Deployment machines

Overview

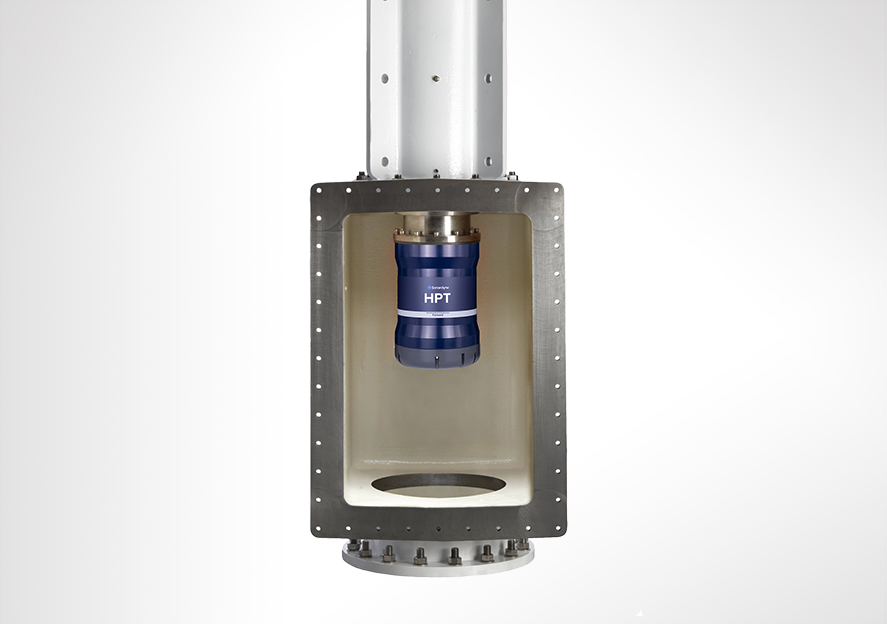

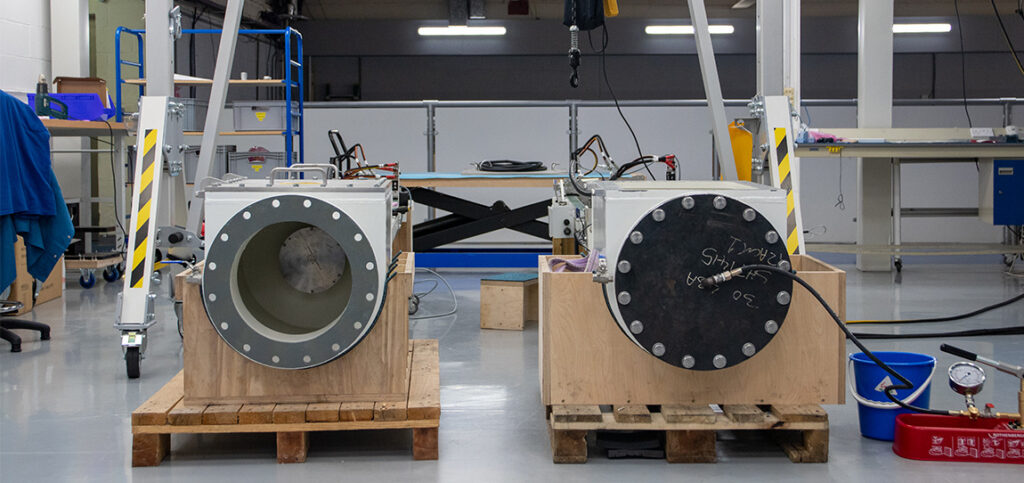

Designed for the deployment of our range of USBL and modem transceivers (including Gyro USBL) and Sentinel IDS sonar heads, our through-hull machine provides survey grade rigidity for use with USBL systems up to seven knots (total through water speed) with the ability to survive short duration exposure to higher speeds.

Where the pole is required to be longer than three metres, or where operational water currents may reach 10 knots (total through water speed), the pole must be installed using our heavy duty installation requirements. For specialist or demanding applications, machines of this general type can be custom engineered to suit customer specific requirements. Please consult us if your application has an operational through water speed greater than seven knots.

