Author: Stephen Auld, Global Business Manager, Subsea Asset Monitoring

Part 2

Part 3

Globally, the installed base of subsea production pipelines and flowlines continues to grow. As well as increasing in number they’re being installed in harder to reach places, in deeper waters, in harsher conditions and with more challenging fluids and gases passing through them.

Whether they’re new or existing subsea assets, understanding the impact of fatigue caused by both high and low frequency vibration is high on operators’ wish lists. At Sonardyne, this is a challenge we’re hearing more and more about from our customers. Integrity monitoring and management of these systems, through the life-cycle, is an increasingly important requirement.

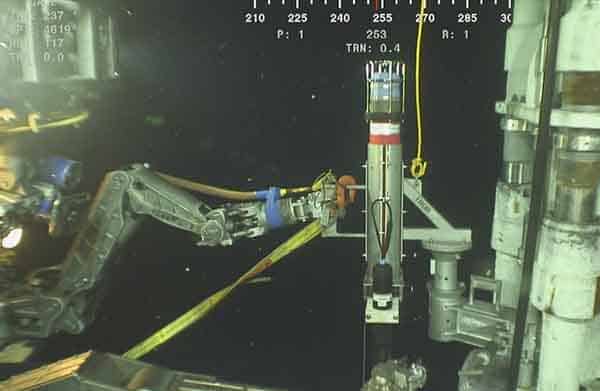

Using traditional methods, i.e. remotely operated vehicles (ROVs) from a manned support vessel, to visually inspect what is happening, is costly, which means it’s often done infrequently, resulting in patchy information. This is especially so for more complex infield pipeline infrastructure, like spool pieces, and is problematic when an operator wants regular or even real-time data.

So, in a cash-constrained environment, how can operators keep on top of their pipeline system integrity while keeping their spending in check? How about an easy to retrofit system that doesn’t impact on your production system and doesn’t need local power or communications links? One trip – and it’s installed. Then you have all the data you need.

Wireless intelligence on the seafloor

That’s just what we can provide. We have a track record in developing and deploying highly configurable remote and wireless subsea asset monitoring systems, enabling operators to monitor pipelines for integrity issues, including pipeline lateral buckling, walking or creeping, caused by axial stress in the pipe and high frequency vibration.

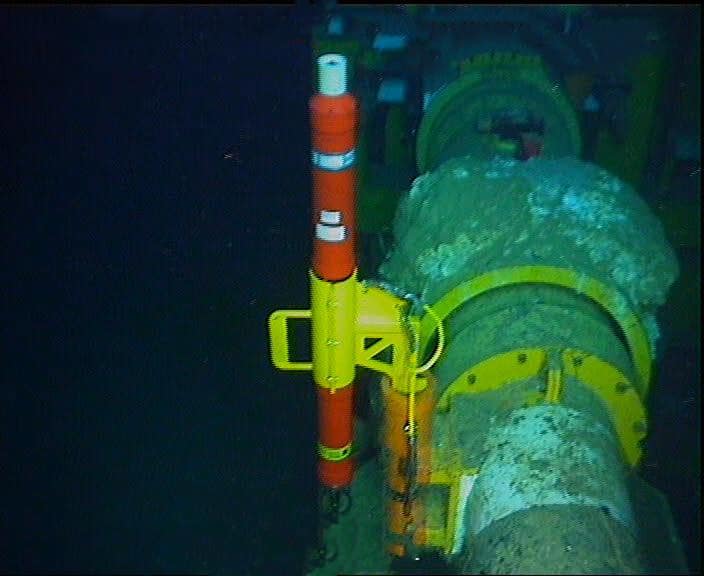

Based on our 6G hardware backbone, our low and high-frequency movement monitoring technologies are easy to configure for any subsea layout or scenario. For example, our Subsea Monitoring, Analysis and Reporting Technology (SMART) sensors are ideal for high-frequency vibration monitoring, while our Autonomous Monitoring Transponders (AMTs) are perfect for more low-frequency movement monitoring. They can also easily be used together.

They’ll measure, record and even part-process the data at source where it can either be stored or transmitted using our Wideband digital through-water communications to the surface – which could be to a topside vessel, platform, rig or unmanned vehicle. That’s all without the need to tap into existing power or communication systems and with no impact on the pipeline system, because all our subsea sensors are battery-powered – some with greater than 10 year battery life. Alternatively, where access to a hardwired umbilical is available, the remote monitoring data can also be via a subsea transceiver then on to the topside using that existing umbilical link.

Once topside, the data can be sent via a cable link, satellite or 4G offshore network to shore, where analysts can help you refine your pipeline management strategies.

It’s SMART

SMART is an all-in-one, easy to deploy, low-power, long-duration, subsea data logging and processing and acoustic telemetry instrument. SMART can interface with a wide range of internal and external sensors and other data sources. It’s often used for recording and processing high-frequency six degrees of freedom movement, often caused by vortex-induced or flow-induced vibrations.

With in-built edge computing capabilities, SMARTs can use either standard or customer bespoke data analysis algorithms to provide small statistical summary data packets. These packets can be acoustically transmitted robustly and efficiently through the water to a topside transceiver. It’s a highly flexible instrument, ideal for those trouble spots where you suspect high-frequency vibration could lead to issues further down the line.

AMT for low-frequency monitoring

However, what about low-frequency, long-period subsea asset movement? That’s where our AMT long-endurance transponder can help. It can autonomously acquire and log acoustic ranges and other sensor data, like temperature and pressure. By deploying a fixed seafloor LBL array of AMTs so that each can make highly accurate range measurements to “mobile” AMTs mounted on a pipeline, for example, they can tell an operator whether, and by how much, their pipeline is moving over time.

Each AMT also has a highly accurate pressure and sound velocity sensor, so that vertical movement of the pipeline, as well as horizontal movement, can be observed. Inclinometers integrated into the AMT can be added as an optional extra to detect any changes to the pitch and roll of the pipe or other subsea asset. It’s ideal for those slower movements, like creeping or buckling, that are hard to detect during periodic ROV inspection campaigns.

Hybrid solutions for all subsea monitoring scenarios

What’s more, we can combine the two, to provide a SMART-AMT. This is a hybrid solution that’s able to capture high and low-frequency movements. It’s perfect for monitoring free-spans or production risers, without having to perform regular visits with your ROV, vessel and crew.

I’ll be covering, in more depth, different ways you can retrieve your data, including using marine autonomous systems, in my next blog.

For all of your projects, we are able to provide full customer support, including project management, array planning, data processing, field support and post-processing software development, enabling the most efficient project outcome for your entire subsea asset monitoring data requirements.

Get in touch if you’d like to find out how we can help you.