Using a hammer to crack a nut? Try using a USV instead

USVs are no longer new. They’ve been used in defence for some time now, for a range of tasks from surveillance to mine counter measures. USVs are being used to survey coastal and offshore waters in hydrographic surveys, for ocean science and in oil and gas

The challenge

Crewed vessels used in offshore construction projects are costly and can even hinder progress. But it doesn’t have to be that way. Other sectors that operate in the marine space are now finding new, smaller, smarter, cleaner tools. They’ve been using uncrewed surface vessels (USVs), so the big, crewed vessels can stick to the jobs they’re good at.

So why are we not using them heavily in offshore construction?

One reason may be because offshore construction was in fact an early adopter. But, at the time, there were only a handful of commercial USV operators whose vehicles were just too big for what was needed, making them unwieldy to deploy from an offshore vessel, defeating the point of the exercise.

Another may be the worry of the complexity involved in offshore construction. Creating complex structures on shore is one thing. Creating them under metres of salt water is entirely another.

Then there is the issue of communication and control over the construction process. Making sure each step is taken exactly as planned is fundamental to the overall success of a construction project.

The solution

USV technology has come a long way since their inception. They’ve been used in defence for some time now, for a range of tasks from surveillance to mine countermeasures. USVs are being used to survey coastal and offshore waters in hydrographic surveys, for ocean science and in oil and gas. They’re being used to go out and gather data, either as a platform for oceanographic instruments or by carrying acoustic communications systems to harvest data from sensors deployed at the seabed. You could think of them being like a remote-controlled Dunker.

USVs are now part of the toolbox across a number of sectors and the levels of sophistication and capability are increasing. Worries about lack of control, the complexity of operations or large clunky kit that isn’t up to the delicate tasks required in offshore construction are today unfounded.

In offshore renewables and oil and gas USVs are being used as part of site and seismic surveys, and then through field life, for inspection operations. They’re also being used for maintenance and repair, by acting as deployment platforms for autonomous underwater vehicles (AUVs), remotely operated vehicles (ROVs) and even aerial drones (UAVs).

The results

Today there’s a wide choice of USVs to choose from. From one-man portable USVs to full sized vessels, and on to fully electric coastal systems and hybrid long-range ocean-going vehicles that can operate for weeks on end. The range of commercial models has also grown. You can buy them outright or purchase a data service where you just order the end result – be it data or an inspection campaign.

USVs can now play a central role in construction operations. They can streamline operations and reduce risk for manned offshore construction teams. When deployed they reduce reliance on heavier, costlier tools and free-up crewed assets to be used on elements of a project where they’ll bring more value.

How to optimise carbon storage monitoring with marine robotics

For a long time, while carbon capture and storage (CCS) in offshore underground reservoirs had been widely regarded as a major way to reduce carbon emissions, it failed to attract the up-front investment needed to make it work. That’s now changing.

The challenge

In today’s far more climate conscious world, sentiment and interest in CCS has very much changed. Significant projects are now being planned. Projects are moving forward in Norway, Netherlands and the UK. Carbon storage licenses are being awarded and wells are being drilled specifically for carbon capture and storage.

Since 1996, CCS projects have been relatively small, yet their potential is vast. On the UK Continental Shelf alone there’s at least 78 gigatonnes of CO2 potential storage capacity – some 200 times the UK’s 2016 emissions*.

From capture to transport by pipeline and injection into a suitable geological formation offshore, there’s a lot to process. But the challenges do not end there. What happens to the CO2 once injected? How will we know if it finds a leak path to the surface?

To answer these challenges and achieve the visions that operators from Equinor in Norway to BP in the UK are promoting, increased capability for marine robotics is required.

The solution

Thanks to the Energy Technologies Institute (ETI) funded three-year research programme back in 2014, this challenge for increased capability of marine robotics has been attained. The project was delivered by a consortium of experienced companies including Fugro, National Oceanography Centre (NOC), British Geological Survey (BGS), Plymouth Marine Laboratory (PML) and ourselves, Sonardyne.

Along with increasing the capability of marine robotics for successful CO2 storage, four key technology elements for large carbon storage and monitoring projects were identified.

The first is a low-power and hence long-endurance autonomous underwater vehicle (AUV). This is required for cost-effective wide-area coverage surveys during baseline and repeat environmental surveys. We found using a combination of our Solstice side scan sonar and chemical sensing worked extremely well.

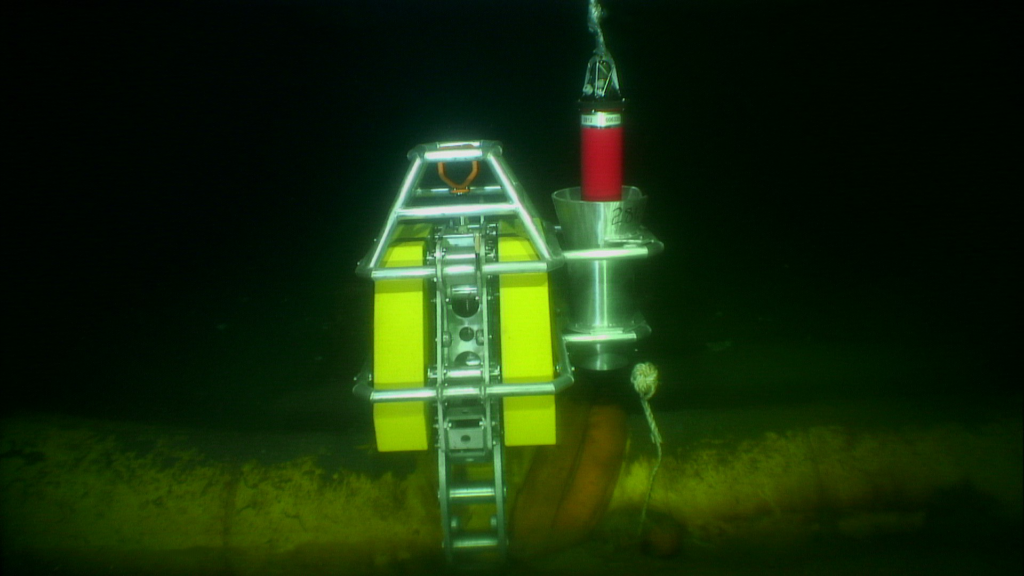

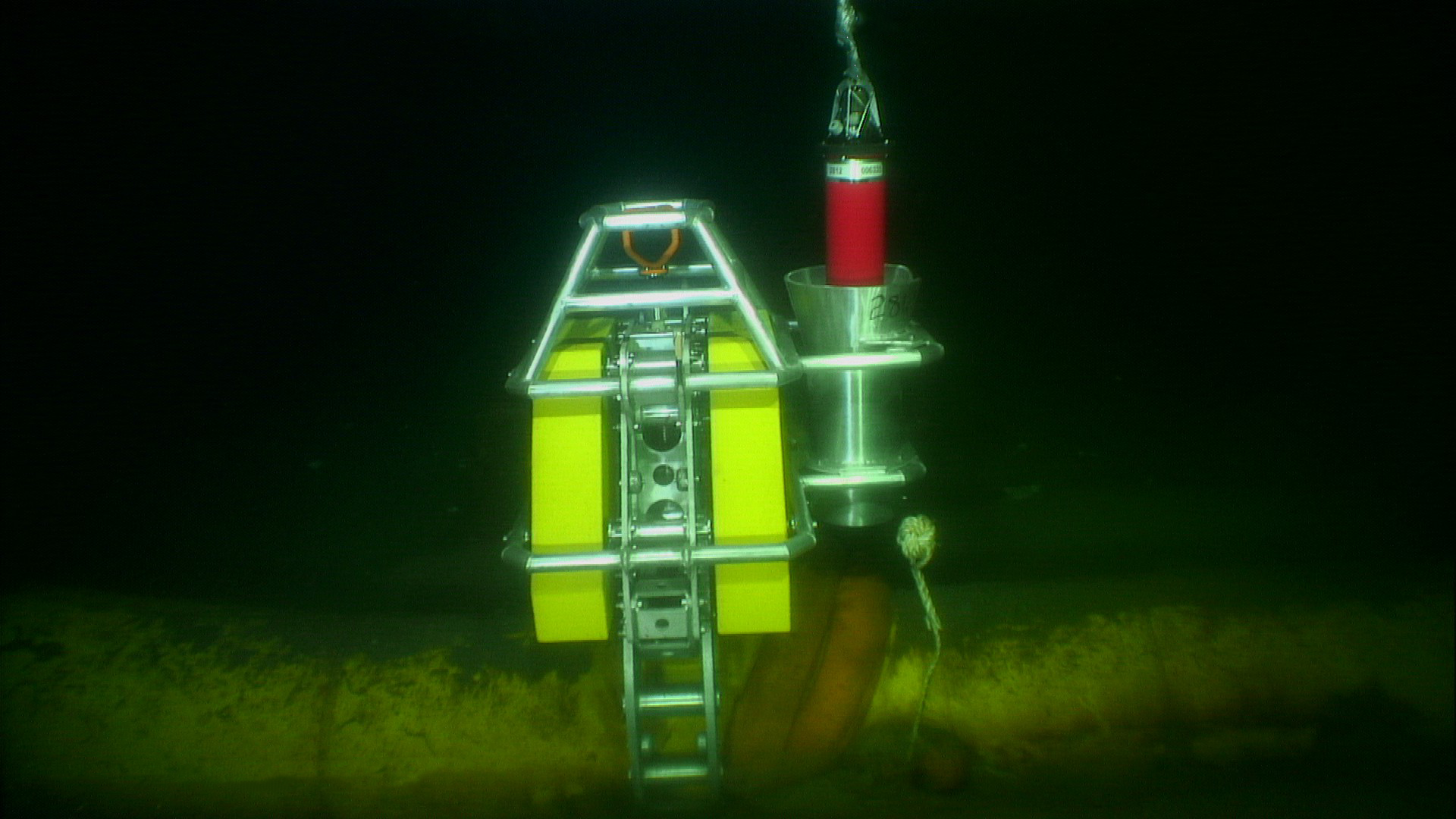

Second and third elements are seabed landers capable of detecting and monitoring any leakage at high-risk locations. These consist of two different landers, one using an active sonar and the second combining passive sonar and chemical sensing.

