Overview

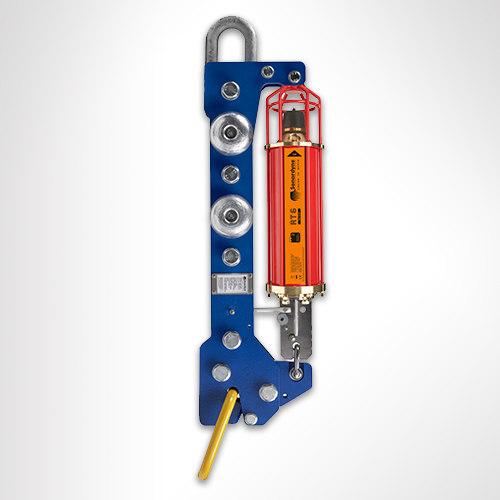

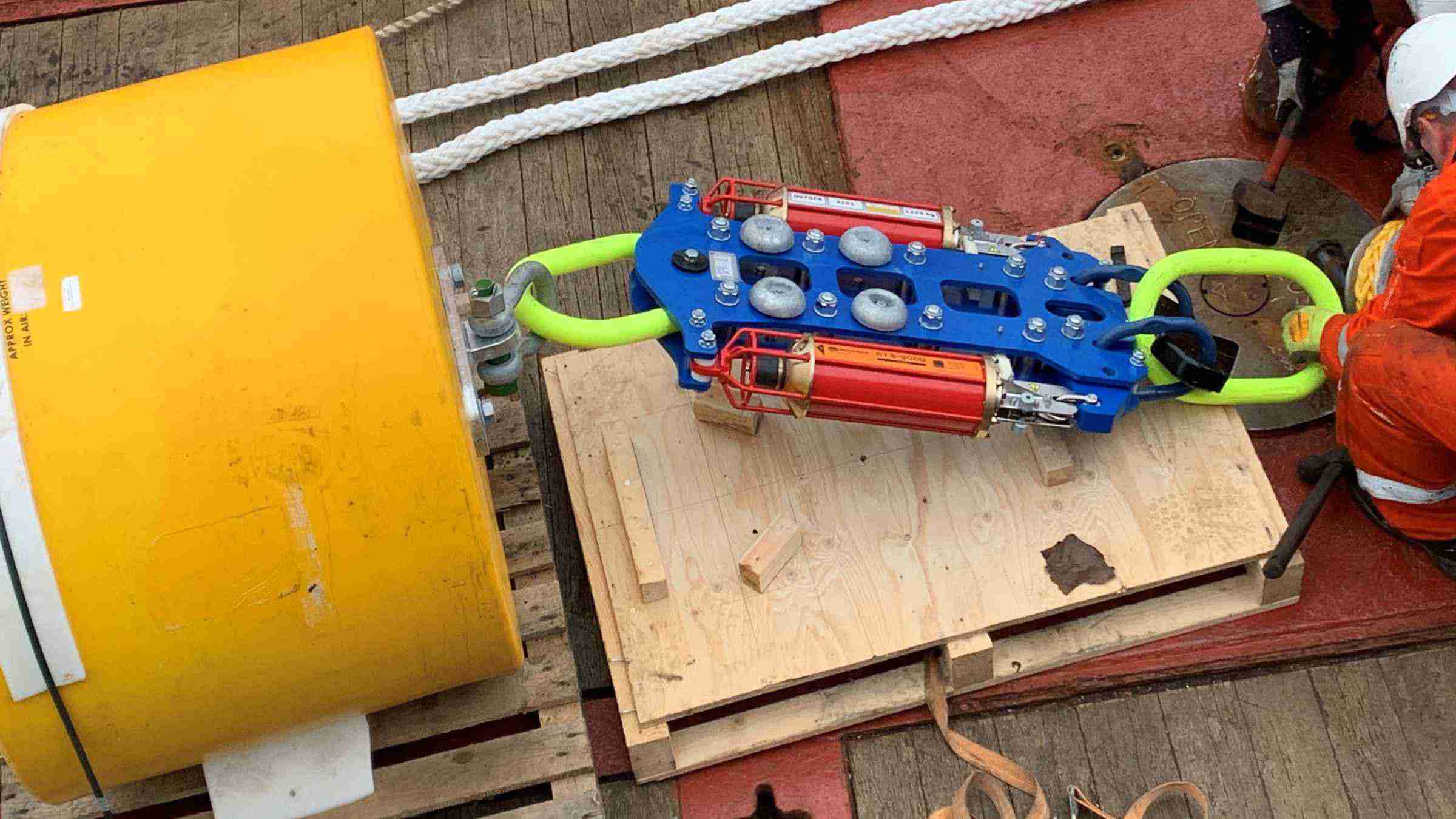

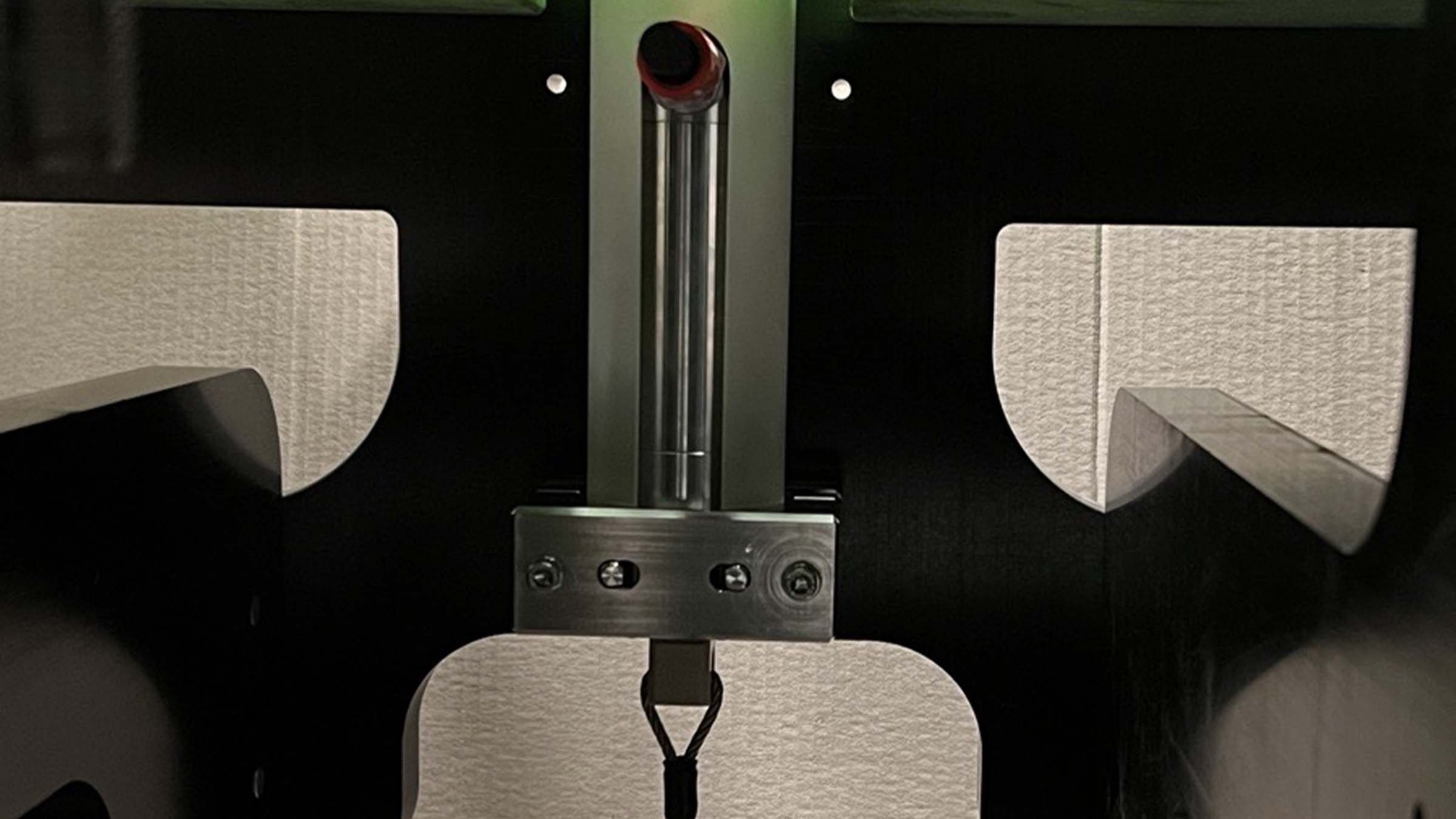

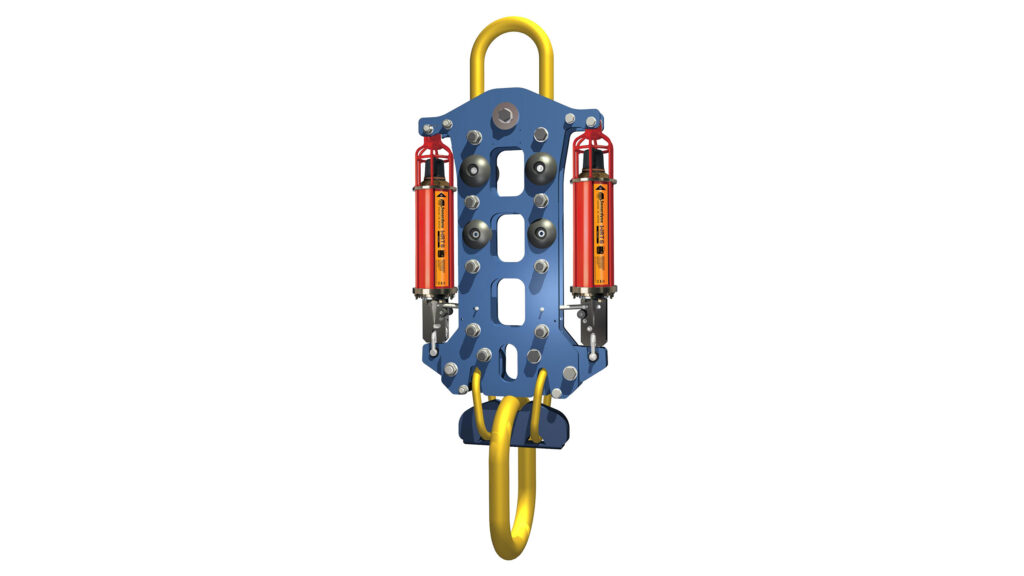

