Subsidence monitoring at offshore oilfields

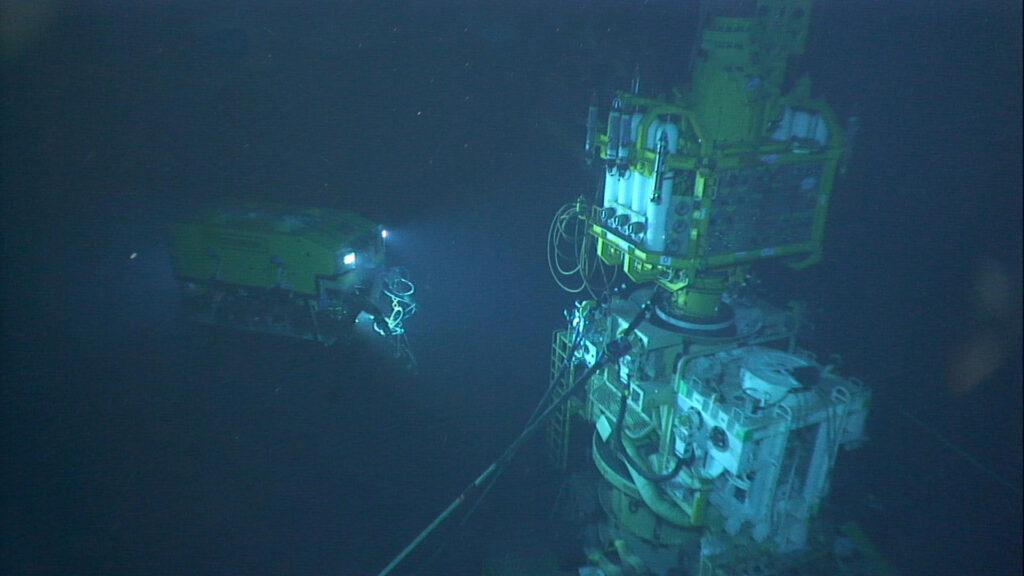

Hydrocarbon production at offshore fields can cause seabed subsidence, potentially triggering dangerous geohazards including earthquakes and even fault slips. A long-term project with Norske Shell measuring seabed subsidence rates offshore Norway has now led to the latest, centimetric accuracy, long endurance autonomous instruments being developed and deployed, field-wide across the giant Ormen Lange gas field.

The challenge

The production of hydrocarbons at offshore fields causes a reduction in the pressure within the reservoir and therefore its ability to support the layers of rock above it. These layers are collectively named the overburden and they relentlessly push down on the reservoir sometimes causing structural instability surrounding the reservoir and deformation of the seabed into depressions known as a subsidence bowls.

The rate of seabed subsidence is of interest to geophysicists for two principal reasons:

Geohazard avoidance Because naturally occurring or production related subsidence has the potential to cause earthquakes and fault slips that can result in hydrocarbon leaks and/or damage to critical seabed infrastructure.

Geophysical interpretation To support identification of changes and minimise uncertainty in the reservoir, inform decision making by reservoir engineers and therefore help to maximize production and minimise risk.

Some offshore fields such as Ekofisk in the North Sea have subsided by several metres over their production lifetime, with average annual subsidence rates of 10-15 cm per year. However, many deep-water fields in regions such as the Gulf of Mexico and the pre-salt fields offshore Brazil exhibit much lower rates on the order of 2-5 cm per year, noting that accurate subsidence information is equally valuable to reservoir engineers operating at these fields.

In 2010, now retired Shell Geophysicist Dr Paul Hatchell set an industry challenge to develop a means to continuously measure seabed subsidence, over many years, that was sensitive enough to detect 1cm/year of vertical movement of the seabed and without breaking the bank in terms of the cost of operating a suitable monitoring solution.

The solution

Measuring subsidence rates to centimetric accuracies on land is comparatively easy using modern survey techniques such as GNSS and satellite altimetry. But radio waves from satellites do not propagate easily in seawater and therefore an alternative measurement approach was required.

