We’re looking back on 2020 – and what a year it’s been. Due to the Covid crisis, remote support has become a key way we have been able to continue to serve you, our customers, to keep your operations on track. But it’s not all been about what we can do remotely – our engineers have also been out supporting customers in the field too.

We took a look at our numbers and thought you might be interested. Our remote survey, engineering and training services went from being a small part of our customer offering prior to the pandemic, to now providing the equivalent of a person constantly, every day. We are supporting our customers remotely across regions spanning from Asia to North America. It’s been quite a steep learning curve to make the transition to remote support and services, but it’s also one we suspect many of you will recognise as you’ve also had to pivot to this new world.

On-site support continues

Naturally, our face-to-face, on-site support dipped over the same period. But, alongside increasing our remote support and services, across survey, engineering and training, we’ve still continued to provide our engineering and survey personnel to customers on site, whether that’s at the dockside, naval base or offshore, from Brazil to Baku. And those numbers have increased as, alongside you, we have worked through each change to Covid restrictions, at home and abroad.

The range of services provided remotely and in-person has also varied hugely, from calibrations and installation project delivery support to real-time survey operations support services. It all depends on client requirements. Back in June, for example, we were able to support P&O Maritime. They required a CASIUS calibration of a replacement HPT 5000 onboard their multipurpose vessel the Topaz Tangaroa while it was in Vlissingen in the Netherlands. To keep their operations on track, we helped them perform the calibration 100% through remote support.

Real-time SLAM – remotely

In August, our training team provided remote training in our new LBL and INS Fusion 2 survey software for a client crew in the US. That meant they were then able to join their vessel in the Gulf of Mexico and roll-out the our survey system on a live project. To reduce the risk of introducing a new system, we provided real-time online remote support and services from our Survey Support Group. This isn’t just having someone on the phone. We were able to supply our Remote Operations Access Module (ROAM) to the vessel so that our surveyors onshore, in the UK, were able to remotely access the Fusion 2 system throughout the project, ensuring everything went smoothly by offering the same service they would normally do in person, remotely. Doing this not only saved logistics headaches – by being able to use locally available surveyors on the vessel – but also meant they saved significant time on the job because they could use the new time saving features in Fusion 2 such as real-time SLAM calibration. That new functionality offered a significant saving on a 1,300 m water depth project.

On other occasions, such as for a recent cable lay vessel CASIUS, we were able to send out one of our engineers to make sure it went ahead glitch free, enabling the vessel to get to its next project with minimal downtime. We mostly mention this project because, while on the visit offshore Italy, our engineer took these lovely photos, which we wanted an excuse to share (you might, just, be able to spot the vessel he was visiting)!

He also shared his thoughts, that there are undoubted benefits to having a field engineer or surveyor physically supporting survey operations or a CASIUS calibration. One of those, in the case of a CASIUS, is being able to verify that the motion reference unit (MRU) has the correct Sonardyne sign convention – which is easiest checked visually, by comparing the movement of the vessel to the pitch and roll values reported in the Ranger 2 USBL system.

Tailored support services

However, what all of these projects show is that the right support for each case can be provided so that a CASIUS, installation support or required training doesn’t upset operational schedules and the customer can receive the same support or service whether it’s done in person or remotely. If you want us to send a specialist offshore, we will. Where we physically cannot do that, we will undoubtedly be able to provide the same support remotely, making sure your projects continue to move forward.

We also don’t think this is just about dealing with the constraints that have been placed on us throughout 2020. Many of these trends, the move towards more remote operations and support, has been coming for some time and we’ve been in discussions on the future of remote support and operations for some time. It’s just been accelerated. So the significant upside to all of this is that we now have a much broader suite of support options for you, not just for now, but into the future, in person and remotely, and we’ll continue to evolve these to meet your needs.

From operational survey support services, where we can remotely dial into your Fusion 2 system, through to field support offshore or at the dockyard for a system upgrade, we’re able to provide a dedicated service to you. Of course, our usual day-to-day customer support will also always remain in place!

Find out more about these dedicated services at the links below.

Remote Field Support

Operational Survey Services

Training

So, 2020 has been an unusual and busy year. Like you, we’ve been dealing with the challenges the pandemic has thrown at us. We’ve also found new solutions that will continue to be used when we come out of the other wise of this world we’re in. And we’re confident it will be a better world.

Get in touch to find out how we can support you.

My two previous blogs in this series looked at how unattended sensors can help solve some of our 21st century warfighting challenges, the sensors that exist today and what you need to think about to make them work. It’s now time to take a deep dive into what goes into making them fit for persistence across the ocean space.

There are three main elements that go into making persistent sensors work: what’s on the inside, i.e. the sensors, processing power, modem capability and batteries; the materials and form factor of their housings; and deployment options. Let’s start with what’s on the inside.

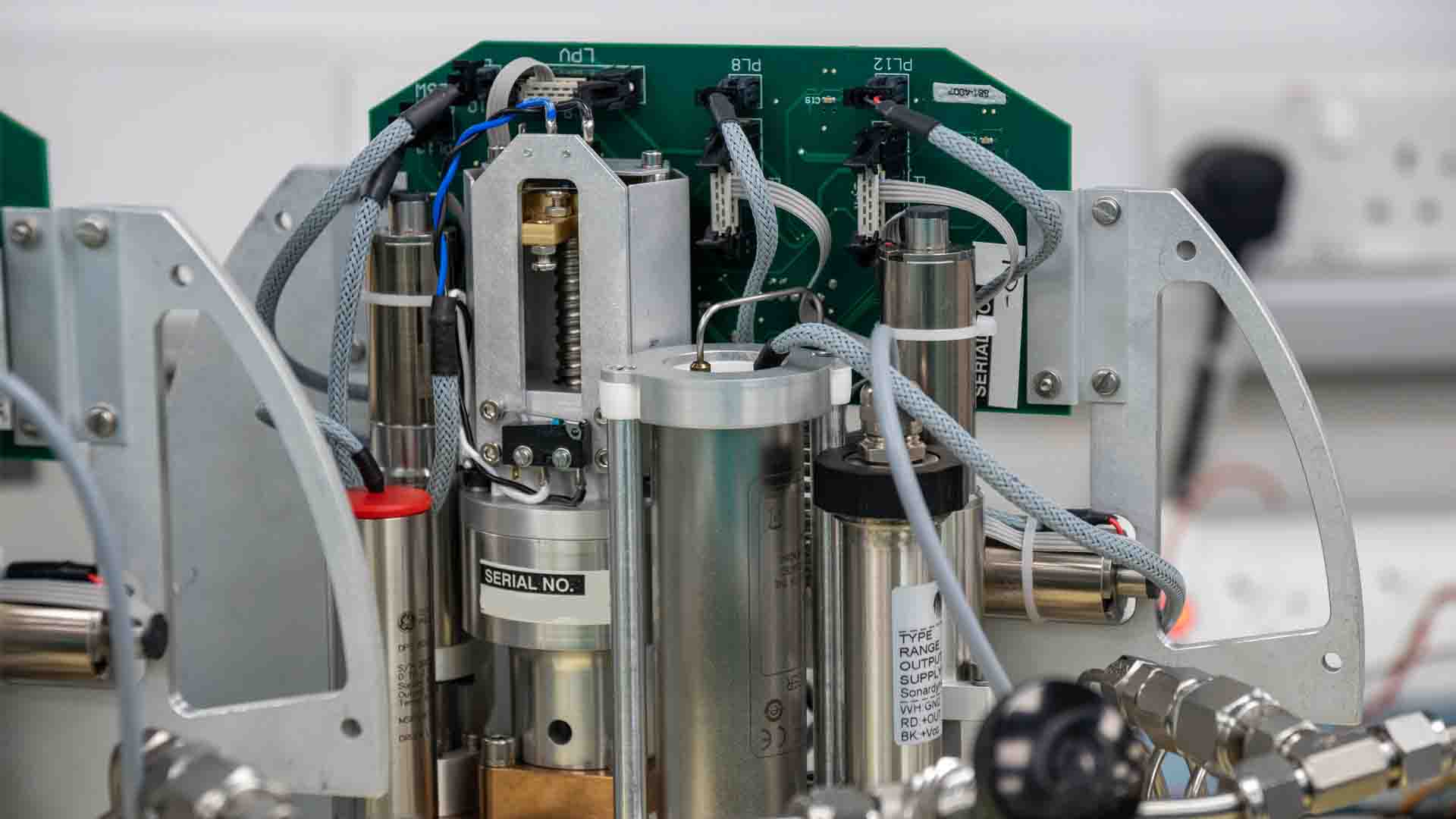

Onboard sensors

We already offer a wide range of sensors integrated into our instruments, including acoustic Doppler current profilers (ADCPs), inclinometers, and pressure, temperature and speed of sound sensors. These sensors help to characterise the environment and in turn inform the mission; helping to fine-tune other sensors and our acoustic systems.