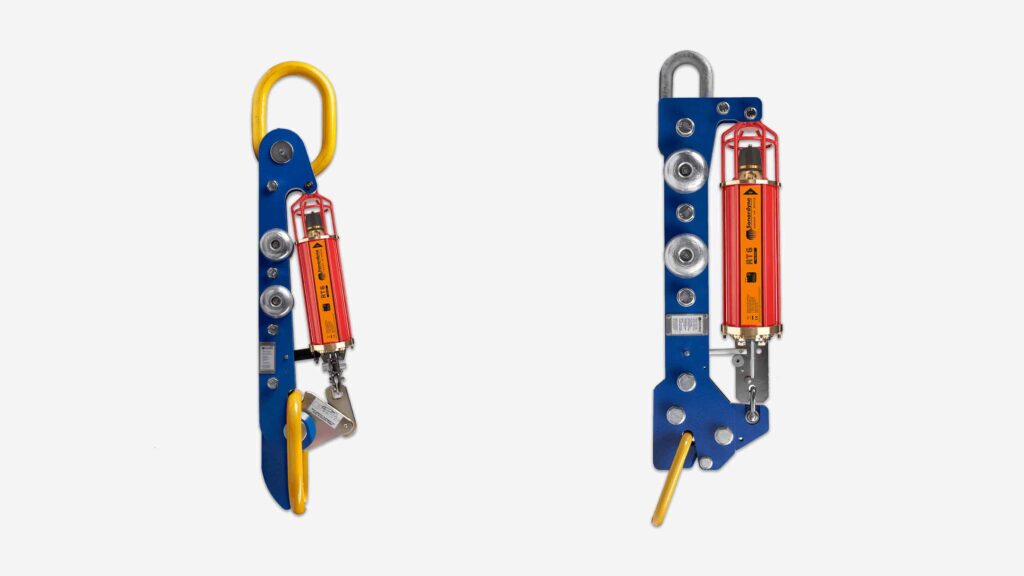

Our range of heavy duty acoustic release frames increase the Working Load Limit (WLL) of RT 6-3000 and RT-6000 acoustic release transponders, enabling you to lift, lower and release heavy loads onto the seabed, including structures and specialist equipment.