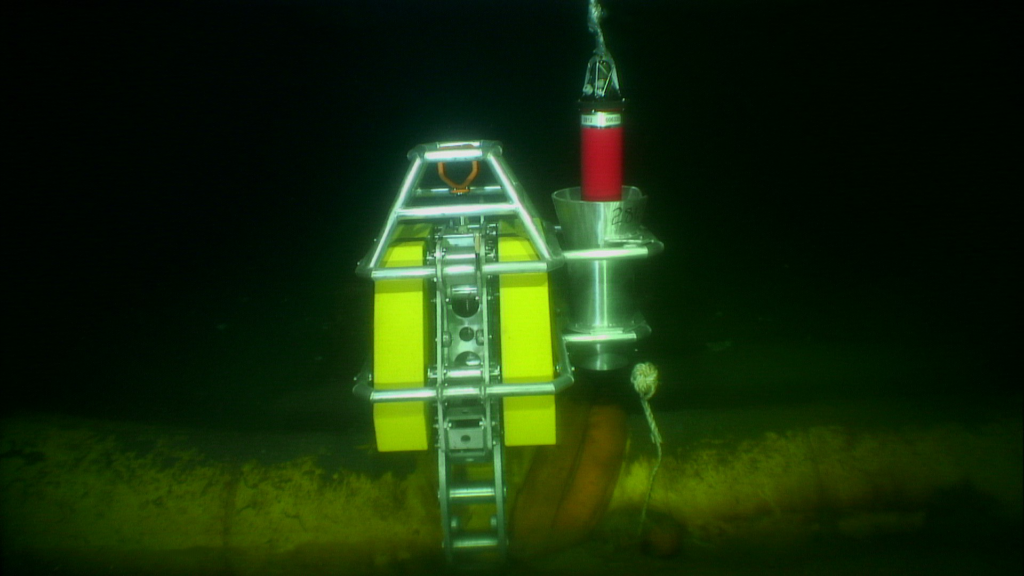

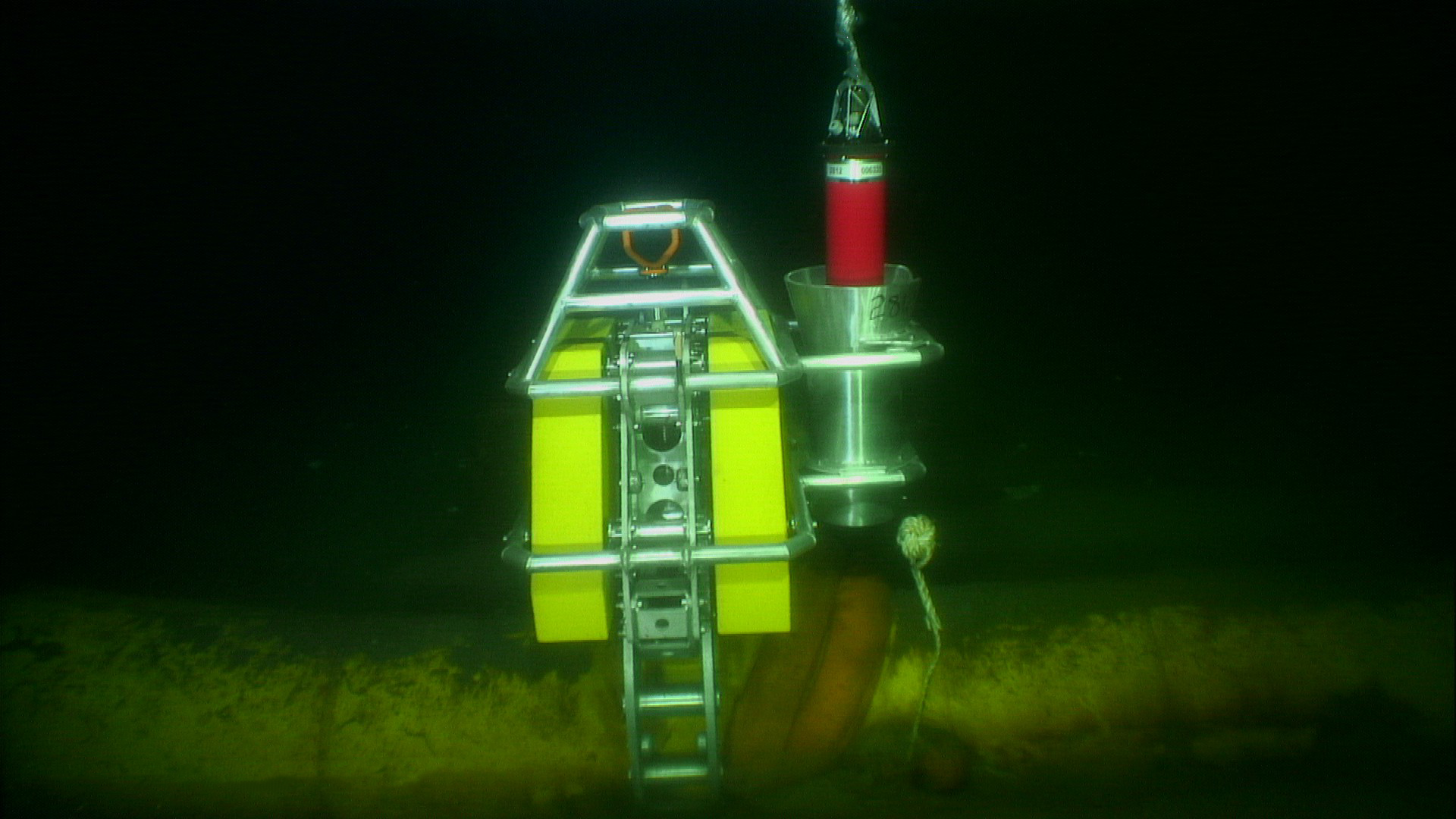

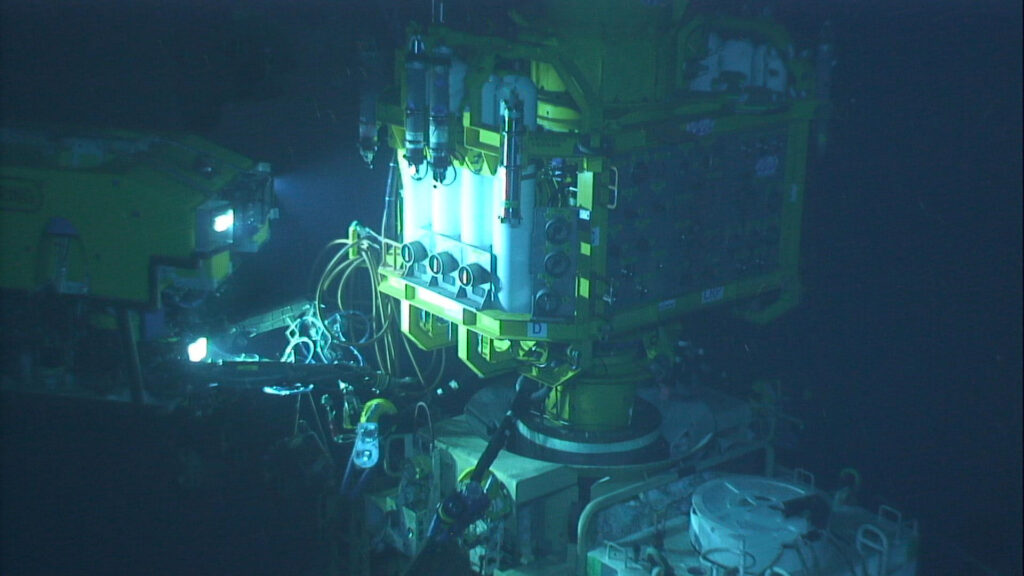

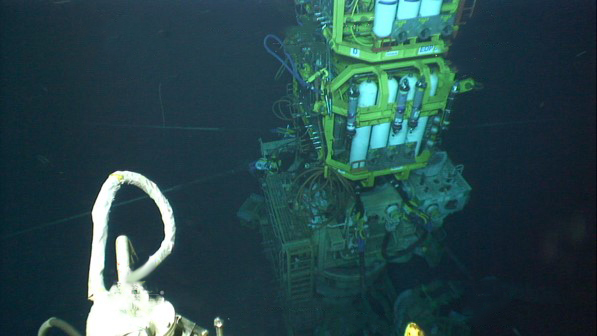

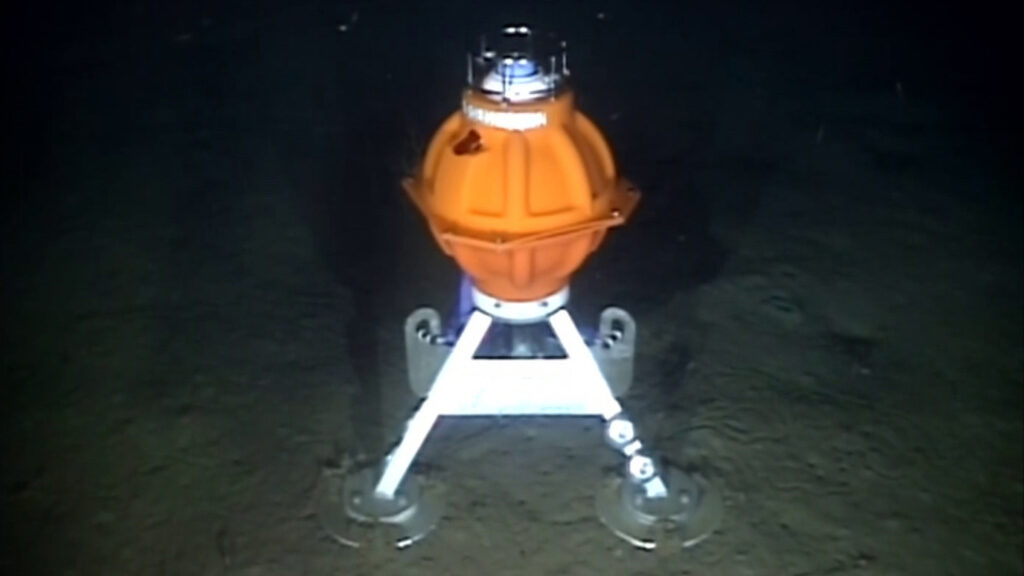

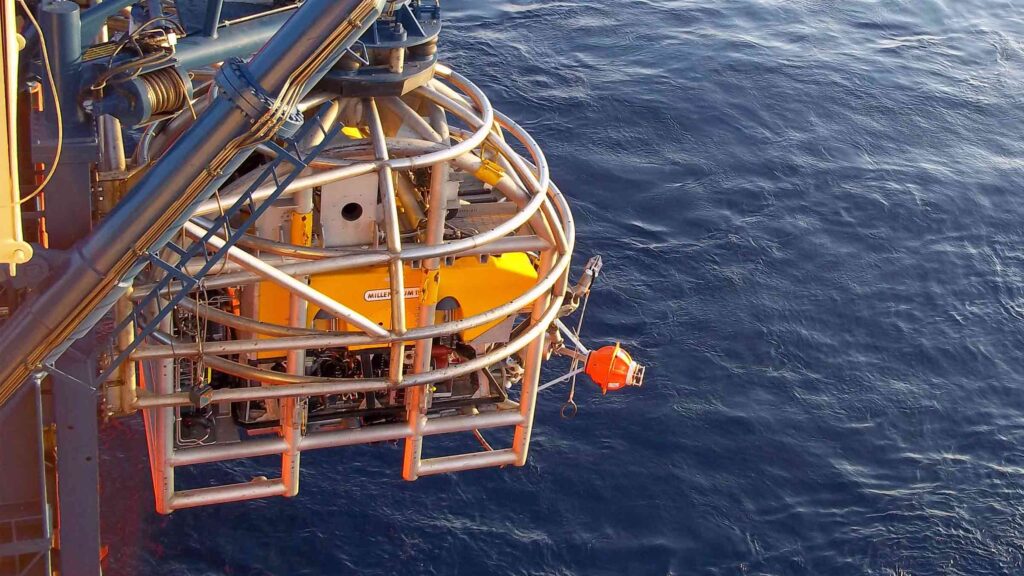

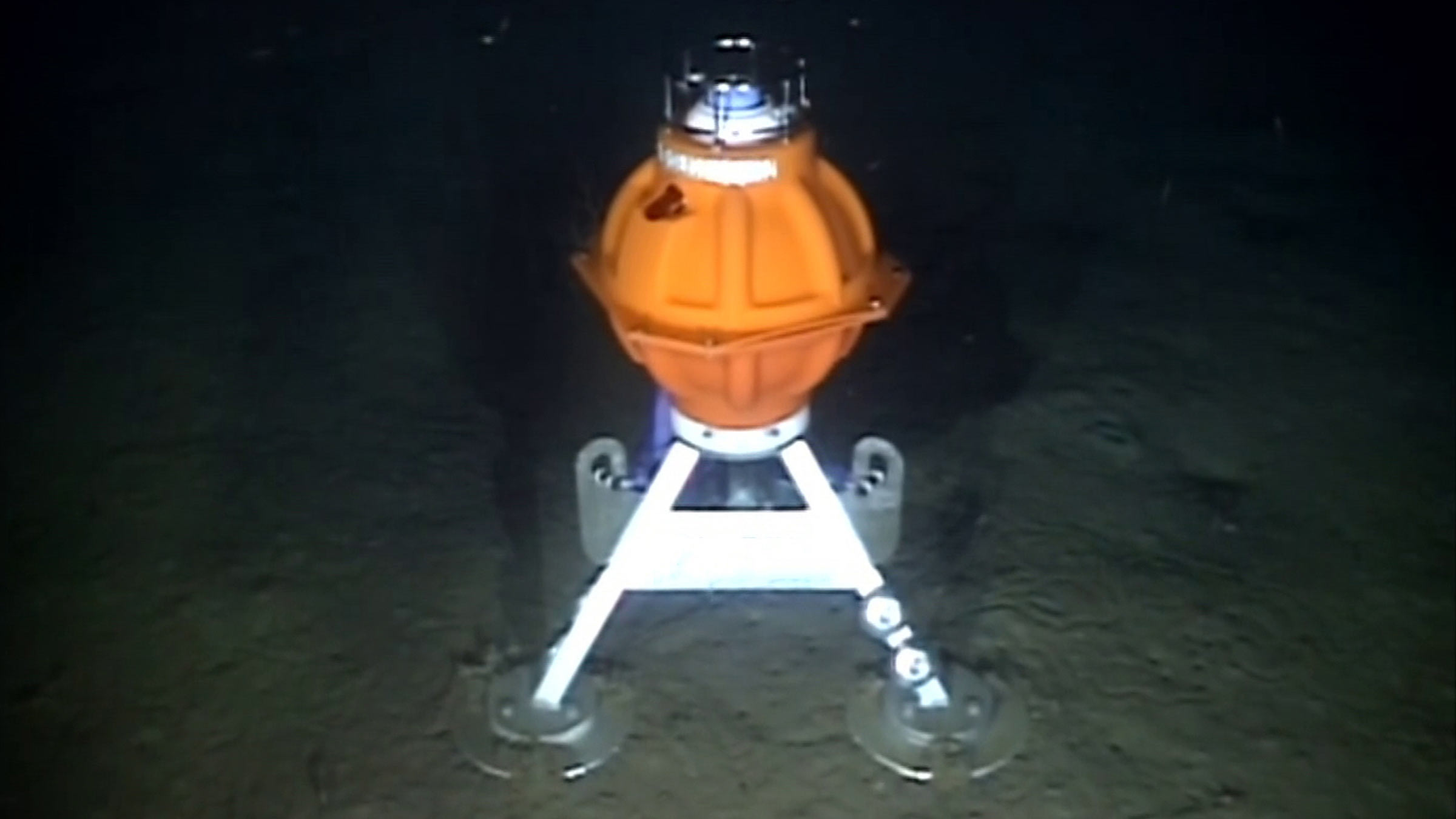

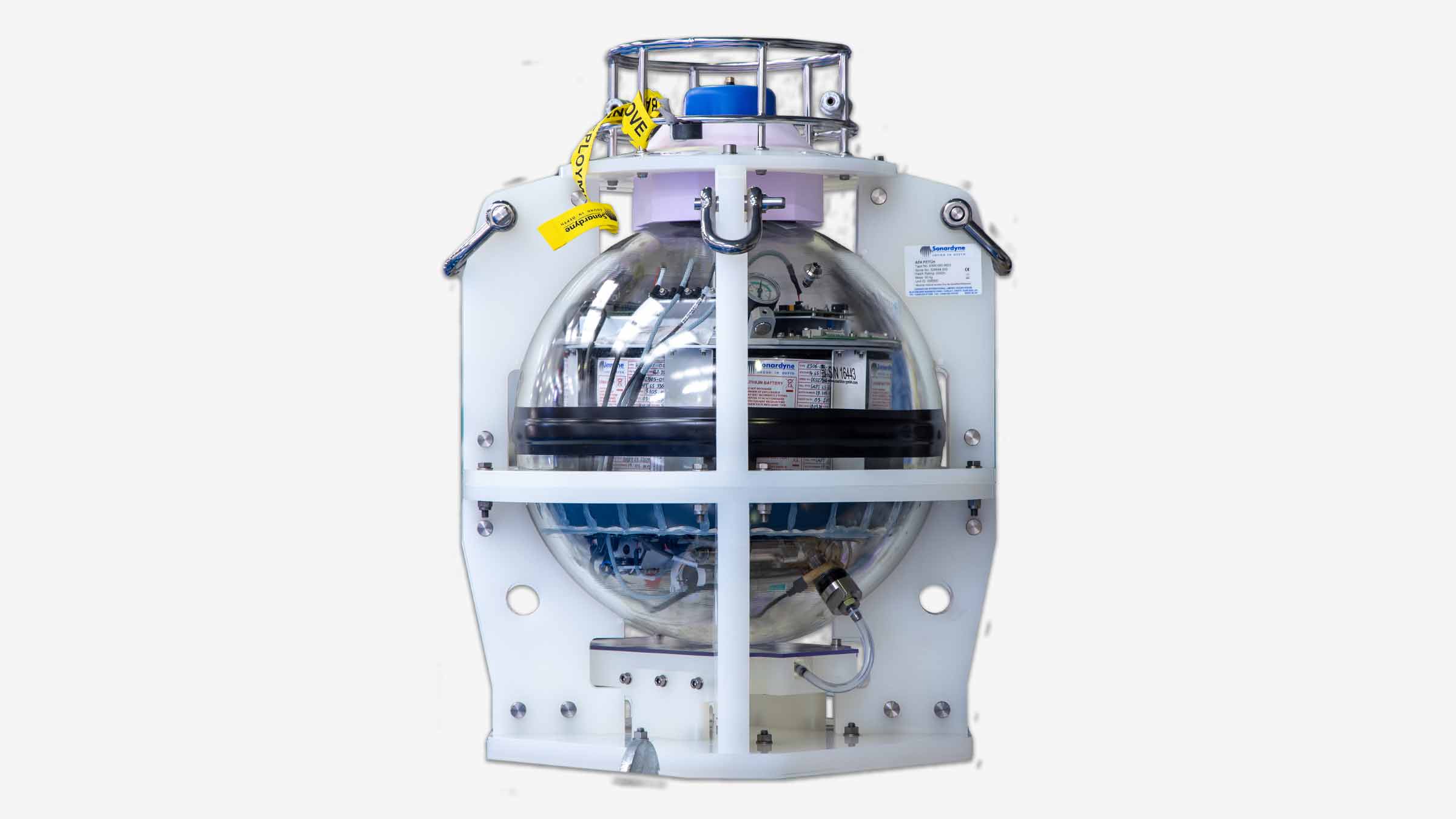

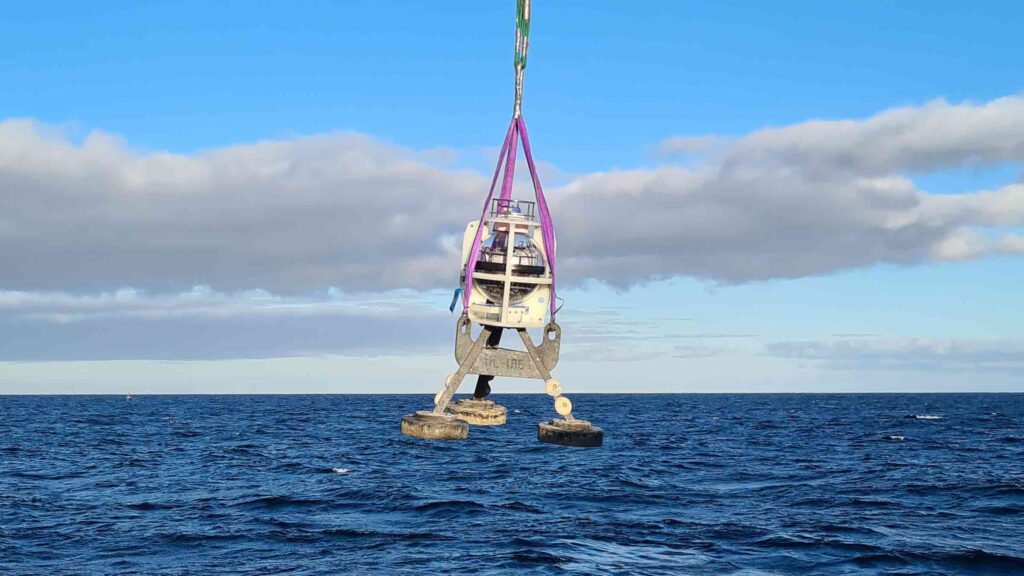

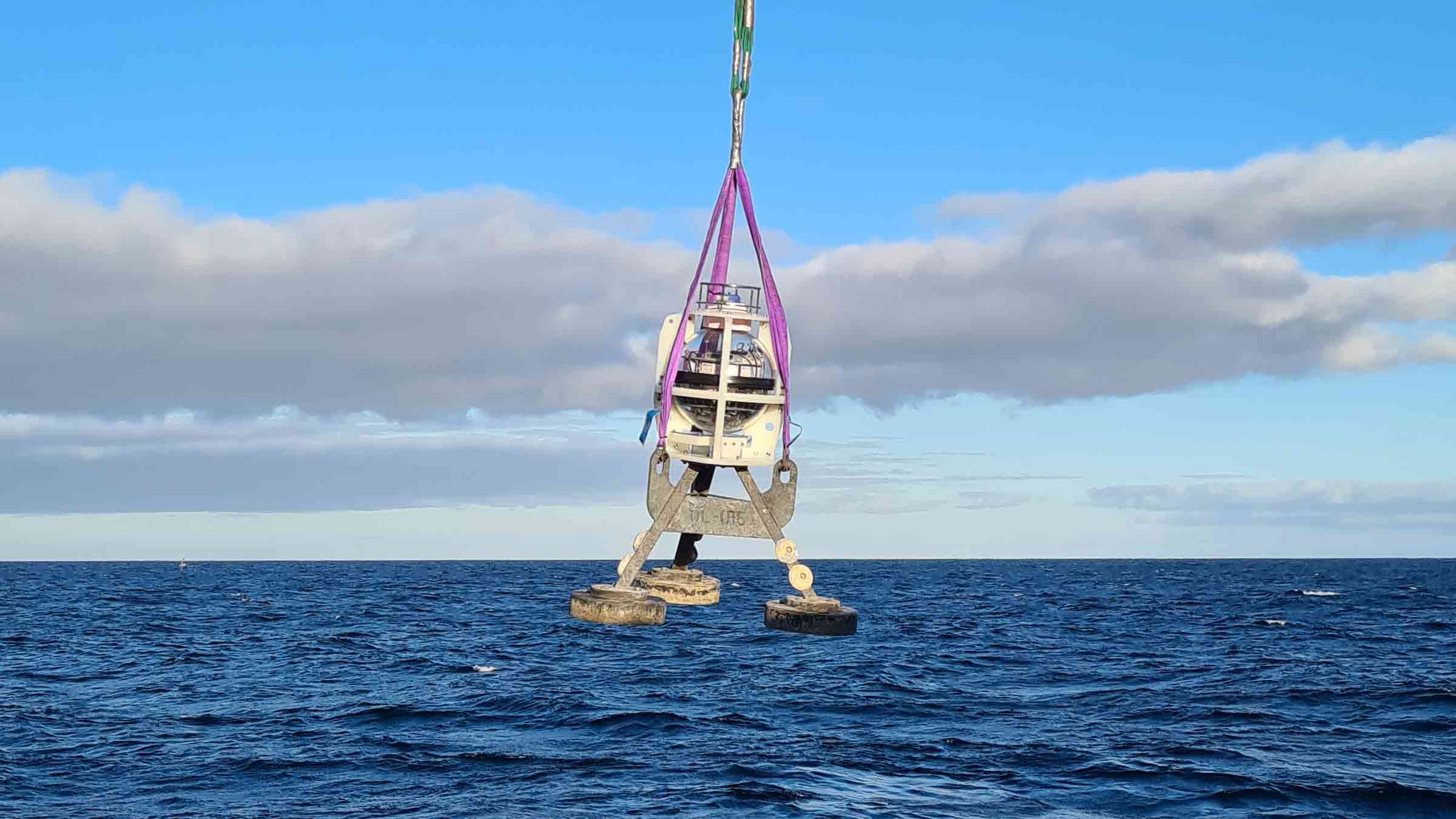

Sonardyne’s custom engineering team therefore implemented a pressure-based subsidence monitoring technique using a seabed deployed instrument called Fetch Pressure Monitoring Transponder (PMT). Each device houses highly accurate pressure sensors and data logging electronics coupled to a wireless acoustic communications modem for data telemetry and enough internal batteries to provide more than 10 years of operational life without human intervention.

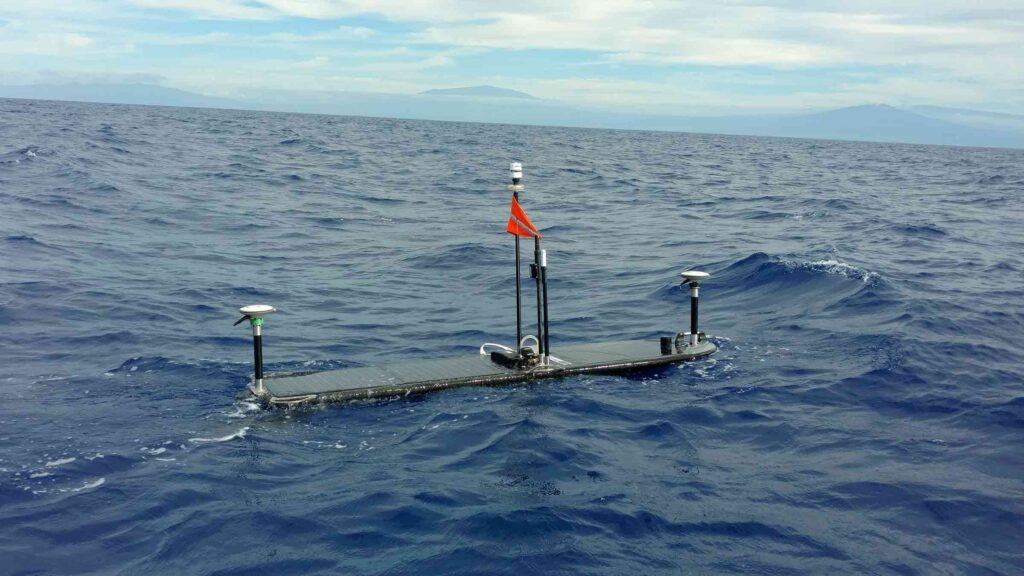

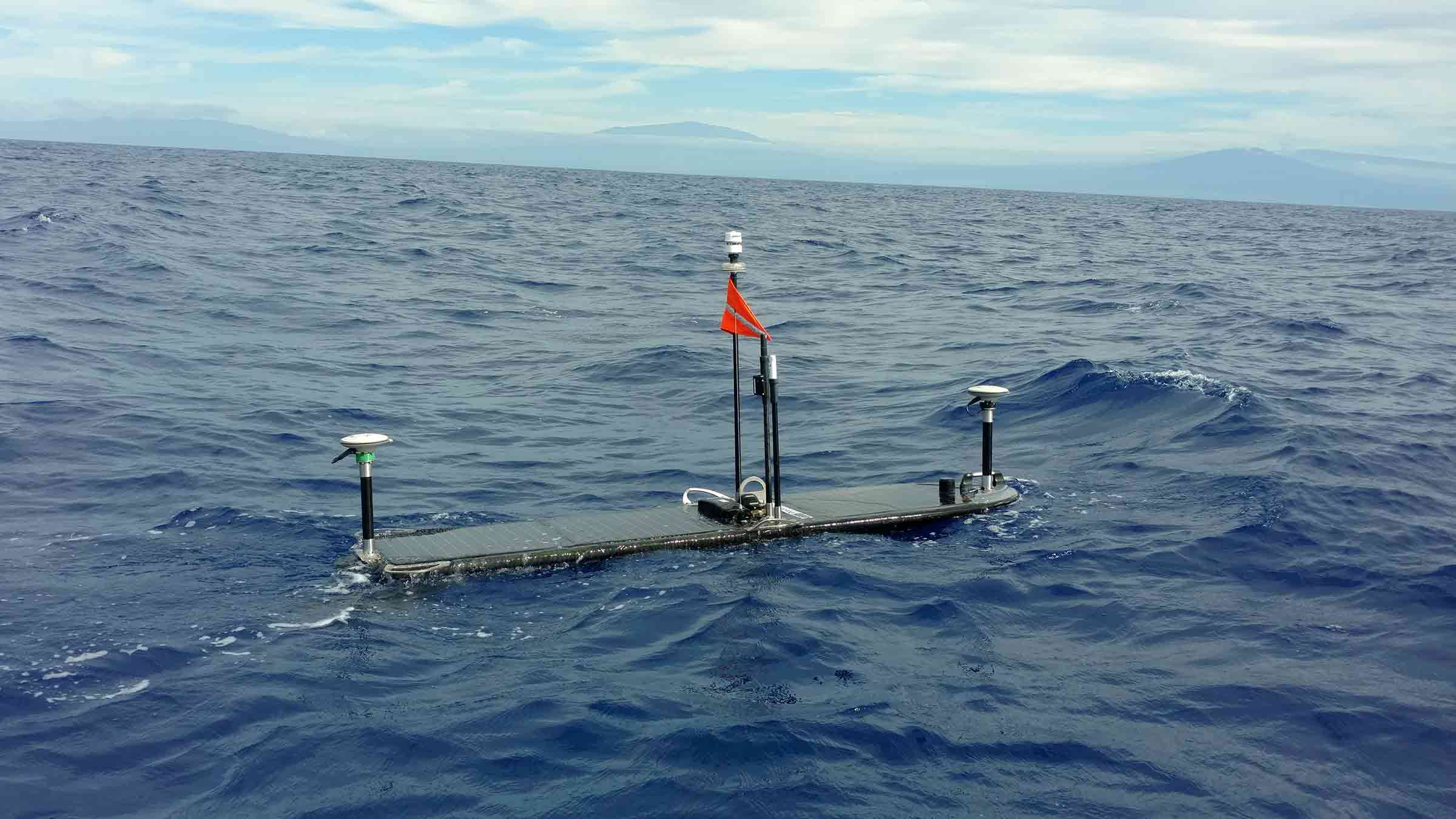

At programmable intervals ranging from minutes to hours, Fetch PMT continuously measures and records raw seabed pressure, ambient temperature, unit inclination (tilt) and sample time data which is then harvested wirelessly by periodically deploying a compatible acoustic modem from a crewed vessel or latterly from Uncrewed Surface Vehicles (USVs). The use of USVs instead of crewed vessels is rapidly becoming the norm for this operation due to the significant reduction in cost and CO2 emissions and elimination of exposure to offshore personnel.