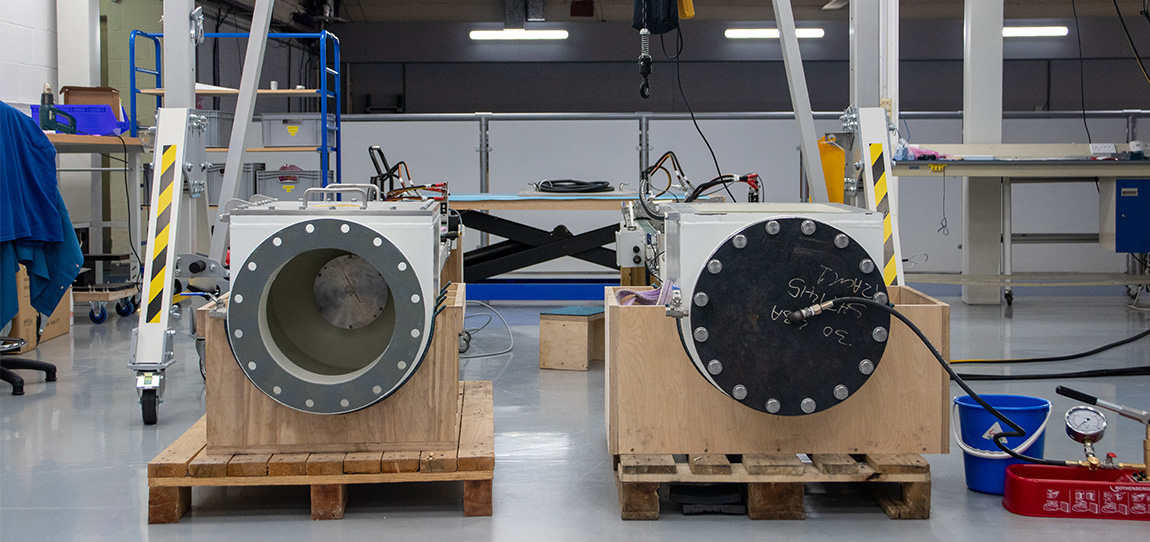

The machine consists of an electronically controlled but hydraulically operated pole running through a sealed bearing section. A service section (or sea chest) is provided with inspection door to allow fitting and servicing access to the transceiver or sonar head. It is designed to fit on to DN350 and DN500 gate valves however, other gate valves are also supported.

The machine can be controlled from a main control panel or locally at the machine. A bridge control is also available as an option. Hydraulic control of the gate valve is provided as an option. The hydraulic power pack and main control can be mounted remotely if the machine is to be configured for Zone 1 Ex rated classification.

The standard machine can be configured to the meet individual vessel requirements by changing the height of the machine and providing adaptor flanges for different size or specification gate valves. We can provide detailed application advice on positioning, installing and commissioning your machine.

At a glance

- Allows you to deploy instruments from your vessel with maximum performance

- Optimised for Ranger 2 USBL (including HPT modem configurations), Marksman LUSBL, Modem and Sentinel IDS systems

