Combining cutting-edge hull design, composite material construction and an advanced control system, the company’s VICTA class DDU offers the speed and endurance of a long-range insertion craft (LRIC) with the stealth and capacity of a swimmer delivery vehicle (SDV). The team behind it has extensive operational experience and the result is a first-of-kind, fly-by-wire craft that can rapidly transition from surface to sub-surface configuration.

VICTA can travel up to 250 nautical miles (nm) at speeds of up to 40 knots on the surface, to swiftly deliver up to eight operatives (two crew and six divers) to their objective area mission-ready. Below the surface, it cruises at 6 knots, with a ‘sprint’ capability of 8 knots, for up to 25 nm.

It’s also easy to transport and deploy into a theatre of operation. At just under 12 m long, it fits comfortably into a standard shipping container and can be deployed from an unmodified surface vessel or port of opportunity. It can even be carried underslung from a heavy-lift support helicopter, such as the CH-47 Chinook.

Going in forewarned

But, it’s when VICTA is on and beneath the surface that Vigilant plays its enabling role. Being able to detect – at range – navigation hazards, before they become a real threat, is mission-critical to the sort of operations likely to feature in VICTA’s play-book. Vigilant is the solution.

With Vigilant integrated into VICTA, complete with its easy to use, intuitive graphic user interface, pilots can visualise the environment ahead to navigate safely and avoid obstacles ensuring safe insertion and recovery of operators, regardless of the mission. Quite simply, it provides a tactical advantage for their operations.

Using sophisticated bow-mounted transducers, Vigilant displays water depth, sub-surface obstacles and features by creating an accurate 3D model of the underwater environment over a 90° field of view. The model is displayed relative to the vessel, overlaid on standard charts in real-time, providing operators with an easily-interpreted topographical image of their navigation track. It may also enable intruder detection, potentially vital in high-risk, high-threat environments.

Unique visualisation

“Vigilant allows us safe and unhindered surface/sub-surface manoeuvring,” says Tim Chicken, SubSea Craft’s Chief Commercial Officer. “Vigilant was selected because of a proven track-record and a compatibility with our proposed concept of operations allowing VICTA to operate safely in confined water-space owing to its unique 2D and 3D visualisation capability.”

For example, pilots can use 2D, for obstacle avoidance, and 3D, for a real-time, three-dimensional view of the world around them, allowing navigation within potentially hazardous coastal – or what are known as littoral – zones where hidden threats, manmade or natural, may be lurking.

Combing all of these unique capabilities, VICTA broadens the options open to maritime, joint and special forces commanders, providing an advantage previously not available with conventional craft. It’s a powerful capability able to support operational requirements ranging from advanced-force insertion through to maritime counter-terrorism and constabulary operations. In all of these scenarios, situational awareness is key.

Unrivalled performance

“One of Vigilant’s main advantages, over competing products, is its range,” says Ioseba Tena, our Global Business Manager for Robotics and Defence. “It can see out to 1,500 m, when in working in 2D mode, and then to 600 m in 3D mode, to help you plot your environment in real time ahead of the vehicle. That type of performance is unrivalled.”

SubSea Craft worked in close partnership with a number of other cutting-edge marine technology and engineering businesses, including Ben Ainslie Racing Technologies (BAR-Tech) and control systems specialist SCISYS. It was built by AC Marine and Composites Ltd. in Gosport. Why not head across to our YouTube channel to hear Subsea Craft’s Bill Barfoot talking about Vigilant and VICTA’s capabilities at DSEI London, in September 2019, where the craft was first revealed.

Find out more from SubSea Craft: www.subseacraft.com

VICTA in numbers

- Length – 11.95 m

- Beam – 2.3 m

- Draught – 0.06 m

- Crew – 2

- Divers – 6

- Fully loaded displacement – 9,315 Kg

- Surface speed – 30/40 kts (cruising speed and top speed)

- Endurance – 250 nm (expandable)

- Dive depth – 30 m

- Subsurface speed – 6/8 kts (cruising and sprint)

- Subsurface range – 25 nm

Underwater positioning technology from Sonardyne Inc. has been chosen by leading integrated subsea and offshore solutions provider, Unique Group, to enhance the company’s offering for its energy sector customers working in the US Gulf of Mexico.