The Fetch PMT data harvesting process can be repeated whenever the most recent data are required with typical intervals ranging from three to nine months. The resulting pressure data are converted to absolute depth and then compared with previous data to calculate the rate of seabed subsidence in cm/year.

However, it is an unfortunate truth that all marine pressure sensors suffer from drift in their output readings over time and left unchecked this drift has the potential to reduce the effectiveness by which seabed depth and subsidence rate can be monitored. To address performance this issue, Sonardyne have employed three interrelated techniques:

We routinely pre-screen and measure the drift rates of all pressure sensors over a few months prior to deployment. Any poorly performing sensors are rejected and the resulting seabed pressure data from selected sensors is adjusted to compensate for the known drift signal.

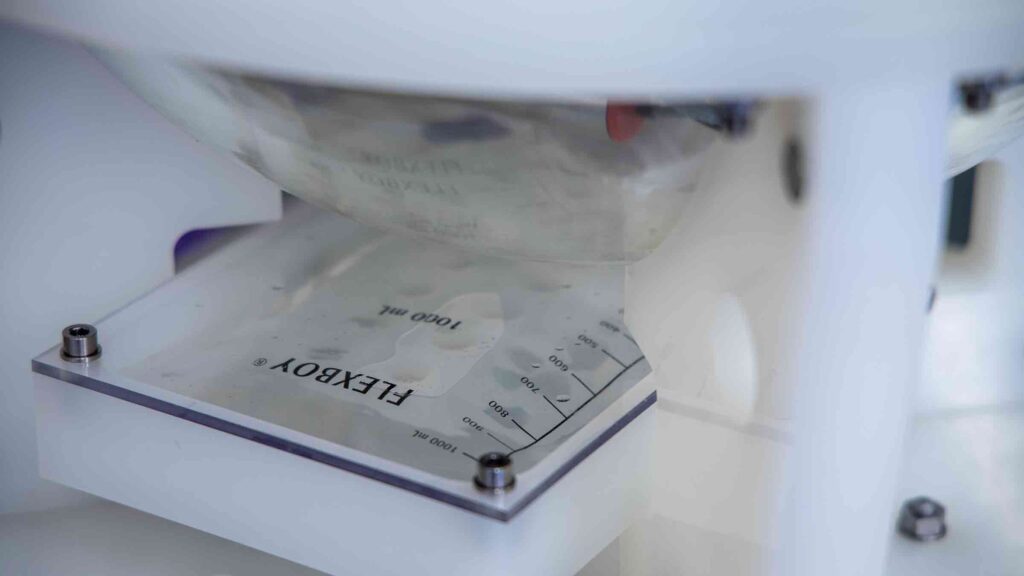

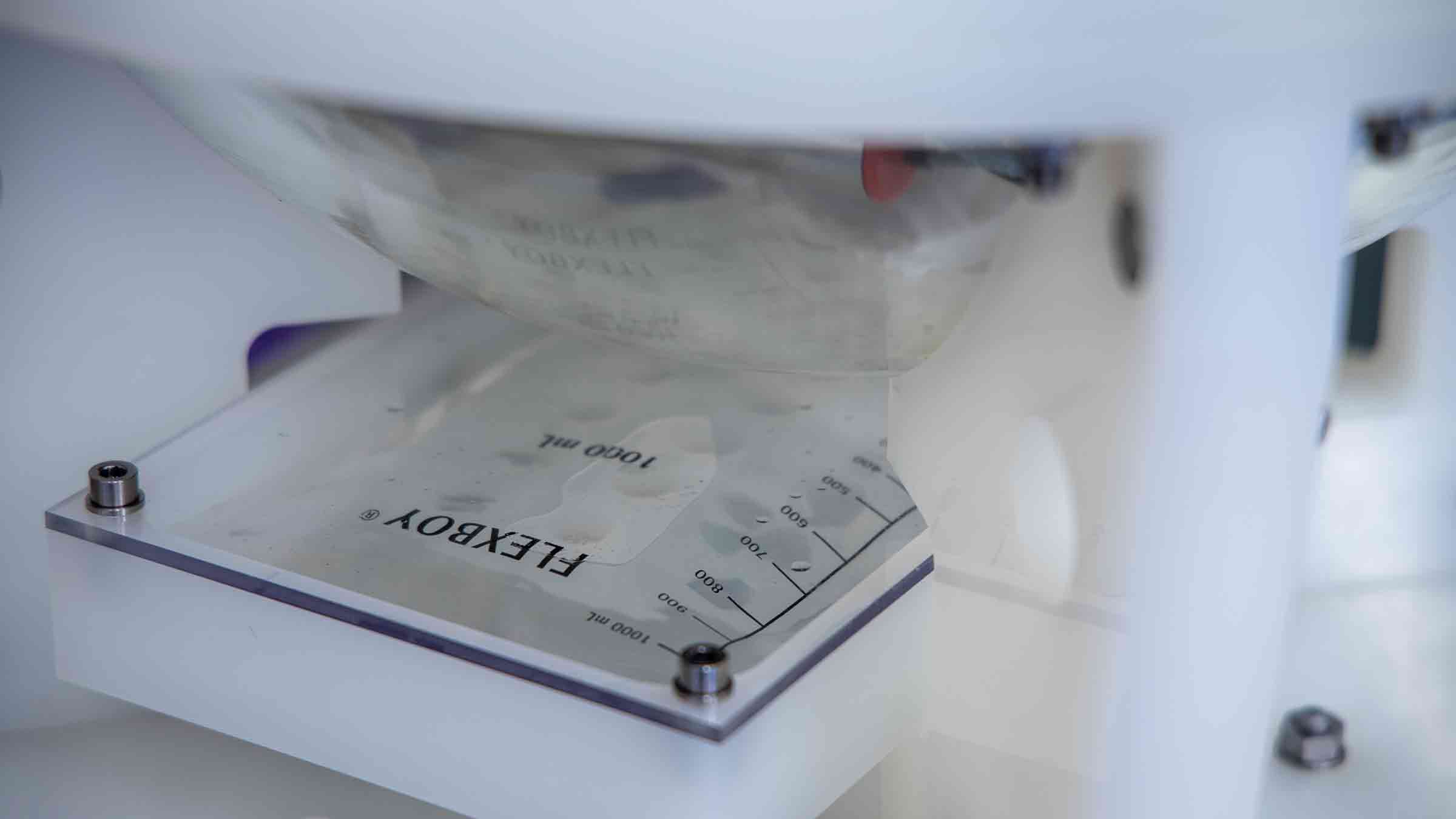

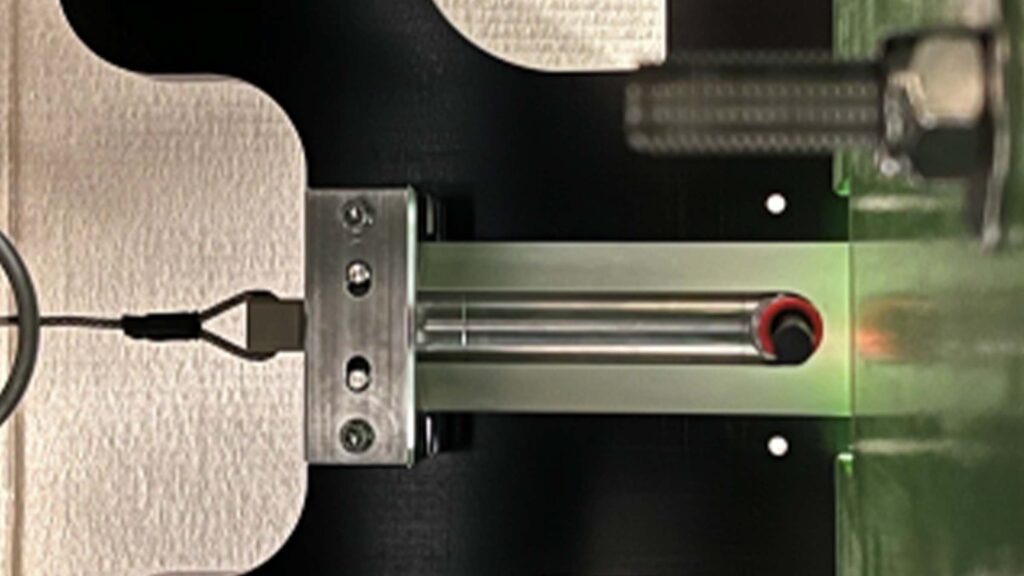

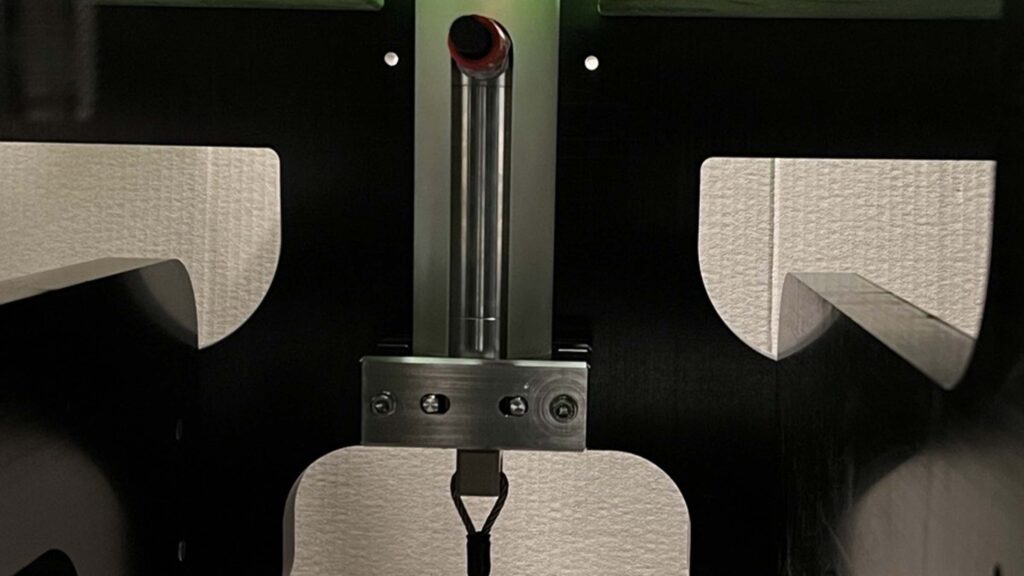

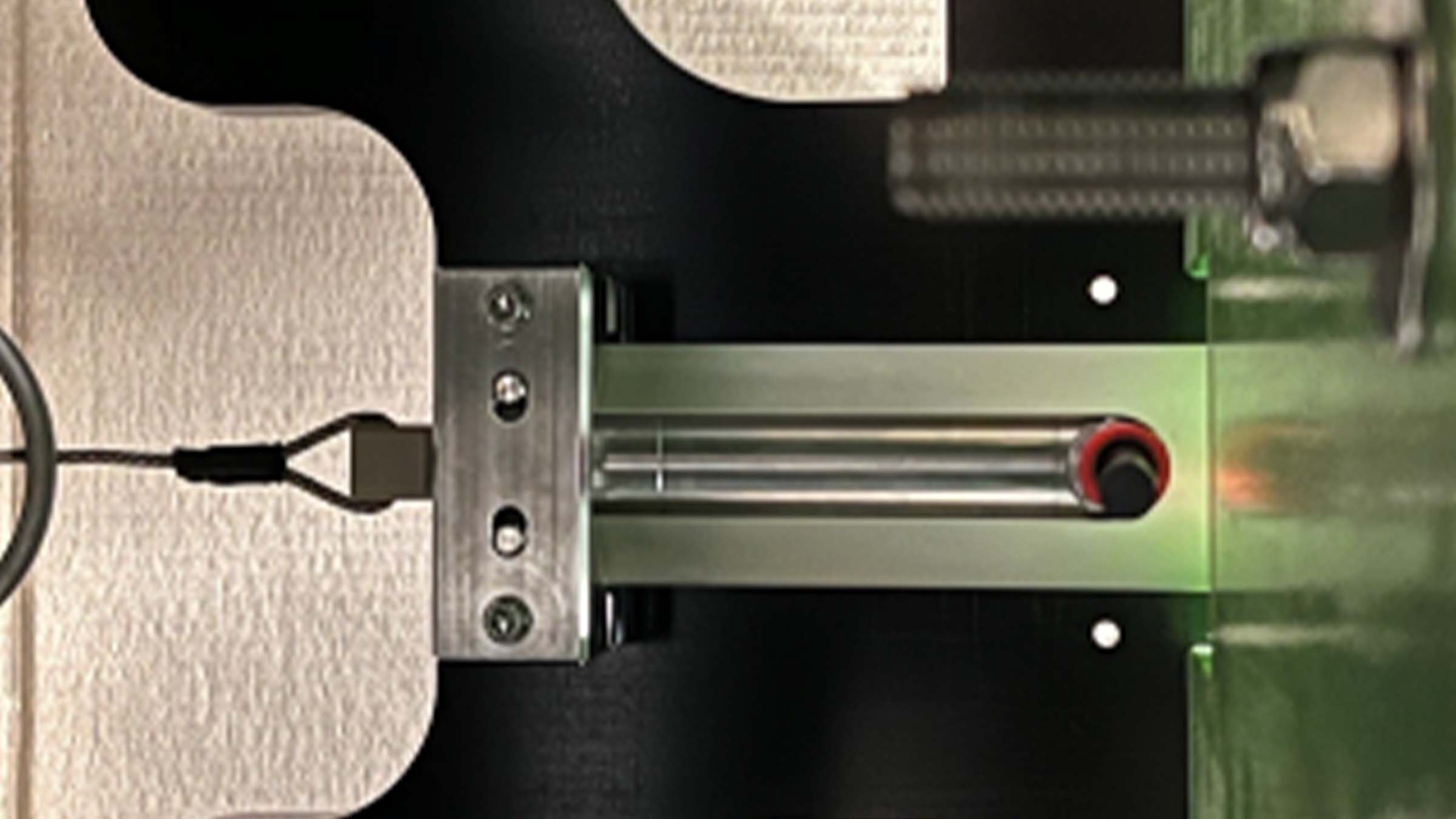

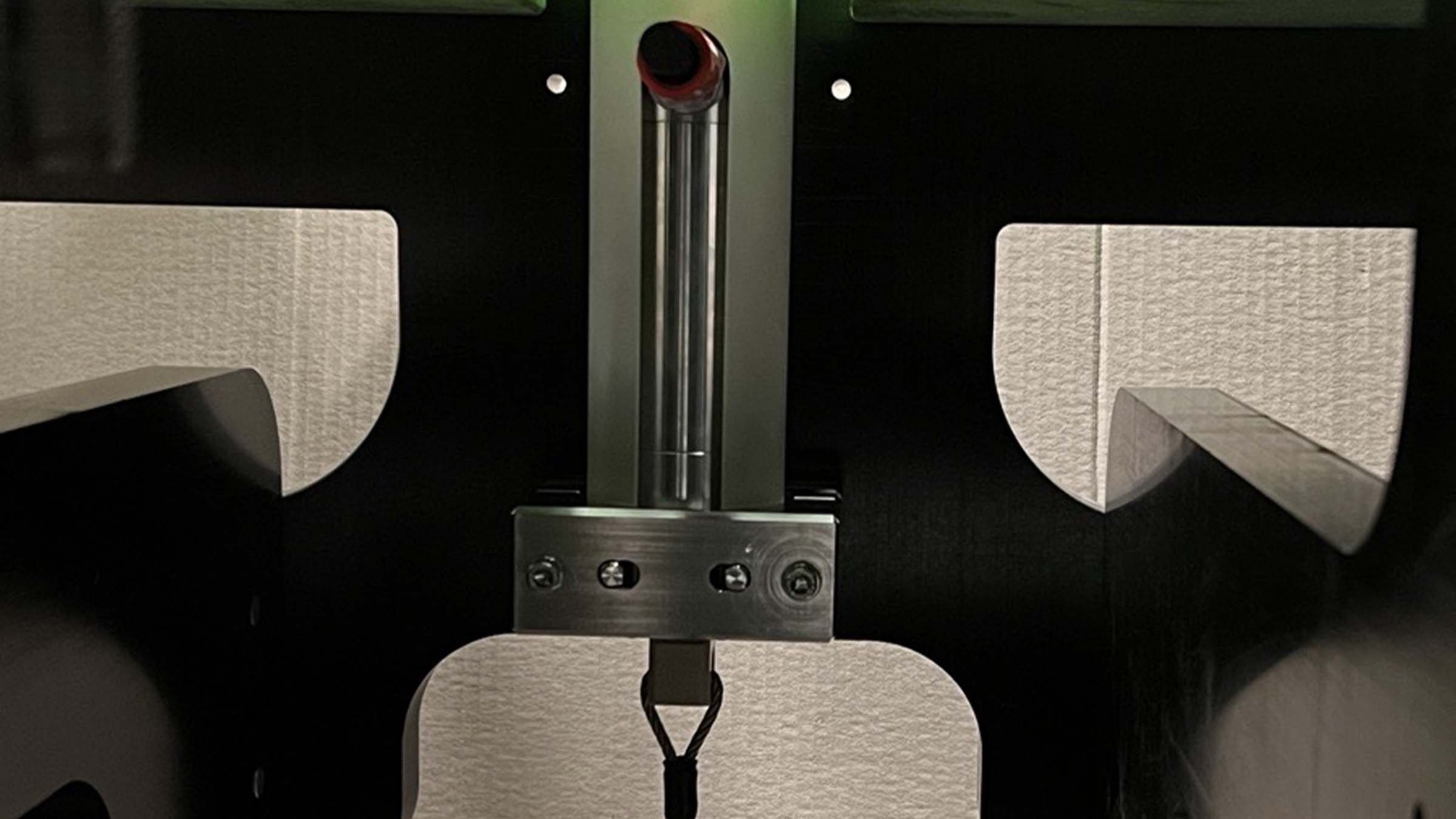

We have developed a patented method of recalibration of the pressure sensors on the seabed using a technique called Ambient-Zero-Ambient (AZA) which is incorporated into our Fetch AZA PMT instrument. This instrument enables regular in-situ drift measurement and removal without recovery of the unit.