The Type 7869-000-01 release frame increases the WLL of a standard RT 6-3000 or RT 6-6000 to 7,500 kg (at 4:1 safety factor) with a breaking load of 30,000 kg. The type 7869-000-05 release frame increases the WLL of a standard RT 6-3000 or RT 6-6000 to 15,000 kg (at a 4:1 safety factor) with a breaking load limit of 60,000 kg.

The Type 7988 release frame has a WLL of 25,000 kg and breaking load of 100,000 kg.

In most cases, both types of release frame can be fitted without any modification to the acoustic release itself and are easily assembled in the field. Manufactured from high-strength steel which is galvanised and powder coated, the releases offer excellent corrosion resistance for long-term deployment.

Applications for which the acoustic releases have been developed include civil engineering, offshore construction, offshore renewables, marine salvage, defence and ocean science.

At a glance

- Working Load Limit of 7,500, 15,000 or 25,000 kg

- Breaking load of up to 100,000 kg

- Choice of depth rating: 4,000 or 12,000 m

- Compact size; just over 1 metre long

- Industry standard lifting rings

Suitable for

- Subsea structure installation

- Research vessels

Did you know?

You can use Ranger 2 and Mini-Ranger 2 to release our RT 6 family?

Frequently asked questions

Datasheets

Manuals and quick start guides

Deploy, retrieve, repeat – made easy with RT 6 acoustic release

Deploying sensors in a strong-current tidal estuary is a challenge. Try retrieving them and then redeploying them back in exactly the same position, multiple times. It’s a task vastly simplified with our RT 6-1000 release transponder, used alongside any of our Ranger 2 family of Ultra-Short BaseLine (USBL) systems.

The challenge

Deploying, locating and retrieving seabed sensors can be a challenge. Choosing reliable sensors that will work for the whole duration of the deployment and provide robust reliable results is just the start. Accurate seabed positioning data that are delivered in real-time to enable dependable acoustic release of the sensors is also required.

An additional layer of complexity is introduced for these kinds of operations when the site in question has a significant tidal range and current regime.

This is just what independent physical oceanography consultancy DynamOcean has been doing in the Rance estuary in Brittany, France. The Rance estuary – where the River Rance enters the English Channel – has one of the largest tidal ranges in France. It averages around 8m between low and high tide. During spring tides this figure can jump to as high as 13.5m!

DynamOcean has been studying sediment transport through the estuary with the aim of measuring current, waves and turbidity in the Rance estuary. To do this, they’ve been using an acoustic Doppler current profiler (ADCP). The measurements are being taken over six months, with recovery and re-deployment of the ADCP – in exactly the same position – every two months. This requires both a reliable acoustic release and accurate seabed positioning in real-time.

The solution

For this project, DynamOcean chose our RT 6-1000 acoustic release transponder. Their choice was guided by several years’ experience in using our Lightweight Release Transponder (LRT) and deciding to upgrade to our newer RT 6-1000.