But the options for sensing are almost endless. Third party sensors can be connected to our unattended instruments via a connector. We support a range of standard commercial-off-the-shelf subsea connectors and can accommodate bespoke solutions too. Our connectors have ports for power, RS232, RS485, CAN Bus and Ethernet. We can work closely with your team to accommodate the right solution.

Sensors Lab

How do we ensure success? At Sonardyne, once we have designed an unattended sensor, we test, test and test again. The oceans never ask for forgiveness. Our sensors lab enables us to carry out accelerated life-cycle tests for all sensors that we plan to use; at the right temperatures and pressures. This means we can stress test instruments to the point of failure, which we do at the proof-of-concept stages.

It means we can also characterise the performance of sensors over time, becoming familiar with their performance and predicting any possible degradation, remembering all the time that we need to design for longevity. We also conduct in-water tests and have a dedicated in-house team whose job it is to identify and quantify any errors before our systems are deployed.

On board processing

Data gathering requires data storage and, increasingly, also processing capability, in order to provide the relevant data that’s required. Our most basic offering stores sensor data in SD cards or equivalent. The data can then be harvested via an acoustic or optical interface. When glass sphere housings are used, the SD cards are duplicated and all data products are stored in two separate and identical repositories.

Edge processing is available with our advanced data acquisition and processing system (ADAPS) option. This highly capable processor can run sophisticated user-specified algorithms, as well as simple data analysis, such as min/max/mean statistics and thresholding for alarms and critical event reporting. By reducing high-bandwidth sensor data to small, critical packets, we can efficiently manage power consumption. That means longer deployment times can be achieved from the internal battery pack. Furthermore, using the sensor’s integrated acoustic modem, “through the water” updates to the edge processing algorithms provides ultimate flexibility and performance over the entire life cycle of the deployment.

Battery options

To be successful, unattended sensors need to work remotely and persistently for extended periods of time. The battery technology on-board will play an important role in helping extend the length of the mission. For short deployments, we use tried and tested Alkaline batteries. A single pack can provide up to 54 Ah. But by using glass sphere housings, we can pack in even more batteries. In this configuration our typical capacity ranges from 180 Ah to 505 Ah. The latter has demonstrated operations lasting for well over 10 years.

Choosing the right battery option depends on the concept-of-operations. Higher capacity adds weight to the instrument. However, it also enables our instruments to gather, process and share more data. At Sonardyne, we have developed in-house algorithms to provide accurate estimates for battery life. Once we understand the requirement, we can configure the right battery.

Materials

Of course, it’s not just what goes into the sensor that matters. Biofouling and endurance are high up on the list of our headaches. Learning how to select the right materials for operation across the world’s oceans takes time. As we have seen in my previous blog, biofouling is a constant threat, particularly where our sensors interface with the water, through which we are sensing.

Since most unattended sensors remain stationary, anti-fouling solutions used on boats or ships that are typically reliant on flow do not work as well for us. At Sonardyne, we conduct continuous trials into materials and anti-fouling solutions. The battle never ends, year-on-year we improve our materials selection process and come up with neat tricks, like copper tape to prevent fouling.

To prevent corrosion, we have a few options. For shorter deployments, we use hard anodized aluminium. For longer deployments, titanium is iron free and will not rust. It is ideal for when you want a sensor to remain in situ for 10 years or more. But it’s costly.

To ensure they can withstand the rigours of underwater operations, we design and push our materials and instruments to their limits. Using our unique hydrostatic pressure test chamber measuring at 750 mm diameter and 2000 mm tall, we can generate 630 bar of pressure, simulating depths of well over 6,000 m. We can cycle the instruments many times, simulating multiple deployments. We also use temperature regulated chambers to cycle through different temperatures at different rates. We need to, as our instruments are as likely to be sitting on a deck in the Arctic as they are to be found in Tropical seas. How the materials behave as they are dropped into the water and are then submerged is vital information that we use to help us choose which ones to use.

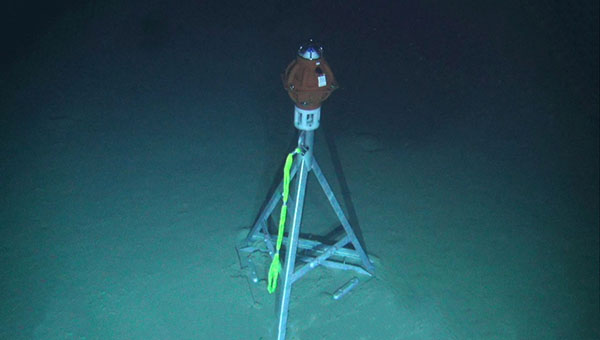

Deployment options

The considerations do not end there. If we want to be truly unattended, that means – once deployed – we want sensors to remain on the seabed throughout the life of the mission. To do this, we offer a range of options from floatation collars (used to moor sensors on the seabed and to easily recover them) to glass spheres on tall frames that can freefall to the seabed and are deployed for periods of more than 10 years.

Our systems are made to operate at all ocean depths from very shallow waters using anti-trawl frames to the depths of the Mariana Trench. Our deployment systems can be built by us or our customers under license – anywhere in the world. Speak to us to discuss your requirements.

Acoustic Data Harvesting

So now you have your sensor. It’s been deployed and it’s gathered, processed and stored data you would like to access. What’s next? Our unattended sensors set themselves apart as they are equipped with leading acoustic communications.

Our underwater acoustic modems are used to regularly harvest data from these sensors. This can be done from either the surface or a nearby unmanned underwater vehicle (UUV). The protocols are secure, ensuring that the sensors respond exclusively to the asset owner; preserving battery and keeping the system undetected while it is not being interrogated.

We can also tailor the waveforms to make them difficult to detect and exploit. Enabling us to send sparse acoustic commands through a network. This means that, if our edge processing pulls the trigger, the sensor can send a pre-defined message. Alternatively, we could acoustically command an actuator to have the sensor float to the surface. Our sensor then becomes a data pod waiting to be recovered or capable of transmitting information when it reaches the surface.

If covertness is not a mission requirement, our commercial acoustic protocols are designed to operate between 14 kHz to 34 kHz, supporting a rich range of telemetry schemes. That translates to two-way communications anywhere between 200 bps to 9,000 bps over tactically significant ranges of up to 12 km. These signals can also be used in support of navigation systems for friendly third-party underwater vehicles (i.e. UUVs) in the vicinity of the sensor.

If your platform must remain covert, then optical free space modems may be a better option. These modems work over shorter ranges, from approximately 5 m to up to 150 m, and can be used to transfer between 10 Mbps to 600 Mbps. They work in the UV and visible light spectrum and work best at depth, away from the sunlight’s interference. Because they work over shorter ranges, it means enemy combatants really need to know where to look for them to find them. As they will only respond to a known modem, they can remain hidden for prolonged periods of time.