We can measure the absolute 3D position of each Fetch PMT unit on the seafloor using a USV based acoustic ranging process called GPS Acoustic Box-in (GPS-A) and can use this information to periodically calibrate the pressure sensor data.

Each of these techniques supports pressure sensor drift removal and therefore an increase to the sensitivity of the subsidence monitoring system towards the golden target of 1cm per year.

The results

High accuracy (circa 1cm/year) continuous seabed subsidence monitoring is now an industry recognized technique for offshore hydrocarbon production.

Several discrete subsidence events (sudden changes in depth) have been detected by the instruments used and this has provided geohazard information which has proven to be extremely useful to reservoir engineers who are tasked with determining the nature and potential causes of these events. Geophysicists also routinely use the information generated to reduce uncertainty in their reservoir models and to aid their decision-making processes as part of proactive reservoir management programmes.

Over the past 15 years, these systems have been deployed many times, starting with early trials at the Norske Shell operated Ormen Lange gas field in 2007, and then field-wide deployments of Fetch PMT and AZA PMT instruments across the globe including in the North Sea, Gulf of Mexico, Norwegian Sea and offshore Malaysia.

The latest deployment at Ormen Lange saw a total of 75 instruments deployed in two phases between September 2019 and October 2020 and these units continue to provide Norske Shell with invaluable subsidence monitoring data from this field, via crewed vessel and remote data harvesting missions conducted using an XOcean USV.

Costs, CO2 emissions and human offshore exposure traditionally associated with gathering oceanographic information have also been reduced by the routine use of USVs instead of ships to collect the data from the seabed wirelessly.

The technology has also been successfully transferred into Ocean Science applications for monitoring plate tectonics, subduction zones and the submerged sides of large volcanoes that, if they break free, can cause catastrophic Tsunamis.

As a result of our efforts to unlock the secrets of our restless sea floor, Sonardyne was recently awarded the 2021 Queens Award for Enterprise in Innovation, the highest award a UK business can receive.

Keeping production flowing by understanding subsea asset movement – wirelessly

An important feature of extending, or even preserving, offshore life of field is to know and understand what is happening with deployed subsea assets. Are they vibrating, perhaps they are slowly walking from their original position, is this happening as a one-off or regularly due to flowline properties? Oceaneering learnt all of this by deploying smart and intelligent sensors at a deep-water development offshore Africa.

The challenge

The worldwide quantity of flowlines, spool pieces, pipeline end termination units, risers and all manner of other installed subsea assets is staggering. All serve as important interconnecting elements in the overall offshore hydrocarbon supply chain. With an aging asset portfolio, it is sometimes very difficult to understand how these assets have been moving during their operational life and what this means to their accumulated fatigue figures and, therefore, safe end-of-life point.

At one offshore field development, Oceaneering, was set a challenge by an international operator. They suspected spool piece movement caused by slugging events, and asked Oceaneering Inc. to provide subsea data for third party analysis so the extent and frequency of movement could be determined. They hoped this would help with the introduction of mitigation measures that would ensure safe and controlled production from the connected producing wells.

With the field located in over 1,000 m of water and with no designed-in points for sensor mounting or hardwired connectivity, this was easier said than done.

The solution

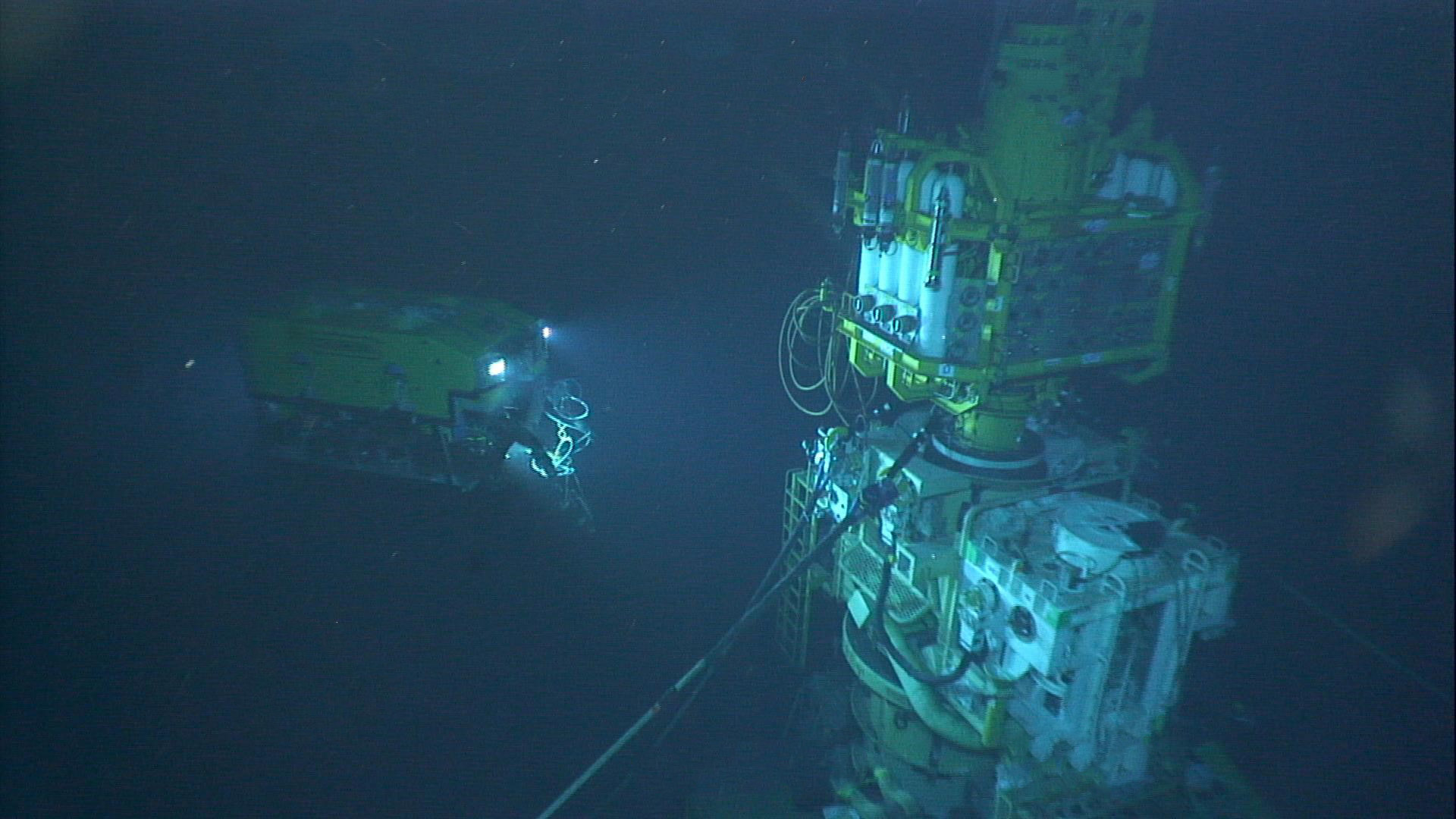

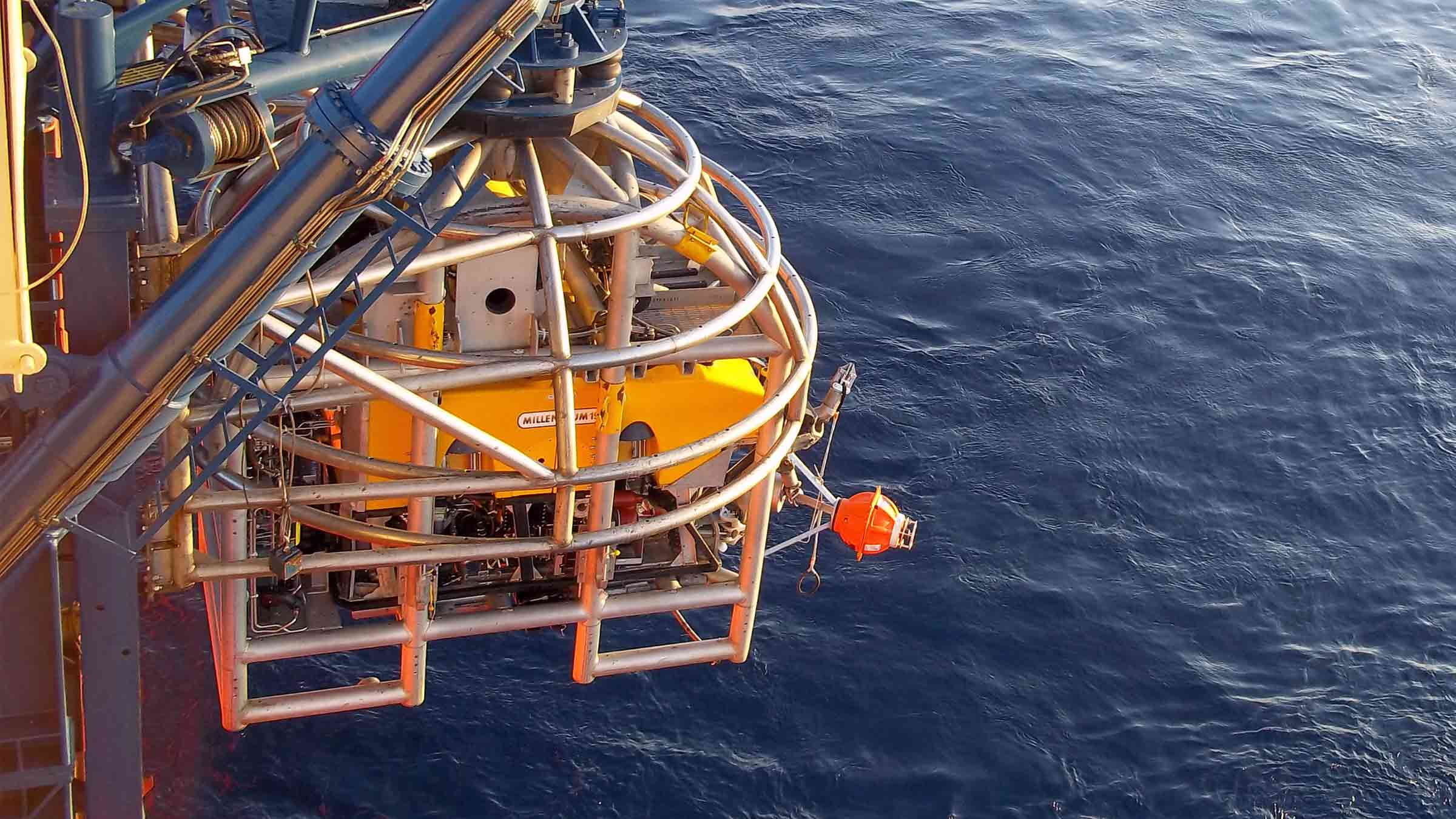

Oceaneering turned to our wirelessly communicating and intelligent monitoring sensors called Subsea Monitoring, Analysis and Report Technology, or SMART for short. Additionally, a series of Autonomous Monitoring Transponders, or AMTs, were deployed within a seabed array to detect any longer period movement that SMARTs would be unable to detect.

Battery operated SMARTs were chosen as they incorporate a low-power inertial measurement unit, or IMU, that can precisely measure the installed sensor’s six degrees of freedom. This means that 3-axes of rotation and 3-axes of acceleration relating to the SMART sensor’s movement can be measured at very high sampling rates over a measurement window set by the operator.

This measurement window, which can be adjusted acoustically at any time from a topside transceiver, can be set between a minimum period of approximately 5 minutes to continuous recording. However, a one-hour measurement window is far more commonplace.

Once the measurement window has ended, SMARTs analyse the recorded raw data, producing and storing one statistical summary file for each window period. When required, these summary files can be requested for wireless transmission through the water column from each SMART’s location to a topside transceiver using Sonardyne’s fast and robust 6G Wideband 2 acoustic protocol on the Dunker 6 LBL and telemetry transceiver.

Importantly for the operator, all SMART raw, time-series, data is securely recorded and saved in-situ for more detailed analysis post-recovery.

Through the combination of edge analytics, low power electronics and acoustic communications, SMARTs could be installed for over a year. Even longer deployments are achievable by supplying larger battery packs or reducing the sampling frequency.

SMARTs are designed for high frequency motion monitoring, but the operator was equally concerned that longer periods of motion were in play that may have caused the subsea asset to gradually move from its installed position. Thus, monitoring for possible flow induced vibration (FIV) and vortex induced vibration (VIV) was also required. To monitor this motion, Oceaneering Inc. chose another Sonardyne sensor called an AMT.

AMTs are used for long-term survey and monitoring applications where instruments are needed to acquire acoustic ranges and other sensor data, like pressure, temperature, and sound velocities, without any surface control. By creating a Long Base Line (LBL) array of static seabed located AMTs with an AMT on the asset needing to be monitored, highly accurate measurements of any horizontal movement of the monitored asset can be measured, accurately timestamped, and logged. Vertical movement of the asset-mounted AMT can also be determined by the recording of precise pressure sensor information and comparing it to those from the control array.

An additional benefit identified by Oceaneering is that data from the AMTs can be wirelessly recovered using the same topside hardware as that of the SMART, resulting in less topside subsystems.

The results

Oceaneering mobilised the equipment in 2018 and it has been in operation ever since. The performance of the SMARTs in determining motion characteristics, coupled with the motion mitigation measures that were introduced, enabled the operator to continue producing safely and within the design life of the installed spool pieces. What’s more, the operator now has a far better understanding of their accumulated fatigue figures for the spool pieces and is able to determine the safe end-of-life point for their subsea assets.

A SMART deepwater invention

Operations in deepwater are a significant challenge requiring the latest generation of subsea equipment and installation techniques. While the majority of operations do go to plan, there are occasions when they don’t and an innovative approach to deepwater intervention is required.

The challenge

Houston headquartered engineering specialists Trendsetter Vulcan Offshore (TVO) were set just such a difficult deepwater intervention challenge. They were brought in to help an operator rectify a completed wellhead at a deepwater site that had suffered from misalignment. The wellhead, which was in more than 2,000 m water depth, had been bent and there were concerns other components might have been damaged.

TVO were tasked with finding a solution to bringing it back to a vertical position. This would allow intervention access to the well for remediation and abandonment operations, so it could be permanently sealed. A key challenge was to carry out this work extremely carefully and in a controlled manner, in order to prevent any further potential damage to the wellhead.