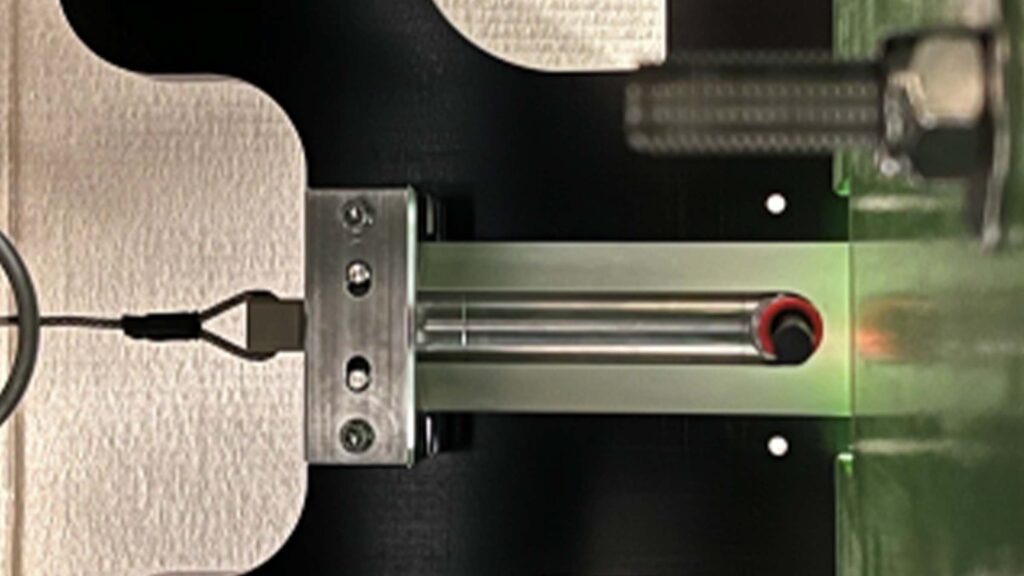

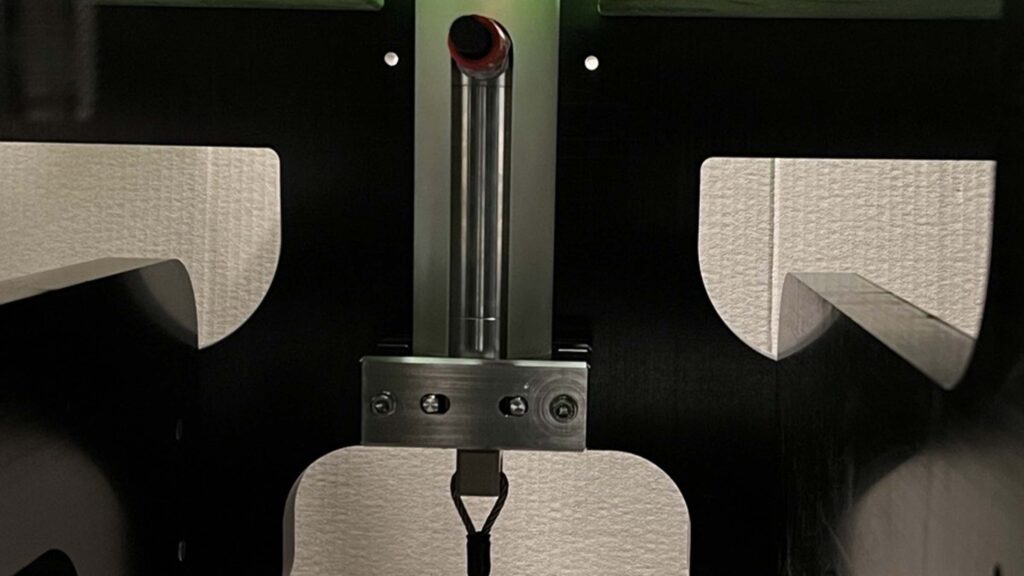

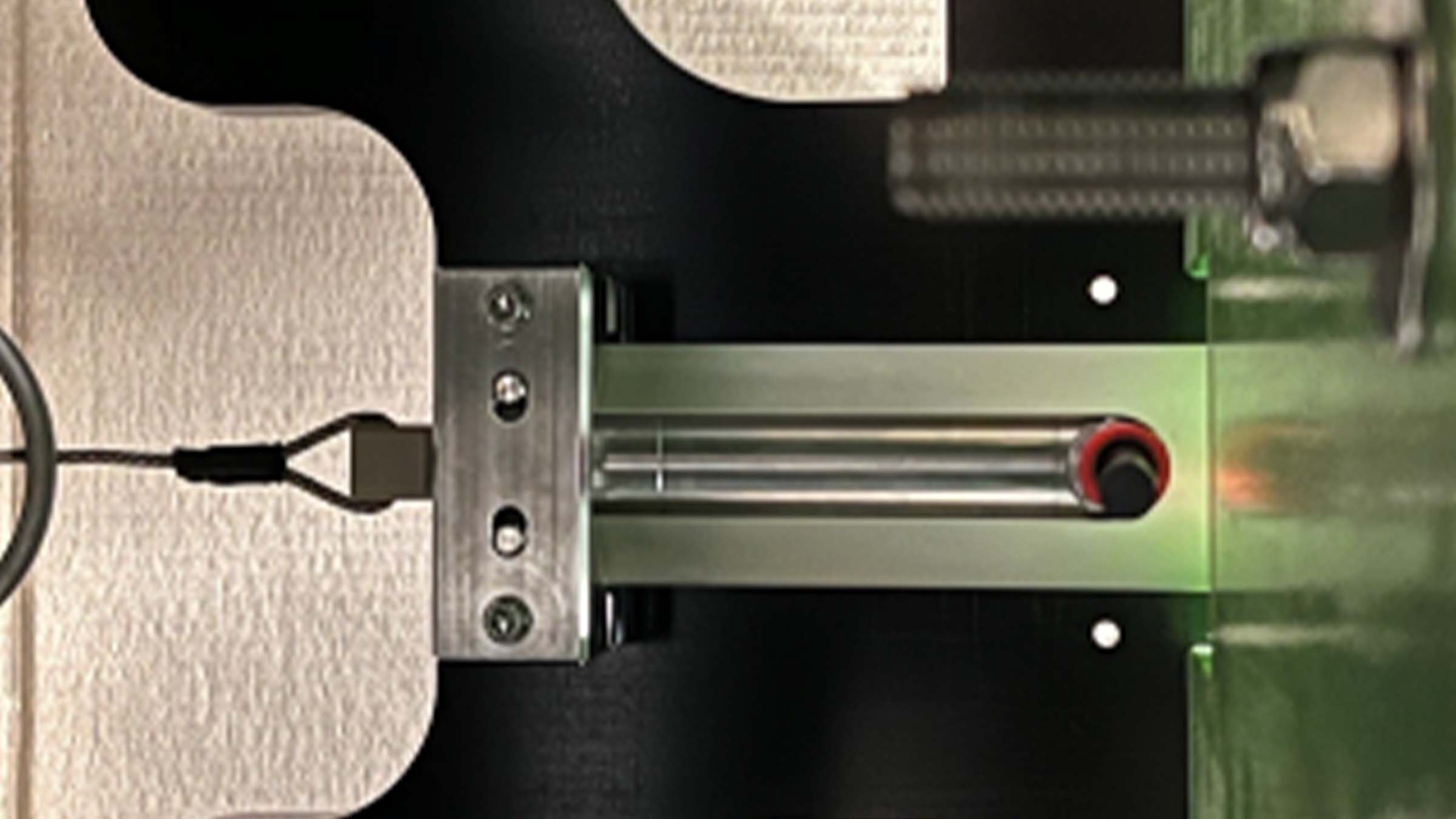

The RT 6-1000 is our entry-level release transponder with features that are far from entry-level. The 1,000 m depth rating, 15-month battery life, optional rope canister and – crucially – the reliable release mechanism made this an ideal choice for the deployment, retrieval and redeployment work DynamoOcean needed it for.

Alongside the RT 6-1000, DynamOcean chose our Micro-Ranger 2, the smallest USBL system we have available at Sonardyne.