- Choice of through-hull, through-tube and over-the-side designs

- Global track record on all types of vessel: new build and retrofit

- Options for permanent or short term installations on vessel-of-opportunity

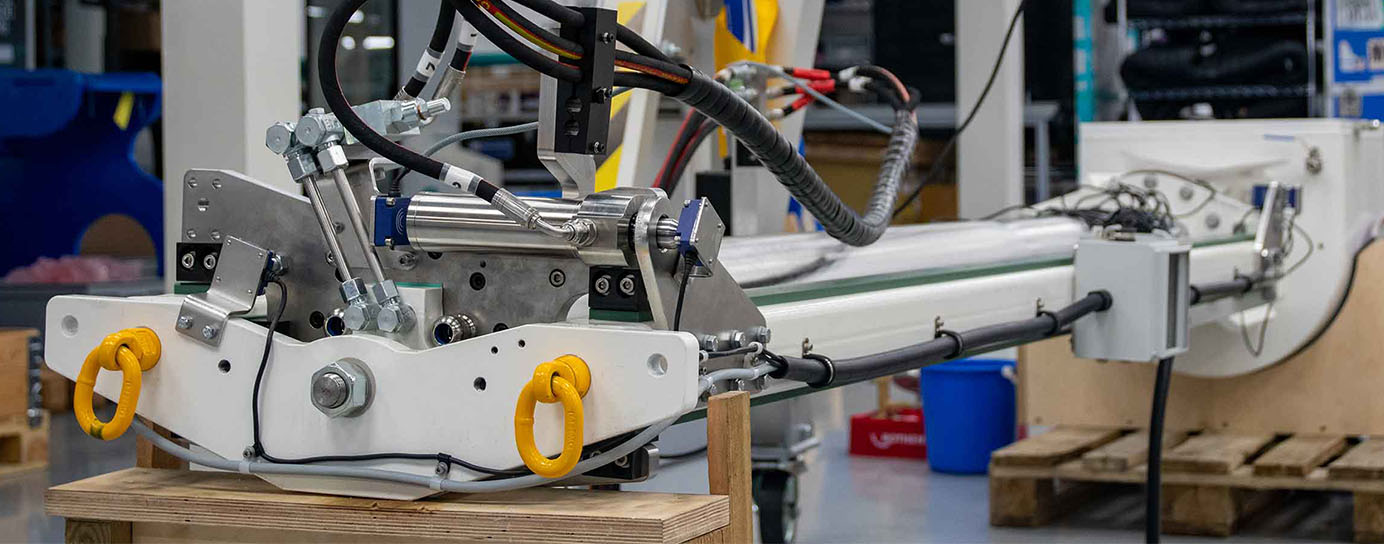

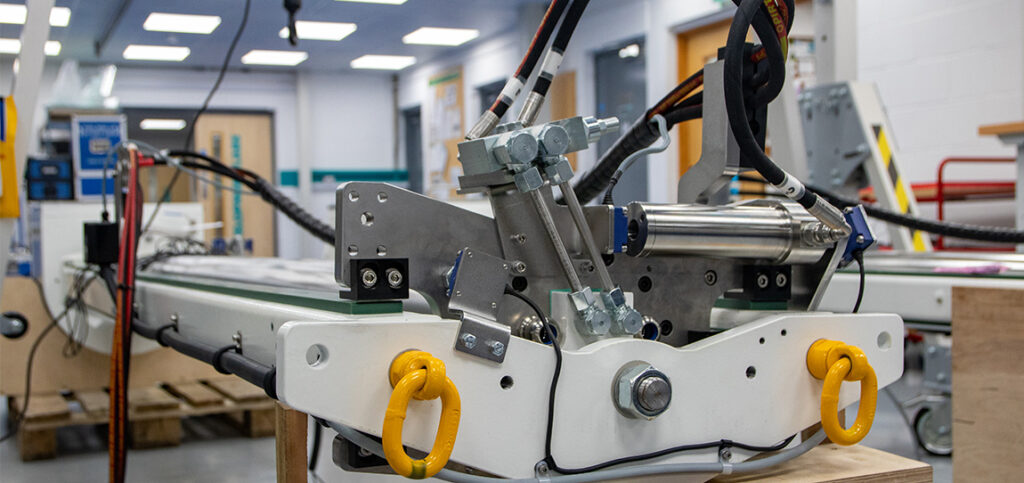

Over-the-side

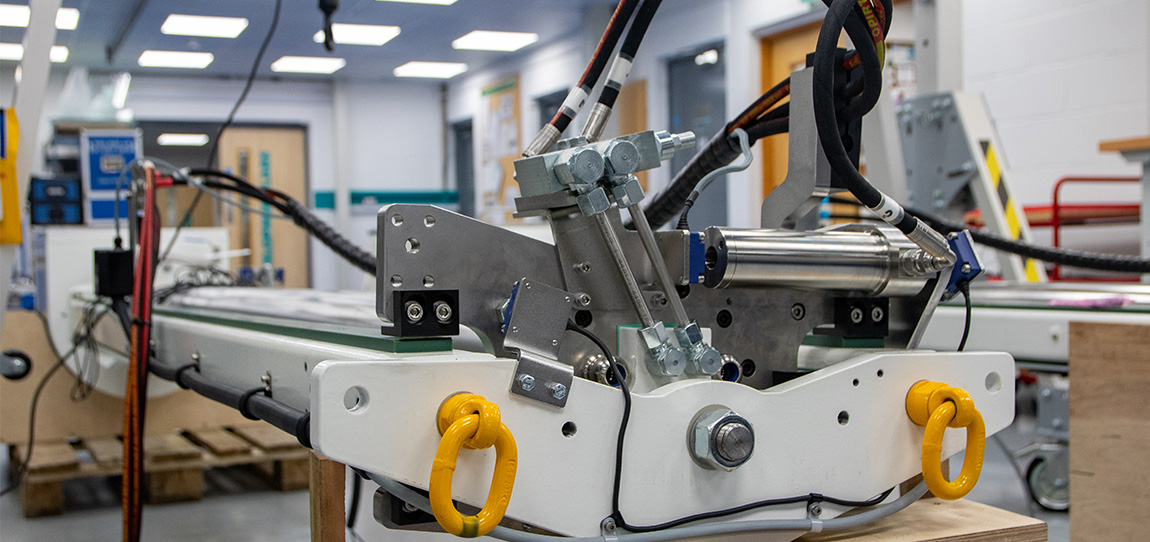

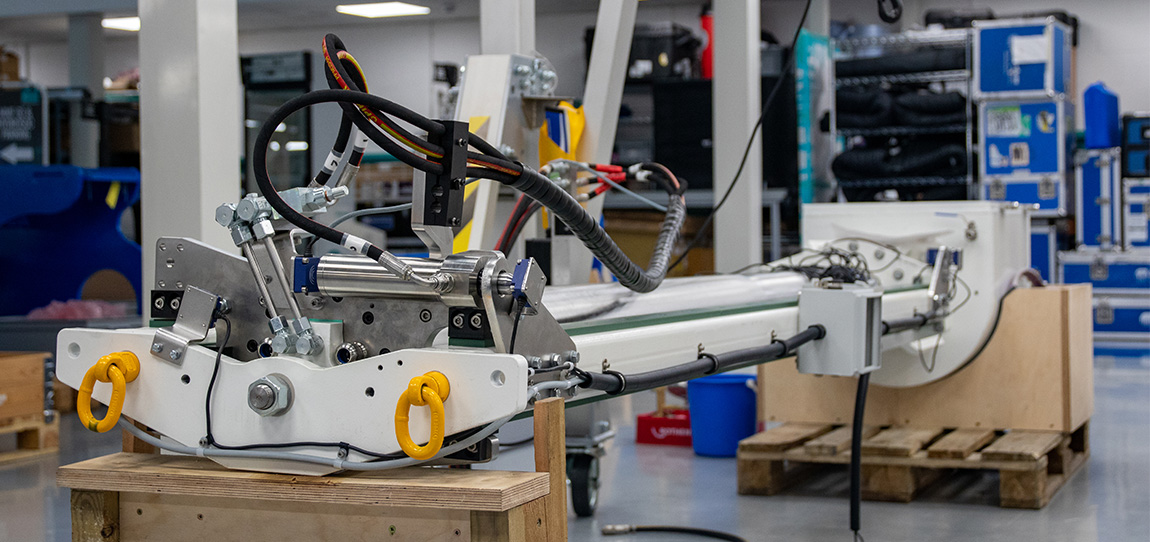

Our modular, over-the-side deployment machine is for vessels where through-hull deployment is not available or practical, or where a temporary installation is required on a vessel-of-opportunity. The design still provides survey grade rigidity without the high cost of dry docking and fitting a gate valve. It can work at operational speeds of up to five knots without degrading USBL positioning performance and to have a survival speed of up to ten knots.

Based on a pivoting sectional pole, the system can be supplied with either a hull or deck mount for the pivot, depending on the vessel arrangement. A brace/lock assembly positioned near the water line and three or four pole sections bolted together to form the arm such that the transceiver on the end of the arm is positioned below the hull by at least 1.5 m. The lower portions of the sectional pole are faired to mitigate against vortex induced vibration which can reduce performance.

The system is not limited to deploying Sonardyne instrument. We can custom engineer adapters for the end of the pole to accommodate third-party sensors.