Two Ranger 2 Ultra-Short BaseLine (USBL) positioning systems, complete with HPT 5000 transceivers and survey-room hardware and software, will be added to Unique Group’s Houston equipment rental pool. The technology was chosen specifically for its ability to be quickly mobilised on vessels of opportunity and to surpass the stringent positioning specifications geophysical and geotechnical customers in the region need for their projects.

Built on Sonardyne’s Wideband 2 acoustic signal technology and 6G (sixth generation) hardware platform, Ranger 2 accurately tracks multiple underwater targets, such as deep towed sonar platforms and seabed coring equipment over extreme laybacks, in coastal or full ocean depths and with position updates every second.

HPT, the system’s vessel-mounted transceiver, is also a highly effective acoustic modem supporting communication with underwater targets equipped with a compatible 6G transponder, so it can track and gather data, as well as send command updates, for example to change logging regimes. Furthermore, Ranger 2 can interface with vessel dynamic positioning (DP) system of any manufacturer, to provide an independent position reference input, all while tracking mobile targets.

This latest acquisition by Unique Group further adds to the company’s global rental pool of Sonardyne Long BaseLine (LBL), Doppler and inertial underwater navigation and positioning technologies.

[blockquote author=” Syed Taqvi, Regional Vice President – Americas, at Unique Group”]”Our capital equipment investment decisions are driven by market demand, and our customers in the Gulf of Mexico are certainly demanding Sonardyne’s Ranger 2 time and time again. It offers excellent positioning from shallow to deep water, it is quick to install on vessels-of-opportunity, and there’s a huge base of trained operators in the Gulf of Mexico who know how to use it to its potential”[/blockquote]

Char Franey, Sales Manager for Sonardyne in Houston said, “Every underwater tracking project is different; different water depths, different vessels to operate from and different targets to position. That’s why we’ve engineered Ranger 2 to be versatile with an impressive features list that come as standard. We’re confident Unique Group will see high utilisation rates for their new Sonardyne hardware this season and beyond.”

Underwater obstacle avoidance technology from maritime defence and security specialist Sonardyne International Ltd. has been chosen for a new design diver delivery unit (DDU) being built by SubSea Craft.

Sonardyne’s Vigilant forward looking sonar (FLS) will provide a critical hazard avoidance capability for the crew and embarked divers of the VICTA Class DDU when navigating on or below the surface.

Using a compact and sophisticated bow-mounted transducer arrangement, Vigilant FLS displays water depth, sub-surface obstacles and features by creating an accurate 3D model of the underwater environment over a 90° field of view. The model is displayed relative to the underwater vehicle or surface vessel it’s fitted to, overlaid on standard charts in real-time, providing operators with an easily-interpreted topographical image of their route ahead.

Vigilant FLS provides this detailed and easy to interpret 3D bathymetry out to 600 m, as well as automated warnings of unseen collision hazards out to 1.5 km, supporting safe navigation for mariners, underwater vehicle pilots and unmanned surface and subsea systems.

SubSea Craft’s VICTA Class DDU offers the speed and endurance of a long-range insertion craft with the stealth and capacity of a swimmer delivery vehicle. It can travel up to 250 nautical miles (nm) at speeds of up to 40 knots on the surface, whilst submerged it cruises at 6 knots, with a ‘sprint’ capability of 8 knots, for up to 25 nm to deploy and recover up to eight operatives (two crew and six divers) to their objective area mission-ready.

[blockquote author=” Tim Chicken, SubSea Craft’s Chief Commercial Officer”]”Being able to detect – at range – navigation hazards, before they become a real threat, is mission-critical to the sort of operations likely to feature in VICTA’s playbook. Vigilant is the solution. With Vigilant integrated into VICTA, complete with its easy to use, intuitive graphic user interface, pilots can visualise the environment ahead to navigate safely and avoid obstacles ensuring safe insertion and recovery of operators, regardless of the mission. As VICTA is designed around the operator, Vigilant was the ideal solution.”[/blockquote]

“Vigilant FLS offers naval forces with unprecedented subsurface situational awareness with unrivalled range,” says Ioseba Tena, Global Business Manager for Marine Robotics and Defence at Sonardyne. “With Vigilant integrated into VICTA, complete with its easy to use, intuitive graphic user interface, pilots can visualise the environment ahead to navigate safely and avoid obstacles ensuring safe insertion and recovery of operators, regardless of the mission. Quite simply, it provides a tactical advantage for their operations.”

