Straight out of the box navigational enhancement for offshore out of straightness surveys

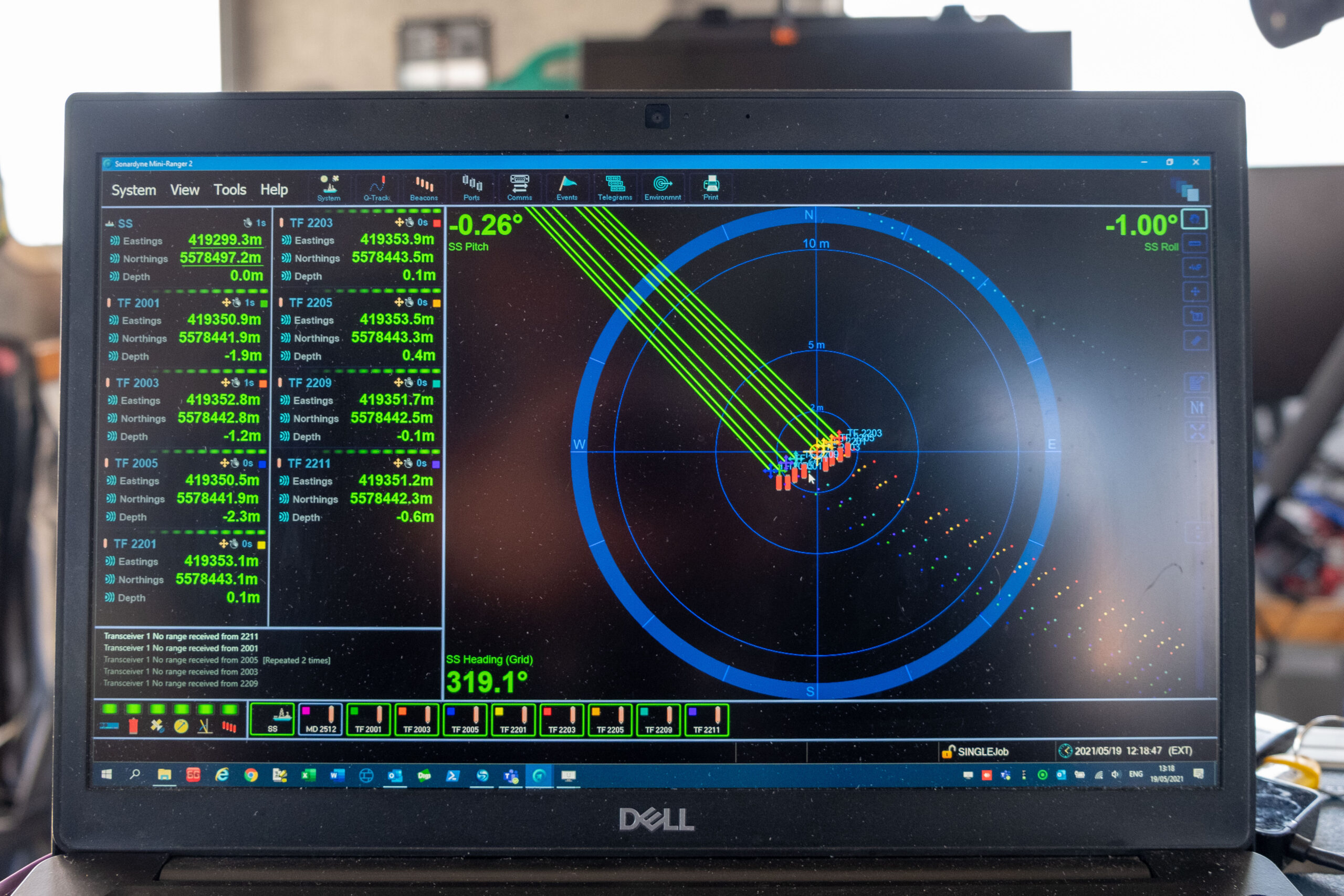

Fugro are already delivering safer, faster and more sustainable offshore operations – as you may have read in our previous case study about the Mini-Ranger 2 USBL system being used to support ROV operations from a USV. Working with us, Fugro are continuing their pioneering remote operations with their fleet of uncrewed surface vessels (USVs) deploying remotely operated vehicles (ROVs) – changing the game for offshore infrastructure surveys. Read on to see how our SPRINT-Nav Mini is being used to enhance multibeam echosounder (MBES) on Fugro’s remote operations, providing incredible results.

The challenge

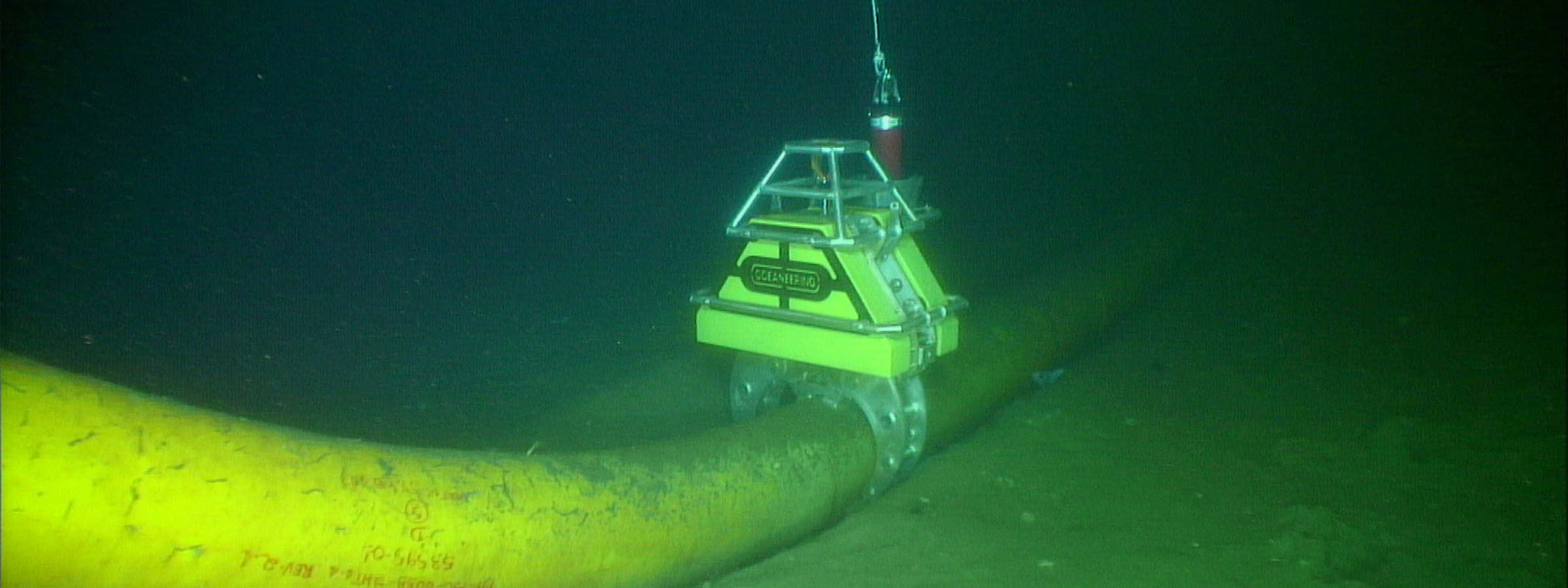

Out of straightness (OOS) surveys are used for acquiring information about the vertical and horizontal configuration of offshore pipelines. They provide operators with information on the presence or otherwise of buckles and bending in a pipeline, which may be engineered or not, and require monitoring during the operational life of the pipeline or flowline asset.