The active sonar lander, based on our Sentry integrity monitoring system (IMS), gives sensitive and reliable automated leak detection capability across a wide area. For instance, around an injection well, Sentry can monitor an area of over 2.3 million square metres, to help visualise that’s equivalent to around 325 football pitches. The passive sonar and chemical lander, uses the smarts from our underwater acoustics capabilities. It’s capable of both detection of leaks, but offers improved verification and has the potential to estimate leak rates at shorter ranges.

The fourth and final element is a surface gateway to enable communication between a shore-based monitoring office and the underwater systems. Such a gateway can be deployed from a fixed platform, from a moored buoy or from an uncrewed surface vessel (USV), many variants of which are now readily available in the market for over-the-horizon data harvesting missions.

We have a range of payloads suited specifically for use on operator’s USVs for their requirements. We also offer our own end-to-end data-harvesting service, when you just want the data without the worry about the interfaces involved in getting it.

Our system of systems approach to CCS was tested on the ETI project. Wideband acoustic communications between the underwater landers and a buoy on the surface was used to forward all data via satellite communications to a server. This type of set-up is well-proven and used globally on tsunami monitoring systems. Display and interpretation of the monitoring data can be simply integrated into a third-party system to allow non-expert users access via a web portal. From here they can see data visualizations and run reports.

The leak target was deployed in the North Sea, east of Bridlington. The NOC’s Autosub Long Range (ALR) was deployed from the small port at Bridlington and towed a short distance off the coast. After the ALR performed a series of tests to demonstrate safe navigation, the leak – a small CO2 leak – was turned ‘on’ with a flow rate of between 16 and 20 litres per minute of gas at depth, depending on the state of the tide.

With the leak “on”, ALR performed a series of different wide-area and fine-area search patterns over five days to seek out the leak. The sensor hub on the vehicle processed in real-time a complex set of Solstice sonar, physical and chemical sensor data, into useful information.

Automatic target recognition algorithms were used to identify any leaks or regions of interest. The system then scored these regions of interest and saved a small “snippet” of the sonar image data. At regular intervals throughout the survey, ALR would surface and send back data via satellite, including navigation data, chemical and physical sensor data and details of snippets of sonar data from detected leaks – an example of which can be seen below.

All of the uploaded data was simultaneously transferred to an internet server which allowed for presentation and interpretation using Fugro’s Metis software. This is an intuitive data delivery platform that allows metocean, vehicle navigation, chemical and sonar snippet data to be combined and displayed. This allowed data sharing across a wide team and supported operational decision making.

During the five days of testing, the ALR travelled a total of 270 km and could have surveyed 54 sq km of seabed in normal operation. However, for the purposes of the demonstration, a total of 16.1 sq km was actually surveyed. Throughout its mission, the ALR was remotely controlled from the shore, mostly from the NOC’s control room in Southampton.

The results

The ETI project consortium demonstrated a functional “system of systems” which can provide operators of offshore CO2 storage sites with a high level of confidence in their safe operation and assist in the provision of regulatory compliance.

We’ve proven it is possible to conduct shore-to-field-to-shore environmental survey operations using a long-endurance AUV. We’ve also shown it’s more than possible to operate well in excess of normal AUV deployments.

This method of working makes it possible to rely on a small local deployment team for CCS projects. The small team can then be supported by remote shore-based operations and a data interpretation team. This cuts both the time and cost of CCS operations considerably.

It is also entirely possible, and has been demonstrated elsewhere, that a further reduction of human decision making can be achieved to reduce operator intervention.

The ETI project demonstrated that it is possible to build highly cost-effective and autonomous sensing systems with on-board intelligence. These systems are both simple to deploy and operate and are very cost competitive with vessel-based or vessel supported AUV survey operations.

The project members have also developed two flexible seabed lander packages capable of extended duration deployments of six months to a year. These can provide localised and still also wide-area monitoring, automated processing of data subsea and communication of that information to surface.

Looking beyond carbon capture, the potential applications of such integrated marine robotic and intelligent remote sensing technologies are many and varied across ocean science, renewables, security and naval domains.

6G modems make the connection between data and decisions

Two years ago Shell Exploration and Production (Shell E&P) approached Metocean organisation RPS Evans Hamilton Inc to expand the capabilities of their service to measure seabed current profile data at the Walker Ridge area in the Gulf of Mexico.

The challenge

Operations in deep and ultra-deep water (6,000 to 10,000 feet) are challenging for drilling, construction and pipeline installation. These challenges can be made safer and more efficient through a good understanding of subsurface current patterns. For this to be effective, wireless transmission of observations to the surface are essential for instant analysis.

This type of data is usually obtained using acoustic Doppler current profilers (ADCPs) mounted near the surface looking down through the water column. As operational depths increase, a second ADCP, placed on the seabed looking-up, provides the additional data.

The most common approach involves deploying the second ADCP for several months at a time. This is set to log bottom currents at intervals from minutes to hours. While this data is extremely useful for site surveys and planning exploration activities, the delay between collection, instrument recovery, download and analysis, means its usefulness is limited. Particularly when needed for supporting on-site decision making during operations (including complying with government directives). A faster way to retrieve the data collected by the ADCP is needed.

The solution

An acoustic modem directly connected to the ADCP provides a cost-effective and increasingly popular option for providing instant access to the data collected. The modem enables access to the data from almost anywhere in the world.

But not all acoustic modems are made equal. It’s vital to make sure when choosing one for use in an application such as offshore drilling, the signal processing and error correction techniques reliably deliver critical data payloads over long distances and, if needed, through acoustically hostile transmission paths.

RPS Ocean Science identified Sonardyne’s 6G (sixth generation) wireless communications platform as the optimum solution. 6G has an enviable reputation across the region. Today it’s the only acoustic technology to have been proven as a successful monitoring solution during a well containment situation.