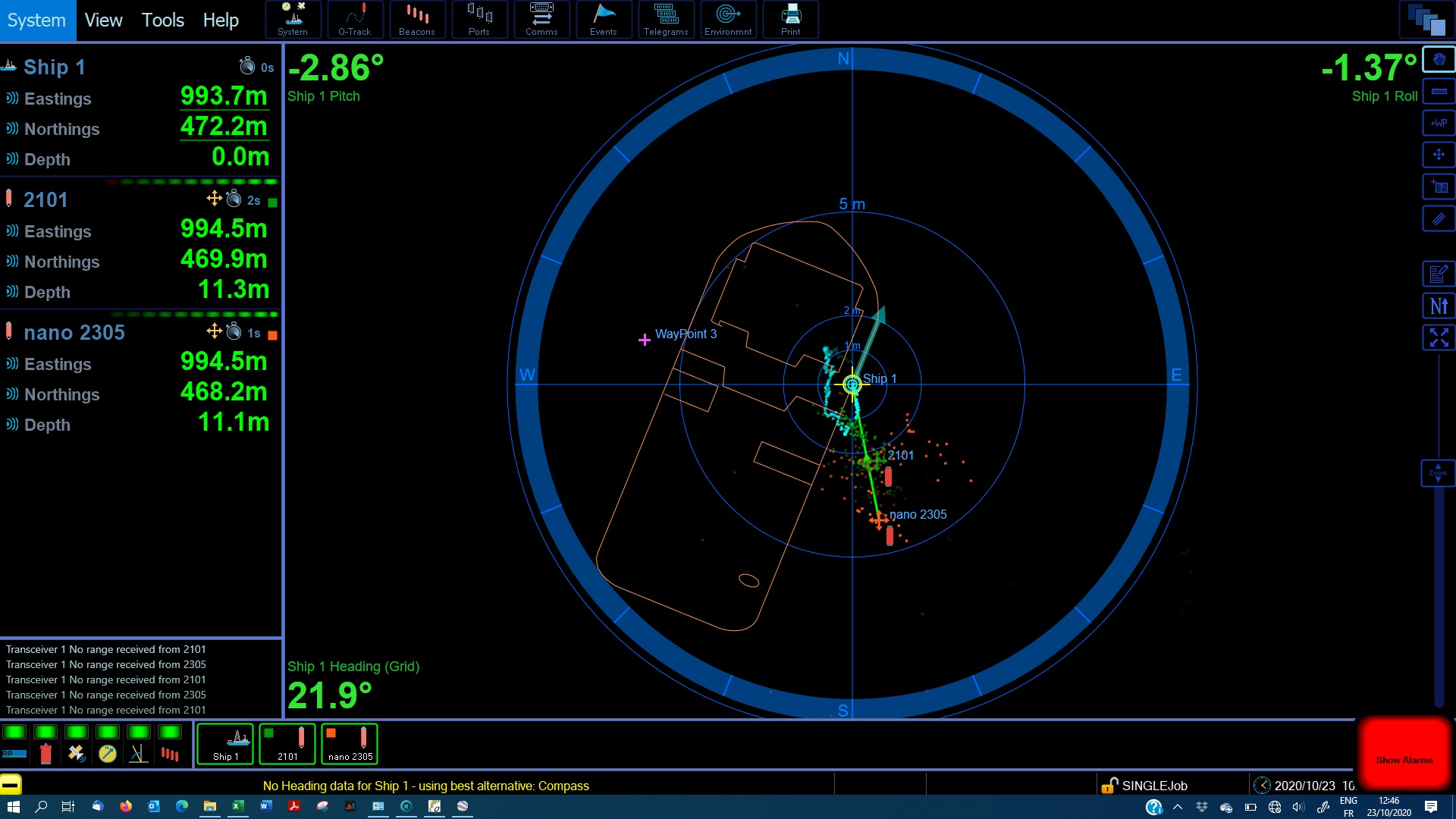

It’s easy to set up and use – even from a RIB or uncrewed surface vessel (USV) – and enables tracking of up to 10 targets out to 995 m range. For this project, it means DynamOcean can instantaneously position its seabed ACDP platform and inspect it using a mini-ROV, which can also be positioned via a Nano beacon using the same Micro-Ranger 2 topside.

Because the RT 6-1000s, Nano and Ranger USBL systems work with the same 6G platform, they can be used interchangeably and seamlessly. The time needed to coordinate each part is minimal and integration with the topside platforms is simple.

DynamOcean’s managing director Eloi Droniou explained the three key benefits they enjoyed when speaking with us about the setup for the Rance estuary project:

“The RT6-1000 integrated within a pop-up buoy on the seabed platform has multiple purposes,” he says, “one, release the pop-up buoy for the recovery of the seabed platform without the need for divers at the end of the measurements; two, measure inclination to make sure the platform is more or less level; and three, position accurately the seabed platform using various Sonardyne 6G topside options.

“With the release of Micro-Ranger 2 and Mini-Ranger 2, DynamOcean was thrilled to be able to not only instantaneously position the seabed platform but also to inspect it using a mini ROV, [which was] positioned using the lightweight and compact Nano transponder.”