The solution

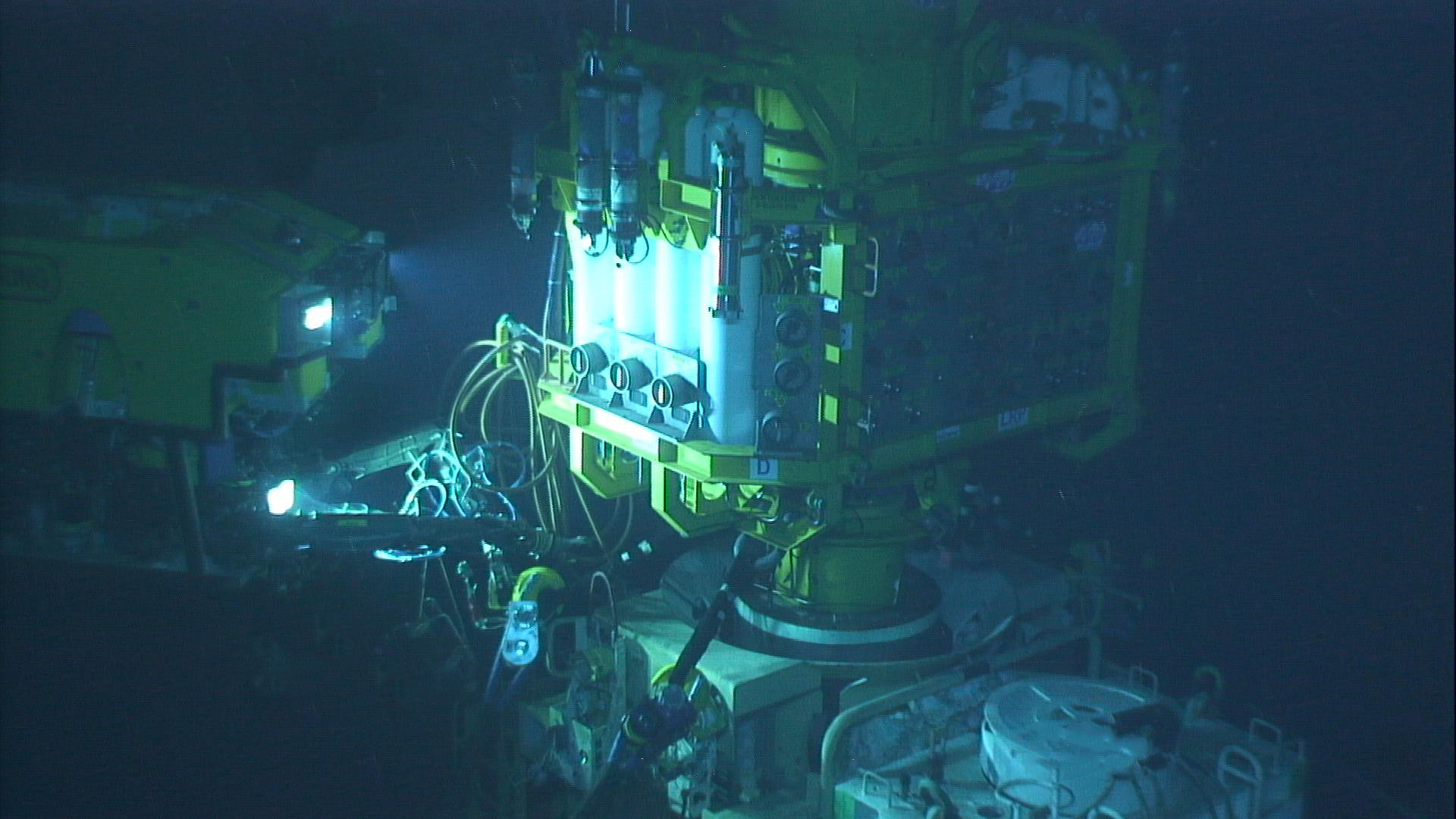

TVO came up with an innovative solution to the problem. It proposed a ring of six subsea tensioning systems, mounted on suction piles positioned in a ring on the seafloor around the wellhead. Each one would be connected via a rope to a Trendsetter-supplied lower riser package (LRP) installed onto the wellhead. By carefully tensioning the ropes, they would be able to then bring the wellhead back into an upright position.

To do this in a safe and controlled way, TVO required a monitoring system which would provide:

- Near real-time feedback of the tension data at each of six load pins installed on the LRP (one each for each of the six tensioners).

- Near real-time inclination data from the wellhead itself

Conventional deepwater intervention solutions

Traditionally, inclination data is acquired by visually checking subsea bullseye levels attached to a structure using a diver, or, in this water depth, a remotely operated vehicle (ROV). Similarly, visual displays on the tensioning systems would be the source of the tension data, also read using an ROV.

However, these techniques add a significant amount of time, given the 30-40 m radius of the circle of tensioning systems, even if, as was the plan, only two would need to be actively tensioned during the righting operation. Bullseyes can also be mis-read.

Another alternative option is to deploy battery powered accelerator and inclinometer measuring bottles, using an ROV. But these would have to be retrieved to the surface after each measurement, so would also mean a lengthy operation, potentially taking days.

Taking an alternative, SMART, real-time intervention approach

Instead, TVO proposed and successfully deployed a wireless, intelligent, digital underwater monitoring solution. This provided near real-time inclination and tension data to the operations team at the surface (around three minutes delay). It comprised of two of Sonardyne’s Subsea Monitoring, Analysis and Reporting Technology (SMART) and six Compatt 6 transponders.

The internal inertial measurement unit in each SMART was used to calculate pitch and roll data from two points either side of the LRP, allowing TVO to calculate the wellhead’s bend angle in the local coordinate frame.

This data was then transmitted acoustically, using the SMART’s internal modem, to the surface at three-minute intervals. The Compatt 6s were interfaced with the load cell shackles at each tensioner point on the LRP and transmitted the tension readings to the surface at less than one-minute updates.

Over

0

m

water depth

0

hour

critical righting operation

0

month

continuous monitoring campaign

The results

The righting operation took just three hours, using an ROV to tension the winches at two key tensioning units, one at a time. In comparison, using the alternative methods would have taken days. Throughout, the TVO team and the operator were able to view a constant near real-time visualization of the inclination of the wellhead and the tension that was being applied at each tensioning system. This was done via an internet-based dashboard developed by TVO, so that any member of the wider team, including the operator, from anywhere in the world could watch.

Making a SMART decision

“It was a very unique challenge. There were a lot of studies and approaches analysed within the customer group before making a decision to what the right approach was. They chose ours, using Sonardyne’s SMARTs and Compatt 6s, and it worked very well,” says TVO’s Kim Mittendorf.

“We really could control the two tensioners with the amount of tension we needed in near-real time. While the ROV was tensioning the winch, more than 2,000 m below us, we could see what direction the wellhead was moving in, how the pitch and roll angle changed.

“All the data was also live streamed to a website so that the customer, offshore and onshore, could monitor the operation in near-real time. This drove their decision making and gave them the comfort to continue with the operation as planned.”

Paving the way for a safe well abandonment

Following the righting of the wellhead, the tensioning and monitoring system was kept in place to allow safe intervention and final abandonment operations to be completed. During this phase, the data transmission rates were reduced to once every few hours.

For redundancy, two of the suction piles had relay Compatt 6s installed on them. This was due to a concern that direct line of sight to the transceiver from one or more of the Compatt 6s wouldn’t be possible.

In addition, the ROV had a ROVNav 6 transceiver, as another backup communications pathway. However, none of these were required as the LRP located SMARTs and the six Compatt 6s connected to the load pins were able to directly communicate with the topside transceiver.

Deepwater wireless well intervention success

The entire campaign proved to be a complete success. Thanks to TVO’s engineering and Sonardyne’s monitoring technologies, the operator was able to safely and efficiently decommission this challenging deepwater wellhead.

Initial skepticism from the operator in using a hydro-acoustic approach for data transmission was also overcome and through the success of the project, further confidence has been built into the technology for future applications.

Pinpointing Precision: Arctia chooses Sonardyne system for subsea surveys

When Finnish state-owned hydrographic services and icebreaking company Arctia need to accurately and reliably position their subsea survey equipment there is only one logical solution.

Arctia provide a wide range of services for Finland’s maritime industry including icebreaking, hydraulic engineering, planning and permit services, fairway maintenance and survey services, hydrographic services and research.

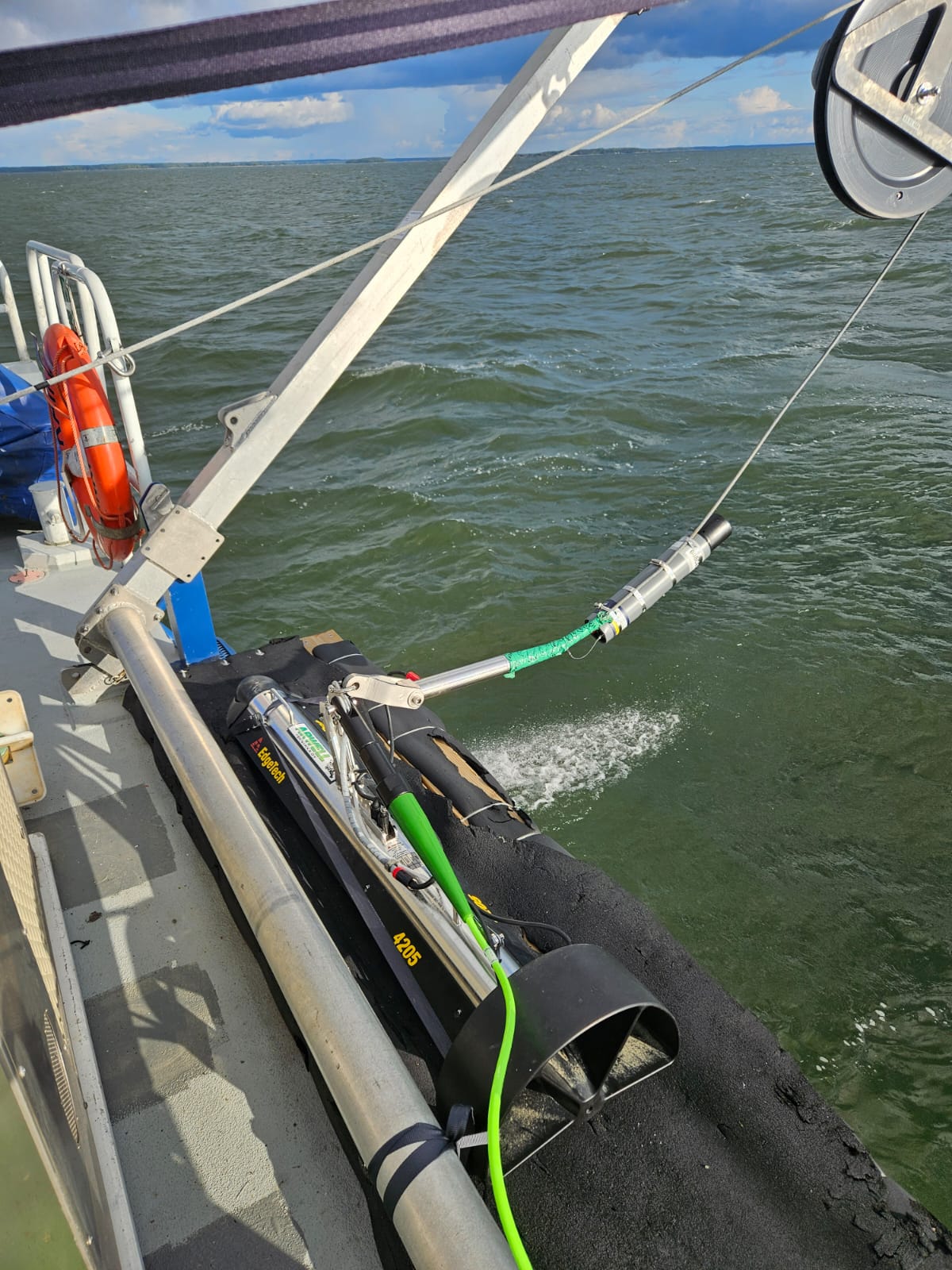

Their services all rely on precise subsea navigation and tracking, especially those using towed survey equipment. This is where Sonardyne come in, Arctia have chosen their Mini-Ranger 2 Ultra Short BaseLine (USBL) system with WSM 6+ transponders for their marine survey services.

Many of their marine surveys are conducted around offshore wind farms where teams of internationally certified hydrographic surveyors and shallow water experts provide tailor-made survey, analysing and planning solutions to meet even the most demanding of customer needs.

Mini-Ranger 2 is one of Sonardyne’s most popular USBL systems, chosen for its small size, value and dependable performance in all underwater environments. It’s the perfect choice for fitting to small survey vessels, moored barges and uncrewed vessels.

For Arctia, it is the perfect partner for towed hydrographic survey equipment such as magnetometers and sidescan sonars used as part of their survey services. With depth ratings of up to 1000 metres and able to operate in temperatures as low as -5 degrees Celsius, it’s ideal for the Baltic Sea and offers the opportunity to upgrade to other versions for depths up to 4,000 metres should Arctia and their customers operate at greater depths in future.

If you have a similar challenge in your subsea navigation and tracking operations, contact us to see how we can help.

Mapping the future for seagrass beds in Plymouth Sound

Seagrass beds are incredibly important ecosystems that offer a range of ecological benefits. Not only do they provide crucial habitats for a diverse array of marine wildlife, especially in coastal areas like Plymouth Sound, they can also store carbon, helping to mitigate the effects of climate change. These underwater meadows serve as nurseries for many species of fish in the early stages of their life, offering them protection and abundant food sources. Additionally, seagrass beds help to stabilise the seabed with their root systems, preventing coastal erosion and maintaining water quality by trapping sediments and nutrients.

However, despite their importance, locating and monitoring seagrass beds using traditional methods, such as survey boats, presents significant challenges. Seagrass typically grows in shallow waters, which can make it difficult for boats to navigate close enough to the shore to obtain accurate data. Traditional survey boats are often large and cumbersome, making them hard to manoeuvre in shallow or rocky areas. This limitation can result in incomplete or inaccurate assessments of seagrass distribution and health.

Furthermore, the process of using boats for surveying can be time-consuming and labour-intensive. It often requires multiple trips and extensive manual labour to map out the seagrass beds accurately. The visibility in shallow waters can also be poor due to water turbidity, further complicating the survey efforts and leading to potential underestimation of seagrass coverage.

