes it excellent for harvesting large amounts of data from seabed nodes.

“Using OD OBN in combination with Flatfish, a 4D seismic campaign in the pre-salt may be executed in a simpler manner, with lower operational cost, lower risk of human exposure and lower environmental impact,” says Jorge Lopez, Manager of Subsurface Technology at Shell Brasil. “On top of this, the nodes also measure seafloor deformation and can continuously monitor for possible subsidence events that may occur during the production of the field.”

The results

In the first phase of the OD OBN project, eight fully functional prototype nodes were built. These comprised of two different concept types and were designed and built by SENAI CIMATEC in Salvador, Bahia together with Sonardyne Brasil.

In 2021, initial tests of seismic data recording were conducted at the Sapinhoá pre-salt field offshore Brazil and interoperability tests between the nodes and the Flatfish AUV were performed in shallow water in Trieste, Italy.

A very intensive laboratory and offshore testing and demonstration program is being conducted over the next 18 months to ensure the OD OBN system meets its operational requirements. This program will increase the maturity of the solution, with tests in pre-salt fields for recording seismic data with the OD OBN prototypes and the communication and data harvesting AUV missions.

In the next phase of the project, starting later in 2022, Shell and Petrobras will sign a new agreement to manufacture 600 nodes and deploy them for three years of reservoir monitoring in a Brazilian pre-salt field.

Maior eficiência, baixo custo de operação, para sísmica em águas profundas através de autonomia submarina

A Shell Brasil, em parceria com a Petrobras, a Sonardyne e o instituto de pesquisa brasileiro SENAI CIMATEC estão trabalhando juntos para trazer uma mudança radical na coleta de dados sísmicos 4D na região do pré-sal em águas profundas do Brasil.

Descubra como estamos colaborando para desenvolver tecnologia autônoma inovadora que tornará o monitoramento desses desafiadores campos em águas profundas mais eficiente, com menos pessoas e menor impacto ambiental.

O desafio

Os dados sísmicos são uma parte essencial da atividade de desenvolvimento de campos offshore, especialmente para apoiar o gerenciamento proativo de reservatórios e a otimização da produção. As técnicas para coletar esses dados evoluíram dramaticamente ao longo das décadas; desde o uso de streamers marinhos para grandes campanhas sísmicas de exploração até o uso rotineiro de veículos operados remotamente (ROV) para implantar nós de fundo oceânico (OBN) para imagens de alta resolução de reservatórios do pré-sal.

No entanto, a coleta de dados sísmicos para imagens de reservatórios do pré-sal continua sendo um trabalho intensivo. Envolve embarcações tripuladas grandes, caras e emissoras de carbono para implantação e recuperação de, normalmente, milhares de nós. Como exemplo, para uma campanha de 10 meses em um dos campos gigantes do pré-sal brasileiro, uma embarcação de manuseio de nós pode emitir cerca de 10.000 toneladas de CO₂. Operações caras e complexas podem reduzir a frequência de levantamentos, inclusive daqueles feitos para coletar o lapso temporal que é chamado de dados sísmicos 4D, necessários para monitorar os reservatórios do pré-sal.

A Shell e a Petrobras nos procuraram acreditando que poderia haver uma forma mais barata e sustentável de adquirir dados sísmicos 4D, além de outros parâmetros, como subsidência do fundo do mar, para ajudar a monitorar melhor os reservatórios. Eles também viram que isso poderia ser feito com um impacto ambiental menor e mantendo mais pessoas seguras.

A solução

Juntos, Shell Brasil, Petrobras e Sonardyne uniram forças com o SENAI CIMATEC para desenvolver um sistema avançado de aquisição de dados sísmicos em um projeto de pesquisa e desenvolvimento promovido pela Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP).

Em seu núcleo está um On-Demand Ocean Bottom Node, ou OD OBN. Este sistema semipermanente do fundo do mar é usado para a aquisição de dados sísmicos de alta resolução e subsidência do fundo do mar.