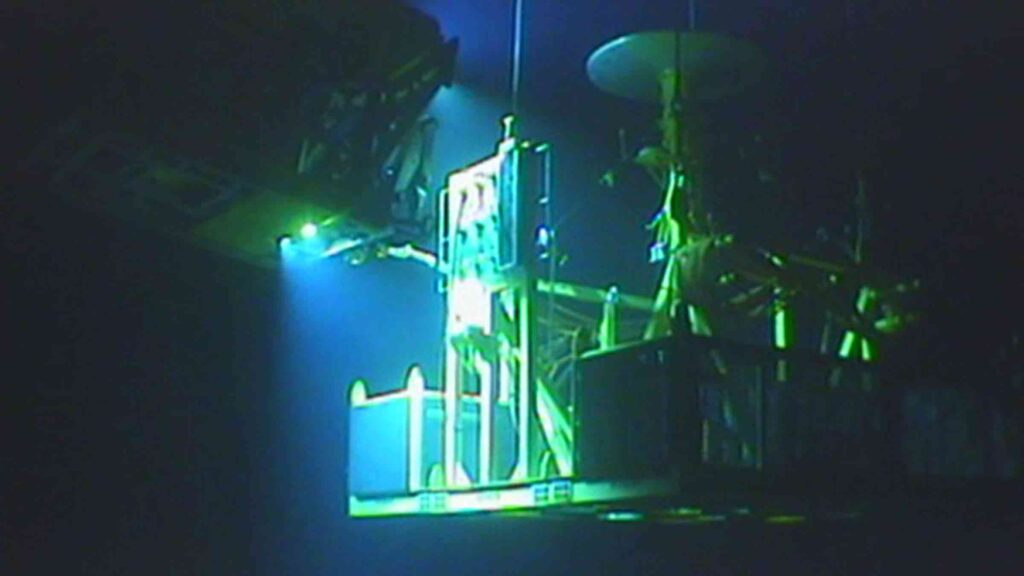

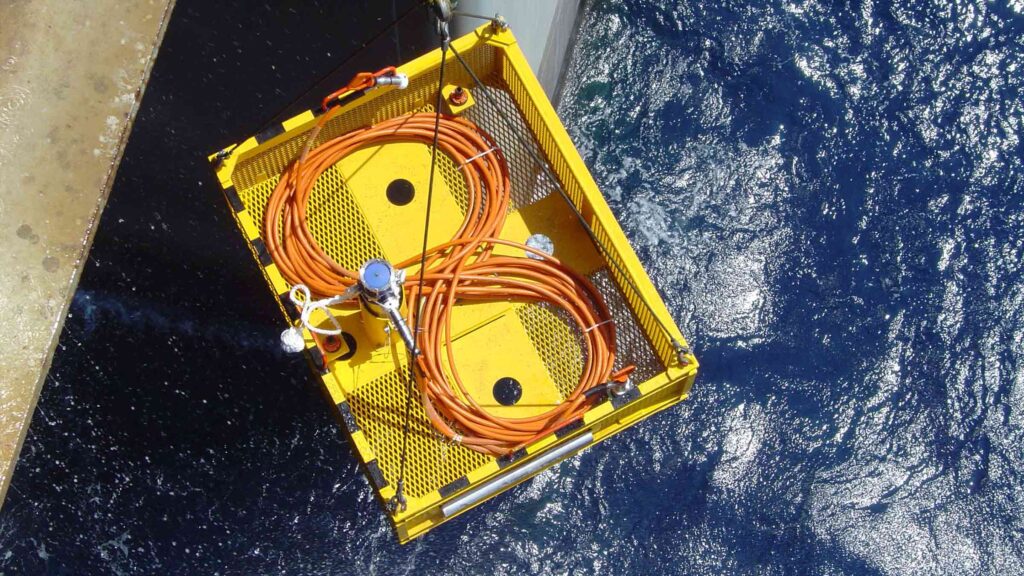

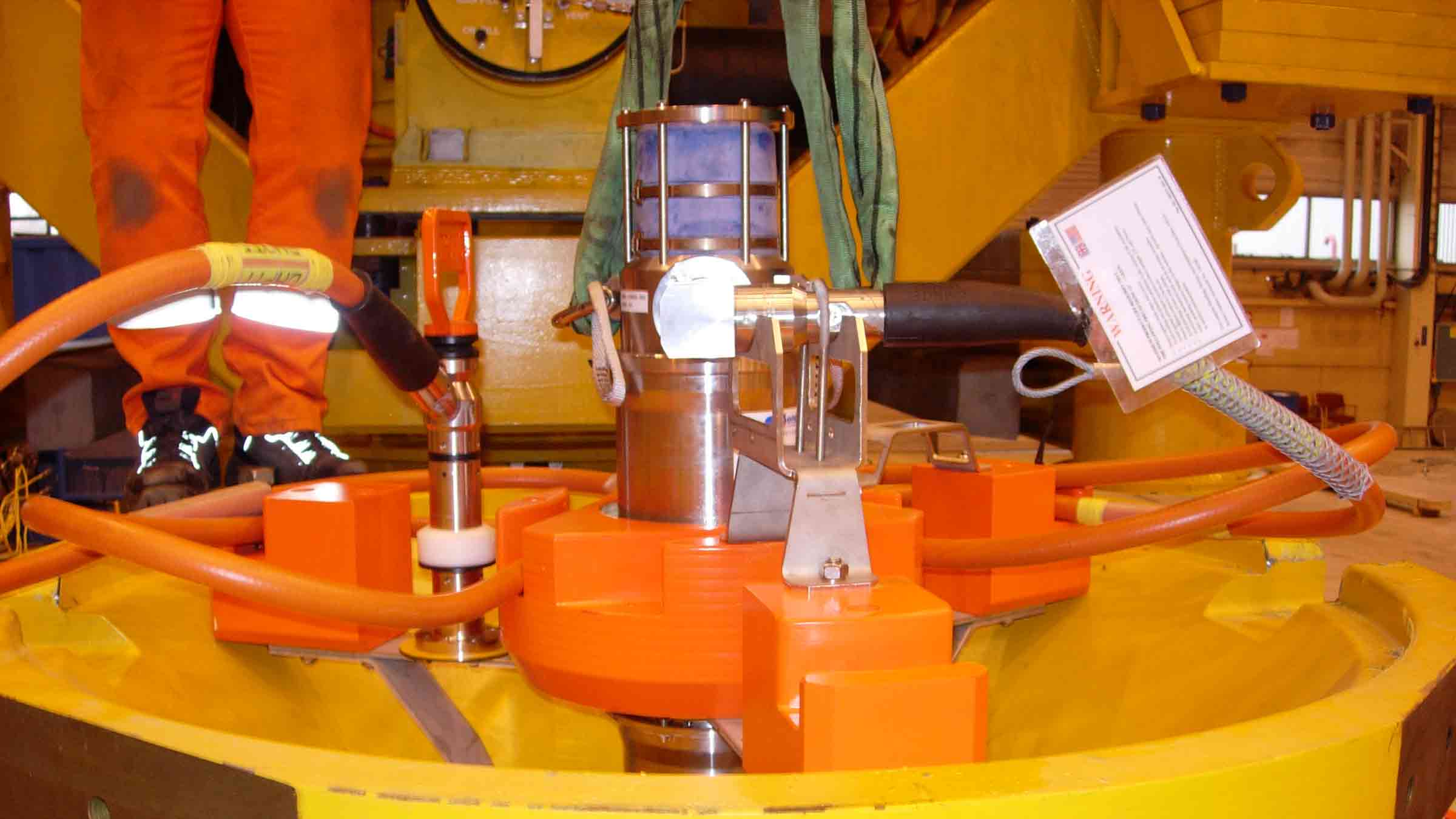

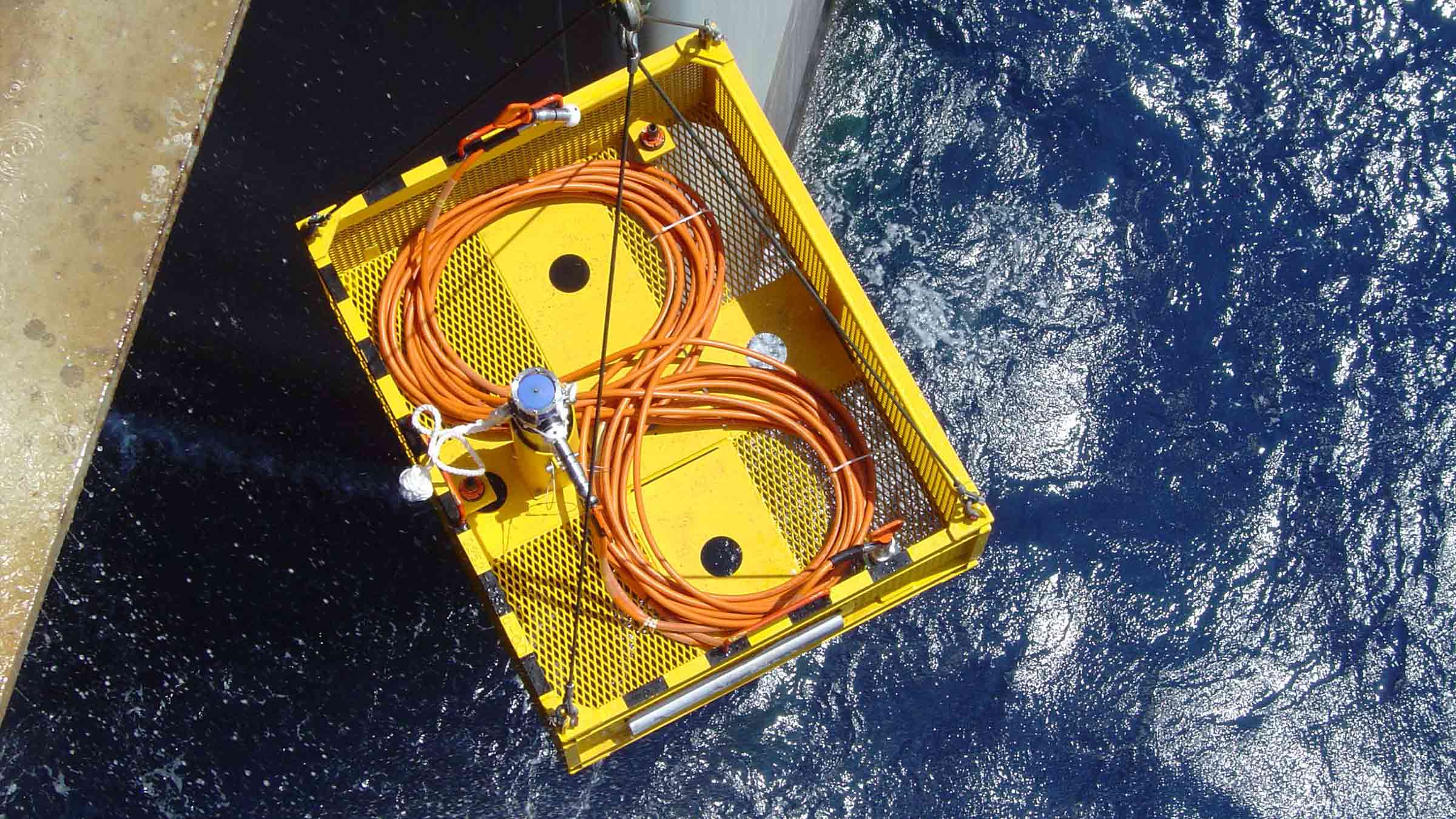

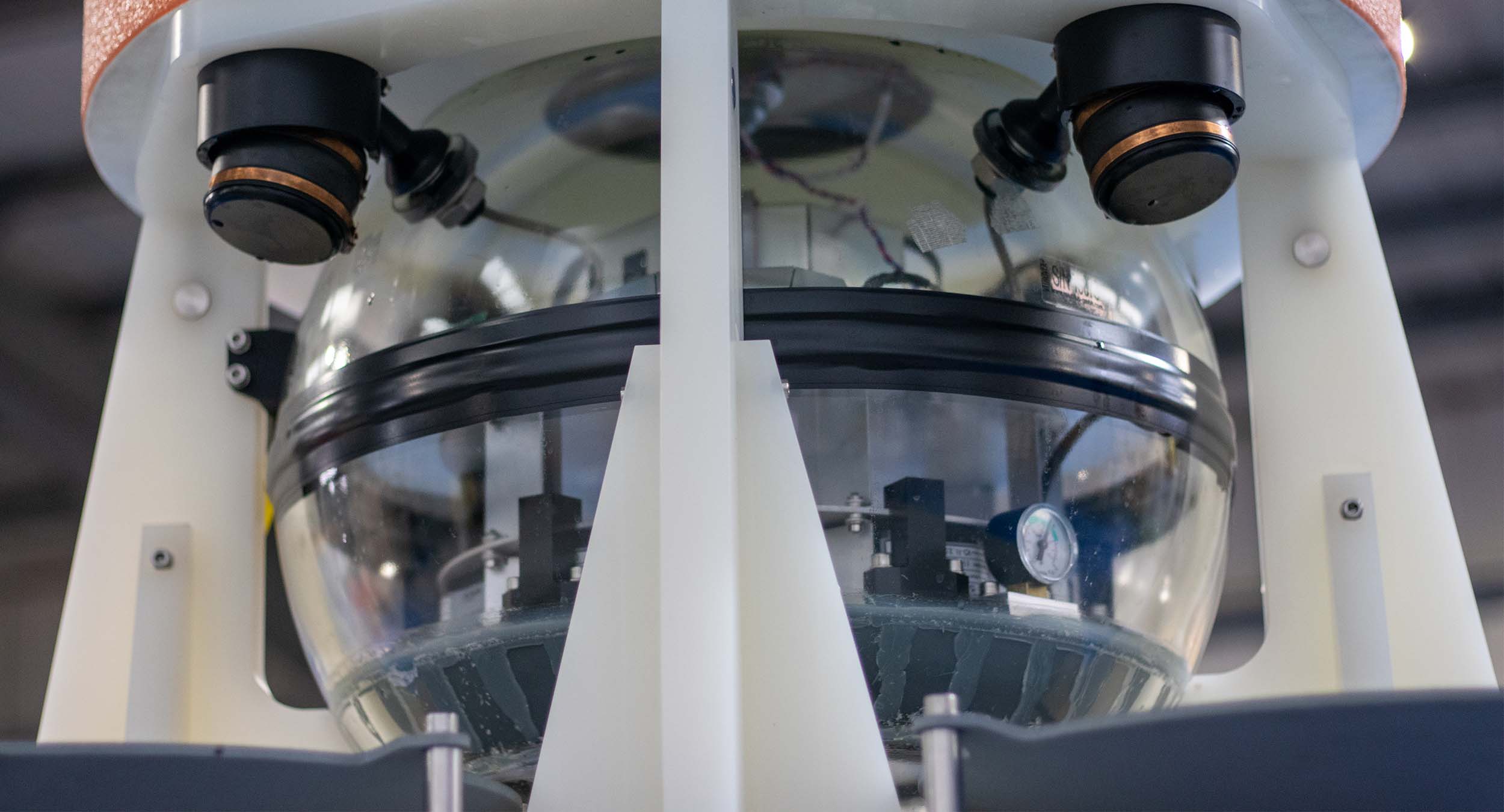

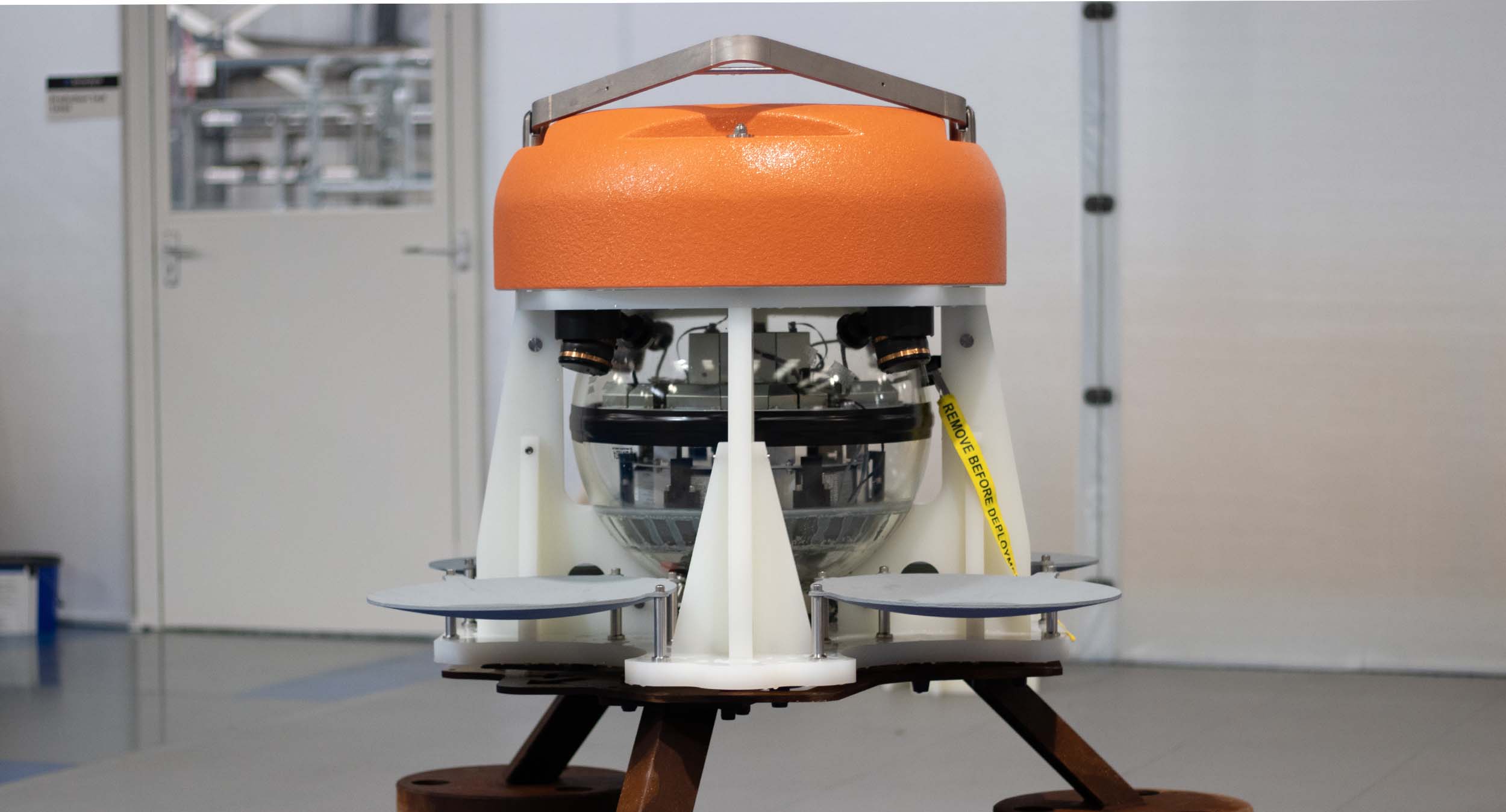

Fugro have been conducting OOS surveys on pipelines for major energy companies in Australia for many years. These surveys were conducted using a Norbit WBMS Narrow Multibeam echo sounder mounted on a Fugro inspection class ROV deployed from Fugro’s 12m Blue Essence® USVs, Maali and Kwilena.