The results

“This allows us to make sure that it has landed properly, without needing any divers,” adds Droniou. “If the landing location is not satisfactory, the seabed platform can be raised from the seabed and moved to another nearby location. The seabed platform can also be inspected with the mini ROV just before releasing the pop-up buoy with the RT 6-1000 to check that everything is in order and verify the instrument’s height above seabed.

“Having the positions of the vessel, the seabed platform and the mini ROV, simultaneously and on the same survey window (Ranger 2 software), is essential for these operations.”

DynamOcean were able to simplify their operation, thus cutting costs and the time needed to position, deploy, retrieve and redeploy sensors for the estuary study. On top of this, because the need for divers was removed the risk associated with the study has also been reduced.

Transponders provide reliable releases for Allton offshore Norway

When placing vital equipment such as Nodes on the seabed you need to be sure that you can retrieve them. During the development process, a lack of other products available in the marketplace that met their requirements led Norwegian technology and service company Allton to turn to Sonardyne for a solution.

Starting life as Petromarker in 2005, Allton has been operating offshore Norway for almost 20 years. The company specialises in: marine subsurface electro-magnetic (EM) data acquisition and imaging for hydrocarbon exploration and production, CO2 measurement, monitoring and verification for carbon capture sequestration and marine mineral exploration. It has now expanded its technology and service offering to include multiphysics joint acquisition of both EM and seismic OBN data.

With their innovative multiphysics platform relying on the data they retrieve from both EM and seismic OBN nodes, Allton need to be one hundred percent confident that they can locate and recover their nodes once they’ve been deployed. This can be from depths of up to 3,500 m in often challenging conditions.

When Allton expanded its operational work department and began the redesign of its subsea equipment, a search began for new and reliable solutions as existing transponders and release mechanisms were unsuitable for their specific requirements.

With several decades of subsea transponder and release manufacturing experience, Sonardyne was an obvious choice for a solution.

Our RT 6 family of acoustic release transponders combine the extensive track record of our previous models with the flexibility of a 6G hardware platform, meaning they can be deployed, located and released using any of our Ranger 2 USBL systems or 6G topsides.

An acoustic release transponder is fixed to a subsea asset so it can be found and recovered. An acoustic signal from a surface vessel locates the transponder on the asset. A second acoustic signal then tells the transponder to release the mechanism anchoring the asset to the seabed so that it can be retrieved.

Having gained a full understanding of Allton’s requirements, our engineering team worked closely with them to custom modify an existing RT 6 model to meet their exact needs. Aleksander Kristiansen, Supply Chain and Asset Manager, from Allton explains, “The custom manufacture of our RT 6-4000 was based on an existing model (RT 6-1000) which Sonardyne modified to suit our operational needs. This included extending its range and adding a secondary burn release circuit.

Working with our customers to fully appreciate their needs and the challenges their businesses face enables us to develop solutions for their specific operations. As Trevor Barnes, Sonardyne Sales Manager, explains: “Allton was looking for a robust, reliable acoustic release to give them confidence in retrieving their equipment from a range of depths. Whilst our RT 6-1000 is perfect for depths of up to 1,000 m, Allton operate in depths of up to 3,500 m so our engineers worked closely with them to develop an RT 6-4000 to enable this. A secondary burn-wire release was also added at their request, as a backup in the unlikely event that the first acoustic release fails.”

Aleksander Kristiansen continued “Sonardyne were always willing to assist and put the right technical expertise onto the variety and wide range of tasks to solve our many, often complex at times, challenges. Their creative ideas were well aligned with our expectations and letting us borrow equipment for an extensive time to conduct in-house testing was much appreciated. It gave us further confirmation that we were making the right choice in the RT 6 releases.”

Allton’s nodes are now fitted with RT 6-4000 acoustic releases to ensure that they can be reliably located and retrieved from the seabed at all their operating depths and in any conditions.

They can now provide data across all of their services with confidence that they have consistent, reliable access to their network of nodes.

Our standard RT 6s come in three depth ratings, 1,000 m, 3,000 m and 6,000 m and all use our workhorse Ranger 2 USBL system or deck topside to command and track. Some models can even be controlled using an Android app.

If you have a similar operational challenge, take the worry out of mooring and retrieving your kit and talk to us today.