Assim como os nós convencionais do fundo do mar (OBN), cada OD OBN contém três geofones e um hidrofone, um sistema de gravação de dados, baterias e um relógio de alta precisão. Os sensores detectam ondas de pressão emitidas por uma fonte do tipo airgun, rebocada por um navio, à medida que são refletidas para cima em direção ao fundo do mar a partir das camadas subjacentes de rocha ao redor do reservatório.

Ao contrário dos nós convencionais, os OD OBNs permanecem no fundo do mar, até 3.000 m, coletando dados sísmicos por até cinco anos. Isso reduz significativamente o custo de repetidas campanhas sísmicas no fundo do oceano, uma vez que a embarcação de manuseio de nós é removida das operações. Também reduz o impacto no meio ambiente e nos ecossistemas marinhos.

A ativação dos nós, a verificação dos alarmes dos eventos de subsidência, a calibração dos relógios internos e a coleta dos dados sísmicos serão realizados por meio de um veículo submarino autônomo (AUV) denominado Flatfish, desenvolvido em um projeto ANP estreitamente interligado, pelos parceiros Shell Brasil, Petrobras, SENAI CIMATEC e Saipem.

O Flatfish encontrará cada nó usando a 6ª geração (6G) de sistemas de posicionamento acústico da Sonardyne. Nossa acústica também suportará telemetria de dados com os nós, para verificações de integridade, configuração e sincronização de tempo acústico. O Flatfish irá então pairar acima de cada nó, por sua vez. Usando uma largura de banda extremamente alta e uma variante baseada em laser com eficiência energética do dispositivo de comunicação óptica BlueComm da Sonardyne, ele coletará sem fio muitos gigabytes de dados sísmicos em apenas alguns minutos.

Esta variante usa dois lasers modulados rapidamente para produzir comunicações bidirecionais simultâneas em um alcance de mais de cinco metros. Ele é otimizado para desempenho de transferência de dados de pico, com velocidades demonstradas de mais de 600 megabits por segundo. Isso o torna excelente para coletar grandes quantidades de dados de nós do fundo do mar.

“Usando OD OBN em combinação com o Flatfish, uma campanha sísmica 4D no pré-sal pode ser executada de forma mais simples, com menor custo operacional, menor risco de exposição humana e menor impacto ambiental”, afirma Jorge Lopez, Gerente de Tecnologia de Subsuperfície da Shell Brasil. “Além disso, os nós também medem a deformação do fundo do mar e podem monitorar continuamente possíveis eventos de subsidência que podem ocorrer durante a produção do campo”.

Os resultados

Na primeira fase do projeto OD OBN, doze nós protótipos totalmente funcionais foram construídos. Estes são compostos por dois tipos de conceito diferentes e foram projetados e construídos pelo SENAI CIMATEC em Salvador, Bahia em conjunto com a Sonardyne Brasil.

Em 2021, os testes iniciais de registro de dados sísmicos foram realizados no campo do pré-sal de Sapinhoá no litoral brasileiro e os testes de interoperabilidade entre os nós e o Flatfish AUV foram realizados em águas rasas em Trieste, Itália.

Um intenso trabalho em laboratório e um programa de demonstração e testes offshore estará sendo realizado nos próximos 18 meses para garantir que o sistema OD OBN atenda aos seus requisitos operacionais. Este programa aumentará a maturidade da solução, com testes em campos do pré-sal para registro de dados sísmicos com os protótipos OD OBN e as missões AUV de comunicação e coleta de dados.

Na próxima fase do projeto, a partir do final de 2022, a Shell e a Petrobras assinarão um novo acordo para fabricar 600 nós e implantá-los para três anos de monitoramento de reservatórios num campo do pré-sal brasileiro.

