The challenge

Sometimes, it’s not always possible to account for all of the variables that an oilfield infrastructure is subject to. This can lead to issues. External vortex induced vibration (VIV) or internal flow induced vibration (FIV), which can sometimes be caused by slugging. Slugging is created by variable or irregular flow of gas and fluids through risers, pipelines, flowlines or spool pieces.

These issues can cause problems for process equipment, impact production efficiency and, critically, accelerate pipeline fatigue. This has knock-on effects for design life. It can even cause pipelines to be displaced, entrenched or erode the supports they stand on.

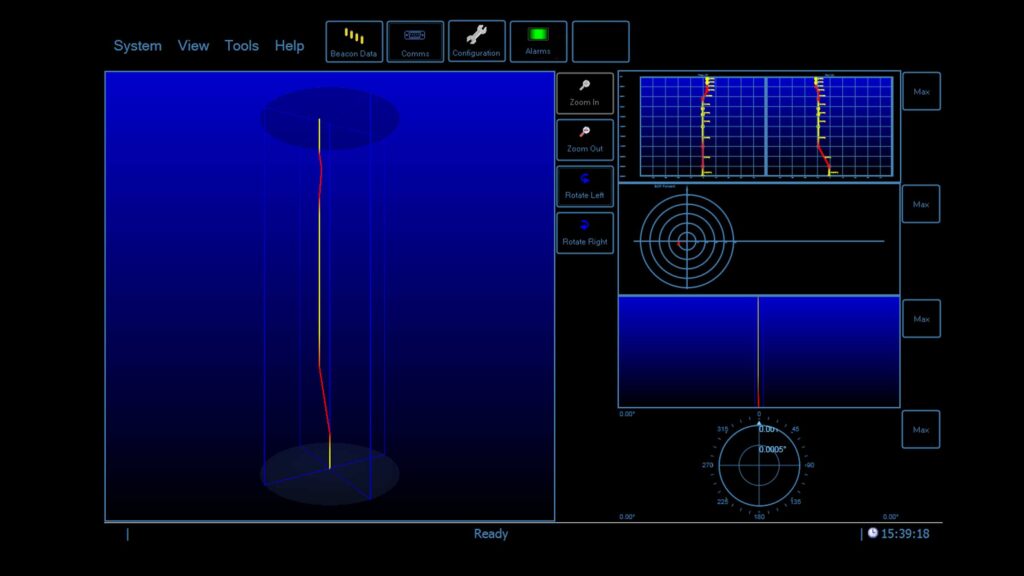

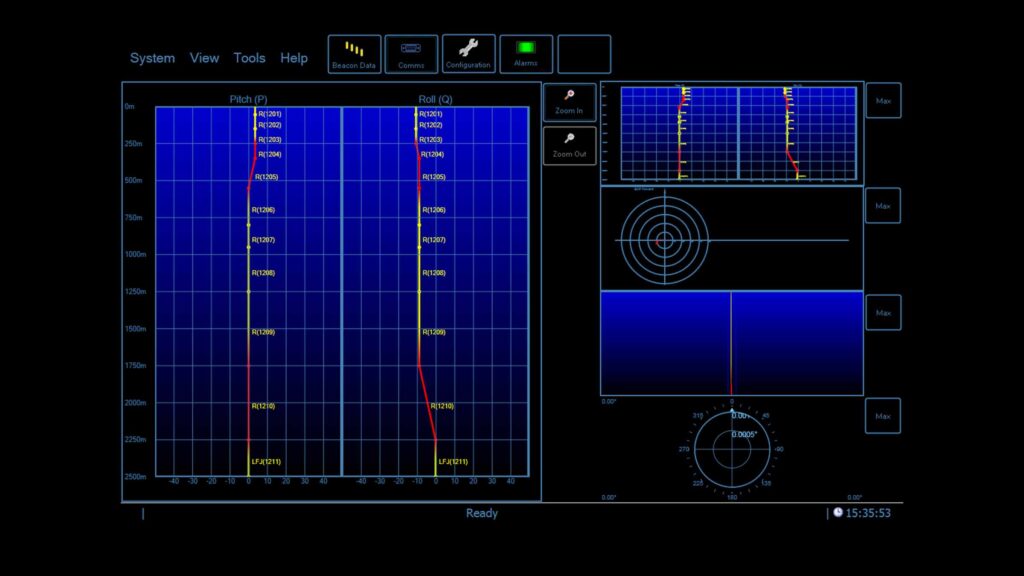

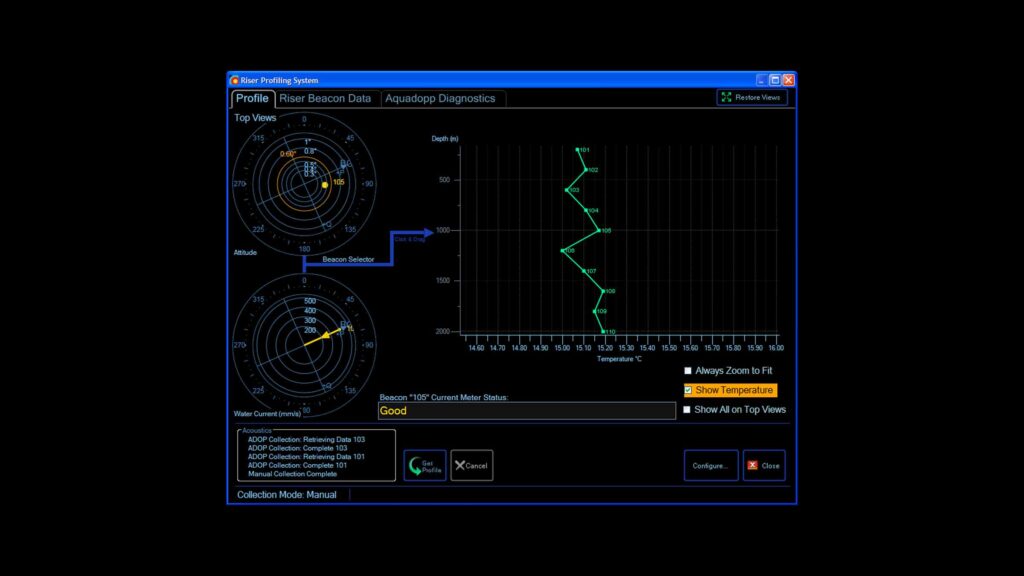

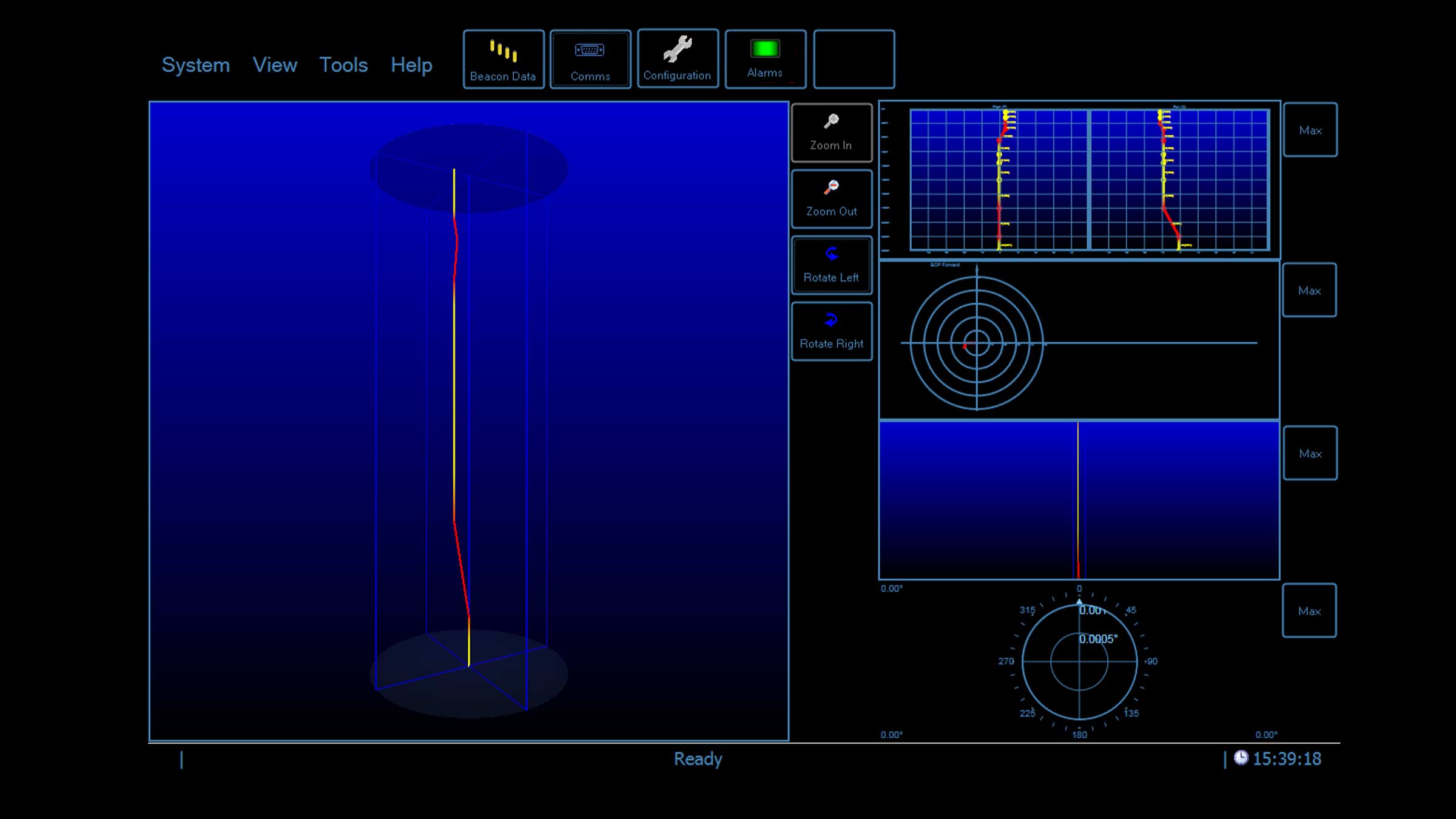

When FIV occurs, pipeline engineers need all the information they can get about just how much this is happening and to what degree. This enables them to re-calculate the remaining fatigue life of the infrastructure and decide on the best remediation methods. Unfortunately, monitoring exactly what is happening – what forces the pipelines, flowlines or spool pieces are being subjected to – can be challenging, especially in deep water.