ROV missions along pipelines can be erratic and unreliable due to the distance between the transceiver (USV) and transponder (ROV) when using just USBL positioning. For Fugro’s OOS survey customers, highly accurate data is essential. This has led to their requirement for the highest accuracy navigation and imaging available to the small ROV.

Fugro set us the challenge to provide a navigation solution that would enable the customer requirements of high-quality data using a small ROV. We worked with Fugro to trial SPRINT-Nav Mini and demonstrate the capabilities of the system.

The solution

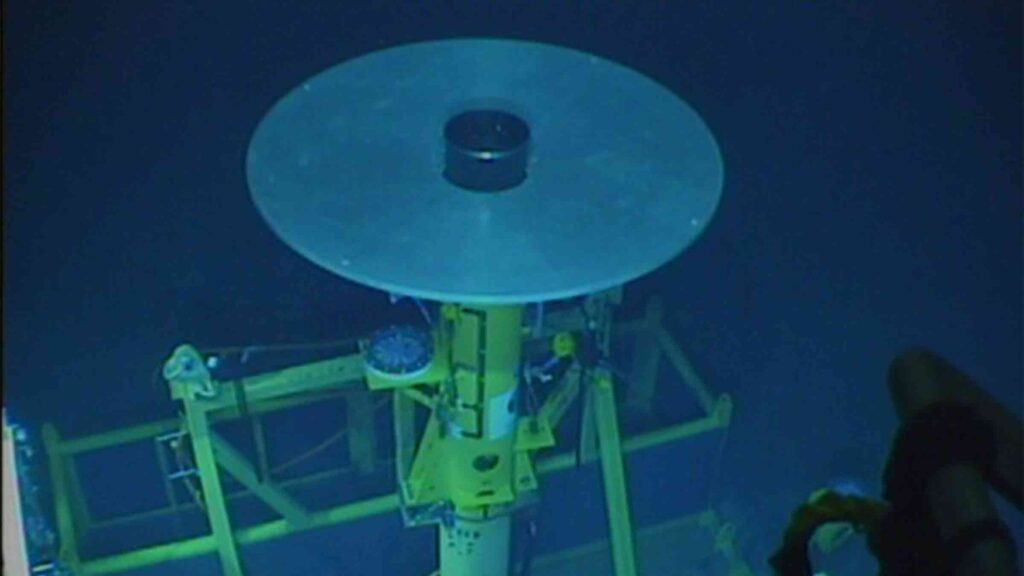

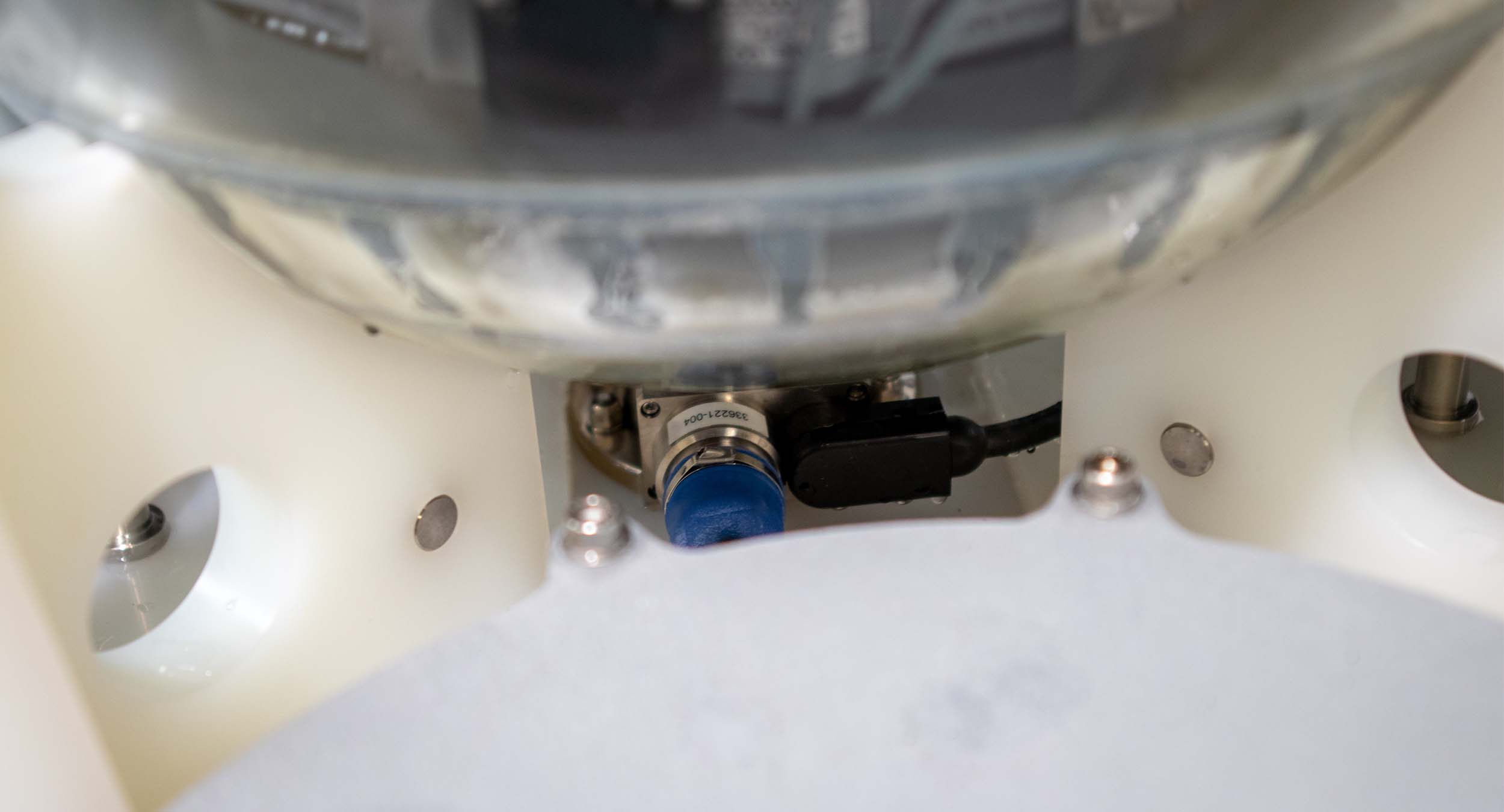

SPRINT-Nav Mini is the world’s smallest hybrid navigator, combining INS, DVL, AHRS and a pressure sensor in one factory calibrated unit. SPRINT-Nav Mini’s true north seeking gyrocompass means that it delivers reliable surface and subsea navigation. Adding this navigation capability to any marine robotic system allows users more control and turns their vehicles into far more accurate inspection and survey platforms.