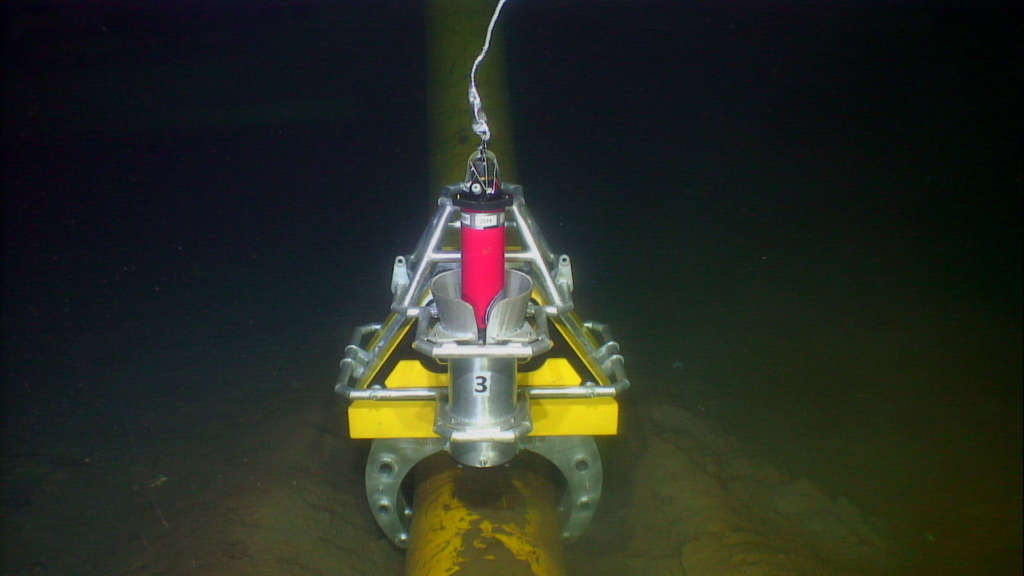

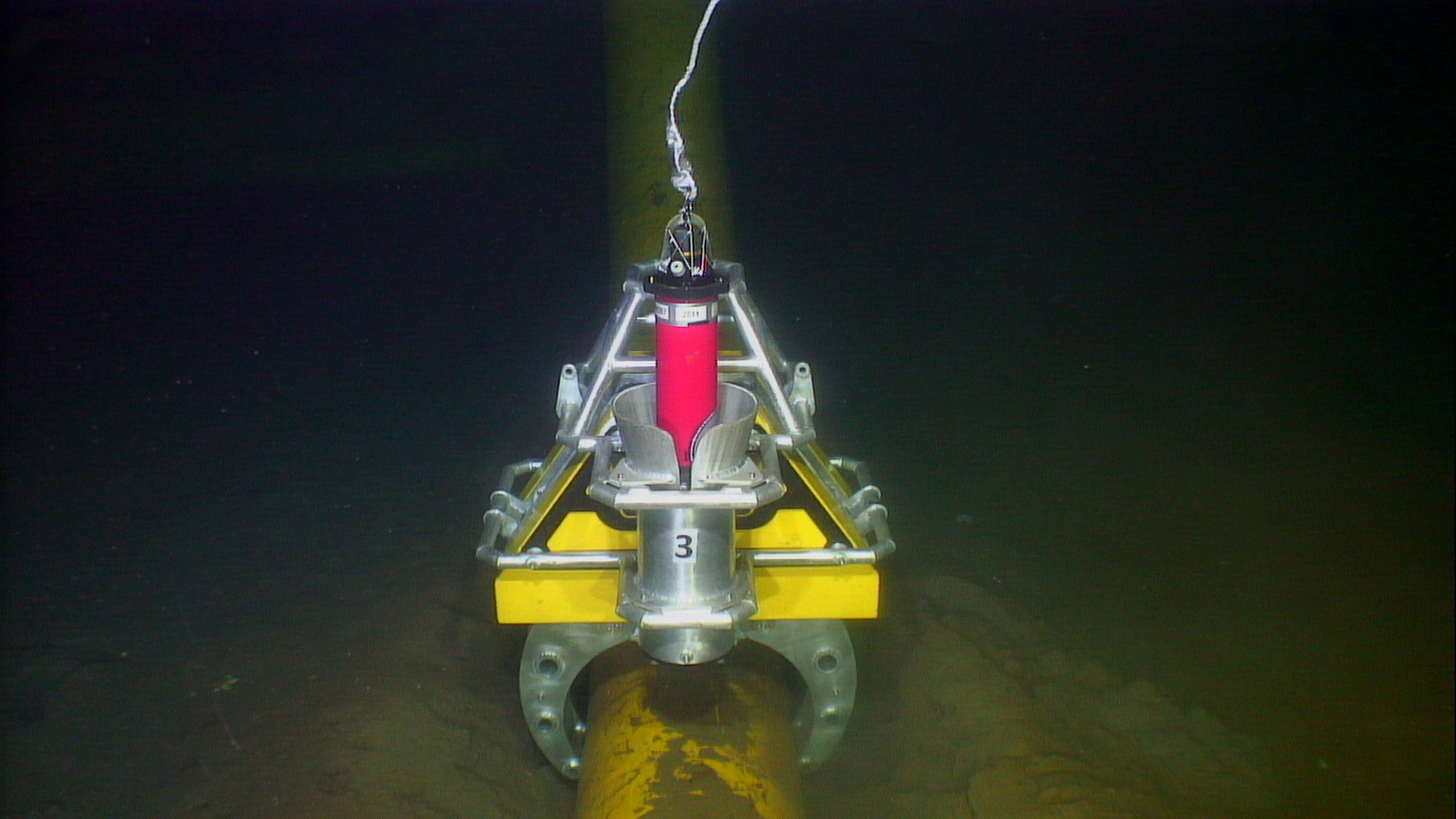

The seabed component of the monitoring system incorporated a Sonardyne Compatt 6 telemetry transponder interfaced with a Teledyne RDI Workhorse 300 kHz ADCP. These were mounted together in a deployment frame. 10,000 feet above, a Sonardyne HPT modem deployed from the rig acted as the surface receiver. It was enclosed within a rugged cage to protect it during deployment and recovery phases, and weighted to prevent drifting in high surface currents.

The HPT was integrated with the data collection system RPS Ocean Science had previously supplied to the rig, this included a 38 kHz ADCP at the surface and load handling system. The Compatt 6G modems and ADCP were deployed by ROV on the seabed at a depth of 9,970 feet, approximately 150 feet away from the rig’s BOP.

After establishing reliable seabed to surface communications, data collection was initiated. The acquisition system is designed to receive and display data from the surface and bottom ADCPs at 10 minute intervals.

Modem 6

0

m

operating depth

0

bps

acoustic comms

The results

Following initial system deployment, the signal analysis tools built into the Compatt 6 and HPT enabled the bidirectional communications link to be optimised for the local conditions. This resulted in highly reliable and low latency data return rates.

Water velocity profiles were generated from approximately three metres to 100 m off the seabed. The profiles were composed of 50, two metre bins. Data was averaged over 75 seconds at a 1 Hz sample rate. Velocity and direction profiles were processed by the subsurface instrument and transmitted to the rig’s data acquisition system where profiles were displayed, along with the velocity and direction profiles from the surface ADCP, on the platform bridge.

The data has been utilised by the metocean team to support exploration operations in daily advisories as well as providing a unique perspective on potential Topographic Rossby Waves thought to be a common feature in the area. Processed data files were also transmitted to our client’s shore-based server and the National Data Buoy Center (NDBC) in near real-time.

A demonstration of the system’s capability took place during the summer of 2015. Since then, the RPS-Sonardyne solution has proven to offer reliable self-contained operation with long service intervals. The configuration of the upward looking ADCP and Sonardyne 6G digital modem technology perfectly complements conventional near-surface and mid-column current monitoring. It also contributes toward lowering operational risk and increasing the safety of drilling, survey and ROV operations in deep water.

Trendsetter Vulcan Offshore uses a SMART solution to monitoring wellhead fatigue

The challenge

An operator wanted to cost-effectively drill a subsea side-track on an existing subsea well to increase reservoir recovery to a floating production facility in 150 m water depth.

That meant drilling from the existing well bore. However, there were concerns that the remaining fatigue life of the existing wellhead would be quickly consumed under the load and strain imposed by the physical size of the current generation of blowout preventers (BOPs) operating from a semisubmersible drilling rig.

A system was required that would significantly reduce the fatigue loading on the wellhead during the drilling operation.

The solution

Houston-headquartered engineering specialist Trendsetter Vulcan Offshore (TVO) provided and deployed its tethered BOP Wellhead Fatigue Mitigation System. Key to the system is our Subsea Monitoring, Analysis and Reporting Technology (SMART) and our Dunker 6 telemetry transceiver deployed temporarily from the vessel for the project.

TVO’s system alleviates the impact of a larger BOP on wellheads by arresting the motion of the BOP stack via four tethers, anchored to the nearby seabed. This reduces wellhead cyclic stresses and extends fatigue life, for both mature and newer wellhead systems.

To ensure safe operation within fatigue limits of the well system, any movement of the BOP and the lower drilling riser is monitored using our SMARTs. In this case, two were installed – one on the BOP and one just above the lower marine riser package (LMRP). They were used not only to monitor the movement of the BOP and bottom of the drilling riser, but also the angle between the two.

Value adding edge analytics

The SMARTs also provided onboard data processing so that just summary packets of information (minimum, maximum and standard deviations), for both rotation and acceleration in all axes were supplied wirelessly, every 15 minutes, to the topside via the Dunker 6, which was deployed from the semi-submersible drilling rig.

Transmitting the processed data alone helps to reduce data overheads and prolong battery life. This is because less data needs to be transmitted to the topside software, which results in the information being transferred and updates performed at a fraction of the time compared to raw data transfer.

At the topside, the data was put through TVO’s fatigue analysis software, installed on Sonardyne’s topside computer for the project, which included algorithms developed by TVO to determine fatigue damage accumulation based on measured motions. The results were then transferred into a 4D Nav user interface dashboard, where the data was displayed. This meant the drilling crew were able to be constantly aware of the fatigue load on the wellhead during their drilling program.

Post drilling, the operator was able to download all the raw data gathered for in depth analysis and calculation of the wellhead’s remaining fatigue life for its future operations.

The results

Combining TVO’s experience within this domain with our broader subsea engineering, communication and positioning technology expertise provided an off-the-shelf solution that could be tailored for this application and would be equally applicable for more complex scenarios.

There is a growing need for BOP fatigue mitigation systems globally, but especially in those markets where there are mature subsea wellhead systems, and this system provides an effective and proven solution.

SMARTs are highly configurable, low-power monitoring and analysis platforms that come with internal six degrees of freedom motion sensors. Get in touch to find out how they can aid your operation.