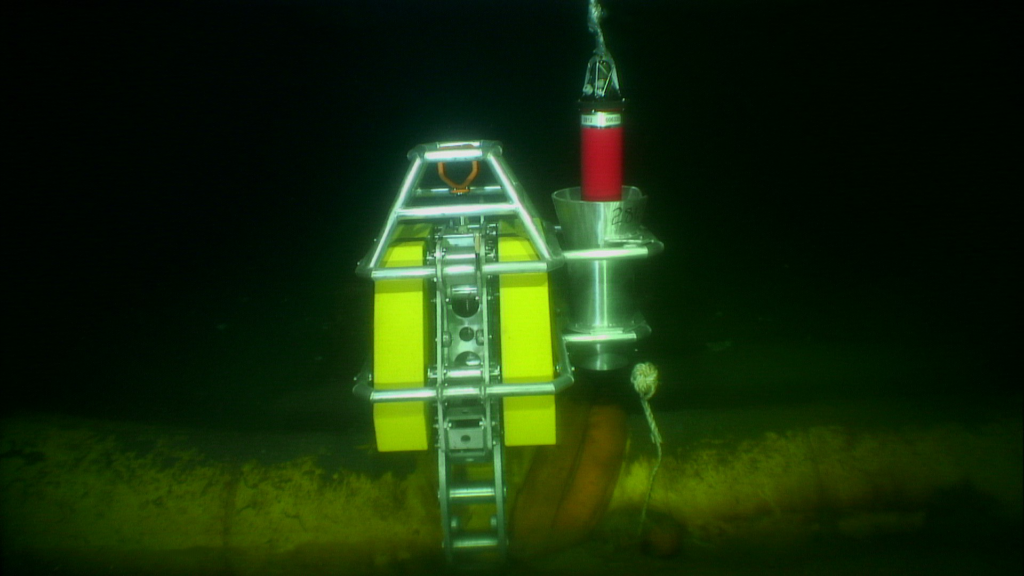

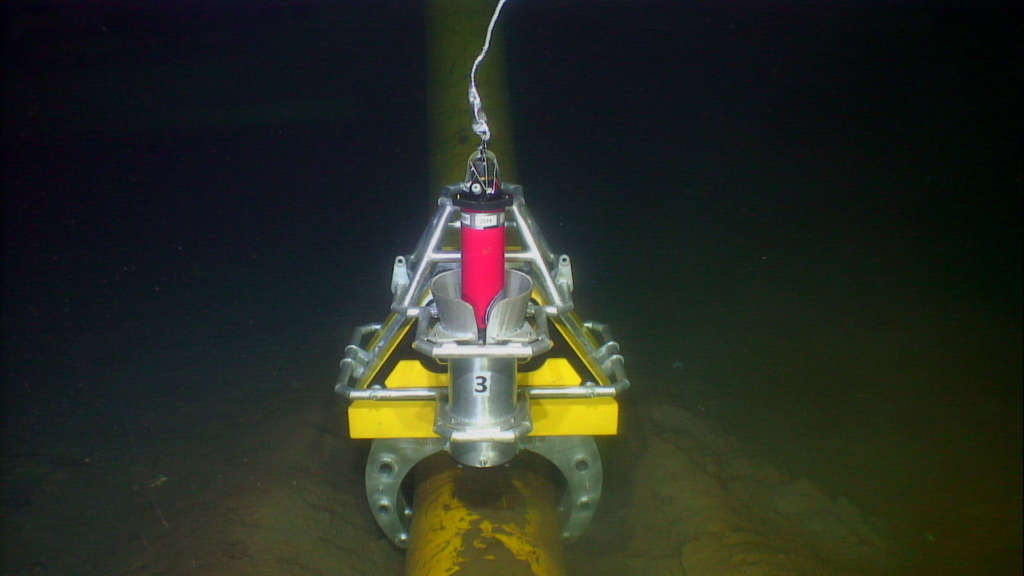

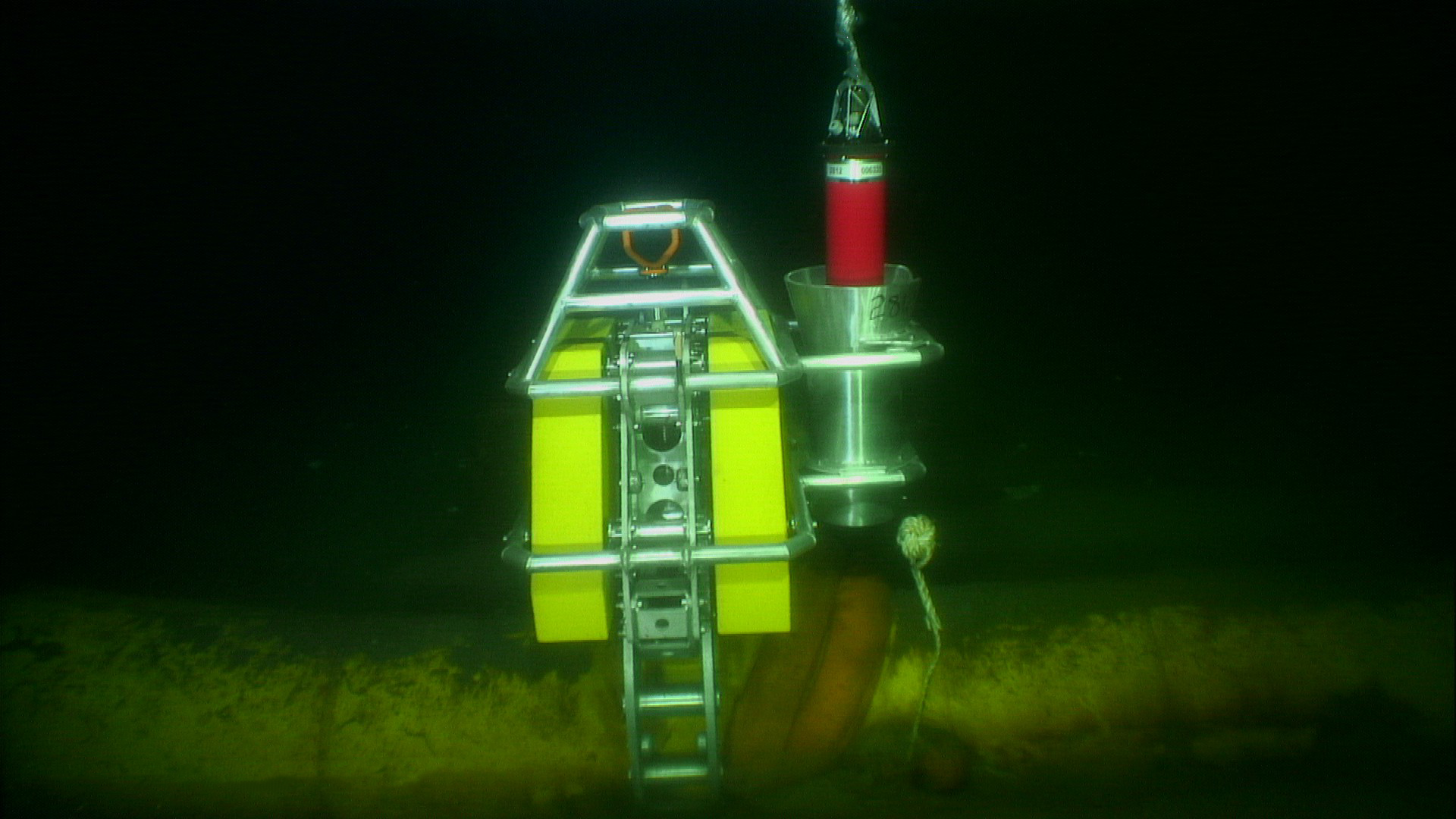

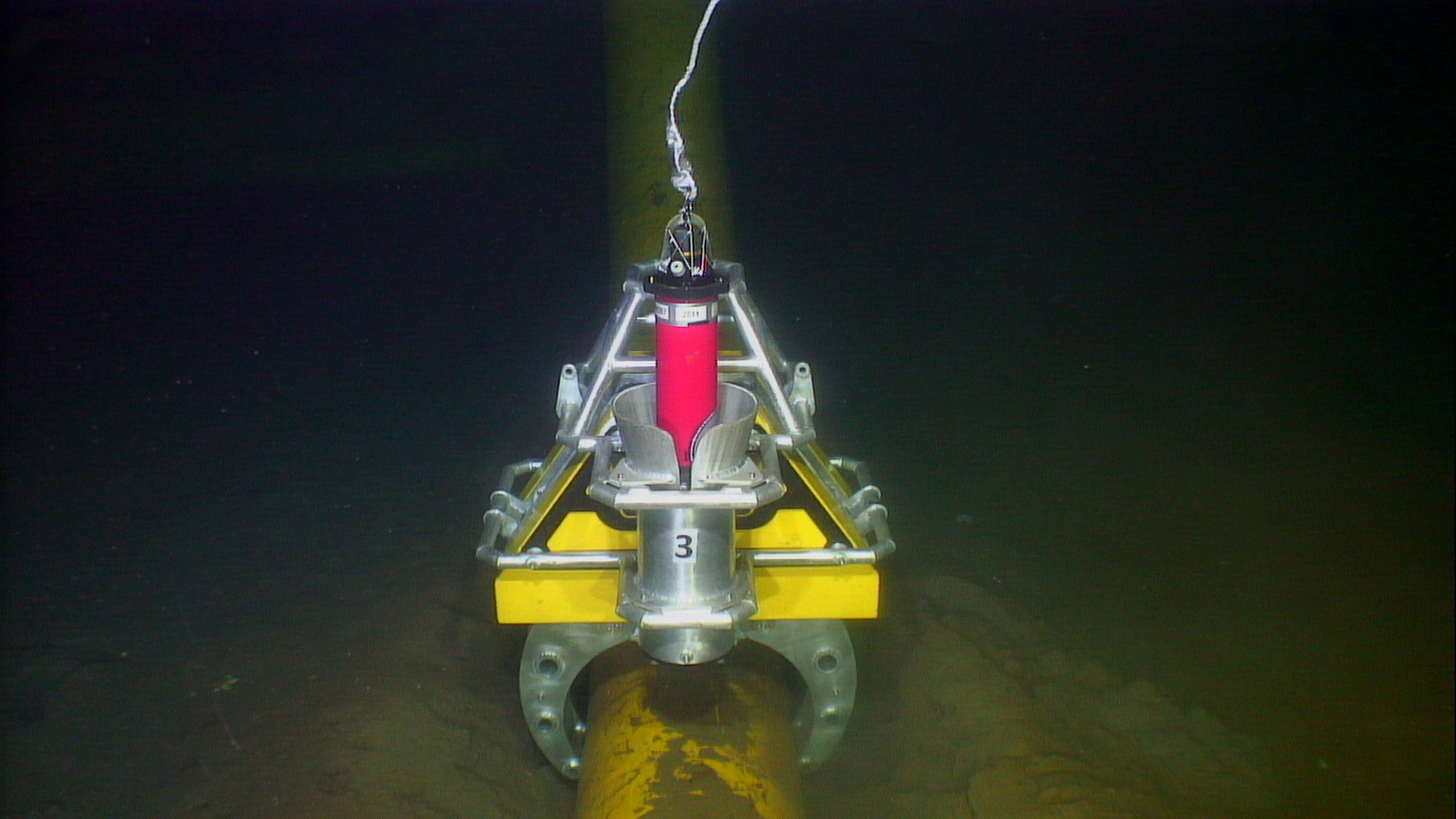

International subsea engineering company Oceaneering International Inc. was asked by an operator to solve this exact problem. They had a number of spool pieces deployed in more than 1,000 metres of water, running between riser bases and flowline termination assemblies. They were being subjected to sudden and frequent slugging movements.

These movements had already resulted in new spool piece supports having to be installed. The operator’s engineers needed to assess the resilience of the new supports and learn more about the vibration the spool pieces were encountering. The challenge was that no motion monitoring sensors had been fitted prior to commissioning. The solution would need to provide accurate and accessible data using a technique that was not cost-prohibitive to install and operate.