With everything you need for navigation packed into a single low Size, Weight and Power (SWaP) package, SPRINT-Nav Mini is simple to integrate into any marine vehicle along with other payload sensors, like Fugro’s MBES. Its impressive precision of 0.05% of distance travelled accuracy on a typical survey alongside our revised heading, pitch and roll specification means that advanced mapping is now possible on smaller platforms deployed from USVs.

“SPRINT-Nav Mini is becoming increasingly vital for geophysical survey operations where SWaP is critical. Users need accurate and high output rate navigation streams for real-time compensation of imaging sensors.” Says John Houlder, INS Product Manager, Sonardyne, “SPRINT-Nav Mini provides robust real-time results that are improved even further once post-processed in our Janus software.”

After demonstrating SPRINT-Nav Mini’s capabilities, Fugro purchased the system and have been deploying it on their inspection ROV, which in turn is deployed from the Blue Essence® USV. With the Fugro team’s input we have been able to revise our specification for SPRINT-Nav Mini, improving its suitability for use with MBES on geophysical survey. These revisions include:

Pitch and Roll: 0.1 to 0.02° RMS

Heading: 0.15 to 0.1° RMS

The results

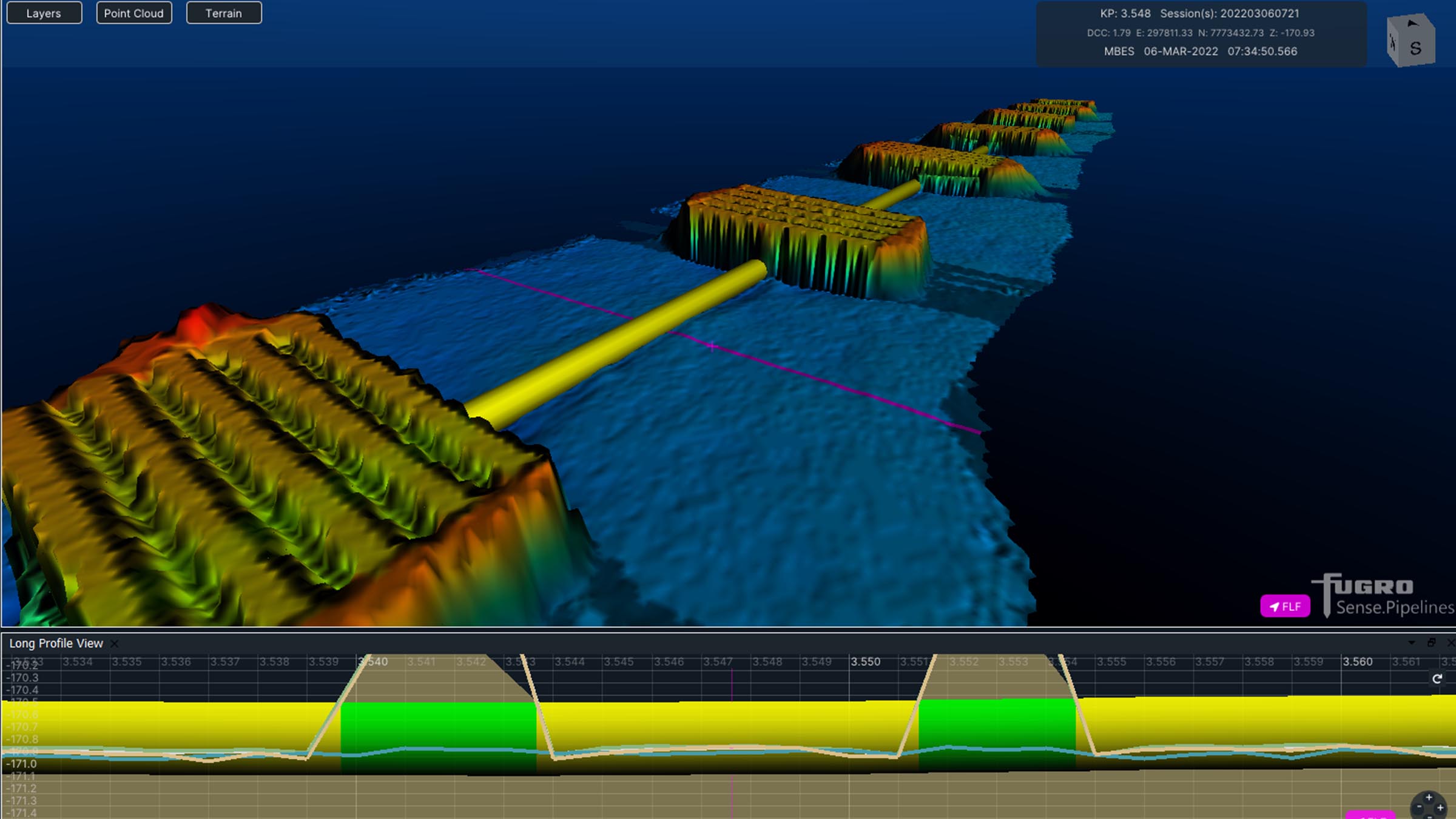

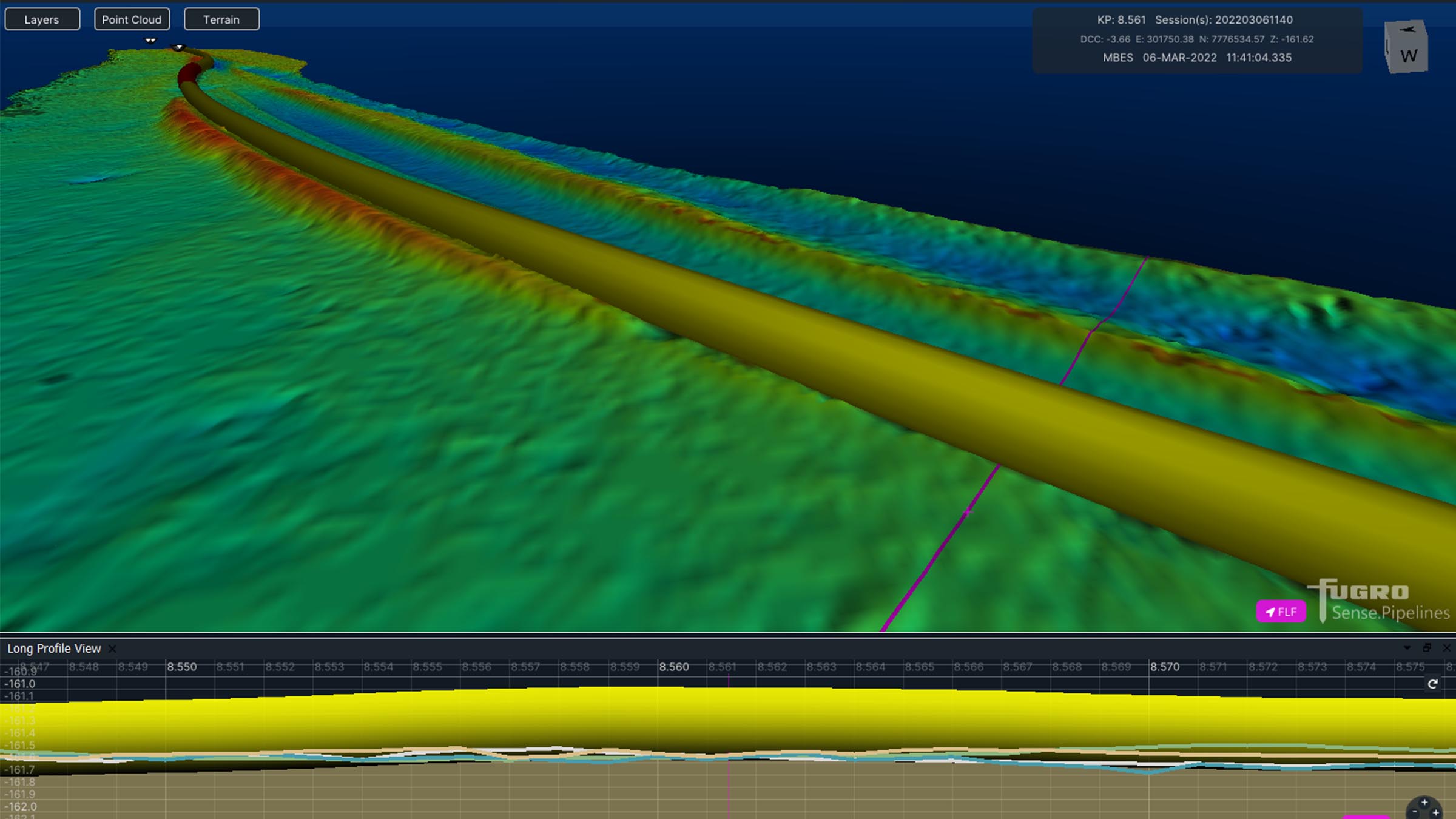

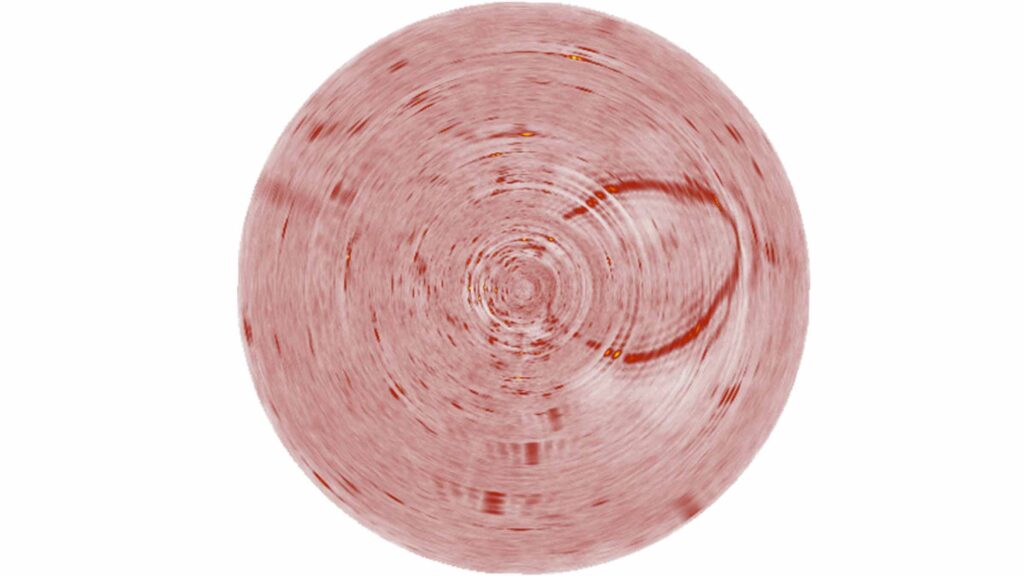

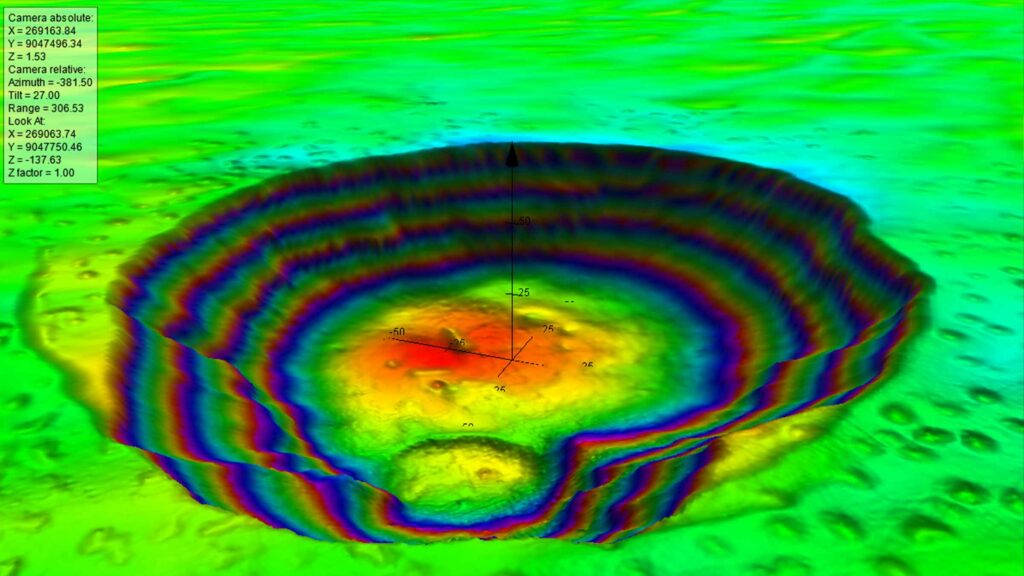

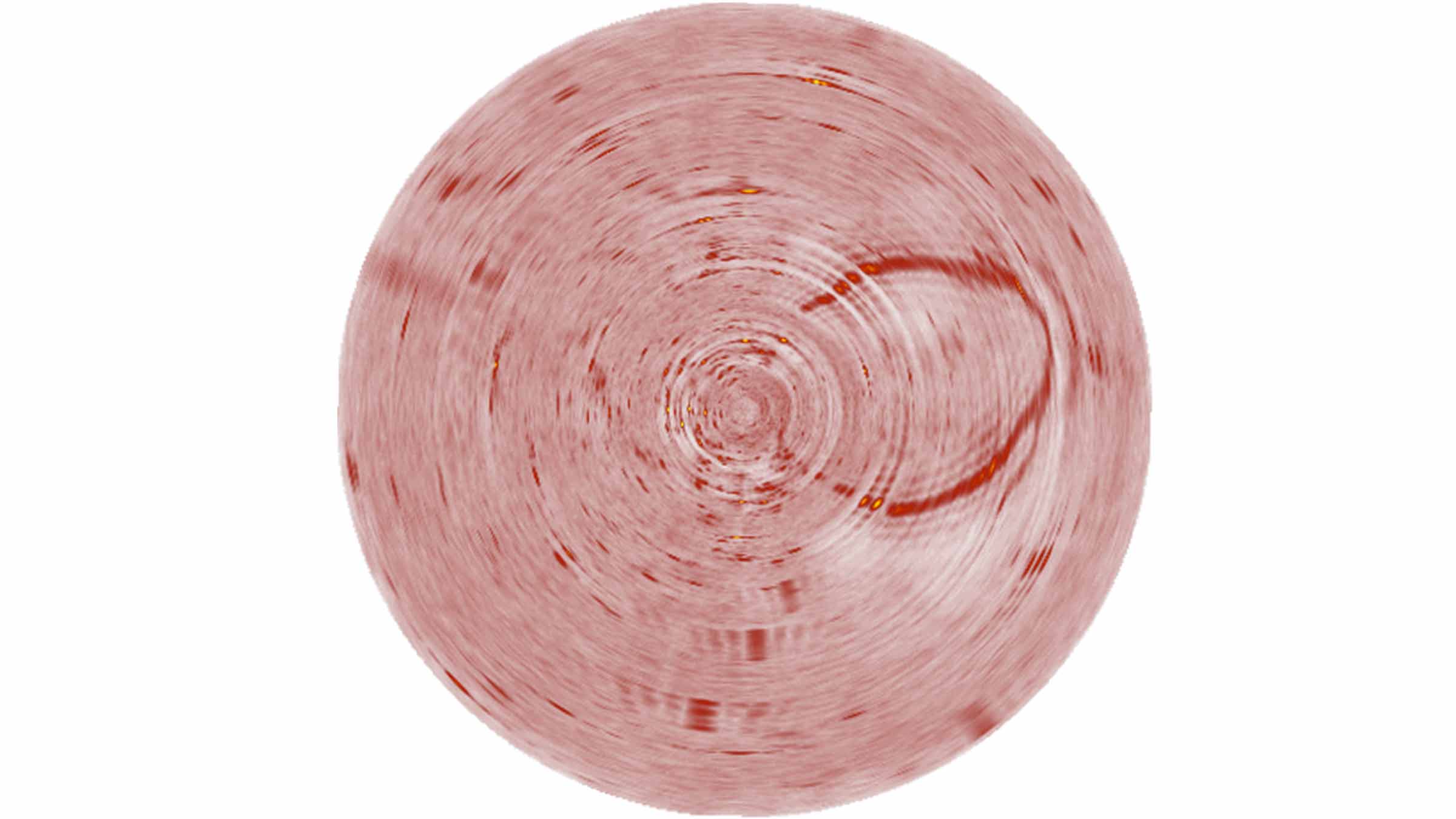

Fugro utilise SPRINT-Nav Mini data within the ROV command and control software, Starfix® navigation, including their Camblock Vision based augmented reality system, and for processing MBES data. In the case of MBES processing, they are also conducting pipeline OOS surveys to a maximum depth of 200 metres.