Finding a solution…

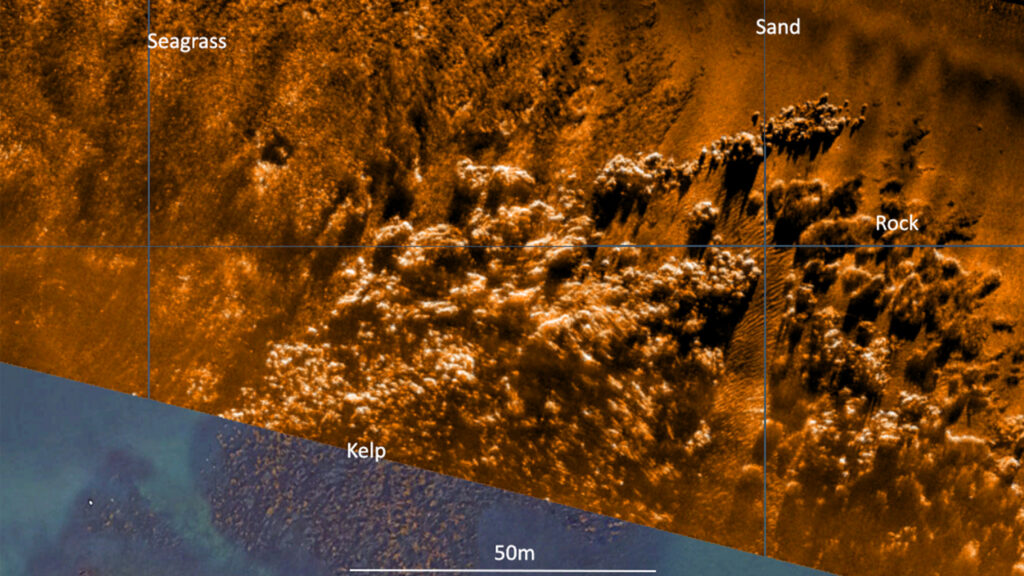

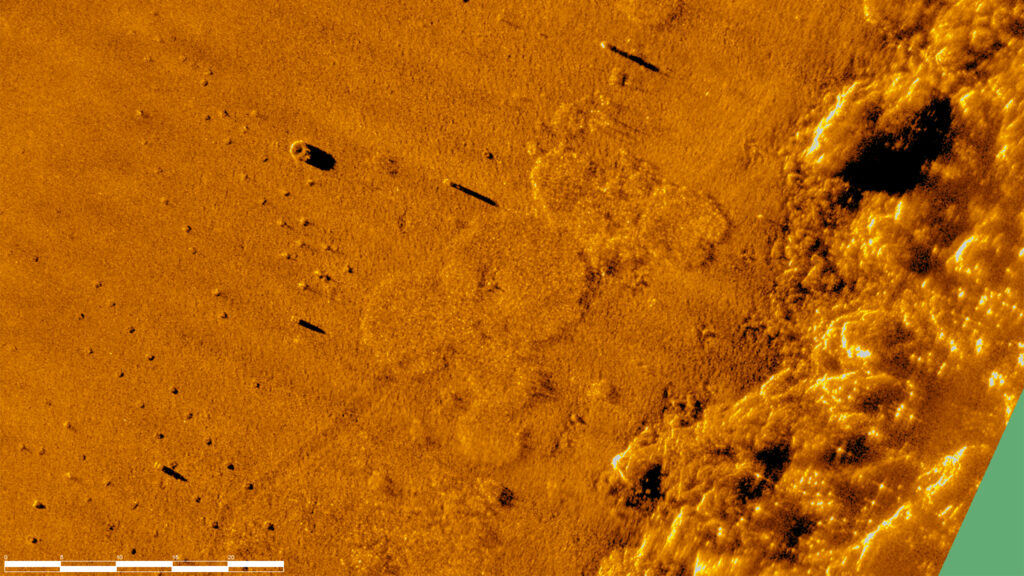

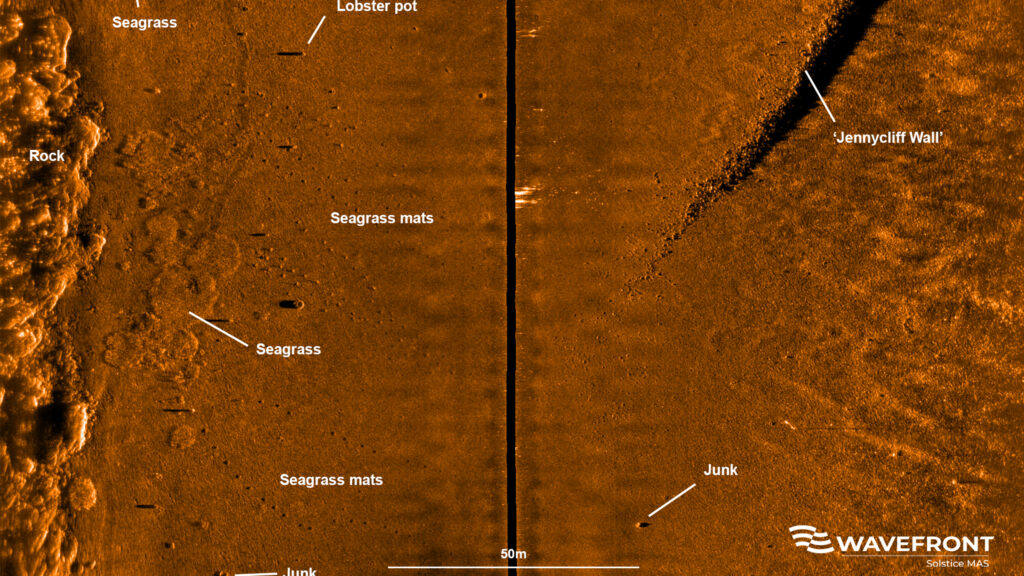

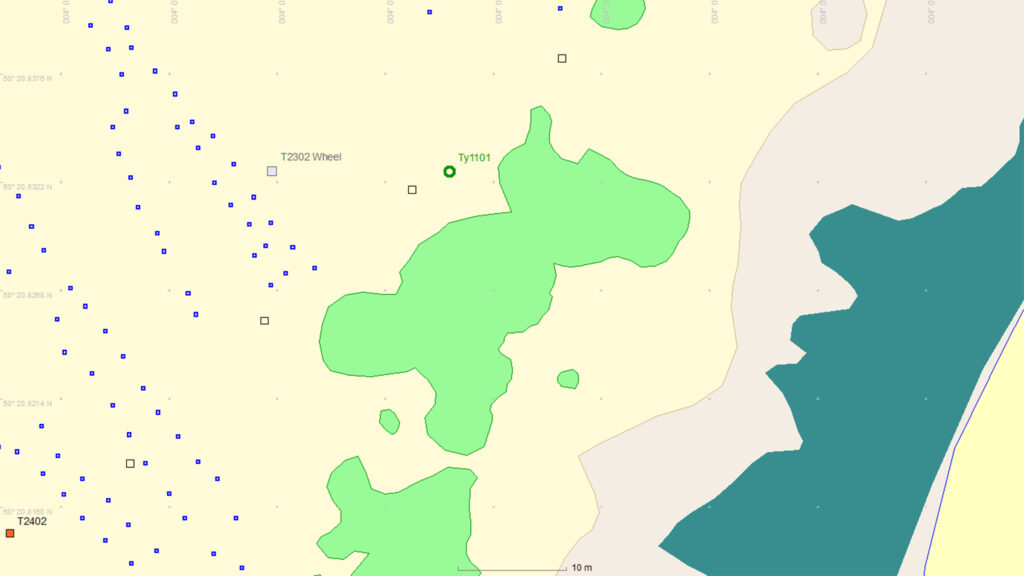

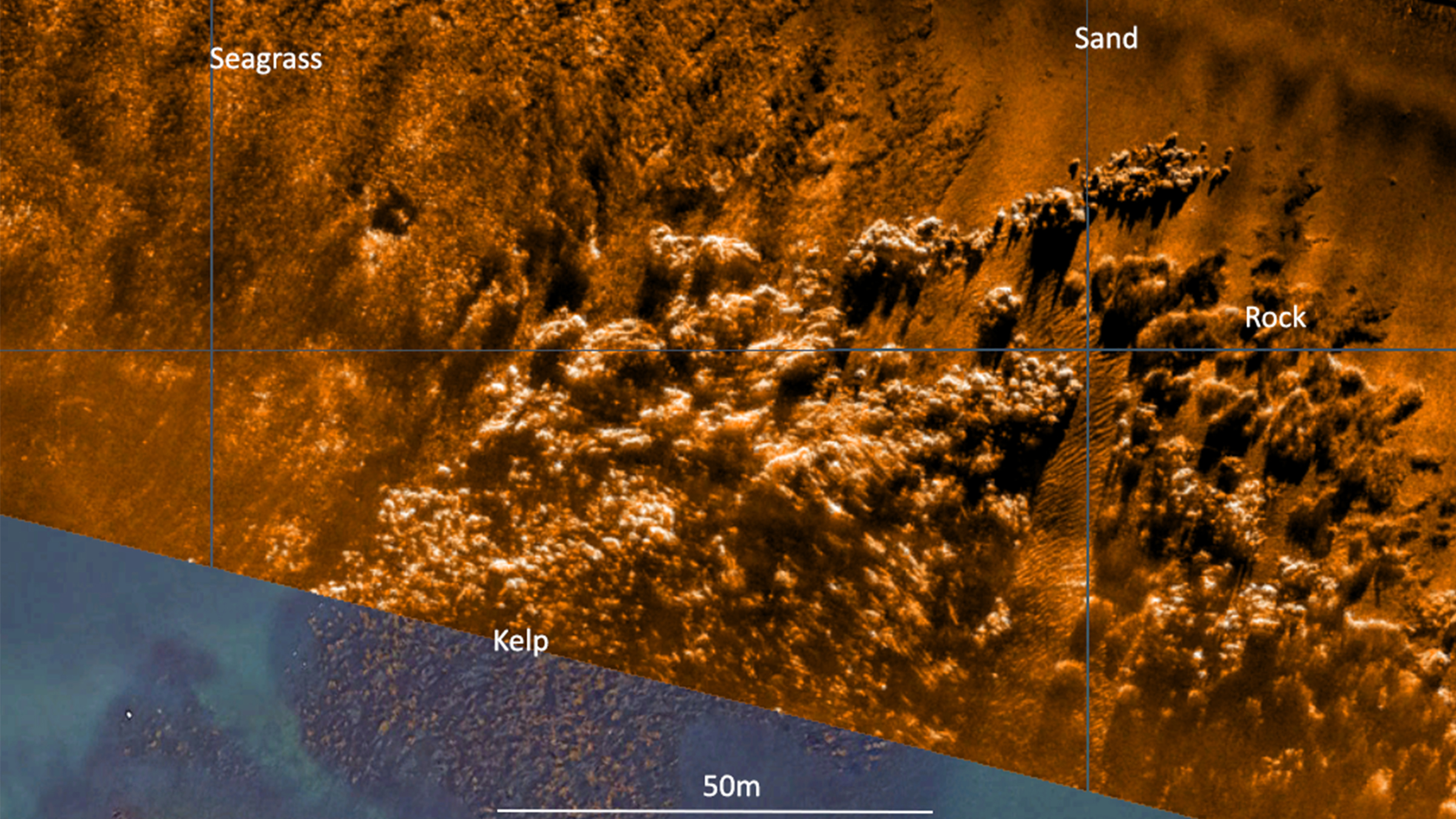

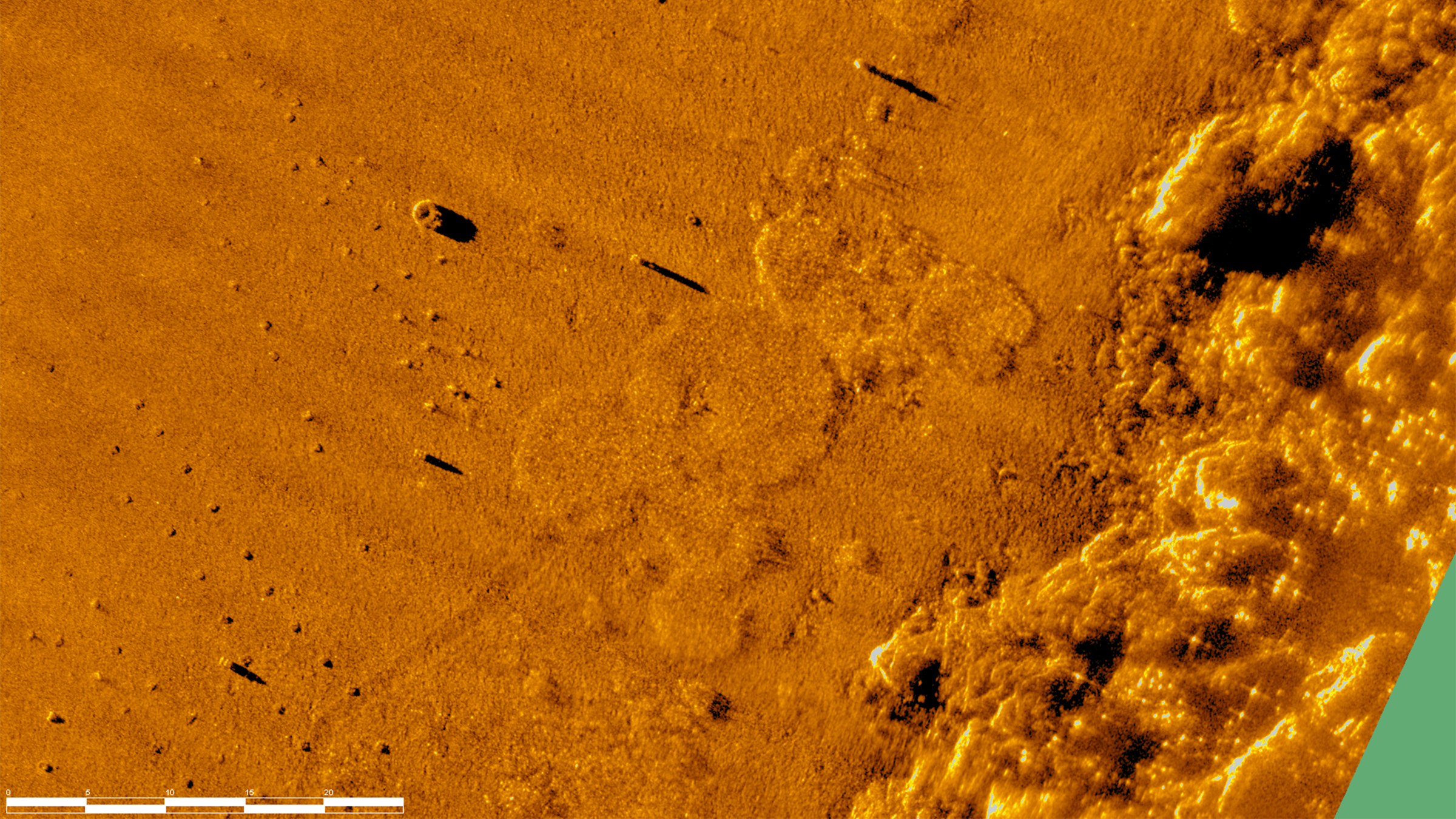

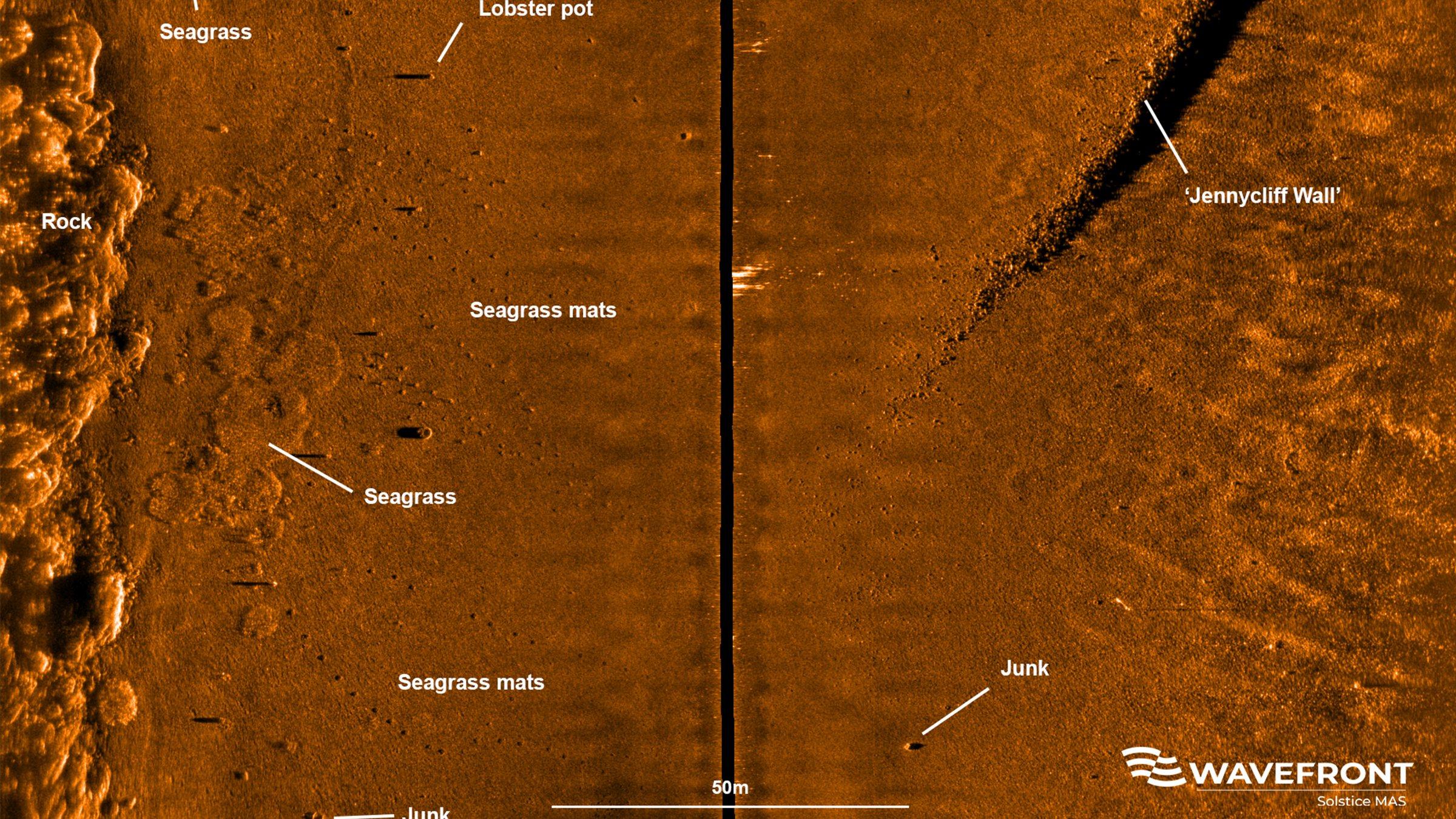

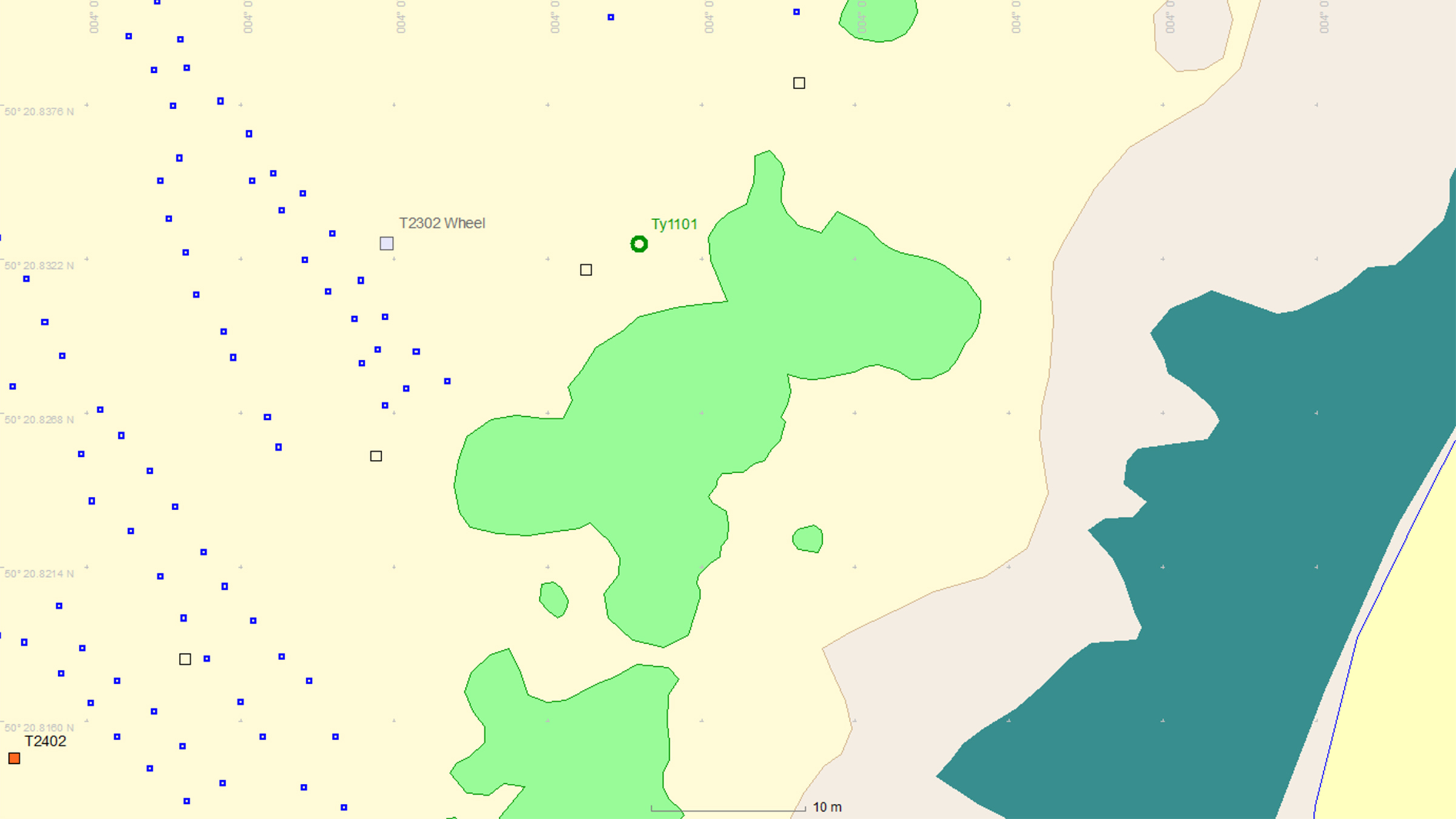

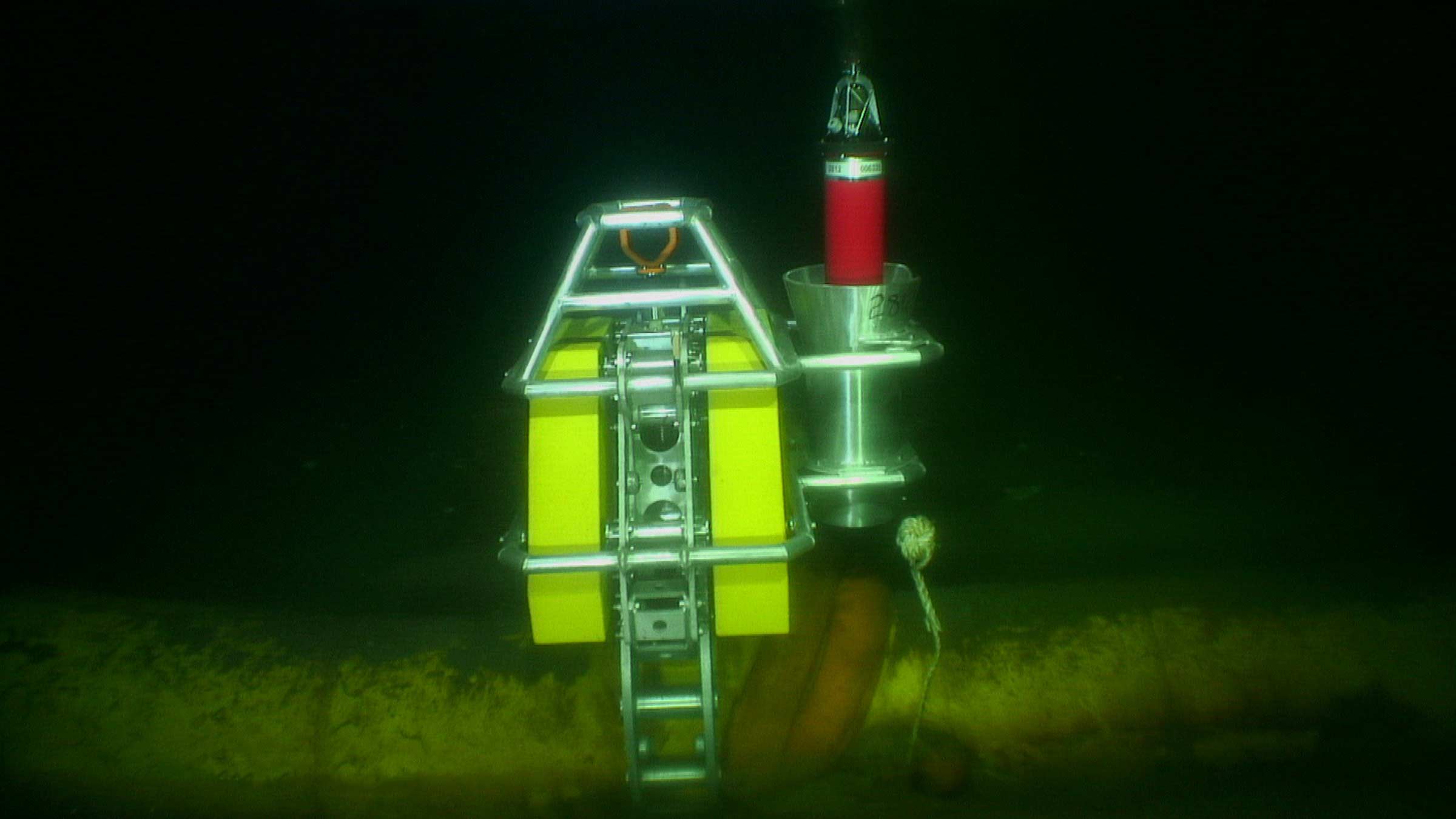

This is where Sonardyne and Wavefront Systems come in. The solution, which combines Sonardyne and Wavefront technology, is a survey boat carrying Solstice MAS™ (Multi-Aperture Sonar) as well as a SPRINT-Nav Mini mounted to a pole, deployed over the side of the boat; this maps the chosen area in 200 m wide strips. Once this survey has been completed, the sonar data that has been captured is then processed to create a map of the seagrass in a GIS. A Remotely Operated Vehicle (ROV) is then sent to the same area to ground truth features on the seabed to check that they are how they have been interpreted by Solstice MAS. The ROV is fitted with SPRINT-Nav Mini, allowing us to track its position underwater and guide it, using the map, to the features identified by Solstice; the ROV is also fitted with a camera and the recorded video can be used to create 3D models of the seabed.

Wavefront Systems’ Solstice MAS uses sound signals to produce high-quality images of the seabed, capable of creating images 200 metres wide at high resolution even in shallow water environments, all while consuming very little power. The Solstice family of sonars are built on unique MAS technology and are designed to fill the gap between standard side scan sonars, which are typically simple in design but give low image resolution, and Synthetic Aperture Sonars (SAS), which are expensive, more susceptible to complete data loss due to platform movement and also produce vast amounts of data. In order to execute more detailed mapping, Solstice MAS requires a high quality navigation sensor, which in this case is SPRINT-Nav Mini.

SPRINT-Nav Mini is an all-in-one vehicle guidance and navigation instrument, which combines AHRS data, Doppler Velocity Logger (DVL), Inertial Navigation System (INS) and depth sensor into a single housing. Having SPRINT-Nav Mini fitted onto the ROV provides positioning input, as well as attitude and heading data.

Creates images

0

m

at high resolution

ROV fitted with

0

D

camera

Solstice creates images

0

m

each side of the vessel

Adopting these technologies on such small versatile platforms opens the possibility of high-grade survey data in shallow waters. As a result of the cross Covelya Group collaboration between Sonardyne and Wavefront Systems, a high-definition map of seagrass beds can be created with a greater degree of accuracy than was previously possible with more traditional methods.

A seagrass restoration project conducted by the Ocean Conservation Trust (OCT) in Plymouth Sound, which involves monitoring, conserving and expanding the existing seagrass beds can be enhanced with the use of an ROV which has SPRINT-Nav Mini fitted to it. To help grow the existing seagrass beds, the OCT are placing seagrass mats on the seabed in Plymouth Sound. A survey boat fitted with Solstice and SPRINT-Nav Mini followed by an ROV fitted with SPRINT-Nav Mini can then be used to monitor and create a map of where these mats have been placed so that they have a better understanding of the success of the restoration and expansion project.

Repeatable, configurable, long-term surveillance

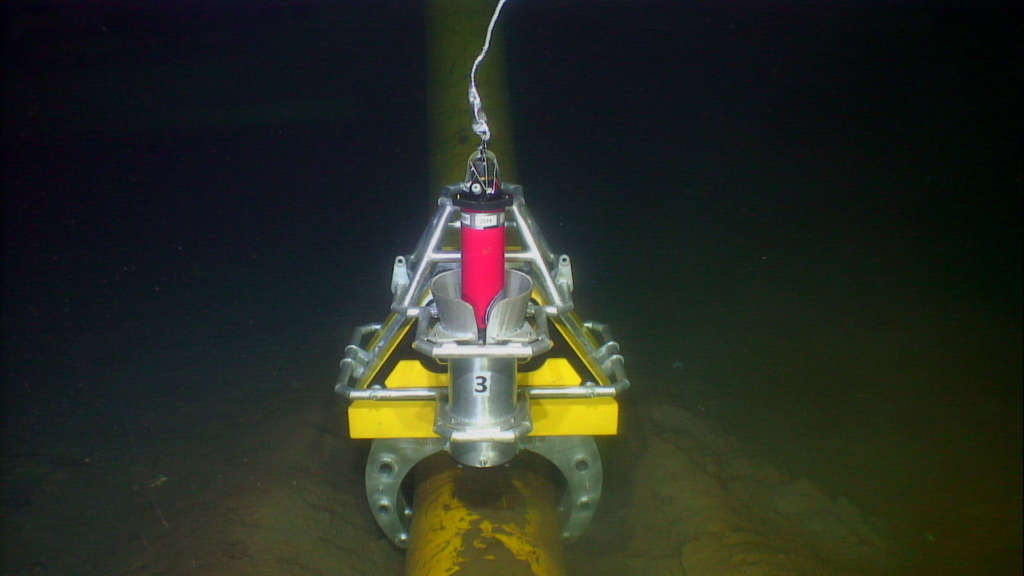

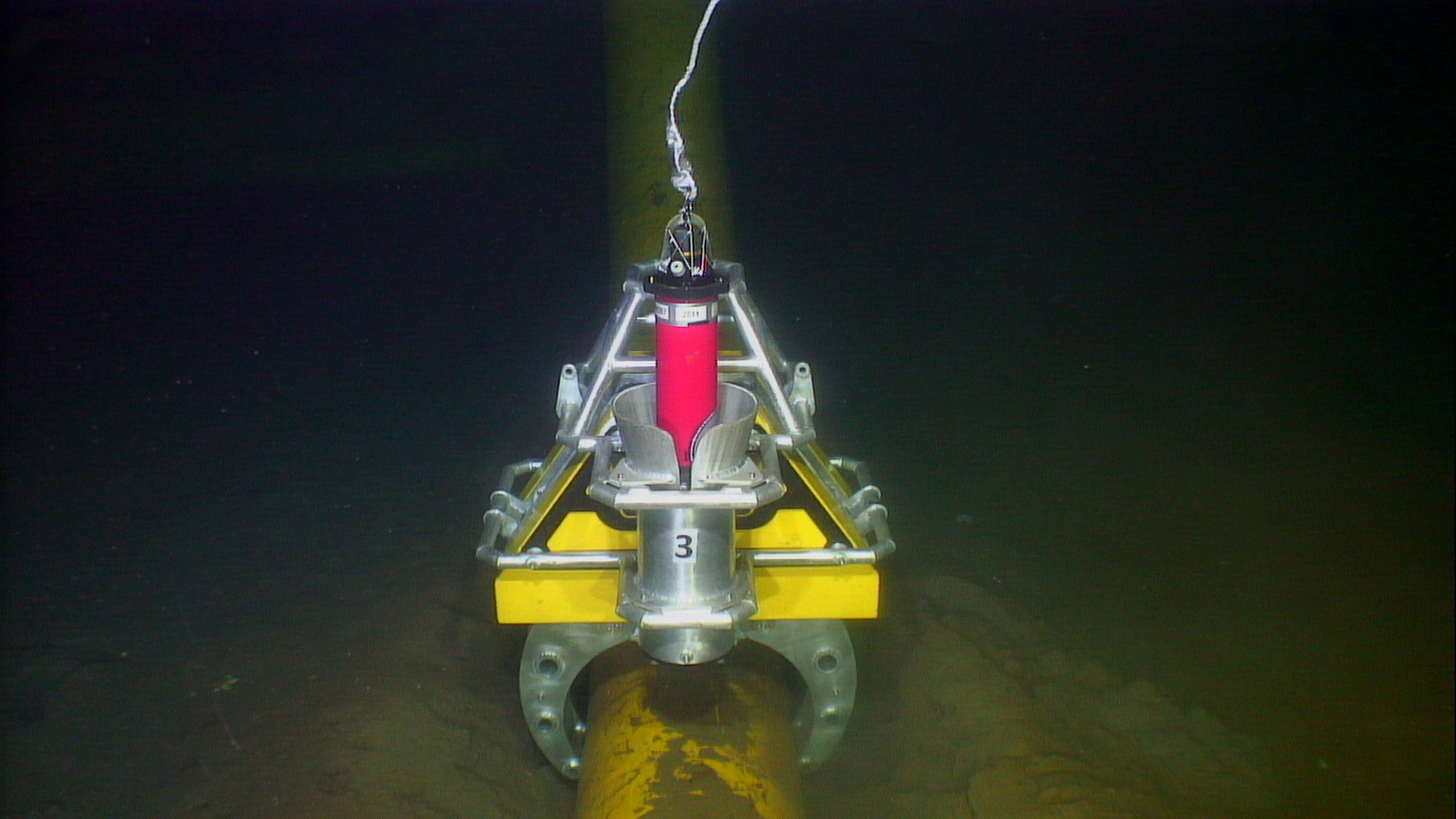

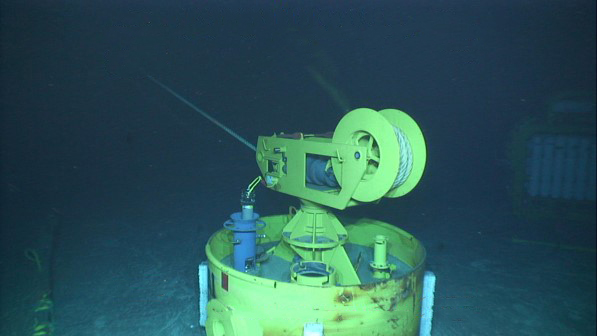

The Autonomous Monitoring Transponder (AMT) is a long-endurance transponder engineered for your long term subsea survey tasks and is capable of autonomously acquiring acoustic ranges and sensor data without surface control.

AMTs can detect subtle movement often not picked up by traditional ROV surveys so it’s ideal for monitoring slow movements, like creeping or buckling pipelines. Using structure and seafloor transponder buckets, they can be ROV-deployed, removed and re-installed to provide insight over time. Your AMTs can be configured to take measurements at specific intervals and be adjusted on-demand by you as your campaign progresses. Data can even be collected in real time using a USV should your operation need it.

As it’s collected, data is time-stamped and logged internally for recovery via the integrated high-speed acoustic telemetry modem. This autonomy allows measurements to be made over a long period of time without requiring a surface vessel or ROV to command the process. This enables new applications that save vessel and survey time so reducing cost and risk.