Taking the next steps

So, in the first blog in this series, I looked at how achieving scale in the underwater domain doesn’t have to come at a high cost. Unattended sensors can monitor choke points, provide persistence and guide the underwater vehicles that are extending our naval forces’ reach. In the second instalment, I covered the challenges we face when deploying these sensors. In this final blog, I’ve looked at what goes in to making these systems so that they will offer the persistence you require. What more do you need to know?

If you have a requirement for persistence in your underwater battlespace, we can help. Get in touch to discuss your needs.

Sonardyne technology has been selected to support the world’s largest and most environmentally sustainable fleet of ocean-going, multi-role robotic vessels, which is being launched by marine robotics company Ocean Infinity.

Sonardyne systems will provide part of Ocean Infinity’s new Armada fleet with key sensor technologies for underwater platform navigation, tracking, control and communications, as well as ensuring uninterrupted surface navigation, even when global navigation satellite system (GNSS) services are degraded or denied.

The Armada fleet will mark a major technological advance, providing sustainable services to all corners of industry from offshore energy, to logistics and transport. The innovative, low-emission robotic fleet that can be launched from any shoreline on the globe was unveiled in February this year (2020), and will initially see 17 bespoke designed state-of-the-art uncrewed vessels added to Ocean Infinity’s existing robotics fleet.

The vessels, initially measuring 21 metres and 36 metres long, will be able to perform offshore data acquisition and intervention in both shallow and deep water operating regions. The vessels will use a range of underwater platforms, including remotely deploying autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs).

Sonardyne’s acoustic communication and inertial navigation technologies were chosen to support Armada because of their performance and flexibility across a wide range of water depths and environments, supporting operations across all sectors in even the remotest locations.

The package includes surface and subsea navigation sensors to remotely support deployment, operations and recovery of underwater robotic systems from an uncrewed vessel, from anywhere in the world. That includes being able to accurately track and control multiple robotics systems simultaneously and provide water current profile information, as well as support vessel dynamic positioning during critical phases of an operation.

Uniquely, the systems also provide navigation redundancy in the event of GNSS outages, which could occur while operating in multipath or shadowed environments, such as fjords or near large structures or where signals are deliberately interfered with.

Delivery of Sonardyne equipment for the first wave of Armada fleet vessels will be made by the end of this year. Further deliveries will be made through 2021.

Alan MacDonald, Sales Manager, Sonardyne, says, “Over recent years, we’ve been focussed in Sonardyne on developing the flexible technologies that are required to support the revolution that is taking place in both surface and subsea marine robotics. Consequently, we’re very pleased to be part of Armada’s pioneering vision to deploy robotics at scale. These systems will help a wide variety of industries to reduce how many people they need to send to sea as well as dramatically reduce CO2 emissions, by deploying these smaller, more efficient vessels out.”

[blockquote author=” Dan Hook, Managing Director, Ocean Infinity”]Our expert team of robotics specialists selected Sonardyne as the clear choice for our robotics ships, to provide underwater navigation, tracking, control and communications and that additional layer of positioning security in areas where GNSS signals might be obscured. We look forward to a long-term working relationship with Sonardyne, as we grow our fleet.[/blockquote]

Initially, all of the first tranche of Ocean Infinity’s Armada vessels will be fitted with Sonardyne’s Ranger 2 Ultra-Short BaseLine (USBL) system augmented by the company’s Marine Robotics Pack. This combination provides remote all-in-one tracking, communications and control capability for underwater deployed robotics so that even more operations can now be done from shore.

These robotic vessels will also be fitted with Sonardyne’s industry leading SPRINT-Nav hybrid navigation instrument, to provide continuous, uninterrupted navigational aiding to underpin safe remote operations, even if GNSS service is impaired due to their remote location or nearby infrastructure. In addition the system produces profiled water column data, which is particularly important during the deployment and recovery of subsea robots.

Wideband Sub Mini 6+ tracking transponders and SPRINT-Navs will also be fitted to the ROVs being deployed and operated by the Armada fleet.

Ocean Infinity expects the first Armada vessel to be delivered in 2021 and, along with the remainder of the fleet, will be controlled and operated by experienced mariners via satellite communication from onshore control facilities in Austin, Texas, and Southampton, England.

In my last blog, we looked at how unattended sensors could help to solve some of our 21st century war fighting challenges, not least how to maximise the use of our crewed and uncrewed assets. We also showed how sensors already exist that can meet those challenges today. In this blog, let’s look at what we need to consider to make them work for you.

There are three things you need to understand:

- 1.Nature is against us

Location: We mean it. Live organisms thrive in shallow waters. It doesn’t take long for biofouling to occur. Typically, this starts with the formation of biofilms, followed by the adhesion of micro-organisms. In shallow water environments, at higher temperatures, it takes just three weeks for biofilm to form and then attract larger colonizers, which in turn attract much larger organisms causing macrofouling. There is little that can be done once the larger organisms take hold, other than recover the instrument and physically remove them. In time they will affect sensor performance and may even stop sensors working altogether. In some regions, biofouling can limit effective deployments to fewer than three months. In cooler and deeper waters, the rate of bio-fouling growth drops, making longer deployments possible. Where an unattended sensor is deployed and how biofouling may affect it needs to be considered as this will determine the duration of deployment.