Rewriting the subsea survey rules

The underwater survey and construction sector is necessarily risk-averse. The potential negative impact from downtime, rectification events or environmental damage caused by changes to procedures and methods can be burdensome. The result is a preference for tried and true methods, techniques and equipment.

The challenge

In recent years, different combinations of subsea positioning technologies have been used in support of survey and construction projects. Whilst delivering an incremental improvement, they have also resulted in increased complexity in integration and operation. Separate inertial navigation systems (INS) and Long BaseLine (LBL) solutions require integration via online navigation software. Along with this, there is the added complication of the physical mounting, calibration and interfacing of INS and Doppler velocity logs (DVL) on remotely operated vehicles (ROVs).

The increased complexity adds cost in training and support, as well as increasing risk through having to control many separate parts from different vendors.

There is clearly a need to be smarter and more efficient. Reducing vessel days increases safety and lessens our environmental footprint. There is no need to lose the accuracy or reliability of subsea positioning or increase the complexity of operations either. If both the number of Compatts needed for an LBL pipeline installation array and calibration routine could be reduced, days – not just hours – of vessel time would also be lowered as would the entire complexity of such projects.

The solution

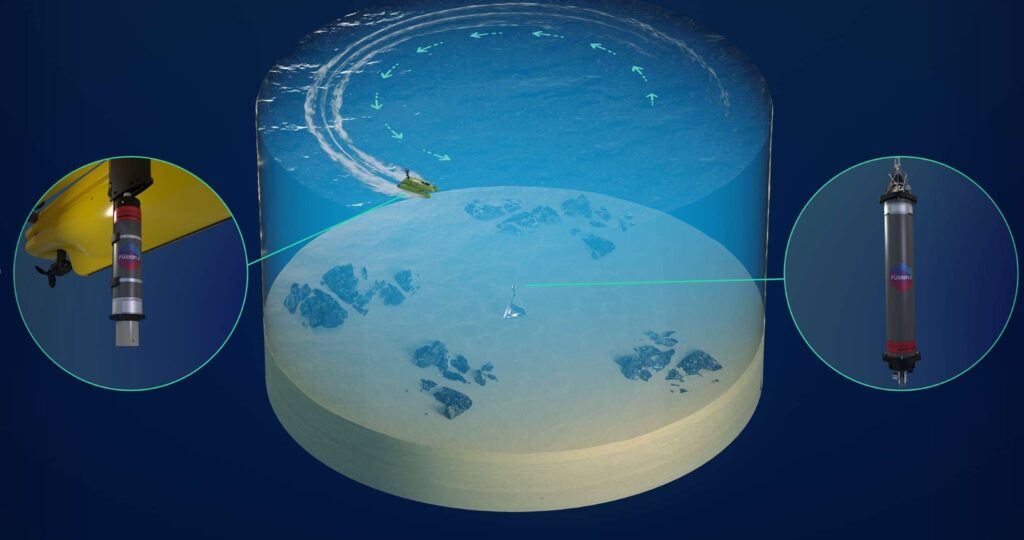

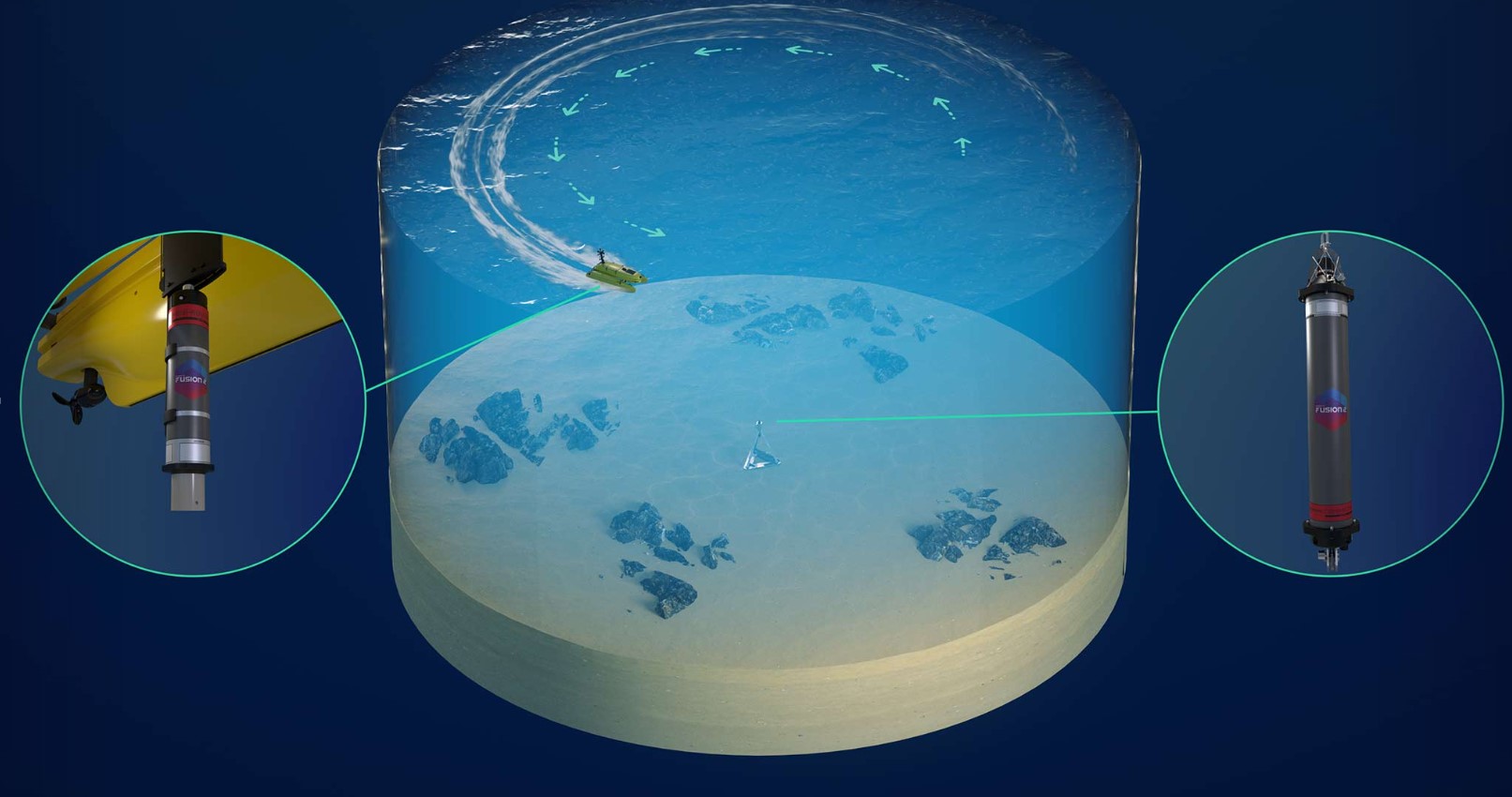

i-Tech 7 adopted our Fusion 2 all-in-one software platform for their INS and LBL operations.

This allowed them to take advantage of the Fusion 2’s real-time simultaneous localisation and mapping (SLAM) capability. Choosing to operate a sparse LBL can deliver a reduction of Compatts. However, if the sparse array cannot be calibrated using traditional LBL baseline calibration, the benefit may be lost. Extra time for performing additional ‘box-ins’ or collecting data to perform post processed SLAM positioning of the Compatts becomes necessary.

This isn’t the case with real-time SLAM. The number of Compatt transponders used to create the ‘sparse’ LBL array is reduced and the calibration of those Compatts is managed by flying the ROV through the array and acquiring the necessary observables to SLAM the array. With careful planning, this real-time SLAM process can be done during other ROV survey operations, such as pre-lay surveys. This removes the entire baseline calibration work flow from the project schedule.

Co-locating our SPRINT INS with a separate DVL onto i-Tech 7’s ROVs was the first step in reducing the complexity of these operations. Using SPRINT enabled the optimisation of sparse LBL operations, reducing the number of Compatts required for an LBL array by 50-66%, with the post-processing SLAM calibrations being managed by us.

The SLAM calibration technique was run alongside arrays with full LBL sections and sparse LBL arrays which were SLAM calibrated. When results were compared they showed centimetric agreement, proving real-time SLAM gives near traditional LBL levels of precision and accuracy.

All the experience and knowledge gained since i-Tech 7’s first use of our SPRINT INS in 2012 has enabled us to build SLAM calibration routines directly into Fusion 2. That step has taken the simplification to a new level. Real-time SLAM operations in i-Tech 7’s 2019 project have far more efficient trajectories than previous operations.

The results

Between August and November 2019, a minimum of 11 vessel days were saved across five separate i-Tech 7 deep water (1,000-1,500 m) projects in the US Gulf of Mexico. Thanks to Fusion 2’s real-time SLAM capability, operators were able to access first oil faster.

Having already reduced the number of Compatts needed for an array – by reducing how much time is spent deploying them and calibrating them – the time allocated on project schedules for the lengthy box-in routines required in a traditional array can also be reduced, if not completely negated.