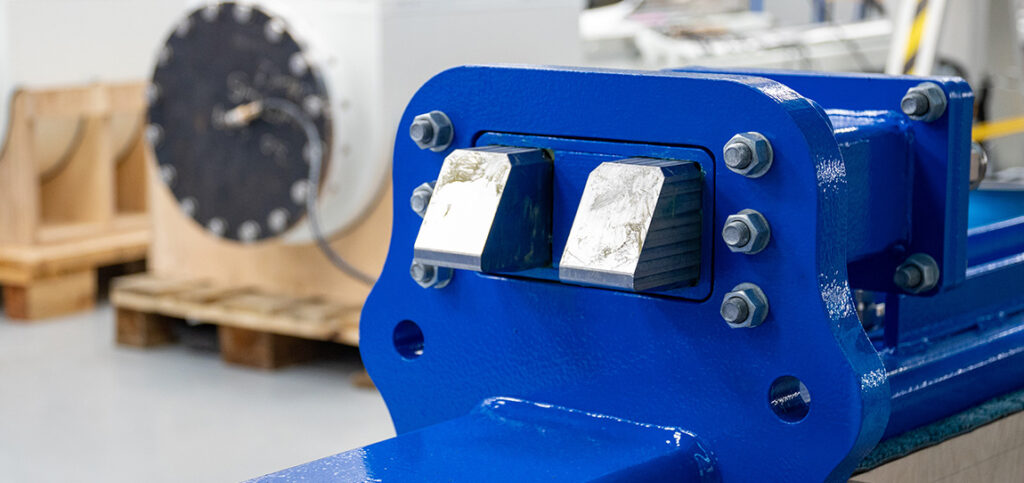

Through-tube

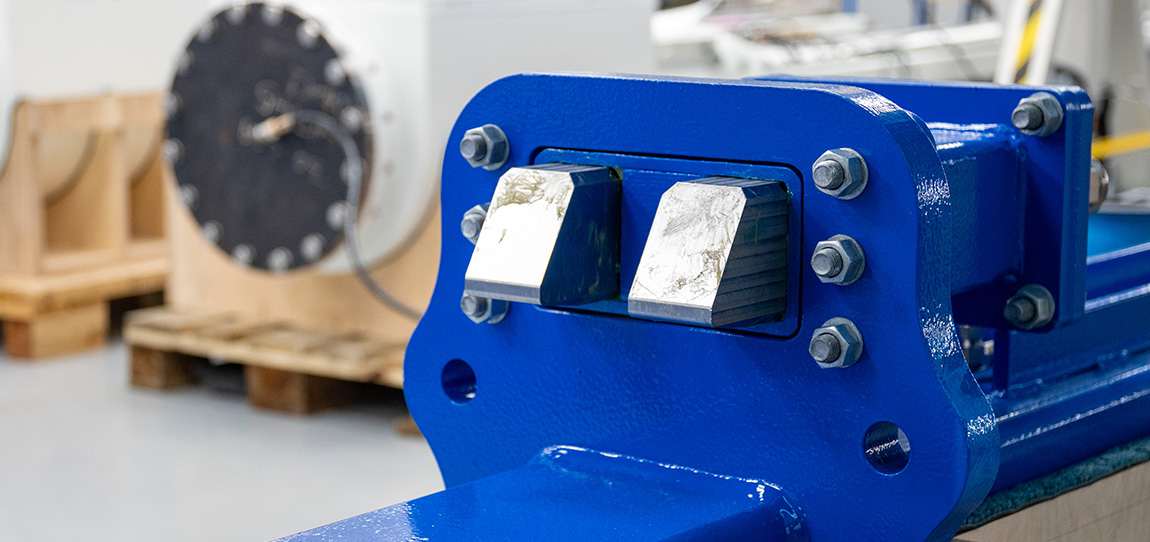

Popular on very large vessels including drilling rigs, our through-tube deployment machine consists of a hydraulically operated pole, a sealed bearing section and a sea chest service section, with inspection door. The whole machine sits on a gate valve which in turn is mounted on the flange of a through hull penetration pipe.