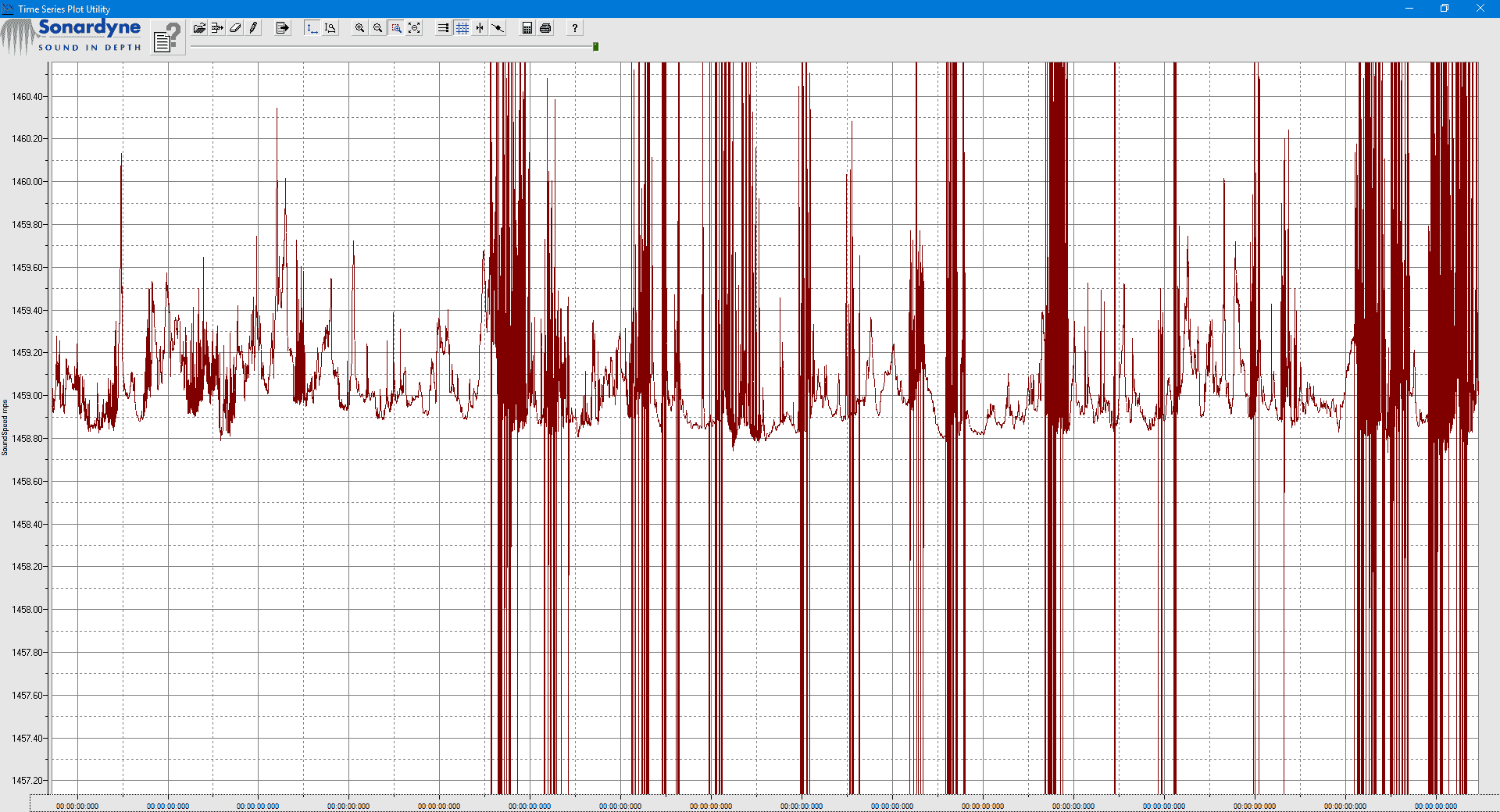

The impact of biofouling on a sound velocity sensor can be very clear.

The impact of biofouling on a sound velocity sensor can be very clear.

Materials: Choosing the right materials to build your instruments with can also impact biofouling growth rates. In addition, the right materials are also critical to ensuring your instruments do not corrode. Iron corrodes when exposed to water. Any material with iron in it is subject to corrosion. Over time, even stainless steel will corrode and rust. For long-endurance missions, the design and manufacture of underwater unattended sensors needs to factor in these considerations to ensure that systems remain corrosion free.

Pressure: Then there is pressure. As we dive, we add about one atmosphere of pressure for every 10 m of water depth. Sensors must be designed to both withstand extreme pressures at thousands of meters of water depth, but also to rapidly cycle through pressurisation and depressurisation, as they are deployed and recovered. This is no mean engineering feat.

Seabed conditions: The seabed can be an unforgiving place – it is varied and complex. Unattended sensors can sink through mud or sand. Corals and rocks can obstruct your line of sight and act as reflectors to acoustic sensors. It is not always flat either and deploying a sensor on a slope or close to a cliff could have an impact on your operations.

Commercial activity: Unfortunately, it is not just nature we have to contend with. Interaction with commercial fishing activity can be a challenge. Many underwater sensors have ended up caught in fishing gear. We know, because we’ve had them knock on our door claiming salvage rights for some of our commercial instruments!

Anti-trawl frames are used to prevent fishing interaction.

Anti-trawl frames are used to prevent fishing interaction.

- 2. Design for endurance

Delivering an underwater sensor to the bottom of the ocean is analogous to deploying a satellite in space. Design practices are similar because the choices we make today are going to be ones we have to live with for the next 10 years. This means there is no room for error. The electronics, the batteries, the connectors and the subsea housing all have to be up to the task. Making the right decisions comes with experience, but also by following practical engineering principles.

Long endurance, tried and tested.

Long endurance, tried and tested.

Start by modelling your operations. Modelling the environment and how your instruments will interface with it is critical as it enables us to work through concepts and designs ahead of fabrication and testing; enabling us to quickly consider new technologies that keep rapidly evolving around us.

Make sure you conduct in-water tests. Once your systems are designed and fabricated, they need to be rigorously tested to their breaking limits. This is our chance to understand the envelope in which they will continue working. Use pressure chambers, vibration tables and temperature-controlled facilities. Consider accelerated cycle testing. Use proof-of-concepts.

Once you are ready, it’s time to go out to sea and deploy your instruments. While typically not as expensive as launching a satellite, this is still a costly endeavour requiring significant planning and effort. It needs to be right.

- 3. So much data

A sensor deployed at sea for 10 years can gather a lot of data. Exactly how much will be limited by the amount of memory on your storage device. Running out of data storage can be avoided by carefully considering which data to store and at which sampling rate. Continuous sampling of data typically also drives higher power consumption, draining valuable battery resource.

This is why edge computing is becoming so important. On-board algorithms can be used to determine at which rate to sample, increasing the frequency if certain events are triggered. On the other hand, processing raw data and turning it into useful information massively reduces storage requirements. A good unattended sensor should be equipped with the capability to store and process all data or store only the useful information.

Information can also trigger events. For example, the unattended sensors can be made to release data pods that float to the surface to relay information. Alternatively, they may contact nearby unattended sensors in a subsea acoustic network to hop data from out in the field to a base station. For certain missions, data can be harvested from unattended sensors using uncrewed surface vessels (USVs) or uncrewed underwater vehicles (UUVs) and then the sensor’s memory banks cleared, to continue the mission beyond its original design. In all cases, you need to consider what information is required and what data you need to get it.

Collecting your data with a UUV or USV offers more options

Collecting your data with a UUV or USV offers more options

Making sensors work for you

Unattended sensors are difficult to engineer, but ultimately it’s worth the work. They can support a multitude of missions such as oceanography, anti-submarine warfare, intelligence, surveillance, target acquisition, and reconnaissance (ISTAR) and field deployed ranges.

Want to find out more about our capability? Join us in the next instalment of this series or get in touch.

Missed the previous instalment? No problem, click here

At Sonardyne we are experts at manufacturing and deploying sensors underwater for prolonged periods of time. We offer solutions that are ready to be deployed now. We configure them with modular building blocks meaning that we can work with customers to meet new requirements. In this series of blogs, Ioseba Tena will be looking at examples of long-endurance sensors we can deploy today, why it’s perhaps not as easy as you think to do this, and, finally, a closer look at how our systems are built. Let’s get started.

Submarines have been a persistent threat since their invention. They are capable of operating while remaining undetected and, therefore, projecting force in remote locations. Since the introduction of nuclear-powered systems, they have been able to remain on prolonged deployments. Today, the threat no longer stops there. Unmanned underwater vehicles (UUVs) and a new generation of extra-large UUVs (XLUUVs), with increased range and more capable payloads, are now being introduced to support incumbent nuclear submarine fleets.

Traditional anti-submarine warfare (ASW), while effective, requires significant investment and ties up our warfighting ships – our nations’ prized assets – to the task of trailing possible contacts. As the number of threats proliferate, we become limited by our ability to grow our fleets. This means we need to find new ways to achieve scale.

Leveraging uncrewed systems for ASW operations

Our own unmanned systems can come to the rescue, helping us to project our own strength and our ASW capability, by detecting threats further away and providing us with the opportunity to react to them sooner; informing our fleet before the threat reaches its target.

What better way to do this than deploying unattended sensors at choke points to help monitor persistently or even to have them support our XLUUV fleet in finding its way? They can be part of the ASW mix, by passively monitoring known routes. Alternatively, they can be used by XLUUVs to upload and download data or take/adjust their marching orders based on recent observations.

Today’s unattended sensors can be formidably capable. We have been operating them for a long time in the commercial and ocean science sectors. Our close to five decades of experience in instrumenting the underwater domain has seen us deliver systems in all types of environments in support of everything from oceanographic missions and long-term geological studies to persistent monitoring of subsea assets. The technology is field proven and can change the game.

What can our unattended sensors do today?

Take for instance our Pressure Inverted Echo Sounders (PIES) used in support of oceanographic missions and measuring average sound speed in the water column. PIES can be configured for autonomous monitoring over periods of several months or multiple years. PIES use an up chirp to accurately measure two-way travel-time through the water column. Simultaneously, they also measure pressure at the seabed. Pressure measurements are converted to depth to find the acoustic distance travelled from the seabed to the surface and back again. By combining the depth and travel time, the average sound speed in the water column can be calculated. An embedded acoustic modem allows you to retrieve that data – i.e. two-way travel-time in seconds and pressure in kilo Pascals.