Author: Stephen Auld, Global Business Manager, Subsea Asset Monitoring

As I’ve set out in the previous two blogs (Wireless Intelligence Made Easy and 21st Century Data Collection) in this three-part series, when you want to understand the fatigue life or integrity of your subsea systems you need two main elements. One is a way to accurately measure what’s actually happening, the second is a way to get that data from subsea to shore.

You also need a way to visualise the gathered information and understand what it all means. My previous two blogs focused on our SMART and AMT monitoring systems and different ways we can wirelessly access the data they gather for you, including using marine autonomous systems such as unmanned surface vessels (USVs) and autonomous underwater vehicles (AUVs).

For this third and final blog in the series, I’ll look at the final element you need; third-party analysts. Here’s where other companies, with their engineering and integrity experts, make use of the data our sensors gather to display, analyse, interpret and report to you on their findings. To put it another way, we measure, we monitor and we deliver data, either in raw or part analysed, summary form, to these trusted specialists.

Depending on what you want to know about your subsea system and how quickly, there are different routes you can take. Here are some options and examples of solutions we have provided to illustrate these various paths.

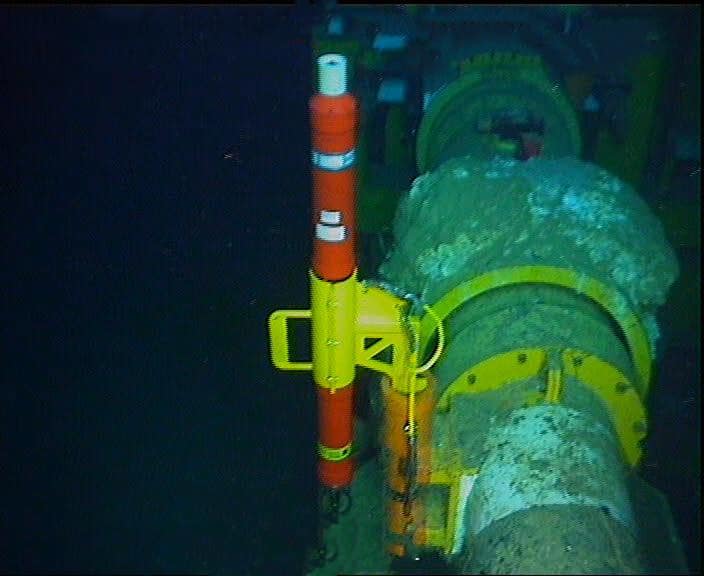

Challenge #1 – An operator was concerned about suspected and periodic vibration of a number of spool pieces within their deep water subsea field development.

- Solution #1 – the operator tasked their subsea inspection, repair and maintenance contractor with installing our monitoring technologies. This provided the data the operator’s external engineering consultancy needed to perform their fatigue analysis work to understand any impact on the spool pieces’ design life.

- Technology used – SMARTS and AMTs

- Data recovery method – Dunker 6 deployed from a production platform

Challenge #2 – An operator wanted real-time data so they could minimise fatigue on an aged wellhead caused by the blowout preventer (BOP) during a side-track drilling campaign.

- Solution #2 – they contracted a tethered-BOP system provider who contracted us to provide our monitoring technology. This enabled them, using third-party provided software, to view in near real-time any excessive BOP motion caused by drilling operations on the well, which could be stopped if the displayed fatigue exceeded a certain threshold.

- Technology used – SMARTS

- Data recovery method – Dunker 6 deployed from a drill rig

Challenge #3 – An operator wished to understand how much two flowline termination assemblies (FTA) were moving within their field development.

- Solution #3 – they used their subsea IRM contractor, who deployed our AMTs to measure movement of the FTAs. This resulted in the contractor designing a timely solution to inhibit the movement they had measured.

- Technology used – AMTs

- Data recovery method – seabed located SMART Dunker 6 hardwired through a control module

So, as I said, we measure, we monitor and we deliver data to your trusted specialists, whether that’s your in-house engineers, third party fatigue analysts or a specialist software provider. We provide them with the sensor information they need to perform their modelling and analysis. This in turn will inform the operator what they need to know about their subsea infrastructure.

Want to know more? Get in touch and we can provide robust sensors and through water, wireless, communication technologies to ensure the integrity and extend the fatigue life of your subsea assets.

Author: Stephen Auld, Global Business Manager, Subsea Asset Monitoring

In my last blog, the first in a three-part series, I looked at how our 6G enabled SMART and AMT acoustic hardware can provide the information you need to understand both high and low frequency movement of your subsea assets’ integrity and fatigue life.