At a glance

- Recommended for long endurance site surveys

- Leave it deployed for six years or more

- Extensive choice of monitoring sensors

- Depth rated to 3,000 m

- Harvest data using a ship, buoy, AUV or USV

AMT has many of the same acoustic functions as Compatt 6, our most popular navigation transponder. It operates in the Medium Frequency (MF) band and is fully Sonardyne Wideband 2 compatible.

Precision pressure, temperature, sound velocity and dual-axis inclinometer sensors are integrated and are intelligently powered up at the requested time and sampling period, providing an ultra-low power platform for up to three years deployment. Sampling regimes can be re-programmed, and recovery of all data can be achieved via the acoustic modem.

The instrument is available with a range of omni and directional transducers, depth ratings and pressure housings dependent on deployment duration and application. Additional external sensors can be easily integrated via the power and communications port.

Acoustics

• Sonardyne Wideband 2 MF band (18 – 36 kHz)

• Over 500 unique addresses, ideal for large array deployments

• Data transfer rates of 100 to 9,000 bps – user selectable

• Omni-directional and directional transducers to suit environmental conditions

• Ranging precision: Better than 15mm

Sensing

• Standard onboard: Temperature, tilt, strain gauge

• Optional onboard: high precision stain gauge, DigiQuartz pressure sensor, high accuracy inclinometer, sound velocity

• Sampling rate: user configurable

• Vessel, USV or AUV data harvesting options

• Optional external: current meters, turbidity sensors

Design

• 3,000 m depth rating

• Aluminium or aluminium-bronze housing depending on environmental conditions and duration of deployment

• Can be deployed for over 5 years without recovery (maxi housing)

• ROV-friendly design: integrated acoustic release mechanism as standard

Ownership

• Warranty: 1 year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export Licence: Not required

• A typical system: multiple seafloor and structure mounted AMTs (typically 6), vessel-based Modem 6 or Dunker 6 or HPT 5000 / 7000, SIU, Monitor software

Specifications

| Feature | Type 8305-3411 | Type 8305-3111 | Type 8305-3113 | |

|---|---|---|---|---|

| Depth rating | 3,000 m | 3,000 m | 3,000 m | |

| Operating frequency | MF (20–34 kHz) | MF (20–34 kHz) | MF (20–34 kHz) | |

| Transducer beam shape | Omni-directional | Omni-directional | Directional | |

| Transmit source level (dB re 1 µPa @ 1 m) | 187–196 dB (4 levels) |

187–196 dB (4 levels) |

190–202 dB (4 levels) |

|

| Tone Equivalent Energy (TEE) | 193–202 dB | 193–202 dB | 196–208 dB | |

| Receive sensitivity (dB re 1 µPa) | 90–120 dB (7 levels) |

90–120 dB (7 levels) |

80–120 dB (7 levels) |

|

| Ranging precision | Better than 15 mm | Better than 15 mm | Better than 15 mm | |

| Number of unique addresses Wideband 1 & 2 | >500 | >500 | >500 | |

| Battery life (listening, disabled) | Alkaline | 833 days | 833 days | 833 days |

| Safe working load (4:1) | n/a | 250 kg | 250 kg | |

| Mechanical construction | Aluminium-bronze | Aluminium | Aluminium | |

| Dimensions (length x diameter) | 1007 x 130 mm | 1034 x 134 mm | 1018 x 134 mm | |

| Weight in air/water | 35/24 kg | 24/12 kg | 24/12 kg | |

| Endcap sensors and options | ||||

| Temperature (±0.1°C) | Standard | Standard | Standard | |

| Tilt switch (±30-45°) | Standard | Standard | Standard | |

| Strain gauge pressure sensor (±0.1%) | Standard | Standard | Standard | |

| High precision strain gauge (±0.01%) Presens or Keller | Optional | Optional | Optional | |

| Paroscientific digiQuartz pressure sensor 1350 m, 2000 m, 4130 m, 6800 m (±0.01%) |

Optional | Optional | Optional | |

| High accuracy inclinometer range: ±90°, Accuracy: ±0.05° over 0 – ±15°; ±0.2° over 0 – ±45° | Optional | Optional | Optional | |

| Sound velocity sensor ±0.02 m/s accuracy under calibration conditions | Optional | Optional | Optional | |

| Release mechanism | n/a | Standard | Standard |

Frequently asked questions

Software and firmware

Software and control hardware

Datasheets

Manuals and quick start guides

Why Fetch is perfect for your operations

Think of Fetch as your underwater data hub. We work with you to integrate your chosen sensors, creating a reliable gateway to your subsea data that you can access remotely whenever needed.