By strategically deploying arrays of PIES we can persistently monitor sound speed profiles across a large body of water. This data can be harvested using our acoustic modems mounted on surface assets like uncrewed surface vessels (USVs) and used in direct support of ASW operations.

Autonomous navigation anywhere

If you need to support underwater navigation, our Autonomous Monitoring Transponder (AMT) is a long-endurance transponder, extensively used for subsea survey tasks and capable of autonomously acquiring acoustic ranges and sensor data without surface control. It can be used to provide a range and a local navigation reference in aid of inertial navigation systems; providing a constant reference to any underwater traffic.

- Deploy it anywhere for prolonged periods of time.

- It can be programmed to wait in silence until activated by a known acoustic signal to then provide a range to a known location, which can be used as a navigation aid.

- It can be programmed to provide updates at regular intervals.

- The AMT can be used as a forward deployed navigation outpost, providing a used to aid the navigation of XLUUV systems.

- It can also be used in support of surface craft navigation when GNSS denial is a threat.

- Surface craft can be equipped with ultra-short baseline navigation systems and navigate relative to an AMT on a known location.

We have decades of experience designing, manufacturing, deploying and recovering unattended sensors. It is in our DNA. PIES and AMT are just two. Do you have a mission in mind? Get in touch with us and we will be happy to explore what is possible.

In the next instalment, I’ll take a look at what actually goes into making these sensors. Yes, it is as hard as you might think.

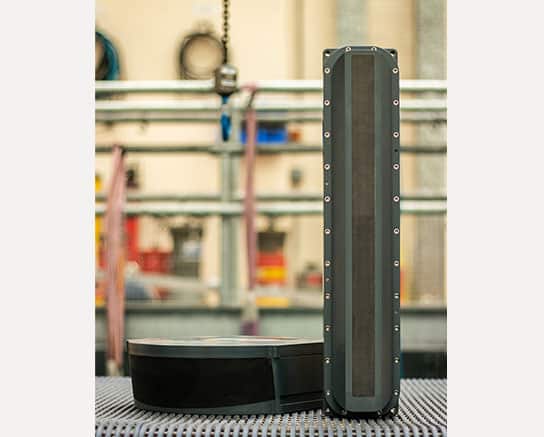

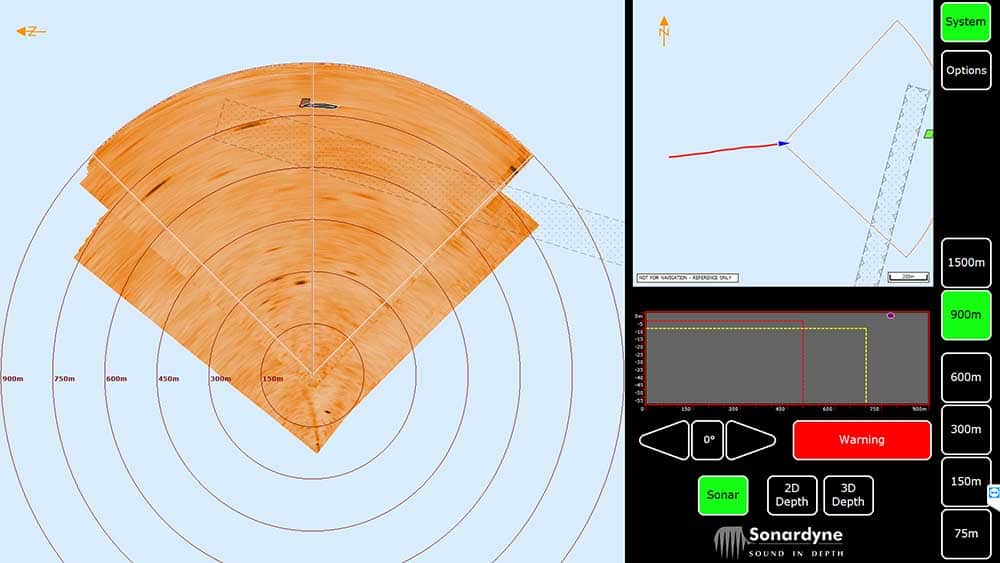

Over the past three years we focused heavily on building our latest obstacle avoidance sonar. We set ourselves significant targets. We wanted our latest forward looking sonar (FLS) to do everything and more than our previous FLS, enabling navigation in challenging environments, such as uncharted or dynamic waters. But we also wanted to design a system compact and low-power enough that it could be easier to install into smaller vessels – even swimmer delivery vehicles (SDV) or uncrewed/ unmanned surface vessels (USVs). And we wanted it to come with a simple, intuitive interface with automated alarms and easy to interpret seafloor bathymetry so that users, from oil tanker captains to underwater gear clad SDV operators, are always aware of their underwater environment in a way that’s easiest for them.

Collision avoidance with Vigilant

The result is Vigilant. We like it and our customers, from Superyacht to SDV owners, do too. But we’re always really happy to try it out on new vessels and in new environments. So we were hugely excited to be invited to demonstrate Vigilant to the Stiletto Maritime Demonstration Platform at the Naval Surface Warfare Center Carderock Division (NSWCCD) in Virginia, US. Stiletto was looking, specifically, for capability demonstration of real-time obstacle avoidance for high-speed landing craft in shallow waters, using vessel-mounted surveillance systems.

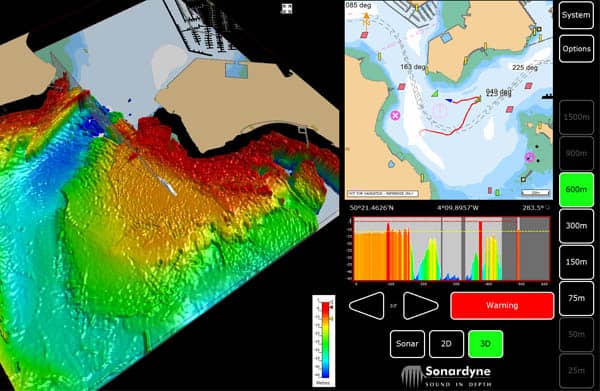

Just in case you don’t know, Vigilant is our long-range, forward-looking sonar for seaborne obstacle avoidance. It works by transmitting acoustic energy into the water, through a 90 degree azimuth and through a vertical plane down to 100 m water depth – deeper than any other system in the market. It then listens for the sonar returns. These are used to detect objects in the water column out to as far as 1,500 m (4,921 ft) away in Vigilant’s Sonar made. In 3D mode, frequency encoded sonar returns are processed through a unique Altitude Confidence Filter (ACF) in order to create a really easy to interpret 3D visualization of the seabed depth and bathymetry and depth of objects in the water column, all out to 600 m (1,968 ft) down to 100 m depth. This data is also retained, so it’s easy for navigators to retrace their steps.

3D bathymetry and long range obstacle detection

The user can seamlessly toggle between Sonar and 3D mode, depending on their navigational requirements – with zero delay in the data displayed on their graphical user interface. So, in open waters, its configurable CAD markers can alert the operator (or a third-party AI based processor) to the presence of a navigationally relevant obstacle, such as coral reefs, rocks, containers or even small ice bergs. In shallow waters and close to shore, they might prefer to see the bathymetry and water depth ahead. The bathymetry is so clear it can even be used to find a good anchorage – and they’ll still get the CAD marker alerts, even when in 3D mode. It’s just these sorts of details the Stiletto team were interested to see.