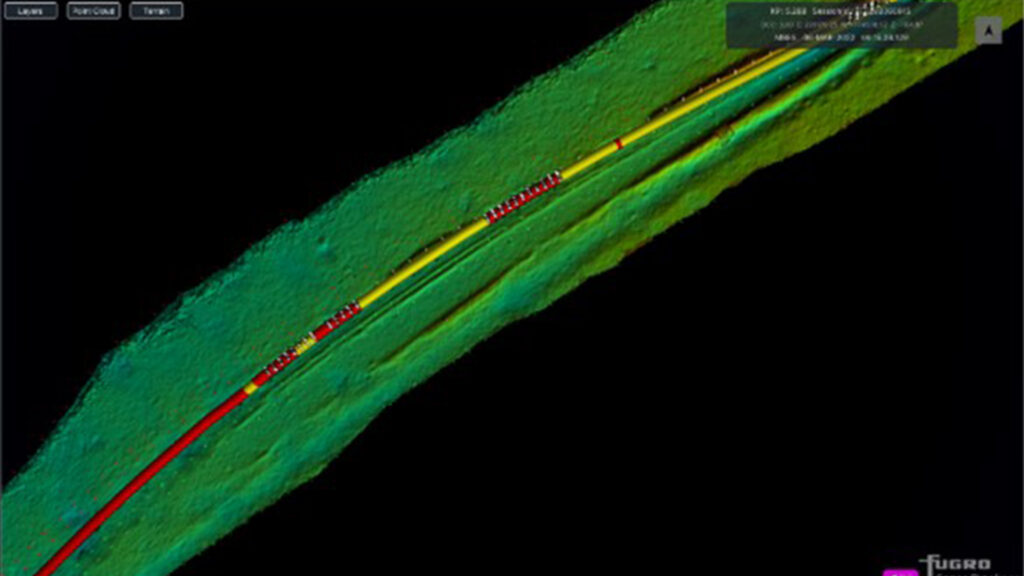

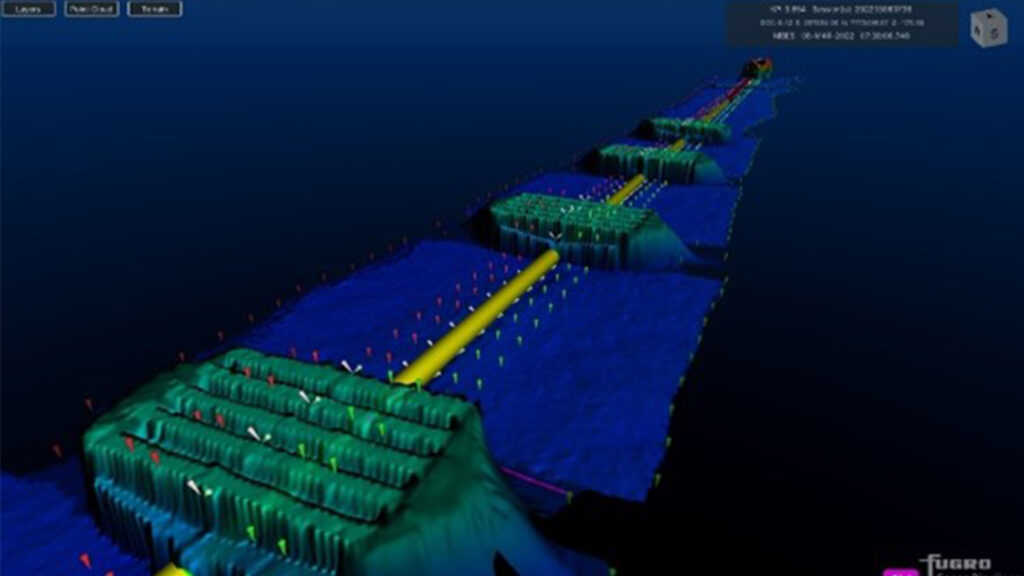

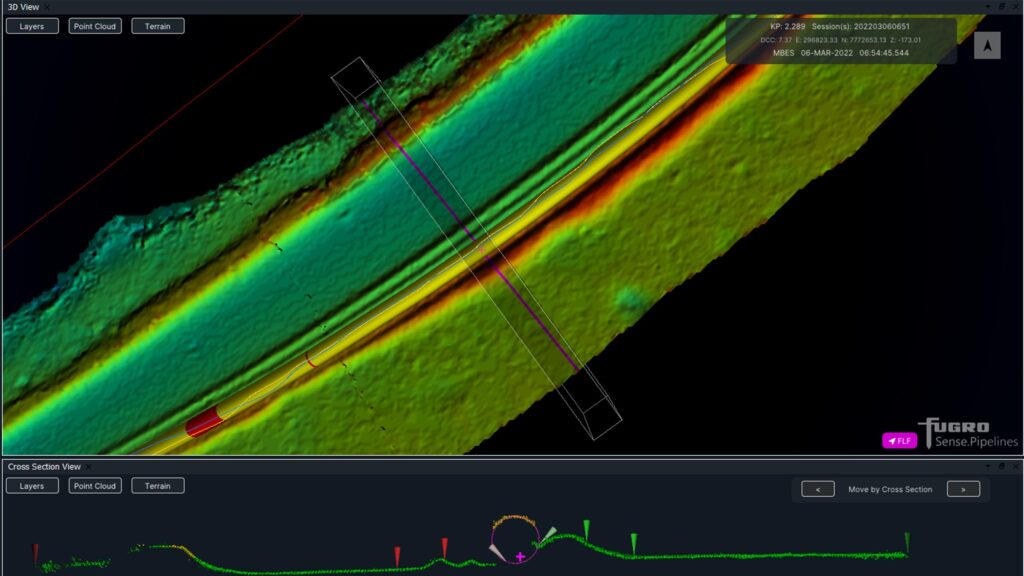