In fact, following a pre-lay survey, an offshore manager asked one of i-Tech 7’s offshore surveyors how long the array calibration would take before pipelay operations could start. The answer? It had already been done.

i-Tech 7 and Subsea 7 have proved the simplification of pipeline installation projects can be smarter, more efficient, quicker and safer. What’s more, they help lessen the overall environmental footprint of major subsea installation projects. This can all be done without losing positioning accuracy or reliability.

Seismic operations in the transition zone

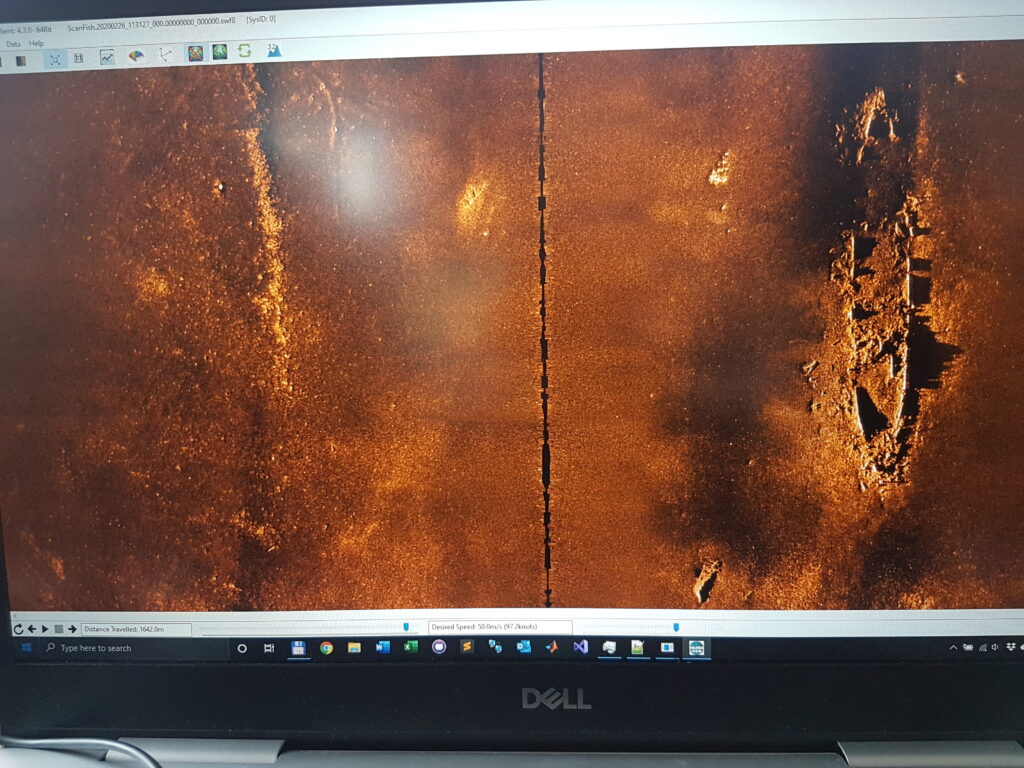

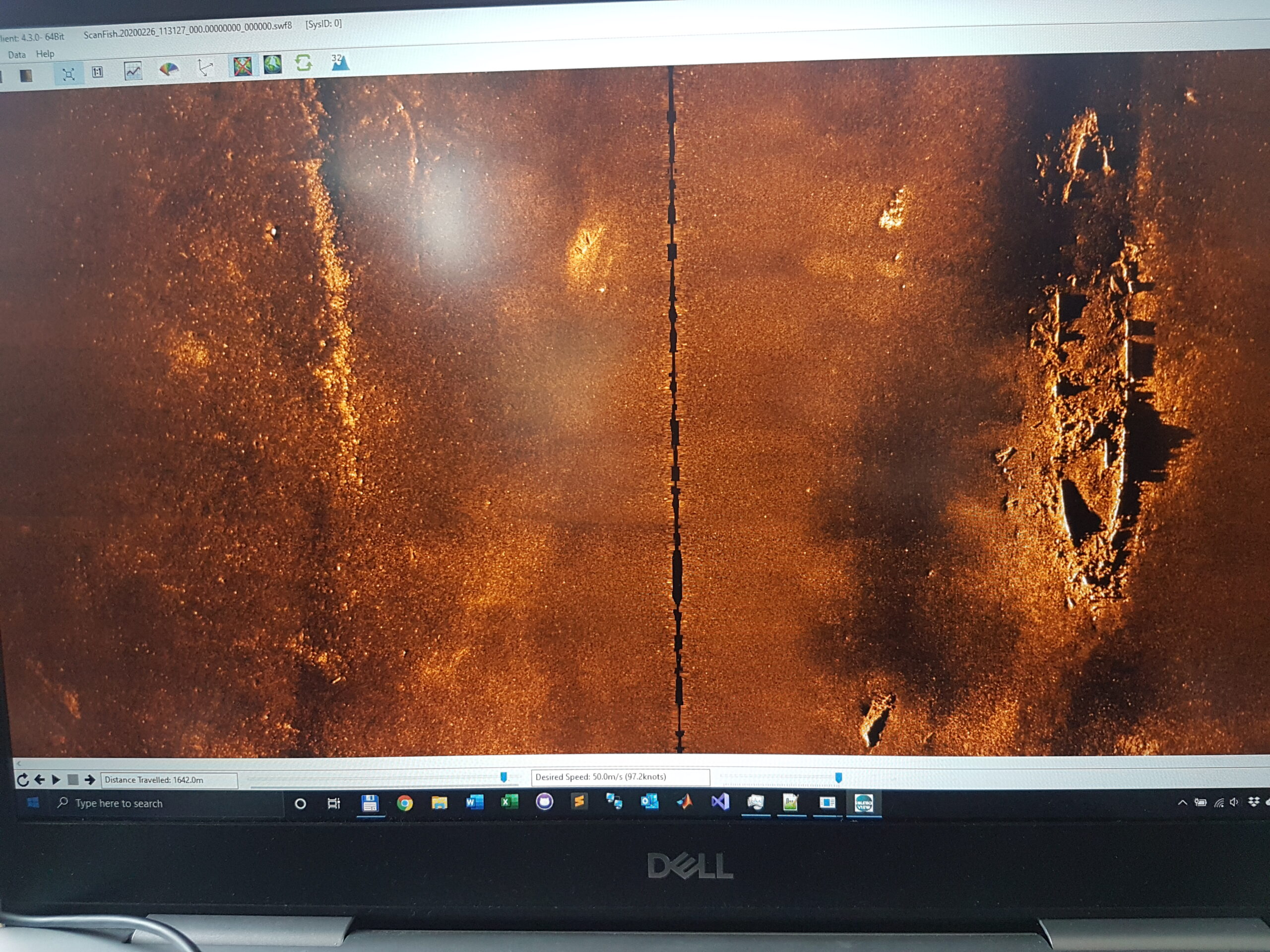

When seismic operations move into very shallow waters, accurately positioning seismic nodes or ocean bottom cables (OBC) on the seafloor can pose a challenge.

The challenge

The transition zone environment is often highly reverberant, the vessels used are often noisy and they can be a considerable distance from the acoustic transponders used to position the nodes. What’s more, shallow water makes nodes especially prone to movement, adding a further complication to proceedings.

Repeated node positioning operations conducted from vessels are costly and time consuming. Noisy environments can inhibit the quality of information and manned vessels are a costly option for completing work that can be done remotely.