These sensors provide seamless, wireless, monitoring for vibration and motion subsea as part of a stand-alone system, without any need for local power or communications umbilical.

So, once you’ve got your monitoring sensors in place, how do you access the information they’re generating? In short, there’s no single answer – that’s because there are now options to suit every scenario, including using marine autonomous systems (MAS).

Vessel or ROV deployed options

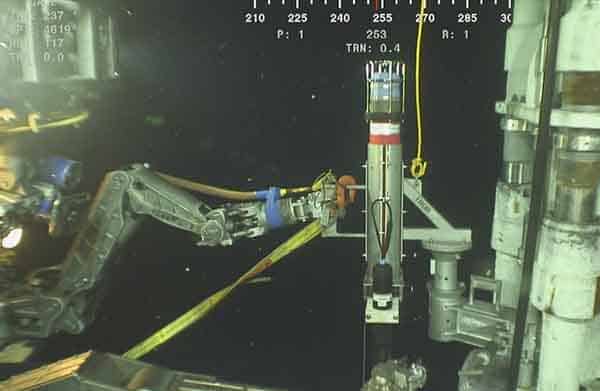

Conventionally, there are three main ways you’d get your sensor data: via a subsea transceiver connected into your control system; by a vessel with an over-the-side Dunker; or by using a remotely operated vehicle (ROV) with acoustic telemetry equipment. Let’s look at all three in a little more detail.

- With a hardwired system, you’d have a transceiver, such as our Dunker 6 or SMART-Dunker, mounted within a tripod on the seabed, connected to a subsea control module or other termination assembly. This subsea transceiver would gather the sensor data acoustically and then send it topside via the main umbilical. For monitoring systems that are spread over a large area, we can create an acoustic daisy chain to hop data to a central transceiver, which then delivers each sensor’s data via the one umbilical.

- For vessel-based data harvesting, if your ship already has Sonardyne 6G enabled transceivers on board, such as our Ranger 2 and Mini-Ranger 2 Ultra-Short BaseLine (USBL) systems, you can use them to acoustically upload the data from any of our sensors – because they all speak the same language. If you don’t have a transceiver on your vessel, you could rent or purchase a Dunker 6 transceiver, which could then be hung over the side of your ship, rig or platform and into the water, to acoustically retrieve your subsea sensor data.

- If you have a ROVNav 6+ fitted on your ROV, you have everything you need to harvest data from our 6G SMART and AMT monitoring instruments. The ROVNav 6+ on the ROV just needs to be within acoustic range to gather the data which it then sends topside via the ROV’s umbilical.

These are the conventional methods we’re all used to. But there are now alternatives. Increasingly, we’re using new ways of harvesting data remotely and wirelessly, at far lower costs and with vastly lower carbon emissions, using unmanned surface and subsea systems.

Data harvesting with unmanned surface vessels (USVs)

First, let’s look at unmanned surface vessels (USVs), sometimes called surface gateways – as they provide a relay, or gateway, for your data. The number of USVs on the market has exploded in just a few years and we’re increasingly able to use them for data gathering operations.

We’ve already been working with a wide range of providers, including L3 Harris ASV, XOCEAN and Maritime Robotics, using a number of different platforms, including Wave Gliders, to head offshore and gather data. Read about work we’ve done with each of these by clicking the links on their names.

The benefits of installing our systems on USVs for data harvesting include a vastly reduced carbon footprint, enabling staff to work remotely, which is crucial in the current Covid-19 environment, as well as reducing costs, making more frequent harvesting missions eminently viable. But there are also operational benefits. For example, we’ve been able to enter the 500 m exclusion zone in order to harvest data, because these systems, being so much smaller than any manned vessel, pose minimal threat to production systems.

Their efficiency is also enhanced thanks to low hull and propulsion noise, so data can be harvested faster than from a noisy manned vessel. Just like a manned vessel, they can also beam the data they gather to shore via Iridium satellite or 4G, depending on local communications availability.

Your data collection options

To make any USV “data-harvest-ready” with our systems is quite simple. Depending on the size of the USV and how much you want it to do, we have a number of options:

- Modem 6 – our acoustic modem family

- Dunker 6 – our LBL and telemetry transceiver for deployment from vessels or USVs

- Or one of our Ranger USBL family of High Performance Transceivers (HPT), depending on the water depth you’re working in and the precision that you want.