We mobilized to the Chesapeake Bay area in Virginia (not to far from my office in the DC Metro area), where NSWCCD’s Combat Craft Division is based, and got set up. At this point we have to thank the Stiletto team for helping us with our sonar head deployment pole. Being a temporary deployment, the sonar head was mounted externally using a pole mount. But we were sent the wrong type of pole, so we needed to make some last minute changes. Thanks to the Stiletto team’s help, we got a new deployment system rigged up on the navy range test craft and we were soon out on the sea trials running over three days – socially distanced of course – in and around Chesapeake Bay. Despite some pretty rough weather on the first day and having to give up mid-day on the third day, as our last-minute deployment pole set-up gave out in what was fairly rough weather, we got some great results.

Meeting mission objectives

The challenges set by the Stiletto project included being able to detect obstacles (such as mine like objects, debris or boats) while the vessel is transiting at speed of up to 10 knots, see out to 914 m (3,000 ft) in up to sea state 3 or greater for longer than 24 hours. Near real-time data would be required, with audible alerts, an easy to use visual display that can overlay on navigational charts, such as EDCIS, with no specialist training required for its use. And the vessel it’s mounted on must be able to beach. We were pretty confident it could achieve all of these tasks and more. For example, we’ve proven Vigilant at up to 25 knots and our ability to detect obstacles out to 1,500 m in sonar mode.

During the trials we were pleased to demonstrate some of these capabilities, including detecting a floating navigation marker at 1,090 m distance in Sonar mode while in less than 8 m water depth and a channel market at 850 m in similar depths.

We’d like to thank the Stiletto team for inviting us to demonstrate Vigilant. If you’d like to learn more about Vigilant, please get in touch.

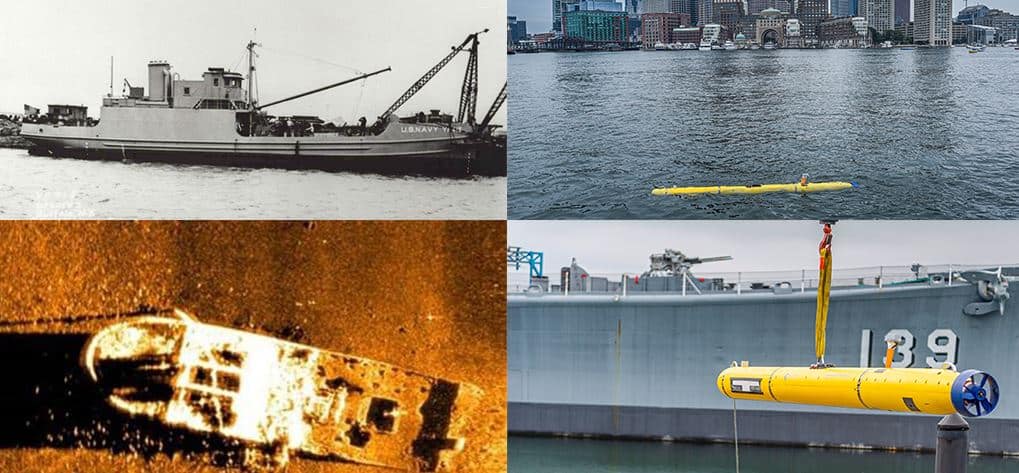

Hunting for wrecks can be a challenging exercise, especially when only an approximate location is known and a wide area of seabed has to be searched. Even then, you need highly trained operators to interpret the sonar data and determine if a target is of interest or not.

A major reason for this is that, often, low frequency sonar systems are selected in order to achieve a wide swath. That means targets of interest can be missed because they just don’t offer the resolution needed. Selecting a sonar with a wide swath can also result in shorter deployments when using an autonomous or unmanned underwater vehicle (AUV/UUV), not because they cover larger areas but because they need more energy.

Wide swath, high resolution

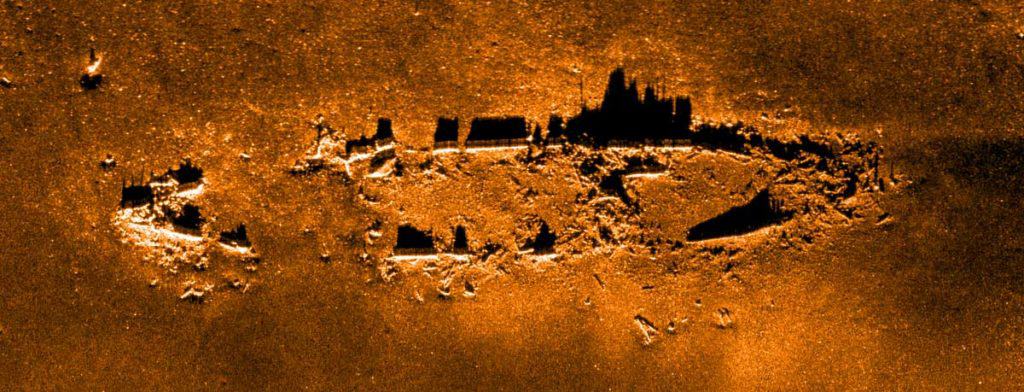

One of the advantages of using our Solstice side scan sonar is that you get a 200 m swath at high frequency resulting in a high area coverage rate and resolution that’s so good even an untrained eye can determine if a target they’re looking at is the wreck you’re hunting for.