The solution

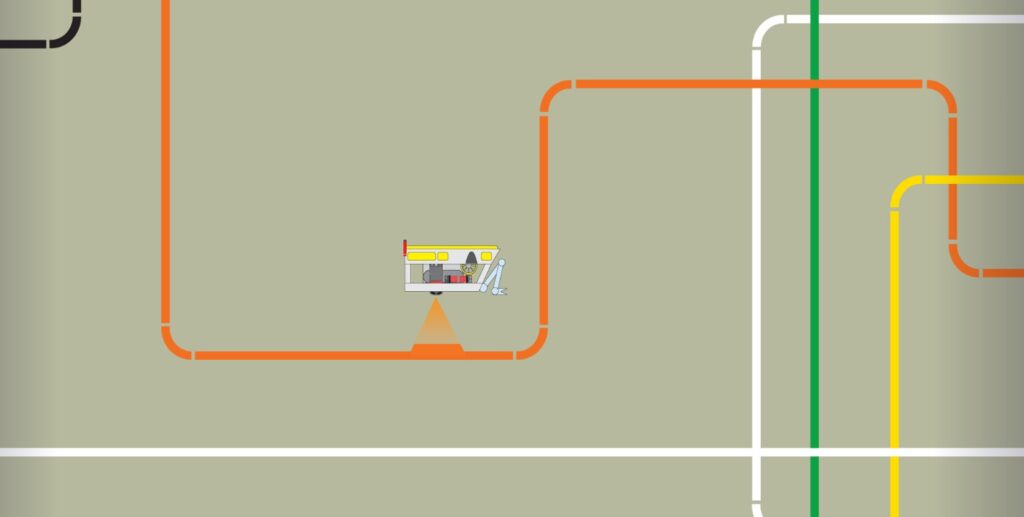

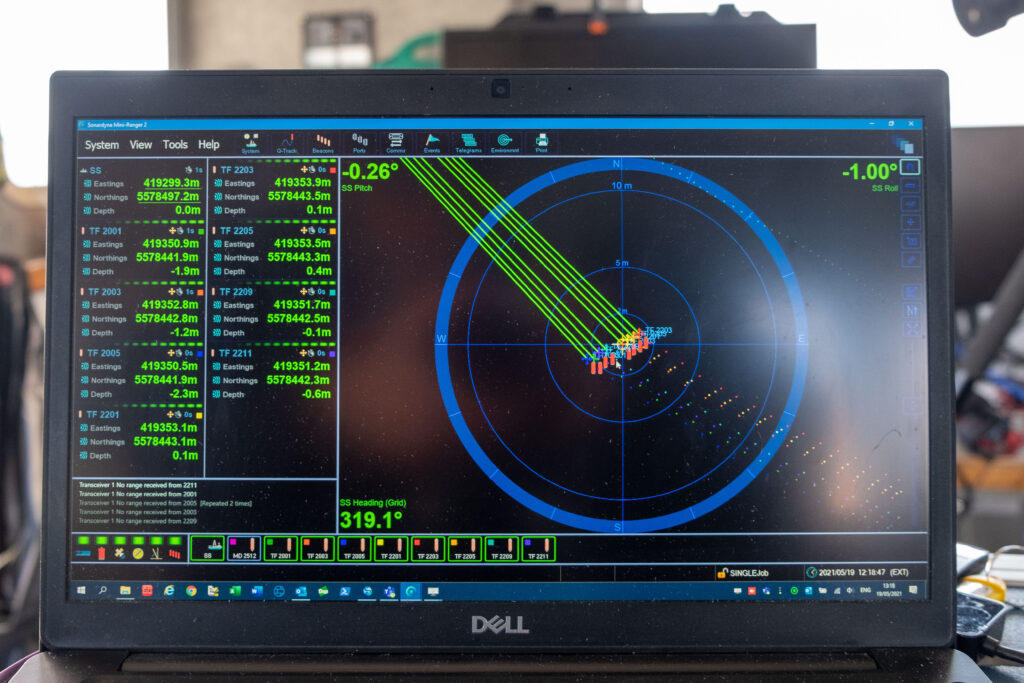

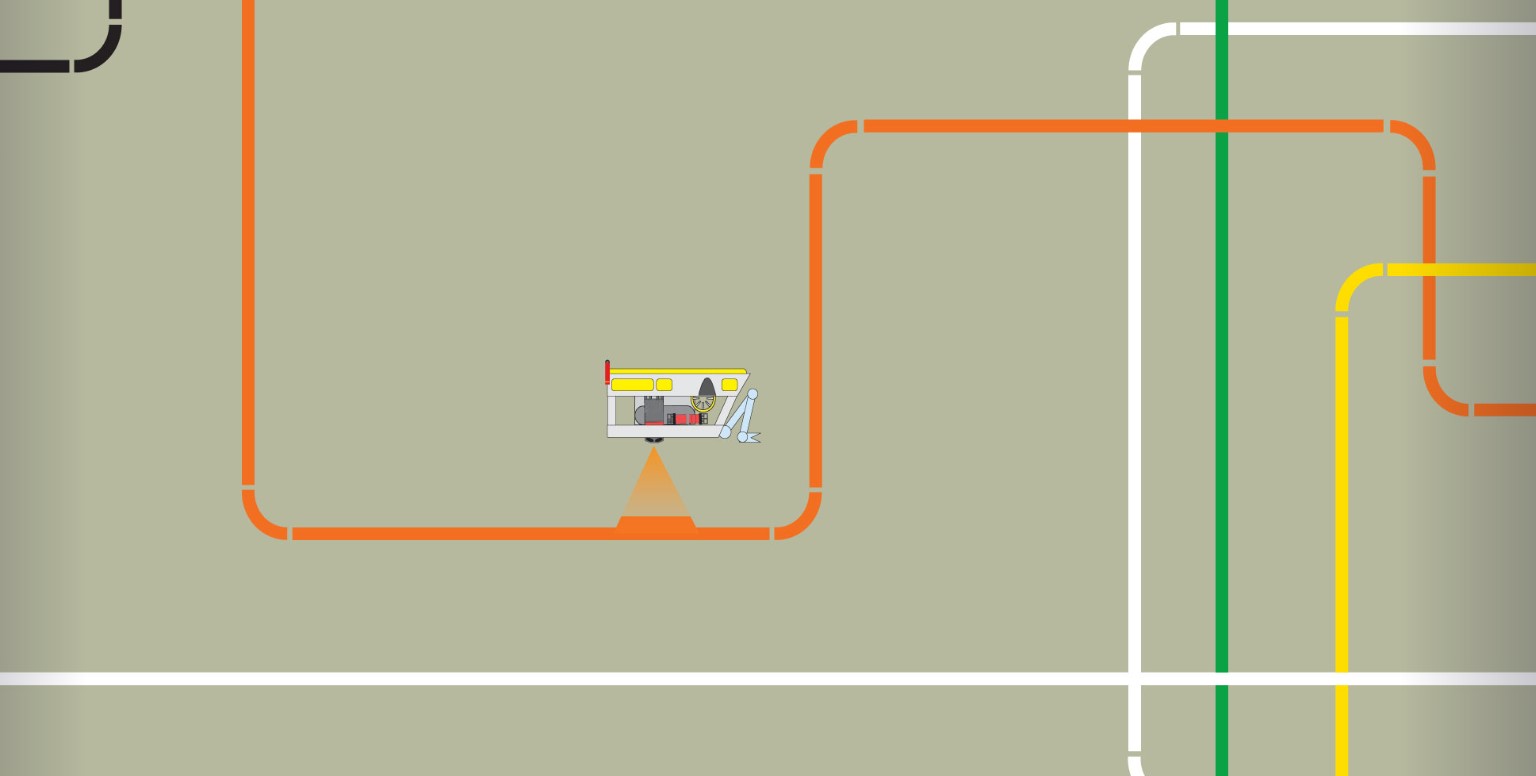

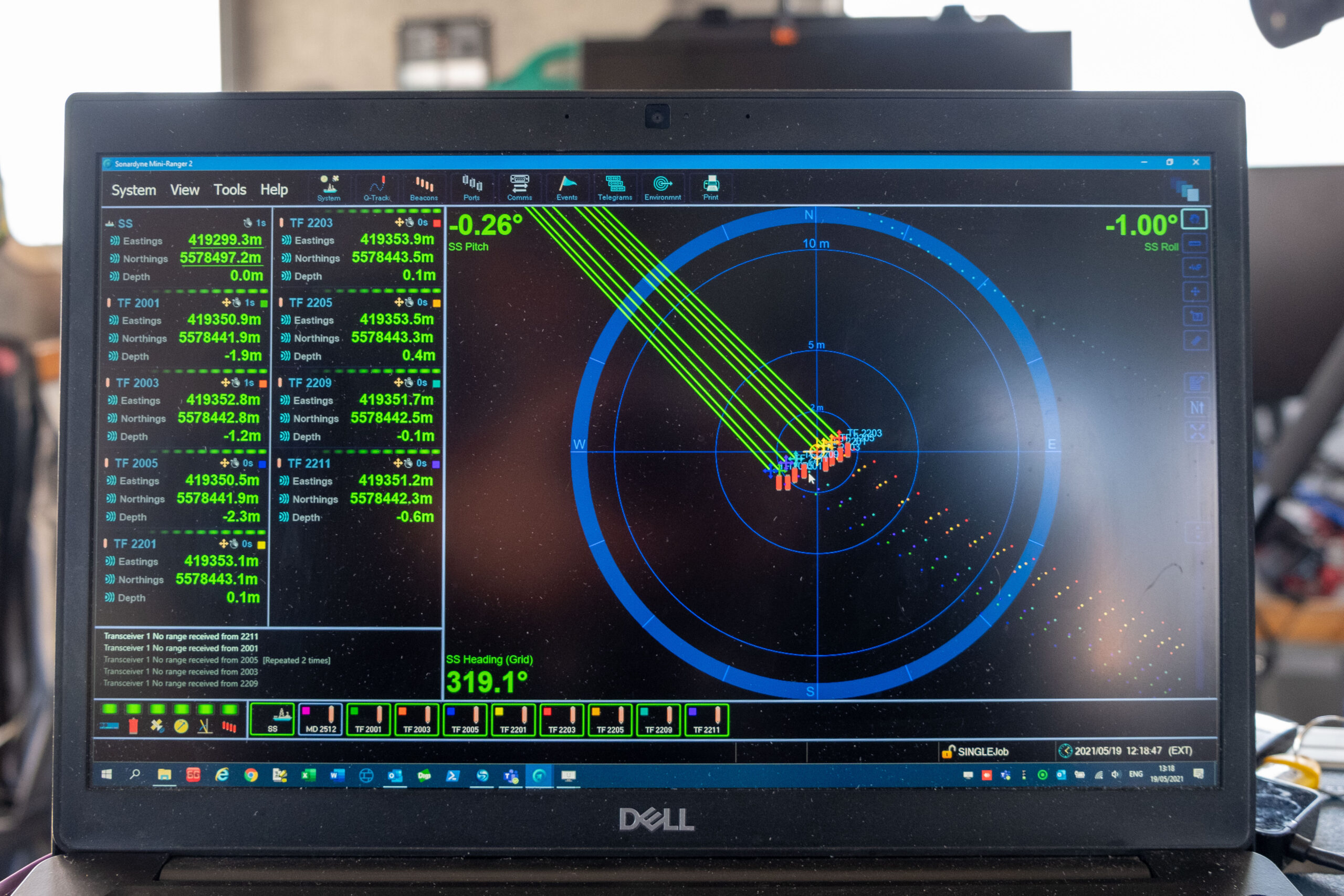

To solve these issues, Sonardyne has created our TZ Transceiver. It’s very compact and simple to operate. Ideally suited to installation on manned workboats and USVs, it’s already being used for conducting acoustic positioning operations with seismic nodes deployed in the transition zone.

The TZ Transceiver works by collecting hundreds of acoustic ranges from transponders such as our TZ/OBC, TZ Transponder and Small Seismic Transponder 6. These are often attached either directly to the seismic node or to a deployment rope nearby. The ranges are merged with the vessel or USV’s GNSS data so that an accurate position of each node can be calculated.

Mounting our TZ Transceiver onto a USV is ideal because it can follow the mother vessel autonomously and position the nodes as they are being deployed. Alternatively, it can be tasked to perform a position verification check to ensure the nodes have not moved.

The results

Fitting a TZ Transceiver to a USV such as the installation on Maritime Robotics’ Mariner USV is a very cost-effective force multiplier. The addition of the transceiver eliminates the need for a manned vessel to conduct the same routine operations.

Weighing in at 1,900 kg, Mariner is 6 m-long, 2 m-wide. It includes a moon-pool and an elevator mechanism for sinking and lowering sensors, such as our TZ Transceiver.

The vehicle is designed for both offshore and coastal applications and can be deployed and operated from a larger manned vessel or even over the horizon from a shoreside office. This increases the productivity of the existing survey crew as well as the overall profitability of seismic operations.

Deepwater data analytics – asset monitoring at the edge

Thousands of kilometres of pipeline, flowline, and interconnecting spool pieces are installed on the world’s sea and ocean floors. They create vast networks and their design can be complex, having to account for a huge array of variables, from water depth to expected flow composition and behaviour.

The challenge

Sometimes, it’s not always possible to account for all of the variables that an oilfield infrastructure is subject to. This can lead to issues. External vortex induced vibration (VIV) or internal flow induced vibration (FIV), which can sometimes be caused by slugging. Slugging is created by variable or irregular flow of gas and fluids through risers, pipelines, flowlines or spool pieces.

These issues can cause problems for process equipment, impact production efficiency and, critically, accelerate pipeline fatigue. This has knock-on effects for design life. It can even cause pipelines to be displaced, entrenched or erode the supports they stand on.

When FIV occurs, pipeline engineers need all the information they can get about just how much this is happening and to what degree. This enables them to re-calculate the remaining fatigue life of the infrastructure and decide on the best remediation methods. Unfortunately, monitoring exactly what is happening – what forces the pipelines, flowlines or spool pieces are being subjected to – can be challenging, especially in deep water.

International subsea engineering company Oceaneering International Inc. was asked by an operator to solve this exact problem. They had a number of spool pieces deployed in more than 1,000 metres of water, running between riser bases and flowline termination assemblies. They were being subjected to sudden and frequent slugging movements.

These movements had already resulted in new spool piece supports having to be installed. The operator’s engineers needed to assess the resilience of the new supports and learn more about the vibration the spool pieces were encountering. The challenge was that no motion monitoring sensors had been fitted prior to commissioning. The solution would need to provide accurate and accessible data using a technique that was not cost-prohibitive to install and operate.

The solution

Oceaneering’s solution used an innovative, wireless approach with Sonardyne’s Subsea Monitoring, Analysis, and Reporting Technology (SMART) sensor as a key element of the project.

SMART sensors are, well, smart. They contain low-power MEMs-based (micro-electric mechanical systems) inertial measurement units (IMUs), subsea processing power and integrated acoustic modem capabilities. This means they can autonomously measure, log and process high-frequency, pipeline or spool piece acceleration and angular rate motion over pre-programmed monitoring intervals.

Importantly, SMARTs, which can be integrated with many different subsea sensors to suit a wide variety of applications, process data at source. This is then sent as small statistical summary packets of data – based on parameters set by the user – through the water column to a surface transceiver. This method reduces the need to send time-series, or raw, data up to the surface for analysis, which prolongs battery life, maximizes bandwidth availability and provides useful information to engineers faster. It’s edge analytics and subsea communication technology in one battery-powered autonomous compact unit. And it’s able to work on extended deployments down to 7,000 metres water depth.

