The Challenge

Detecting cables or pipelines on the seabed and checking or monitoring cable depth are essential requirements in the development and management of most offshore energy projects. With a global target of 80 GW of offshore wind to be built annually by 2030, these tasks are also now on the critical path.

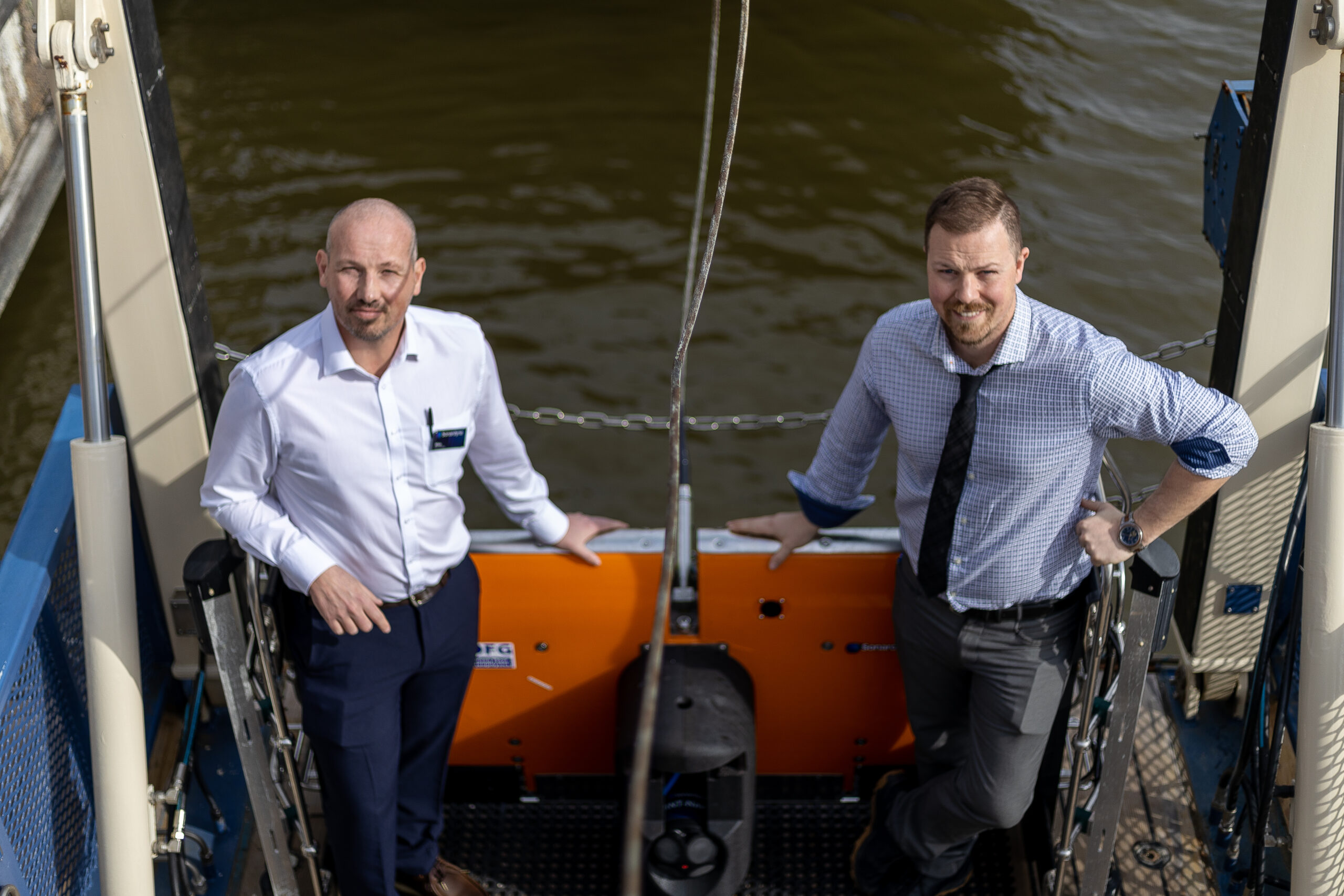

Magnetometers or gradiometers (comprising an in-line array of magnetometers) are a key tool for these operations. Accurately knowing the position of these instruments in the water throughout a survey ensures that target detection resolution is as high as possible. So, Canada-based Ocean Floor Geophysics’ (OFG) has developed the Hypermag gradiometer.

Rather than towing a magnetometer or gradiometer from a vessel or ROV, OFG’s Hypermag has been designed with multiple vector magnetometers installed in a scalable array that can be integrated directly onto a remotely operated towed vehicle (ROTV), such as EIVA’s ScanFish. This removes any positional uncertainties seen when using a layback offset when towing a magnetic sensor. The multi-vector gradiometer could then acquire compensated magnetic data in real-time

OFG possesses advanced multiphysics capability, particularly in fusing acoustic data with magnetic and electromagnetic field data, in this case magnetic field interpretation across multiple three-vector sensors. The team, therefore, required optimum shallow water positioning of the ROTV to demonstrate the gradiometer at its highest capability. “A high-quality, accurate navigation solution is a key component in achieving the full potential from our next generation of magnetic vector gradiometer sensors,” says OFG CEO Matthew Kowalczyk. “In shallow water environments, such as near-shore windfarms and UXO survey sites, it can also be one of the most difficult datasets to produce.”