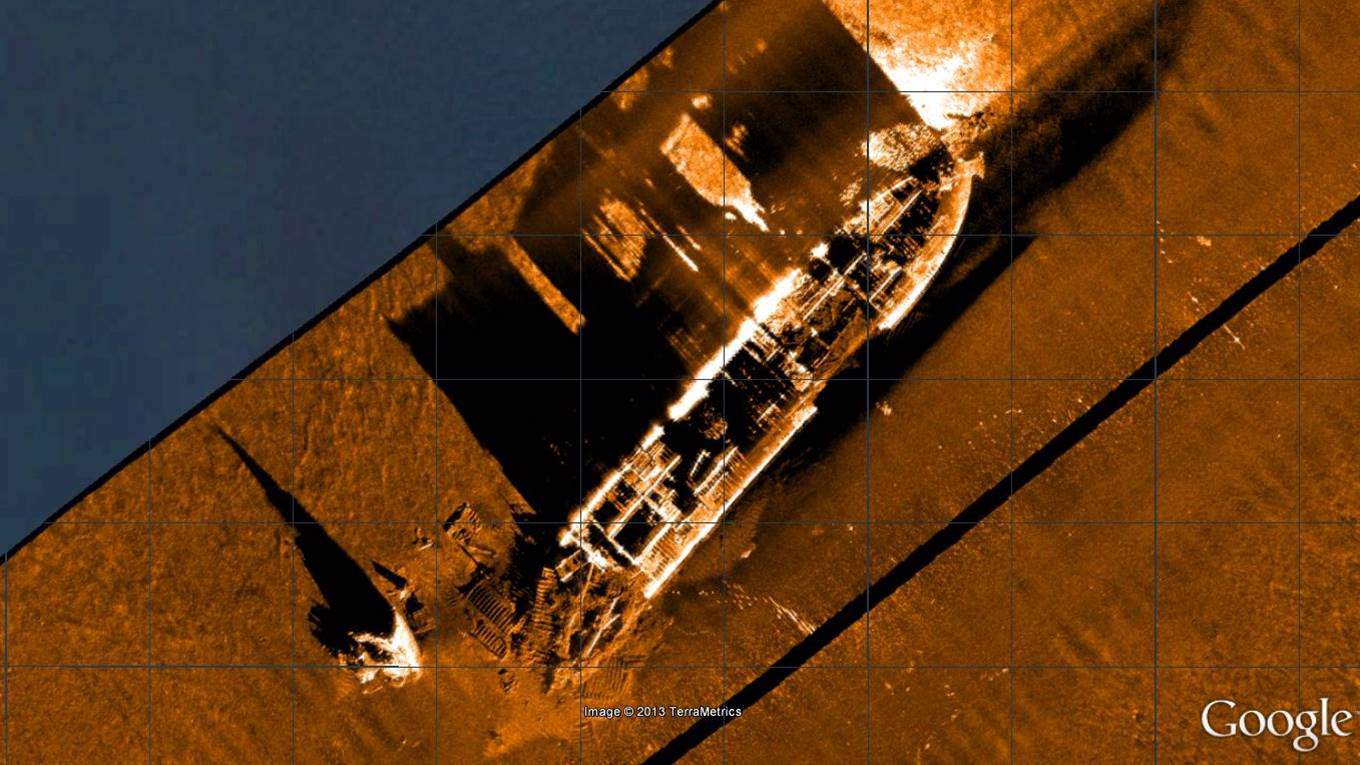

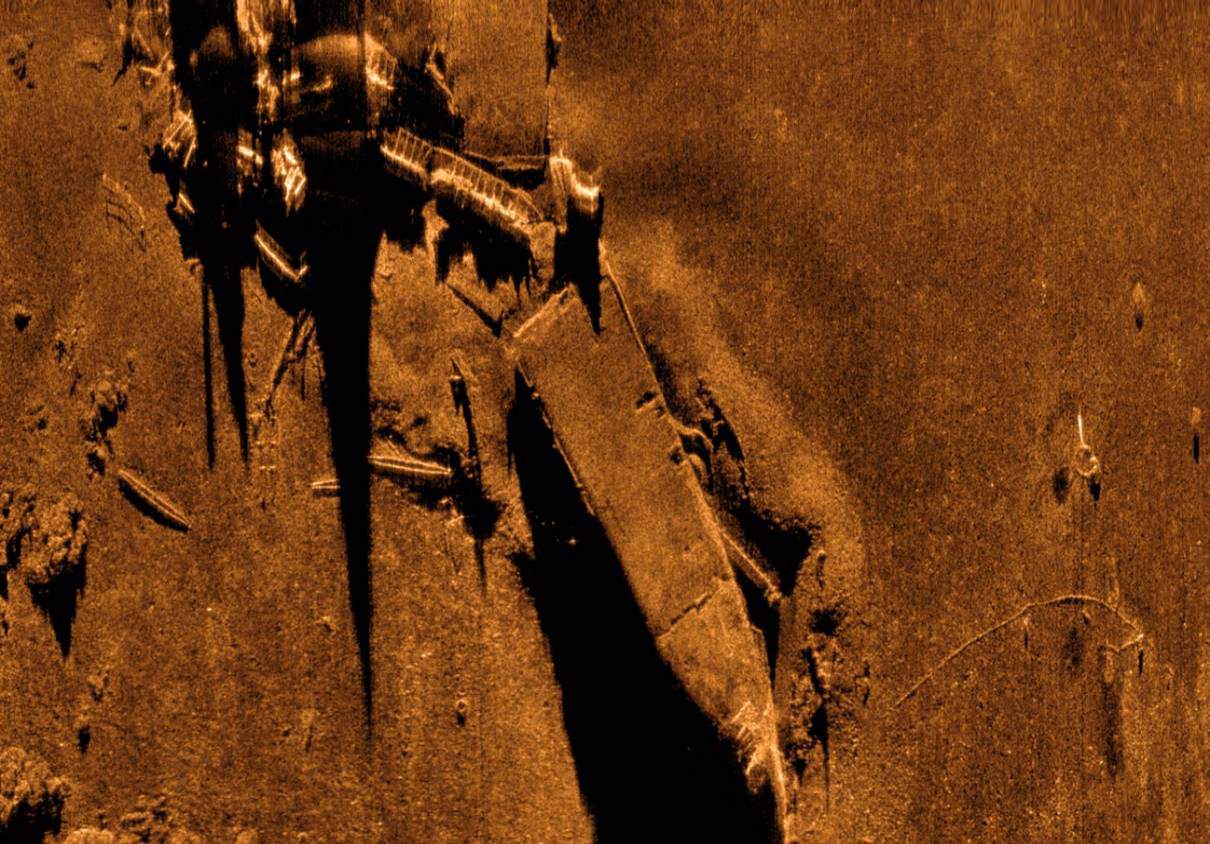

A General Dynamics demonstration using a Bluefin-12 UUV integrated with a Solstice MAS for the Royal Australian Navy (RAN) is a great example of this capability. During sea trials, as part of the RAN’s SEA 1778 Program to develop mine countermeasures, the Solstice data located the 1944 wreck of the USS YF-415.

General Dynamic’s Greg Jennings explains: “We initially found the USS YF-415 while performing acceptance testing with our SEA 1778 customers from Thales and the Royal Australian Navy. We were required to demonstrate the 24 hours endurance of the Bluefin-12 and chose to perform a large survey in an area where there were charted shipwrecks, in hopes of finding something interesting. When we came back to shore Monday evening and reviewed the data, I was stunned to find this beautifully intact wreck in a location where no wrecks were charted. The team was particularly excited about the find because we were really interested in capturing imagery of a shipwreck.”

In the following days, the team spent some more time logging the position of the wreck and searching other known wrecks in the area. It wasn’t until several weeks later, after Jordan Corbin, the Program Manager, contacted the Massachusetts Board of Marine Archeology, that they learned that it was the USS YF-415.

It was a sobering discovery. The USS YF-415, now resting in 240 ft water depth near Boston Harbor, was a type of barge used to transfer goods. In 1944, the vessel was conducting a routine obsolete ammunition dump when signal flares caught fire and ignited shells, leading to a series of explosions that sank the ship.

“The story really hit home for me because the ship had left dock just across the Back River from my home. It was quite sobering to learn of the tragedy behind the wreck. I hope that the families affected can find some solace in the beauty of the wreck. The imagery also shows large schools of fish surrounding the wreck, demonstrating how the sea has turned this gravestone into a monument to life.”

Side scan sonar for endurance UUVs

Solstice has been the multi-aperture sonar (MAS) of choice for General Dynamic’s Bluefin-12 since 2014 and is now also factory fit as standard on the Bluefin-9 as well.

The Bluefin-12’s offers long-range endurance, being able to run for 24 hours. The integration of our Solstice MAS, and on-board data processing features were key to the demonstration for the RAN. Its capabilities enable the Bluefin-12 to successfully provide ample mission-time and effective data collection and processing, yielding important information to help any team using it to assess and refine their mission. It also meant that the General Dynamics team were able to discover and enable the identification of the USS YF-415.

Ideal also for towfish

But while Solstice was initially designed for integration into UUVs, for wide area, high resolution mapping, whether that’s for survey, search and salvage, environmental monitoring or unexploded ordnance (UXO) survey operations, it’s also great from other platforms including towfish, as we demonstrated in a joint project with another Covelya Group company, EIVA. We trialled Solstice onboard EIVA’s ScanFish 3D remotely operated towed vehicle (ROTV), with great results, as you can see below.

With our SPRINT INS (inertial navigation system) onboard, and tracking using our Mini-Ranger 2 USBL system, it proved to be a real alternative to traditional synthetic aperture sonar (SAS) systems. Read more about the ScanFish 3D with Solstice here.

We’ve also deployed Solstice from our trials’ vessel, Echo Explorer. While not ideal – mounting the sonar from a vessel couples it to the sea surface, so it’s a harsh test – we’ve still gathered some superb imagery of wrecks, including the US liberty ship James Egan Layne, which was hit by a torpedo from a German U-boat near the Eddystone reef. Attempts were made to tow her ashore, but her stern collapsed causing her to sink.

We also really like this imagery of the MV Fylrix, a general cargo ship which was towed and anchored in Jennycliff Bay, near Plymouth, after suffering severe listing, before eventually sinking. The vessel was irrecoverable and ended up being used for underwater explosives training. The image below was also generated using Solstice on a pole mount from Echo Explorer.

Get in touch with us to find out how Solstice can support greater coverage in higher resolution for your mission.

As an engineering company, we like numbers – very precise numbers in fact. While those numbers normally relate to water depth, range, frequency or days of vessel time saved using our equipment, etc., we’re currently getting to grips with some new numbers relating to our energy use and carbon footprint.