Your advanced seabed geodesy projects demand precision and reliability. We’ve developed Fetch to deliver both, through seamless integration with our Ranger 2 system for efficient data collection.

We understand your commitment to reducing operational costs and environmental impact. Fetch helps you achieve both through long-term deployment capabilities and remote data harvesting, minimising vessel time and emissions.

Fetch your subsea data

Fetch is a long-life subsea sensor logging node with a battery life option of up to 10 years that enables data to be wirelessly extracted via its integrated high speed acoustic modem. We’ve designed every aspect of Fetch to support your underwater monitoring needs, from its high-capacity battery packs to its compatibility with our Ultra-Short BaseLine (USBL) positioning systems. Our team brings decades of experience in subsea technology to help you achieve reliable, long-term monitoring success.

An innovative free-fall deployment system ensures your Fetch lands upright every time, saving you valuable vessel time and cost.

Your Fetch can be configured with an array of different sensors to suit your monitoring applications. Standard sensors include high accuracy pressure, temperature and sound velocity as well as inclination. Other sensors can be integrated internally or externally as required.

Smart power management means the subsea sensor logging nodes only activate when needed, maximising battery life. Data captured by the active nodes is time-stamped and stored on an SD memory card ready for retrieval,

You can configure your sampling regime before deployment and update it in-situ via the acoustic modem which is also used to recover the data to the surface. The 9,000 bits per second modem transfer rate enables data to be extracted in minimal vessel time so reducing your operational costs.

When you’re ready to retrieve your Fetch, a simple acoustic command brings it safely to the surface under its own buoyancy ready for collection.

Specifications

| Feature | Type 8306-3873 | |

|---|---|---|

| Depth Rating | 3,000 or 6,000 m | |

| Operating Frequency | MF (20–34 kHz) | |

| Transducer Beam Shape | Directional | |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 190-202 dB (4 levels) | |

| Receive Sensitivity (dB re 1 µPa) | 90-120 dB (7 levels) | |

| Battery Life (Capacity) | 5 years typical (10 years option) (dependent on sensors and sampling interval (180 Ah)) |

|

| Mechanical Construction | Glass sphere, galvanised stand and duplex stainless steel guards and connectors |

|

| Operating Temperature | -5 to +35°C | |

| Storage Temperature | With Batteries | 0 to +30°C |

| Without Batteries | -5 to +35°C | |

| Weight in Air/Water | Fetch | 40/10 kg (upthrust buoyancy) |

| Stand | 60/52 kg | |

| Sensors and Options | ||

| Temperature (±0.1°C) | Optional | |

| Tilt Switch (±30–45°) | Standard | |

| Paroscientific DigiQuartz Pressure Sensor (±0.01%) 1,350 m, 2,000 m, 4,130 m, 6,800 m |

Optional | |

| Strain Gauge Pressure Sensor (±0.1%) | Standard | |

| High Precision Strain Gauge (±0.01%) Keller or Presens | Optional | |

| Sound Velocity Sensor ±0.02 m/s Accuracy Under Calibration Conditions |

Optional | |

| High Accuracy Inclinometer Range: ±90°, Accuracy: ±0.05° over 0 – ±15°; ±0.2° over 0 – ±45° |

Optional | |

| Release Mechanism (Screw-off) | Standard | |

| Connector Type | Impulse MCIL-8-MP | |

Software and firmware

Datasheets

Manuals and quick start guides

Performance

• 3,000 or 6,000 m depth rated

• Vessel, USV or AUV data harvesting options

• Anti-trawl fame option available

• High capacity primary lithium battery pack – up to 10 year deployment life

Design

• Integrated modem with data rates ranging from 100 to 9000 bps

• Customisable sensor payloads

• Glass sphere, titanium parts (except duplex s/steel guard), polypropylene shell

• Easy to set up with configuration and sampling period programmable via telemetry link

Acoustic

• Integrated modem with data rates ranging from 100 to 9000 bps

• 500 Unique addresses, ideal for large array deployments

• Sonardyne Wideband1, 2, 2+ and HPR 400 USBL mode compatible

Set-up

• Warranty: 1-year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export License: Not required

Why Fetch AZA is perfect for your operations

Your Fetch AZA system offers a comprehensive solution transforming your ocean monitoring operations across multiple applications, including environmental surveys, seabed deformation monitoring, and low-cost in-situ ocean surveillance. Unlike traditional pressure sensors, which suffer from drift over time, the Fetch AZA technology autonomously recalibrates in-situ.

A unique control system periodically cycles the pressure sensor from ambient seabed pressure to near-zero, enabling comparison to a highly accurate low-pressure reference sensor for calibration. The reference sensor is never subjected to ambient pressure and is accurate to changes of less than a millibar, or about 1cm of head of water.

The sensors are low power, allowing for long endurance deployments, and provide time-stamped data, which is often critical to your commercial or scientific objectives. With their in-built data storage and high-speed modem capacity, they can support your data collection and harvesting using a wide range of other Sonardyne and third-party sensors (High precision temperature and sound velocity as well as inclination) and are compatible with any Sonardyne 6G equipment, including Ultra-Short BaseLine (USBL) systems and modems.

For science

These capabilities have created an instrument that revolutionises seabed measurements, across ocean science and the commercial sectors. Scientists can now undertake measurements, critical to understanding tectonic processes, at a resolution they’ve never been able to achieve before.

Scottish Association for Marine Science (SAMS) research using Fetch AZA

For business

In the commercial sphere, Fetch AZA meets upstream production companies’ long-term goals of measuring 1 cm/year of vertical movement across their energy fields. These fine-scale measurements provide a powerful tool for proactive reservoir management throughout their lifecycle. This is a key enabler for maximising economic recovery.

Its remote capabilities represent a significant operational advantage, as data can be retrieved using Uncrewed Surface Vessels (USVs) from over-the-horizon locations, eliminating the need for expensive crewed vessels and reducing your costs, personnel risks and environmental impact.

This combination of remote operation, sustained accuracy, and precise repeatability makes the Fetch AZA an ideal choice if you are seeking a reliable, cost-effective ocean monitoring solution.

Performance

• Self-calibrating pressure sensor

• 3,000 m and 6,000 m depth rated versions

• MF and LMF operating frequency options

• Up to 10 year battery life

Design

• Neutral buoyancy in water for easy recovery

• Anti trawl frame option available

• Glass sphere, duplex s/steel guard, PVC shell, titanium ports construction

General

• Well suited for USV data harvesting

• Can be configured with a wide range of sensors

• Different deployment and recovery options provide flexibility for your operations

Support

• Work side-by-side with our Projects Group from concept to deployment

• Work with our experienced team about our USV data harvesting service

• 24-hour support, whenever and wherever you are in the world

• Systems are manufactured and tested before delivery at our world-class in-house facilities

Specifications

| Feature | Type 8306 | |

|---|---|---|

| Depth Rating | 3,000 m | |

| Operating Frequency | MF (20–34 kHz) | |

| Transducer Beam Shape | Directional/omni-directional | |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 190–202/187–196 dB | |

| Receive Sensitivity (dB re 1 µPa) | <85 dB | |

| Communications | Acoustic modem & Bluetooth wireless | |

| Battery Life (Lithium) | 10 years typical, (504 Ah) (dependent on sensors and sampling interval) | |

| Mechanical Construction | Glass sphere, duplex s/steel guard, PVC shell and titanium ports | |

| Operating Temperature | -5 to +35°C | |

| Storage Temperature | With Batteries | 0 to +30°C |

| Without Batteries | -5 to +35°C | |

| Mass | With Stand | 145 kg |

| Without Stand | 62 kg | |

| Weight in Water | With Stand | 830 N |

| Without Stand | 25 N (negative buoyancy) | |

| Sensors and Options | ||

| AZA In-situ Self-Calibration Mechanism | Standard | |

| High Precision Temperature Sensor (±0.015°C) | Standard | |

| Transfer Pressure Sensor | Quartz, (±0.01%) | Standard |

| 2nd Quartz | Option | |

| Ambient Pressure Sensor | Strain Gauge, (±0.01%) | Standard |

| Strain Gauge, (±0.19%) | Option | |

| Low-Range Pressure Sensor (Strain Gauge, 2 bar (±0.01%)) | Standard | |

| Sound Velocity Sensor ±0.02 m/s Accuracy Under Calibration Conditions |

Option | |

| MEMS Inclinometer (±1°) | Standard | |

| High Precision Inclinometer (±0.05°) | Option | |

| Acoustic Baseline Ranging | Option | |

| Release Mechanism (Screw-off) | Option | |

| Battery Disconnect Fob | Standard | |

| Stand/Mud Feet | Option |

Software and firmware

Datasheets

Manuals and quick start guides

Transponders provide reliable releases for Allton offshore Norway

When placing vital equipment such as Nodes on the seabed you need to be sure that you can retrieve them. During the development process, a lack of other products available in the marketplace that met their requirements led Norwegian technology and service company Allton to turn to Sonardyne for a solution.

Starting life as Petromarker in 2005, Allton has been operating offshore Norway for almost 20 years. The company specialises in: marine subsurface electro-magnetic (EM) data acquisition and imaging for hydrocarbon exploration and production, CO2 measurement, monitoring and verification for carbon capture sequestration and marine mineral exploration. It has now expanded its technology and service offering to include multiphysics joint acquisition of both EM and seismic OBN data.

With their innovative multiphysics platform relying on the data they retrieve from both EM and seismic OBN nodes, Allton need to be one hundred percent confident that they can locate and recover their nodes once they’ve been deployed. This can be from depths of up to 3,500 m in often challenging conditions.

When Allton expanded its operational work department and began the redesign of its subsea equipment, a search began for new and reliable solutions as existing transponders and release mechanisms were unsuitable for their specific requirements.

With several decades of subsea transponder and release manufacturing experience, Sonardyne was an obvious choice for a solution.

Our RT 6 family of acoustic release transponders combine the extensive track record of our previous models with the flexibility of a 6G hardware platform, meaning they can be deployed, located and released using any of our Ranger 2 USBL systems or 6G topsides.

An acoustic release transponder is fixed to a subsea asset so it can be found and recovered. An acoustic signal from a surface vessel locates the transponder on the asset. A second acoustic signal then tells the transponder to release the mechanism anchoring the asset to the seabed so that it can be retrieved.

Having gained a full understanding of Allton’s requirements, our engineering team worked closely with them to custom modify an existing RT 6 model to meet their exact needs. Aleksander Kristiansen, Supply Chain and Asset Manager, from Allton explains, “The custom manufacture of our RT 6-4000 was based on an existing model (RT 6-1000) which Sonardyne modified to suit our operational needs. This included extending its range and adding a secondary burn release circuit.

Working with our customers to fully appreciate their needs and the challenges their businesses face enables us to develop solutions for their specific operations. As Trevor Barnes, Sonardyne Sales Manager, explains: “Allton was looking for a robust, reliable acoustic release to give them confidence in retrieving their equipment from a range of depths. Whilst our RT 6-1000 is perfect for depths of up to 1,000 m, Allton operate in depths of up to 3,500 m so our engineers worked closely with them to develop an RT 6-4000 to enable this. A secondary burn-wire release was also added at their request, as a backup in the unlikely event that the first acoustic release fails.”

Aleksander Kristiansen continued “Sonardyne were always willing to assist and put the right technical expertise onto the variety and wide range of tasks to solve our many, often complex at times, challenges. Their creative ideas were well aligned with our expectations and letting us borrow equipment for an extensive time to conduct in-house testing was much appreciated. It gave us further confirmation that we were making the right choice in the RT 6 releases.”

Allton’s nodes are now fitted with RT 6-4000 acoustic releases to ensure that they can be reliably located and retrieved from the seabed at all their operating depths and in any conditions.

They can now provide data across all of their services with confidence that they have consistent, reliable access to their network of nodes.

Our standard RT 6s come in three depth ratings, 1,000 m, 3,000 m and 6,000 m and all use our workhorse Ranger 2 USBL system or deck topside to command and track. Some models can even be controlled using an Android app.

If you have a similar operational challenge, take the worry out of mooring and retrieving your kit and talk to us today.

Navigating new waters: How real-time current monitoring can transform port operations

Port of Aberdeen, Scotland's largest berthage port – previously known as Aberdeen Harbour, was established in 1136 by King David I of Scotland. It is the oldest existing business in Britain, with a history spanning almost 900 years.

Construction of the port’s South Harbour started in 2017 after years of planning. Completed in August 2023, the £420 million expanded port was the largest marine infrastructure project in Trust Port history. It offers 2,800 metres of deep-water berths to a maximum depth of 14.8 metres (MWHS).

The harbour extension is aimed at attracting vessels and project activity – such as cruise ships and offshore renewable energy (ORE) operations – which would have previously gone to European ports capable of handling their requirements. This increased activity will support local jobs, attract local supply chain spend and investment.

A key feature of South Harbour is its ability to berth large ships. To ensure safe passage for these vessels, it’s important to have accurate and detailed data within the harbour. With its long history, Port of Aberdeen has this information for the North Harbour and is continuing to build a comprehensive understanding of the water movements within South Harbour. This data can then be used to enhance navigational safety and operability within the port.

Sonardyne’s Origin® 600 Acoustic Doppler Current Profiler (ADCP) enables users to monitor waves, currents and turbulence. Its built-in acoustic modem enables remote access while it’s deployed. This allows battery and storage checks, the opportunity to inspect and upload data, reconfigure schedules and run quality control, all whilst the ADCP is on the seabed. Enabling users to make time-critical decisions with near real-time data delivery.

Realising the potential for gathering valuable, high quality data to support their operations, Port of Aberdeen approached Sonardyne’s Aberdeen office to hire an Origin 600 for an initial six month period.

“We’re delighted that Port of Aberdeen chose to hire an Origin 600 to monitor the water movement within South Harbour. The knowledge they will gain from the data is vital to help them provide the best possible service for their customers and operators within the port. We look forward to working with them on this project and beyond.” Thomas Blair, Operations Manager, Sonardyne, Aberdeen.

The Origin 600 was deployed, using Sonardyne RT 6 1000 and 3000 release transponders, in the port district on 20th March 2025. Its onboard data processing via implementation of Edge ‘apps’ enable it to deliver information on the wave environment, together with the speed and direction of water column currents, and the timing of tides – fundamentally slack tides. All the data is processed and stored on the unit until Port of Aberdeen are ready to harvest it. This can be done without retrieving the ADCP via its onboard acoustic modem.

In June 2025 the unit was temporarily retrieved to recharge the battery and will be redeployed for a further three months in an alternative, suitable location.

“Origin 600’s ability to monitor and report on the behaviour of currents throughout the water column whilst remaining on the seabed makes it an ideal choice for projects where actionable information is critical for operational safety, just as we have seen with Port of Aberdeen’s South Harbour. What’s more, Origin 600’s real-time reporting capability can be used to support and inform dredging activities, opening up a further avenue where this instrument can help Port of Aberdeen. I’m truly excited to see the full extent of the outputs from this project and how the Origin ADCP data will be applied moving forward.” Michelle Barnett, Business Development Manager – Ocean Science, Sonardyne.

As more current and tidal data is gathered, Port of Aberdeen will be able to use it to enhance operability within the port.

“Port of Aberdeen relies on accurate, reliable data to drive informed decision-making. Having a company with this technology right on our doorstep is a significant advantage – not only in helping us achieve our own objectives, but also in supporting our customers, stakeholders, and port users in delivering their work scopes and projects efficiently and effectively.” Benji Morrison, Harbour Master, Port of Aberdeen

Origin 600 being deployed in Port of Aberdeen South Harbour

If you have a similar project or challenge, talk to us about how Origin ADCPs or other Sonardyne technology can help.