The results

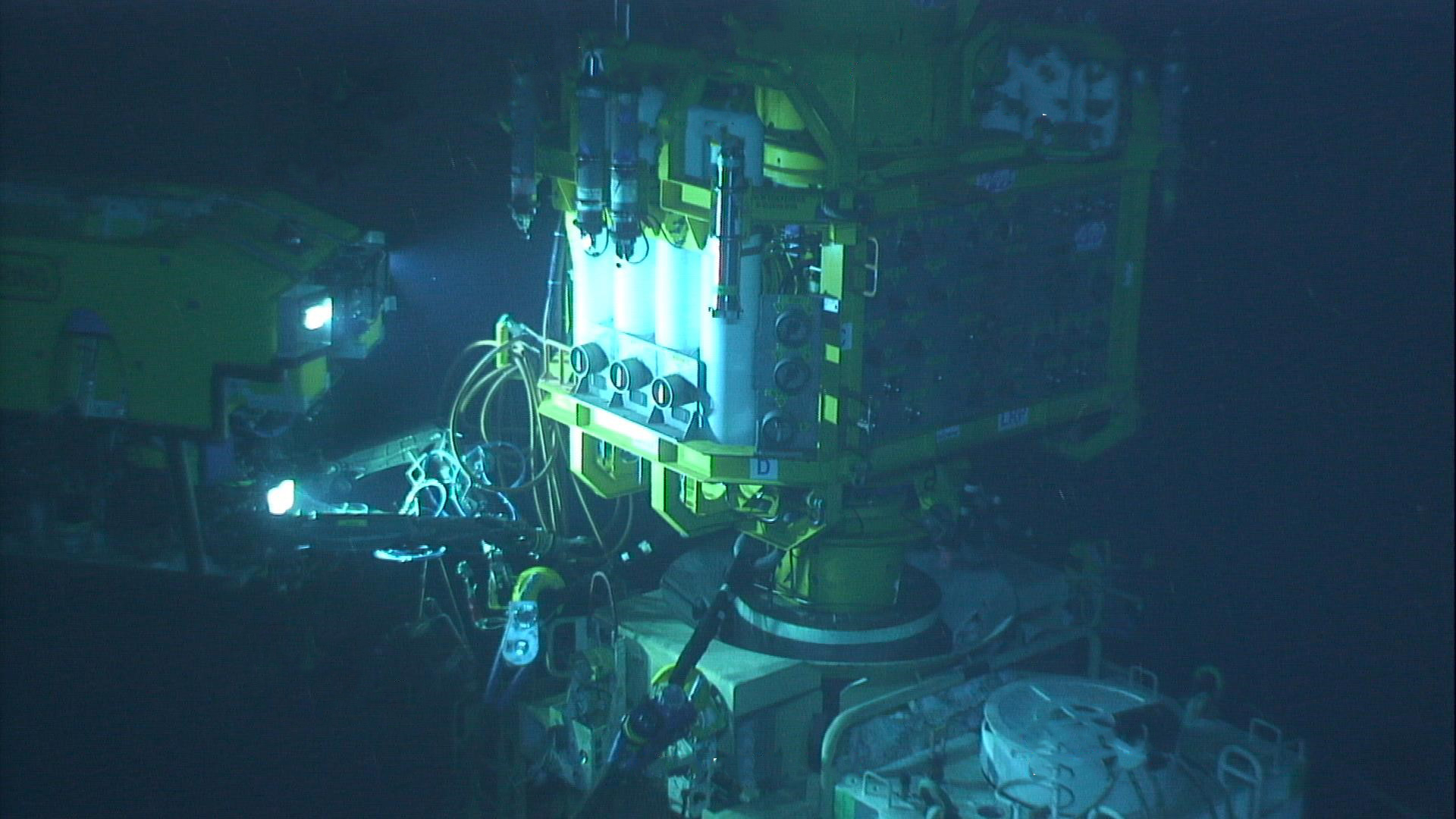

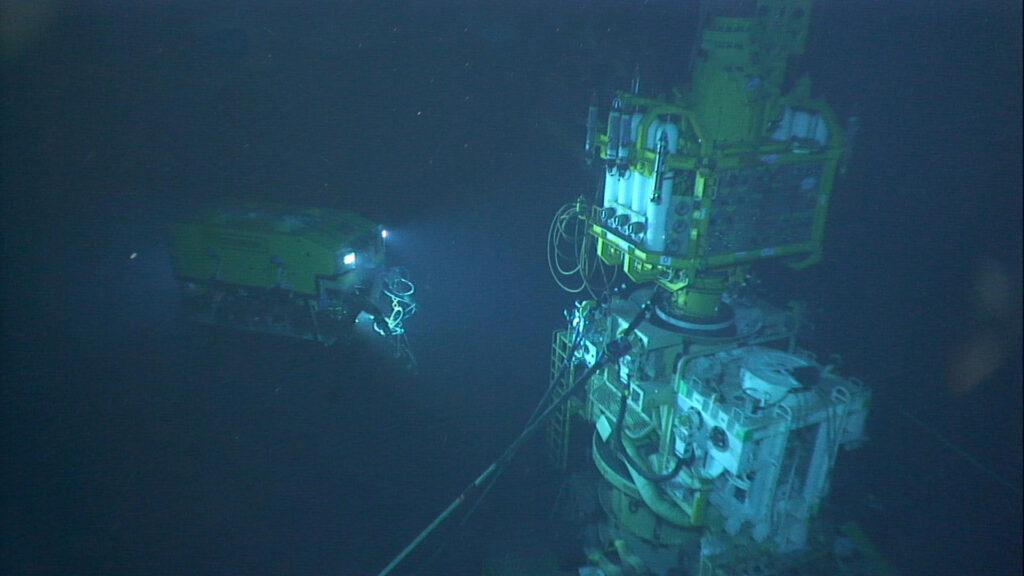

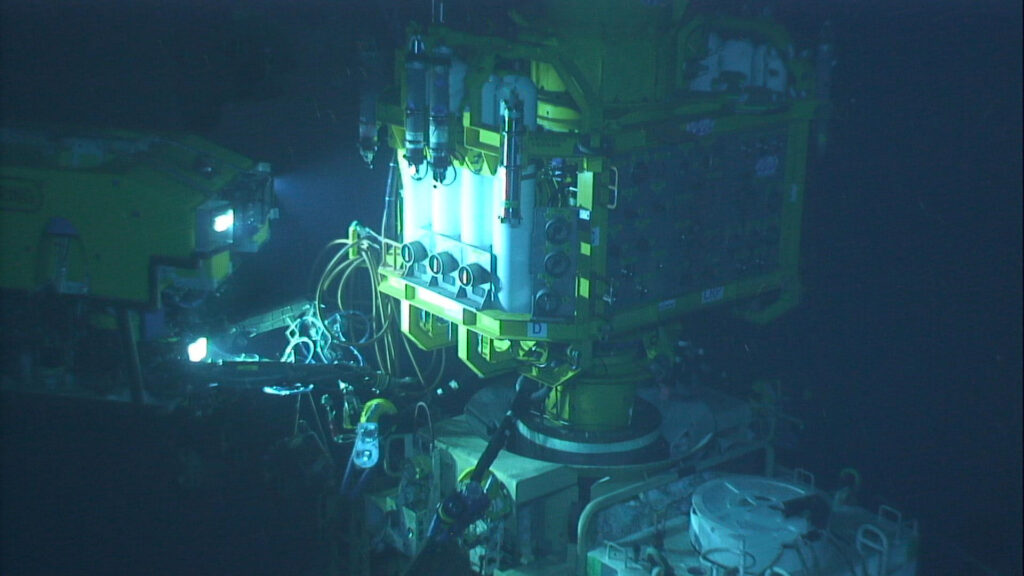

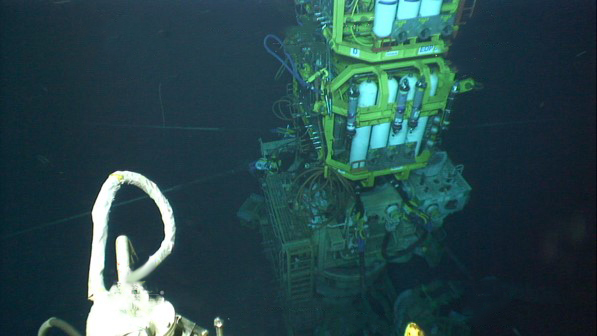

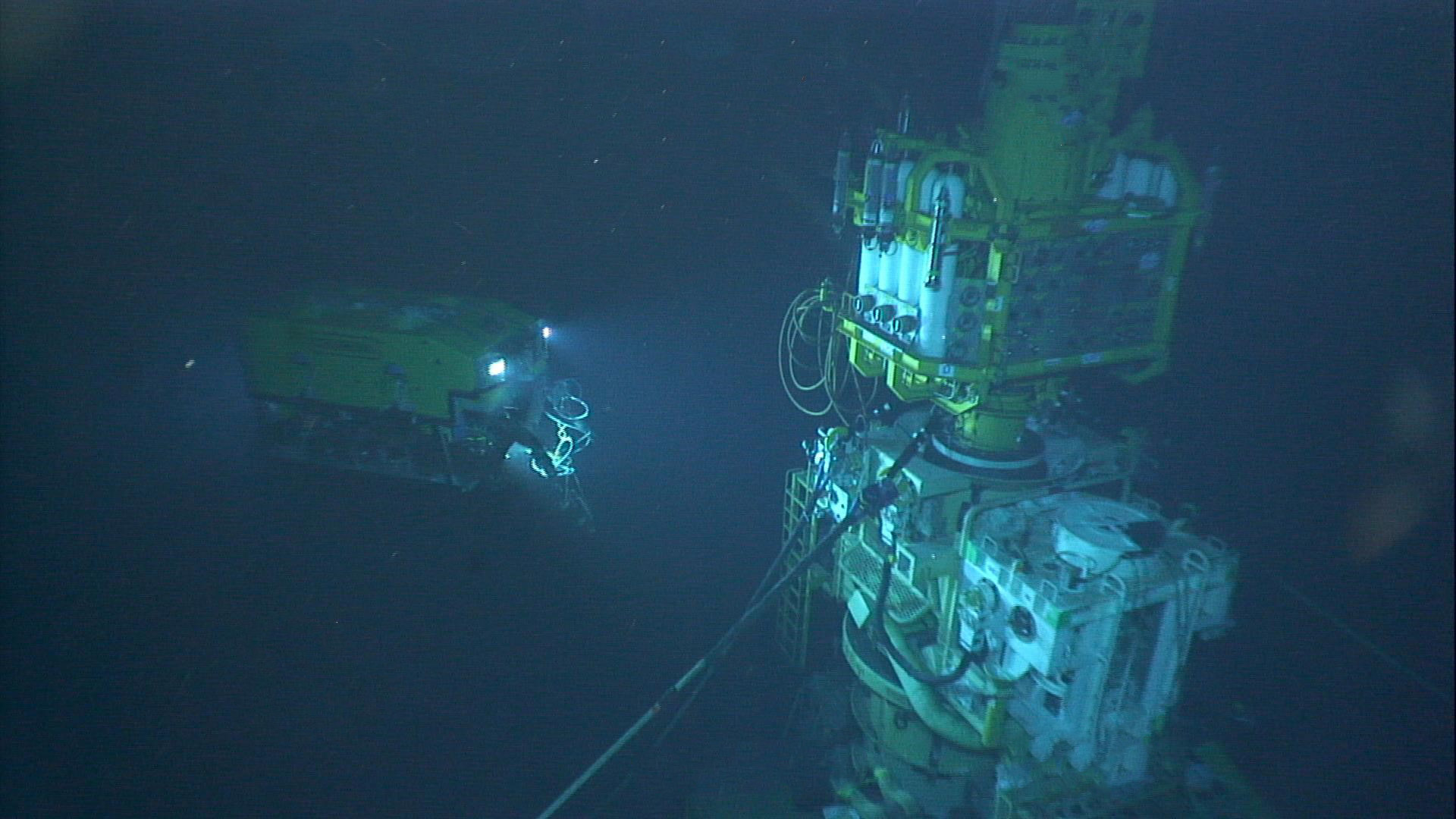

The righting operation took just three hours, using an ROV to tension the winches at two key tensioning units, one at a time. In comparison, using the alternative methods would have taken days.

Throughout, the TVO team and the operator were able to view a constant near real-time visualization of the inclination of the wellhead and the tension that was being applied at each tensioning system. This was done via an internet-based dashboard developed by TVO, so that any member of the wider team, including the operator, from anywhere in the world could watch.

Making a SMART decision

“It was a very unique challenge. There were a lot of studies and approaches analysed within the customer group before making a decision to what the right approach was. They chose ours, using Sonardyne’s SMARTs and Compatt 6s, and it worked very well,” says TVO’s Kim Mittendorf.