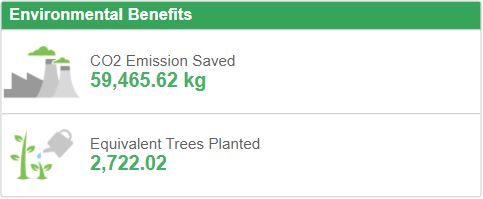

At the beginning of this year, we had 1,316 solar panels installed by Clean Earth Energy across the three buildings that make up our UK headquarter campus; Ocean House, Fathom House and Haven House. Each unit measures 201.5 cm × 99.6 cm, so in total they cover 2,641 m² (or just under 13 tennis courts). They’re the latest, most efficient panels and inverters on the market; JA Solar 405W high-efficiency PERC half-cell modules and SolarEdge inverters, respectively, which unlike earlier generation panels, allow us to individually monitor every panel for efficiency and performance.

A solar powerhouse – or rather three powerhouses

Together, our rooftop solar farm amounts to 533 kW that will generate in our part of southern England around 470,000 kWh per year. We estimate this will cover a minimum of a third of the energy consumption across our three buildings. That’s an annual 120 tonnes of CO2 equivalent emissions (CO2e) we have prevented from being emitted, not to mention the clean energy going back into the national grid when we’re not consuming it. It’s a great investment and one which has been several years in the making.

But while we’re hugely pleased to have these panels up and running, solar power generation is just the latest energy saving initiative we’ve committed to. In 2018, we invested in a Building Management System (BMS), which has learning algorithms to make the most efficient use of energy. It looks at how the building is heating and cooling to maximize efficiency, using things like destratification fans to move heat in a large space. We also changed all our light bulbs to LED panels and upgraded our heating systems to the most efficient types, including adding heat pumps. The result was that, between 2015-2019, energy consumption across our Blackbushe site was reduced by 23.5%. We’ve also reduced our travel overheads (even prior to Covid-related restrictions). What’s more, the electricity we are buying is all renewable, under a 100% renewable electricity supply we have, and now, thanks to the solar arrays, we’re putting more renewable power into the grid under Ofgem’s Renewable Energy Guarantees of Origin (REGO) scheme.

Calculating CO2e savings

Needless to say, for the past few years we’ve been formally calculating our carbon footprint, using the government approved PAS 2060 Specification, which has shown that, between 2018-2019, we reduced our emissions from 1,047 to 737 tonnes. With the solar panels coming online this year, we’ll see another dramatic drop in our 2019-2020 numbers.

All of these initiatives tie into our ISO 50001 Energy Management System Standard certification, which provides a framework of requirements relating to more efficient use of energy and continued improvement of energy management, so our efforts certainly do not and will not end here. We’re already looking at what more we can do. We’re also compliant with Energy Saving Opportunity Scheme (ESOS) Regulations and the Streamlined Energy and Carbon Reporting scheme.

Reduced waste as well as energy consumption

Of course, our impact on the environment doesn’t end there. We have also been focusing on reducing our waste streams across our sites globally, diverting more to recycling and doing more on a paperless basis. This has resulted in the removal of many tonnes of paper from our archives over the past 11 months, all of which has been recycled responsibly by a specialist. Our product design and manufacture through to recycling also follow European directives such as the Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE), using quality, sustainably sourced recyclable components.

There’s more to come, but if you’re interested in what we’ve done to date, feel free to get in touch.

Rheinmetall Canada Inc. has added underwater defence technology specialist Sonardyne’s Sentinel Intruder Detection Sonar (IDS) in its solution portfolio.

Rheinmetall Canada will integrate Sentinel IDS into its command and control system to enhance its overall security offering for harbour and port infrastructure protection. The company has already ordered its first Sentinel IDS for a customer as part of an integrated asset protection system.

Sentinel is the most widely deployed IDS in the market, providing reliable detection, tracking and classification of underwater intruders, from divers to unmanned vehicles, even in acoustically hostile harbour and port environments. It is easy to integrate and able to detect divers out to 900 metres and swimmer delivery vehicles to up to 1,500 metres in real-time. It can also be deployed in a wide range of configurations, from pillar mounted to surveillance or patrol vessel deployment and from seafloor based mounts to harbour wall deployment.

Sentinel IDS is also scalable. Individual and multiple Sentinel IDS sonar heads can be co-ordinated from a single command and control station, which can be seamlessly integrated into existing centralised security management systems.

Dan Zatezalo, Technical Sales Manager – US Maritime and Defense, at Sonardyne, says, “Intruder detection is changing. It’s not just divers that port and harbour infrastructure owners now have to worry about, it’s the increasing range of underwater unmanned vehicles (UUVs). Sentinel offers a proven, reliable, commercial, off-the-shelf (COTS) technology, widely deployed across ports, harbours, marine terminals, naval ships and floating oil production facilities across the world.”

[blockquote author=” Pietro Mazzei, vice-president, Rheinmetall Canada”]”As a leader in C2 and critical infrastructure protection we continue to enhance our solution by adding sub-surface detection and identification capabilities and are pleased to include Sonardyne’s Sentinel IDS system as part of our offering.”[/blockquote]

Integrated marine services company C-Innovation (C-I) has chosen a suite of Sonardyne’s underwater positioning and navigation systems to support its operations offshore Brazil.

Remotely operated vehicles (ROVs) on board six ROV support vessels (RSVs) in the country will be equipped with Sonardyne inertial, gyrocompass, and Doppler technologies, as well as hybrid acoustic-inertial systems.

Specifically, C-I has ordered SPRINT inertial navigation systems (INS), a Lodestar attitude and heading reference system (AHRS), Syrinx Doppler velocity logs (DVLs) and Sonardyne’s hybrid acoustic-inertial underwater vehicle navigation instruments, SPRINT-Nav. C-I has also ordered a quantity of Sonardyne’s Compatt 6+ transponders and Wideband Sub-Mini 6+ (WSM 6+) transponder/responders for tracking structures and vehicles.

Most of the vessels (including Bongo, Santos Service, Joe Griffin and Deborah Kay) will be working for Petrobras, and one vessel (Cabo Frio) will be working for Karoon Energy. The scope of work is subsea inspection, maintenance and repair operations (IMR) and ROV support.

Five of the six vessels, which start contracts in Brazil this year, are already equipped with Sonardyne’s Ranger 2 Ultra-Short BaseLine (USBL) positioning system, which is used for both dynamic positioning (DP) reference and deep water target tracking.

SPRINT-Nav combines Sonardyne’s SPRINT sensor, Syrinx 600 kHz DVL and a high accuracy intelligent pressure sensor packaged in a compact deep-rated housing that’s simple to integrate on both remote and autonomous underwater platforms. The tight integration of inertial sensor and raw acoustic aiding data at a low level enables SPRINT-Nav to regularly exceed the most stringent of positioning specifications, making it an ideal choice for vehicle guidance, station keeping and long endurance navigation.

[blockquote author=” Tomás Peixoto, Survey Manager at C-Innovation”]”We’re pleased to continue the relationship we have with Sonardyne, building on a long-standing partnership and with the local technical support that they offer here in Brazil. With these latest orders, we’re ensuring our fleet continues to provide unmatched services to our customers.”[/blockquote]

Speaking from Sonardyne’s base of operations in Rio das Ostras, Brazil, Sonardyne Sales & Applications Manager Andre Moura, says, “With the region’s majors committing to new and expanded field developments, the number, scope and value of engineering, procurement, installation and construction (EPIC) contracts placed here in recent months has risen significantly. The versatility and consistent high performance offered by our solutions means that C-Innovation can be confident they will see a return on their equipment investment throughout the life of the projects. That confidence, together with our in-country servicing and support, in turn helps to underpin their ongoing success in the market here.”