- If you’re also doing positioning, you may want our Gyro USBL – removes calibration requirements so great for using on dynamic vessels of opportunity.

- Acoustic Communications Module – ideal for gliders, all the electronics you need, housed in a compact form factor, with a remote transducer

- Wave Glider Transceiver (WGT) – all the electronics you need, including a satellite link, with a remote transducer

Each of these systems can interface in several different ways with the vehicle’s management system for access to the previously recovered data. When instructed to do so, the unmanned vehicle can then transmit the recovered data via Iridium or for example a 4G cellular network back to shore.

Get in touch if you want to learn more about this amazing technology.

Letting the underwater drones do the work

Another option is to use underwater drones, or autonomous/unmanned underwater vehicles (AUV/UUV) for your data gathering missions. In fact, your AUV/UUV may already be equipped for data collection, if it has an AvTrak 6 or AvTrak 6 OEM Nano telemetry transceiver on board.

- AvTrak 6 OEM – our vehicle-ready, self-contained vehicle tracking and communications transponder

- AvTrak 6 – as above, but within our subsea housing

Once the data has been harvested, your AUV can either transit to a wired subsea transceiver or meet up with a USV, to offload its data. Of course, it could also be recovered by a conventional vessel using a Sonardyne transceiver or by downloading the data once the AUV has been recovered on the back deck.

If there’s a substantial amount of data to be retrieved, our BlueComm free space optical modem enables multiple megabytes of it to be offloaded, quickly. This is perhaps more relevant in seismic data acquisition operations, but could also be useful when monitoring requires a high level of data transfer, for example, downloading raw or time series subsea asset motion data.

Just as you can with an AvTrak, with an integrated BlueComm your vehicle can gather data then offload it either to a BlueComm hardwired into the subsea infrastructure to then send down the umbilical or to a manned or unmanned surface vessel, with a corresponding BlueComm receiver. To put it another way, we no longer have a problem handling high bandwidth data subsea!

Conclusion

So, what’s the upshot of all of this? In a nutshell, when you’re monitoring subsea assets using our equipment there are numerous ways, both conventionally and now also using MAS, such as USVs and AUVs, to access as much data as you would like wirelessly. And this isn’t just for subsea asset monitoring, it can be for data collection from any type of subsea sensor.

In my next blog, I’ll take you through what happens now you have your data and who helps you to understand what’s happening in your subsea system.

We can help and assist on all aspects of data harvesting missions, including organising the most appropriate and efficient data gathering platform for the task. Get in touch to find out how we can help you.

Author: Stephen Auld, Global Business Manager, Subsea Asset Monitoring

Part 2

Part 3

Globally, the installed base of subsea production pipelines and flowlines continues to grow. As well as increasing in number they’re being installed in harder to reach places, in deeper waters, in harsher conditions and with more challenging fluids and gases passing through them.

Whether they’re new or existing subsea assets, understanding the impact of fatigue caused by both high and low frequency vibration is high on operators’ wish lists. At Sonardyne, this is a challenge we’re hearing more and more about from our customers. Integrity monitoring and management of these systems, through the life-cycle, is an increasingly important requirement.

Using traditional methods, i.e. remotely operated vehicles (ROVs) from a manned support vessel, to visually inspect what is happening, is costly, which means it’s often done infrequently, resulting in patchy information. This is especially so for more complex infield pipeline infrastructure, like spool pieces, and is problematic when an operator wants regular or even real-time data.

So, in a cash-constrained environment, how can operators keep on top of their pipeline system integrity while keeping their spending in check? How about an easy to retrofit system that doesn’t impact on your production system and doesn’t need local power or communications links? One trip – and it’s installed. Then you have all the data you need.

Wireless intelligence on the seafloor

That’s just what we can provide. We have a track record in developing and deploying highly configurable remote and wireless subsea asset monitoring systems, enabling operators to monitor pipelines for integrity issues, including pipeline lateral buckling, walking or creeping, caused by axial stress in the pipe and high frequency vibration.

Based on our 6G hardware backbone, our low and high-frequency movement monitoring technologies are easy to configure for any subsea layout or scenario. For example, our Subsea Monitoring, Analysis and Reporting Technology (SMART) sensors are ideal for high-frequency vibration monitoring, while our Autonomous Monitoring Transponders (AMTs) are perfect for more low-frequency movement monitoring. They can also easily be used together.