The ideal deployed length is dependent on your particular application, but in general terms it is best to minimise the deployed pole length to achieve a specified acoustic performance. Typically, a length of between one and three metres below the hull has been found to be acceptable. The pole is very rugged and is designed to be highly resistant to vibration caused by vortex shedding. Operational speeds of up to ten knots through the water may be achieved safely with the ability to survive short duration exposure to higher speeds.

We provide detailed application advice on positioning, installing and commissioning the machine. The sea chest, when the gate valve is closed, provides easy access to the retracted transceiver or sonar for service and inspection purposes. The gate valve also allows the machine to be removed without dry docking. An optional hydraulic drive for the valve is available.

The machine can be controlled from a main control panel or locally at the machine. A bridge control is also available as an option. The hydraulic power pack and main control can be mounted remotely if the machine is to be configured for Zone 1 classification. The standard form of machine can be simply configured to the meet individual vessel requirements by changing the height of the machine and providing adaptor flanges for different size or specification gate valves.

For specialist or demanding applications, machines of this general type can be engineered to suit your specific requirements.

Through-hull

Choose this machine if you’re permanently installing a Sonardyne system on your vessel. Can be retrofitted in existing vessels as well as new.

Over-the-side

Choose this machine if you’re using a vessel-of-opportunity for a short-term project. Can be installed alongside in a harbour and is easy to transport.

Through-tube

Choose this machine if your large vessel has an existing stem tube that can be utilised. Machine is supplied in sections for easy on-site assembly.

Support

Our knowledge base boasts a wide range of articles from our customer support team about deployment machines – from how to protect them, to deployment machine maintenance.

Specifications table

| Feature | Type 7950 Through-Hull Transceiver Deployment Machine | ||

|---|---|---|---|

| Deployment Machine | Transducer Pole | Nickel based (Inconel 625) coated steel pole for corrosion resistance | |

| Guide Sealing Section | Contains bronze support bearings plus high integrity 2 stage seal | ||

| Service Section | Removable door access to the transceiver without the need to lift the machine | ||

| Operational Speed | Standard | 7 knots operational (15 knots survival) | |

| Heavy Duty | 10 knots, operational (15 knots survival) | ||

| Emergency Operation | Manual hand pump | ||

| Length | Maximum available deployed length is 3 m to face of transceiver | ||

| Weight | 1,200 kg | ||

| Gate Valve | Hydraulic drive available (DN350 and DN500 gate valves available on request) | ||

| Power Supply | Nominal 440 V 50-60 Hz 3-phase 3.0 kW (690 V 50-60 Hz 3-phase available) | ||

| Limit Switches | Sense position of the transceiver pole and the gate valve. Enable safety interlock | ||

| Hydraulic Power Pack | Dimensions (HxWxD) | 632 x 908 x 300 mm | |

| Weight | 60 kg | ||

| Tank volume | 50 litres Mobil DTE 24 | ||

| Working pressure | 100 bar operational (180 bar max.) | ||

| Main Control Cabinet | Dimensions (HxWxD) | 600 x 600 x 210 mm | |

| Weight | 25 kg | ||

| Supply | 24 V dc (internally generated from 440 V) | ||

| Local Control Box | Dimensions (HxWxD) | 300 x 150 x 159 mm | |

| Weight | 5 kg | ||

| Supply | 24 V dc from main control cabinet | ||

| Bridge Control (Optional) | As the local control box with dimmer control (flat plate version also available) | ||

| Certification | DNV, ABS, Lloyds, BV, CCS, RMRS (others on request) |

Frequently asked questions

Protect your deployment pole & vessel

How to bleed air from a Through-Hull Deployment Machine

Introduction to Through-Hull Deployment Machine

How to create an alarm to warn that the transceiver deployment pole has been left deployed

How to enter Transceiver & Lodestar Offsets for Optimised USBL

Do deployment machines require any kind of maintenance?

What type of grease does the Type 7950 through-hull deployment require?

What type of hydraulic oil does the Type 7950 through-hull deployment machine require?

Which USBL Deployment Machine is most suitable for my vessel?

Deployment

Resources

Software and control hardware

Datasheets

Did you know?

Our deployment machines have been optimised for Ranger 2 USBL, Marksman LUSBL, Modem and Sentinel IDS systems