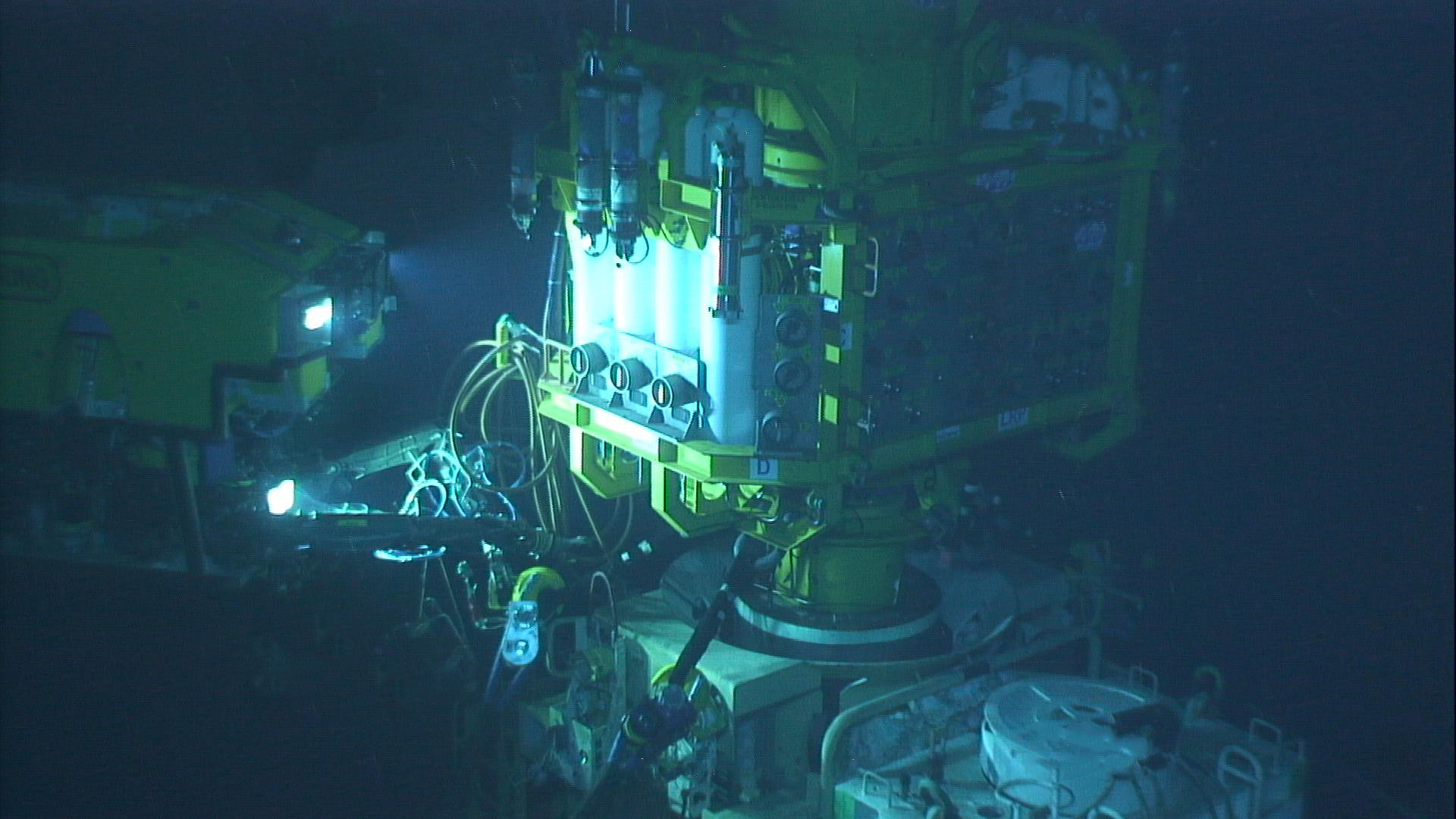

“We really could control the two tensioners with the amount of tension we needed in near-real time. While the ROV was tensioning the winch, more than 2,000 m below us, we could see what direction the wellhead was moving in, how the pitch and roll angle changed.

“All the data was also live streamed to a website so that the customer, offshore and onshore, could monitor the operation in near-real time. This drove their decision making and gave them the comfort to continue with the operation as planned.”

Paving the way for a safe well abandonment

Following the righting of the wellhead, the tensioning and monitoring system was kept in place to allow safe intervention and final abandonment operations to be completed. During this phase, the data transmission rates were reduced to once every few hours.

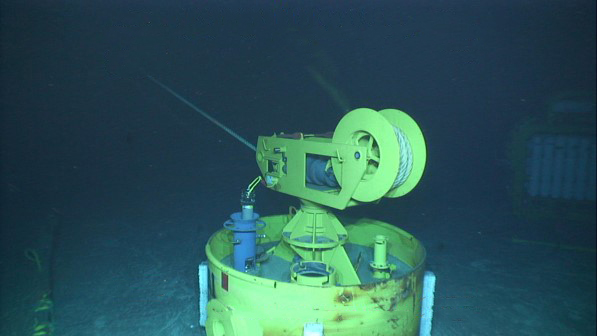

For redundancy, two of the suction piles had relay Compatt 6s installed on them. This was due to a concern that direct line of sight to the transceiver from one or more of the Compatt 6s wouldn’t be possible.

In addition, the ROV had a ROVNav 6 transceiver, as another backup communications pathway. However, none of these were required as the LRP located SMARTs and the six Compatt 6s connected to the load pins were able to directly communicate with the topside transceiver.

Deepwater wireless well intervention success

The entire campaign proved to be a complete success. Thanks to TVO’s engineering and Sonardyne’s monitoring technologies, the operator was able to safely and efficiently decommission this challenging deepwater wellhead.

Initial skepticism from the operator in using a hydro-acoustic approach for data transmission was also overcome and through the success of the project, further confidence has been built into the technology for future applications.