They’ll measure, record and even part-process the data at source where it can either be stored or transmitted using our Wideband digital through-water communications to the surface – which could be to a topside vessel, platform, rig or unmanned vehicle. That’s all without the need to tap into existing power or communication systems and with no impact on the pipeline system, because all our subsea sensors are battery-powered – some with greater than 10 year battery life. Alternatively, where access to a hardwired umbilical is available, the remote monitoring data can also be via a subsea transceiver then on to the topside using that existing umbilical link.

Once topside, the data can be sent via a cable link, satellite or 4G offshore network to shore, where analysts can help you refine your pipeline management strategies.

It’s SMART

SMART is an all-in-one, easy to deploy, low-power, long-duration, subsea data logging and processing and acoustic telemetry instrument. SMART can interface with a wide range of internal and external sensors and other data sources. It’s often used for recording and processing high-frequency six degrees of freedom movement, often caused by vortex-induced or flow-induced vibrations.

With in-built edge computing capabilities, SMARTs can use either standard or customer bespoke data analysis algorithms to provide small statistical summary data packets. These packets can be acoustically transmitted robustly and efficiently through the water to a topside transceiver. It’s a highly flexible instrument, ideal for those trouble spots where you suspect high-frequency vibration could lead to issues further down the line.

AMT for low-frequency monitoring

However, what about low-frequency, long-period subsea asset movement? That’s where our AMT long-endurance transponder can help. It can autonomously acquire and log acoustic ranges and other sensor data, like temperature and pressure. By deploying a fixed seafloor LBL array of AMTs so that each can make highly accurate range measurements to “mobile” AMTs mounted on a pipeline, for example, they can tell an operator whether, and by how much, their pipeline is moving over time.

Each AMT also has a highly accurate pressure and sound velocity sensor, so that vertical movement of the pipeline, as well as horizontal movement, can be observed. Inclinometers integrated into the AMT can be added as an optional extra to detect any changes to the pitch and roll of the pipe or other subsea asset. It’s ideal for those slower movements, like creeping or buckling, that are hard to detect during periodic ROV inspection campaigns.

Hybrid solutions for all subsea monitoring scenarios

What’s more, we can combine the two, to provide a SMART-AMT. This is a hybrid solution that’s able to capture high and low-frequency movements. It’s perfect for monitoring free-spans or production risers, without having to perform regular visits with your ROV, vessel and crew.

I’ll be covering, in more depth, different ways you can retrieve your data, including using marine autonomous systems, in my next blog.

For all of your projects, we are able to provide full customer support, including project management, array planning, data processing, field support and post-processing software development, enabling the most efficient project outcome for your entire subsea asset monitoring data requirements.

Get in touch if you’d like to find out how we can help you.

Brazilian geoscience services company OceanPact Geociências has chosen deep water positioning technology from Sonardyne Brasil Ltda. to support its geophysical, geotechnical and environmental research operations across the region.

Ranger 2 Ultra-Short Baseline (USBL) systems have been installed on board OceanPact’s research vessel Seward Johnson and RSV Austral Abrolhos to precisely track the location of underwater equipment and sensor packages deployed from the ships, including seabed corers, towed sensors and data loggers. Both vessels are currently on hire to Brazilian oil major Petrobras.

Ranger 2 USBL is a popular choice for conducting research at sea as operations can start as soon as a vessel arrives on location. This helps maximise valuable ship time. It has the capability to track multiple underwater targets simultaneously to beyond 11km, works in shallow or deep water and is able to remotely configure and communicate with compatible instruments. This operational flexibility was a key factor in OceanPact’s investment decision.

[blockquote author=” Raphael Melo, Survey Manager from OceanPact Geo”]”For geophysical, geotechnical and environmental research and survey operations in Brazil we rely on the highest specification and highest reliability systems. Sonardyne’s equipment has proven to be both during our previous long-term rentals. This is why we have chosen now to permanently acquire this equipment for two of our vessels. Having the reassurance of local technical and operational support from the Sonardyne team here in Brazil is a big advantage for us also.”[/blockquote]

Andre Moura, Sales & Applications Manager at Sonardyne Brasil Ltda. says, “This order from OceanPact further embeds Ranger 2’s reputation in the region. For those wanting accuracy and versatility, it’s proven itself time and again while also meeting the toughest specifications from oil and gas, science and survey companies.”