Mini-Ranger 2 for the next-level USV operations

Fugro is expanding the possibilities of remote marine operations with its growing fleet of SEA-KIT X-class uncrewed surface vessels (USVs) and eROVs. Read on to learn how our Mini-Ranger 2 Ultra-Short BaseLine (USBL) positioning system supports their remote capability.

The challenge

Leading geo-data specialist Fugro has a clear goal – to achieve safer, faster and more sustainable operations. One of the ways it’s doing that is by using uncrewed surface vessels (USV) to carry out subsea inspection, construction support and hydrographic and geophysical surveys operations.

Fugro’s fleet is initially being built with several 12 m-long SEA-KIT X class USVs, named Blue Essence™ by Fugro, with larger SEA-KIT designs planned. These vehicles are operated over-the-horizon from one of Fugro’s onshore global onshore remote operations centres (ROCs).

The Blue Essence™, Fugro Maali 12 m USV can be remotely launched and recovered by personnel at the ROC.

To ensure accurate control and high quality data gathering during its operations using the ROV, Fugro needed a suitable underwater Ultra-Short BaseLine (USBL) positioning system. In particular, Fugro was focused on shallow water inspection operations in 5 – 150 m water depth, that would involve long layback tracking.

The solution

Fugro selected our Mini-Ranger 2 Ultra-Short BaseLine (USBL) underwater positioning system and a Wideband Sub Mini 6+ (WSM 6+) transponder/responder for tracking the ROV.

Mini-Ranger 2 provides a high level of performance without the complexity of a deep water USBL system. It’s compact and easy to install, yet supports tracking, telemetry and control with an operating range of 995 m, extendable to 4,000 m.

At its heart is our HPT 3000 transceiver. It’s low weight (9.5 kg in water) and power draw, so it has minimal impact on any USV’s key performance budgets. It’s optimized for use in shallow water, high elevation and long lay back operating scenarios, making it ideal for Fugro’s shallow water operations, as well as much deeper water work.

HPT 3000 is compatible with all our 6G transponder options, supporting a wide range of functionality, including tracking, telemetry and control. That can be with up to 10 targets simultaneously, whether that’s ROVs, AUVs or divers. It’s also popular for use in ocean data gathering, thanks to its high data rate data collection capability from underwater.

The results

Fugro’s first SEA-KIT Blue Essence™, called Fugro Maali, was delivered to its base in Perth, Australia, in early 2021. Mini-Ranger 2 was configured with an external AHRS and SVP, as well as Fugro’s Starfix® GNSS, to ensure the best possible results from the system.

The vehicle was put to work straight away on an entirely remote nearshore inspection of three gas trunklines off Australia for the Woodside-operated North West Shelf Project – an industry first.

The inspection covered 1,300 km and included a multibeam survey, visual inspection using the ROV and a cathodic protection assessment of the gas trunklines to comply with Woodside and regulatory requirements, with operations controlled from Woodside’s King Bay Supply Facility and Fugro’s ROC in Perth.

Since then, Fugro Maali has carried out further campaigns through 2021 and into 2022, including subsea asset inspection, benthic habitat mapping and high resolution pipeline surveys.

“We couldn’t be happier with how the Mini-Ranger 2 has performed to date onboard the Fugro Maali USV,” says Matt Lussu, Principal Hydrographic Surveyor, Fugro. “We’ve seen reliable USBL positioning even in moderate sea states. We’ve also had good results with shallow water tracking, even when then ROV is several orders of water depth away from the transceiver.”

Fugro took delivery of its second Blue Essence™ USV in 2021. A third USV is about to be operational in the Middle East. A fourth is in sea trials and a the fifth in build, all with Mini-Ranger 2 onboard. In 2023, the company is also expected to take delivery of its next range USV, the Blue Eclipse™, an 18 m vessel, built by SEA-KIT and based on its XL-class design.

For the USV delivery, we worked closely with Fugro and SEA-KIT to deliver this integrated remote USV operations capability, ahead of the X-Class USV’s first operations offshore Australia.