For the high-frequency motion, SMARTS were installed on each spool piece at a location between the riser and flowline termination assemblies. To monitor lower frequency movement on one of the spool pieces, another Sonardyne technology was used: Autonomous Monitoring Transponders(AMTs).

AMTs are most commonly used for long-term survey and monitoring tasks where instruments are needed for acquiring acoustic ranges and sensor data without surface control. They time-stamp data and log it internally, to be retrieved when it’s needed at the surface.

By creating a Long BaseLine (LBL) array of “static” AMTs, to which “mobile” AMTs installed on a spool piece and fitted with sound velocity sensors can range, highly precise measurements of any horizontal movement of that spool piece can be monitored and logged. By fitting the mobile AMTs with Digiquartz pressure transducers, vertical motion could also be tracked accurately within the array.

Before installing the SMARTs and AMTs, Oceaneering surveyed the seabed location. This was done to determine the LBL array design and SMART and mobile AMT positioning. Oceaneering designed and built ROV-installable spool monitoring clamps. This allowed the SMARTs and AMTs to be easily attached to the spool pieces. For the LBL array, four AMTs were placed in tripod stands at predefined locations for optimal ranging.

Following installation, confirmation that all the SMARTs and AMTs were working and a post-installation survey, the autonomous and intelligent instruments were then just left to do their work. A huge benefit of both instruments’ design is that they can be left unattended for three years thanks to their internally monitored lithium primary cells.

Anyone with these instruments deployed in their field has a choice in how to collect the data generated. If it’s close to a topside facility, they can deploy a Sonardyne Dunker 6 transceiver permanently, via a deployment pole for the duration of the monitoring, or temporarily over-the-side, via a winch or A-frame.

If the subsea infrastructure is more remote, they could periodically send a support vessel or an unmanned autonomous surface vessel with a Dunker 6 to harvest the data. For this project, while the site was deep, it was close enough to the customer’s production facility. Oceaneering chose temporary deployments, using the Dunker 6 from an onboard crane, as and when data collection was required.

The results

Since commissioning in the summer of 2018, continuous SMART monitoring of the spools, at four-minute intervals has taken place. Packets of data from both SMART and AMT devices, including raw runtime data, have routinely been sent to the surface. Once received, it has been analysed and used in predictive modelling. This has enabled the operator to calculate the accumulated fatigue and remaining operational design life of their assets.

Gaining access to the spools’ motion characteristics has been invaluable to the operator. It’s data they would have been expensive to access through other means. It has led to a deeper understanding of each spool’s motion frequency, rotation angles and cycle times. Where previously the operator had concerns about the remaining operational life of the spools, they now know the operational life is within the limits of the productive life of the field.

This is a great result for the operator, but also for Oceaneering and Sonardyne. By working together we were able to find a cost-effective and viable solution for the operator and future customers with similar challenges. By combining our expertise and flexible instruments as an integrated solution, the supply chain is able to tackle operators’ deepest challenges, quite literally.

Long ROV excursions, high elevation tracking, noisy waters – not a problem

As it stands, underwater positioning is not always easy. But some environments – like shallow waters – are more challenging than others. If you don’t have good subsea positioning accuracy, you won’t have a good baseline or repeatability for comparing new survey data with old.

The challenge

Recently, our long-term customer, CCC, was engaged to carry out subsea pipeline external inspections offshore the United Arab Emirates.

It was a periodic integrity survey of an operator’s pipeline network, some of it dating back to the 1960s and 1970s. The subsea inspection campaign amounts to approximately 2,000 km of pipeline inspection distance, covering 316 pipelines over various offshore fields.

In the past, baseline data could be three metres out – and that was acceptable. Now, more than half a metre is unacceptable and repeatability is key for creating a solid baseline that can be matched for future surveys.

The main challenge for CCC was the shallow water the pipelines are situated in – as little as 5.5 m depth and not more than 30 m. Added to the shallow water complications were the length of the ROV excursions. For safety reasons, their ROV sometimes had to navigate more than 70 – 100m away from the vessel and its transceivers.

When conducting operations in shallow water you inevitably put a lot of man-made noise from engines and the ROV into the water. Surface reflections and high signal to noise, also add to the potential reduction in accuracy of subsea positioning when using a USBL system.

Long ROV excursions can be inclined to become unreliable or erratic simply because of the distance between transponder and transceivers. When combined with shallow waters, further difficulties arise. The distance between the seabed, the transceiver head, the top of the beacon and the angle of the distant vessel’s acoustic transceiver complicates and interferes with the transmission of data.

The solution

The platform used to undertake the subsea external inspection was the CCC owned and operated Saab Seaeye Leopard 1706 remote operated vehicle (ROV). Fitted with three HD cameras, Valeport bathy suite, mini SVP, CP, UT, laser line generator, MCS PRC system and two Kongsberg M3 profiling sonars. The fully equipped ROV was tracked using our Mini-Ranger 2 Ultra-Short BaseLine (USBL) system from our CCC Maritime 2 multipurpose dive support vessel.

The Ranger 2 Pro USBL system is found on all of CCC’s vessels. Because of the shallowness of the water, CCC decided to use a Mini-Ranger 2, which has a beam plot that suits these needs, and Wideband Sub-Mini 6 Plus (WSM 6+) beacons, which are proven to be reliable when operated in shallow water.

But, they still needed to deal with noise in the water, which could impact their USBL effectiveness. They decided to optimise their USBL. An ROV-mounted gyro and motion sensors were added to help improve the position with pitch, roll, attitude and heading, when the USBL started to jitter. But, because they weren’t fully integrated, it didn’t really do what they needed.

Then, we introduced them to SPRINT-Nav. SPRINT-Nav is an all-in-one navigational instrument, which combines a SPRINT INS sensor, Syrinx 600 kHz Doppler Velocity Log (DVL) and a high accuracy intelligent pressure sensor in a single unit. SPRINT-Nav tightly integrates all the raw sensor data, including individual DVL beams, to provide its high performance.

One of its advantages is, with bottom lock enabled, it doesn’t matter if you lose your USBL. The integrity of the positioning solution is preserved until your next acoustic fix comes in. This had a great advantage for CCC in achieving subsea positioning repeatability and reliability.

With SPRINT-Nav 500 fitted to their Leopard, the shallow water inspections project became far simpler. CCC achieved the best of both worlds – USBL and a high-performance INS. The USBL position is fed to SPRINT-Nav from Mini-Ranger 2 and it outputs a corrected position, based on the information from its INS and the DVL.

The results

When an ROV goes on a long excursion away from their vessel now, it doesn’t matter. If the USBL tracking drops out or if it starts jittering, SPRINT-Nav still knows where it is. The survey and data acquisition team on board the vessel were amazed; straight out of the box, SPRINT-Nav kept the ROV on course.

CCC achieved survey accuracy below half a metre, thanks to the SPRINT-Nav. Excellent positioning and repeatability were obtained, a critical need for quality inspection projects. Furthermore, CCC now has full confidence in the start and end position and doesn’t even require any post-processing.

Deepwater structure installation made easy

For five decades, we’ve been working to make subsea developments safer, cleaner and more efficient than ever before. Our aim is always to mitigate risk for our partners, reduce the complexity of deepwater structure installations and increase efficiencies so projects cost less and teams spend less time offshore.

The challenge

When offshore contractor China Offshore Fugro Geosolutions (COFG) approached us looking for ways to improve the installation of multiple deepwater structures, we were excited to support their operation. The project required the installation of four pipeline end terminations. Measuring up to 15 m long, 10 m high and weighing as much as 45 tonnes each, the challenge was to accurately place each structure efficiently and reduce the time needed for the project to be completed.

These kinds of deepwater installations are usually done by installing a gyro frame and placing a subsea gyro into it, with a battery, a modem, sound velocity sensor, and maybe also a depth sensor. These then need to be wired up, turned on, and fingers crossed that it’ll all work. The various connections, components and necessary wiring between each, create multiple opportunities for things to go wrong.

The solution

Gyro Compatt 6 is a compact and versatile positioning transponder with a subsea gyro used to simplify structure positioning. From one instrument everything can be monitored and controlled from the topside using our Ranger 2 6G Ultra-Short BaseLine (USBL) positioning system or Fusion 1 or 2 Long BaseLine (LBL) software. What’s more, it’s quick to recharge on deck, making it a perfect choice for multi-structure installation campaigns.

Onboard the HSYS 201, COFG already use our Ranger 2 USBL positioning system, our Fusion LBL software and a ROVNav 6 transceiver onboard their ROV, all of which work seamlessly with our 6G USBL family of products, of which the Gyro Compatt 6 is a part.

This compact unit is much more than a positioning transponder. The unit combines an LBL transponder Wideband acoustic positioning, Lodestar attitude and heading reference sensor (AHRS), a depth sensor and sound velocity, plus an integrated high-speed acoustic modem. By combining these technologies into one small unit, a single yet highly versatile and easy to install instrument can provide high update rate wireless attitude, heading, heave, surge, sway, pressure, sound speed and acoustic positioning of any subsea object.

There is no need for the traditional gyro frame and subsea gyro technique and all the wiring and crossing of fingers that goes along with it. By deploying the Gyro Compatt 6, ranges from the LBL array can be gathered in real time by a ROVNav 6 LBL ROV transceiver onboard the ROV, and, in turn, tracked in the LBL array.

The results

With just the Gyro Compatt 6 installed and secured for structure monitoring, COFG’s installations were successfully carried out on the Liuhua 29-1 gas field development in water depths ranging from 520 m to 1120 m, between mid-October and the end of November 2019. Each of the four installations was made much easier – with reduced stress, fewer complications and in less time.

Jia Wu, Operation Manager, Engineering Survey Division at China Offshore Fugro Geosolutions (Shenzen) Co. was pleased with how their Gyro Compatt 6 performed.

“This all-in-one system offers us the biggest advantage for the operation, being easier to use, smaller in size and more efficient for preparation,” he says. “It is more convenient to secure as well as recover and does not require wiring between components, compared with a conventional gyro basket (transponder plus battery plus gyro).”

Do you need to simplify a deep water structure installation project? Speak with an expert today.

Over-the-horizon uncrewed ocean data collection

Seabed monitoring over large areas has entered the age of autonomy, thanks to a combination of our long-endurance, wireless Fetch seabed sensors and a wide choice of uncrewed surface vessels (USVs) able to wirelessly collect their data. Read how Shell is making use of both for ocean data collection.

The challenge

A/S Norske Shell is running a long-term seabed monitoring campaign over the giant Ormen Lange gas field, 120 km offshore Norway, using an array of our Fetch pressure monitoring transponders (PMTs) in 800 – 1,100 m water depth at the field.

Fetch PMTs accurately collect pressure, temperature and inclination data at the seafloor, at pre-programmed intervals. Using this data, any vertical displacement of the seabed can be calculated. The data will help Norske Shell to proactively inform its reservoir management strategy. Each incorporates a high-speed acoustic modem, allowing stored data to be extracted at any time, wirelessly through the water, on demand.

During previous seabed monitoring campaigns, Norske Shell used a vessel of opportunity to travel out to the field to harvest the data using wireless acoustic communications. However, regularly visiting the sensors to gather the information they contain comes with costs, emissions and puts employees in potential harm’s way offshore.

The solution

We provided a full seabed to shore data collection service. Using a USV, controlled remotely, over the horizon, we visited the site and collected all the Fetch PMT data, without a single person having to travel offshore or from their home office.

The USV, an XOCEAN XO-450, was “posted” via cargo ship to Norway for the project and was launched by local marine operations service provider SafePath AS. The USV, piloted by XOCEAN staff in Ireland, then carried out the full mission, covering 300 km from Kristiansund and back, over just three days.

Throughout the mission, all those involved in the project, including Sonardyne’s remote operations specialists in the UK, XOCEAN’s pilots and Shell’s geophysicists in Norway and the US, remained working from their home offices where they were able to quality check and then receive the data, live.

0

km

offshore Norway

Up to

0

m

water depth

Meets

0

%

UK gas needs

The results

One of the largest data harvesting missions using a USV, to date, achieved safely, quickly and with significantly lower emissions and costs than could otherwise be achieved. An estimated 5.4 tonnes less CO2 per day was emitted compared with a manned vessel had been used. XOCEAN offset any remaining emissions created by its vessel.

As well as minimizing risk to personnel, reducing costs and emissions, using a USV for data collection also meant the time download the data was halved, thanks to the maneuverability and low hull and electric propulsion noise of the USV.

Planning your next ocean data collection mission? Read our white paper to find out how to move to uncrewed.

Or let us handle your next ocean data collection mission with our USV Data Harvesting Service.

Read more about why Sonardyne instruments were chosen for Ormen Lange here.