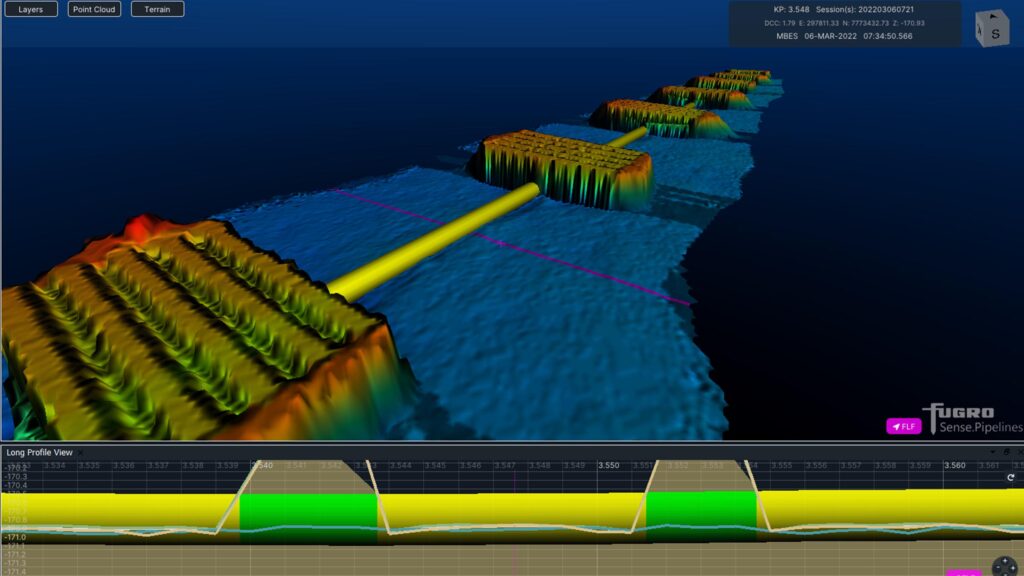

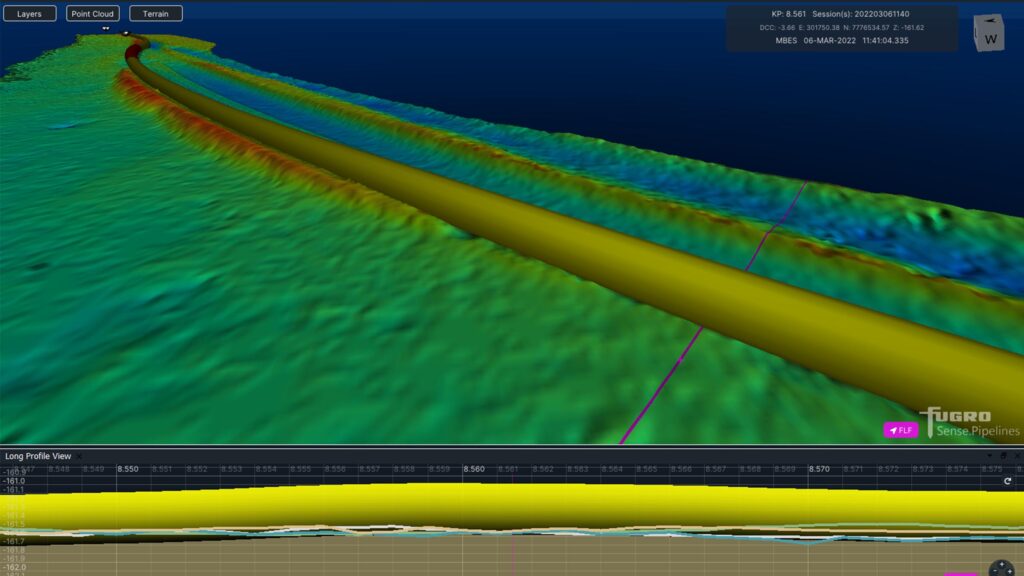

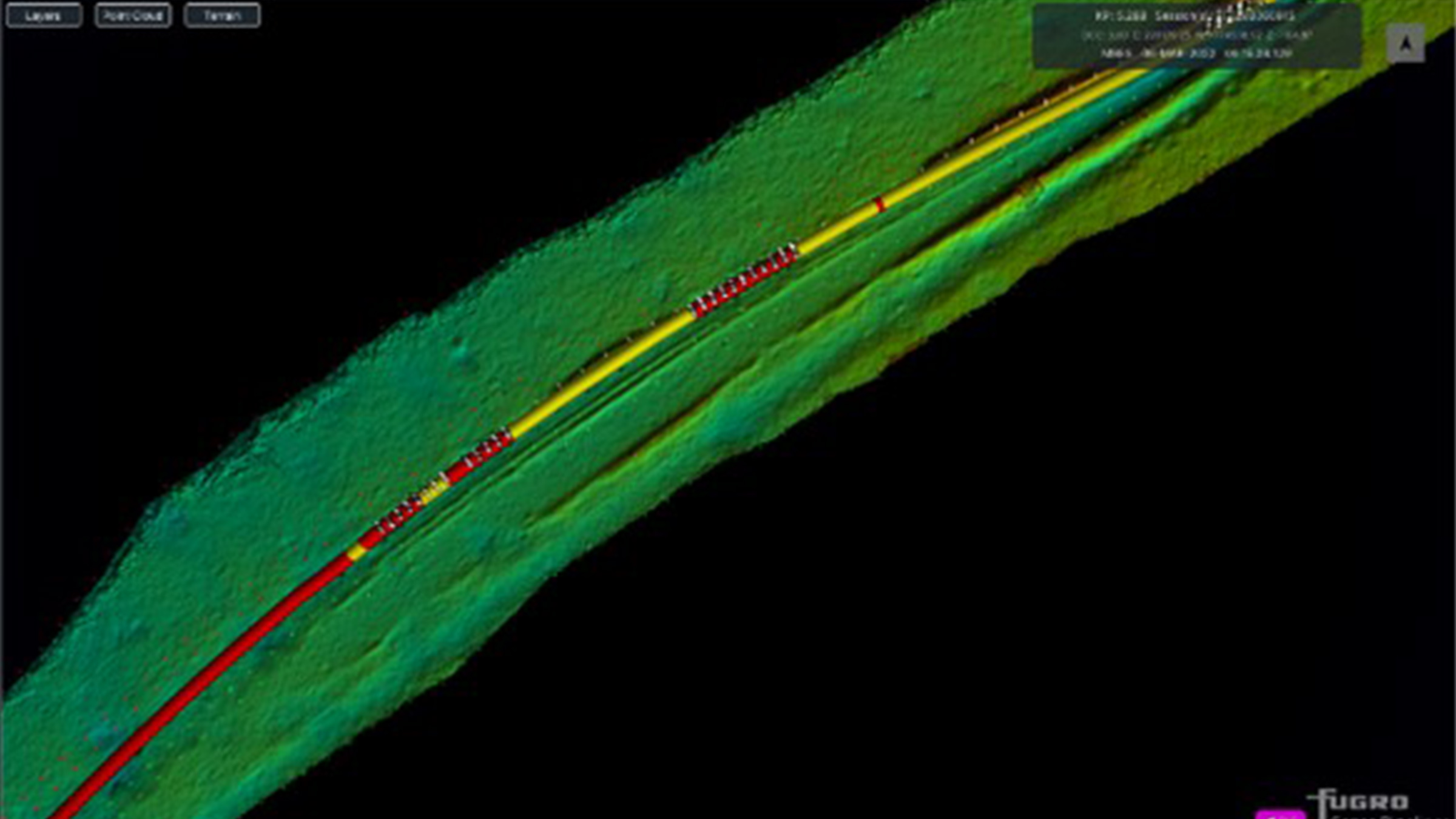

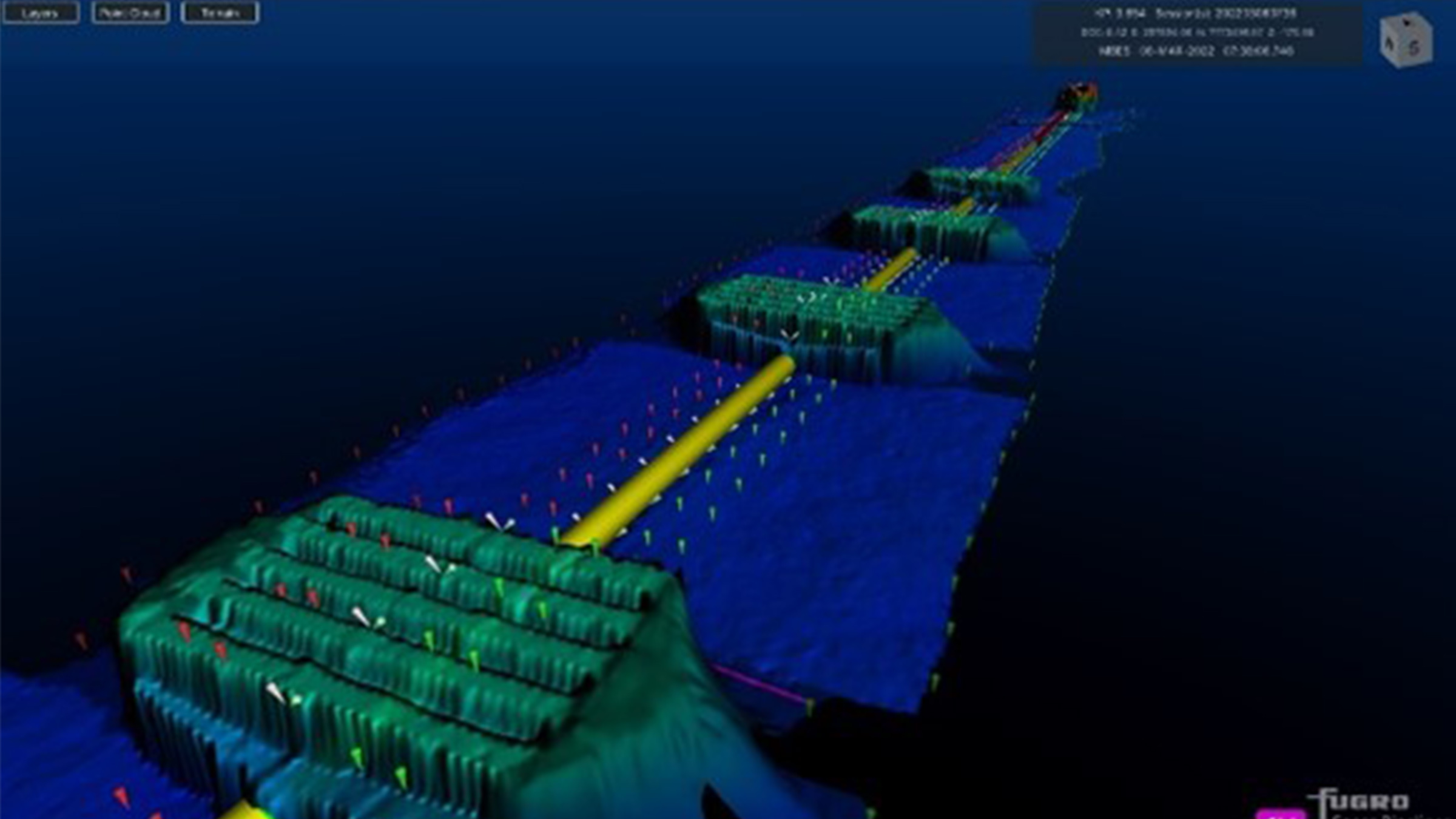

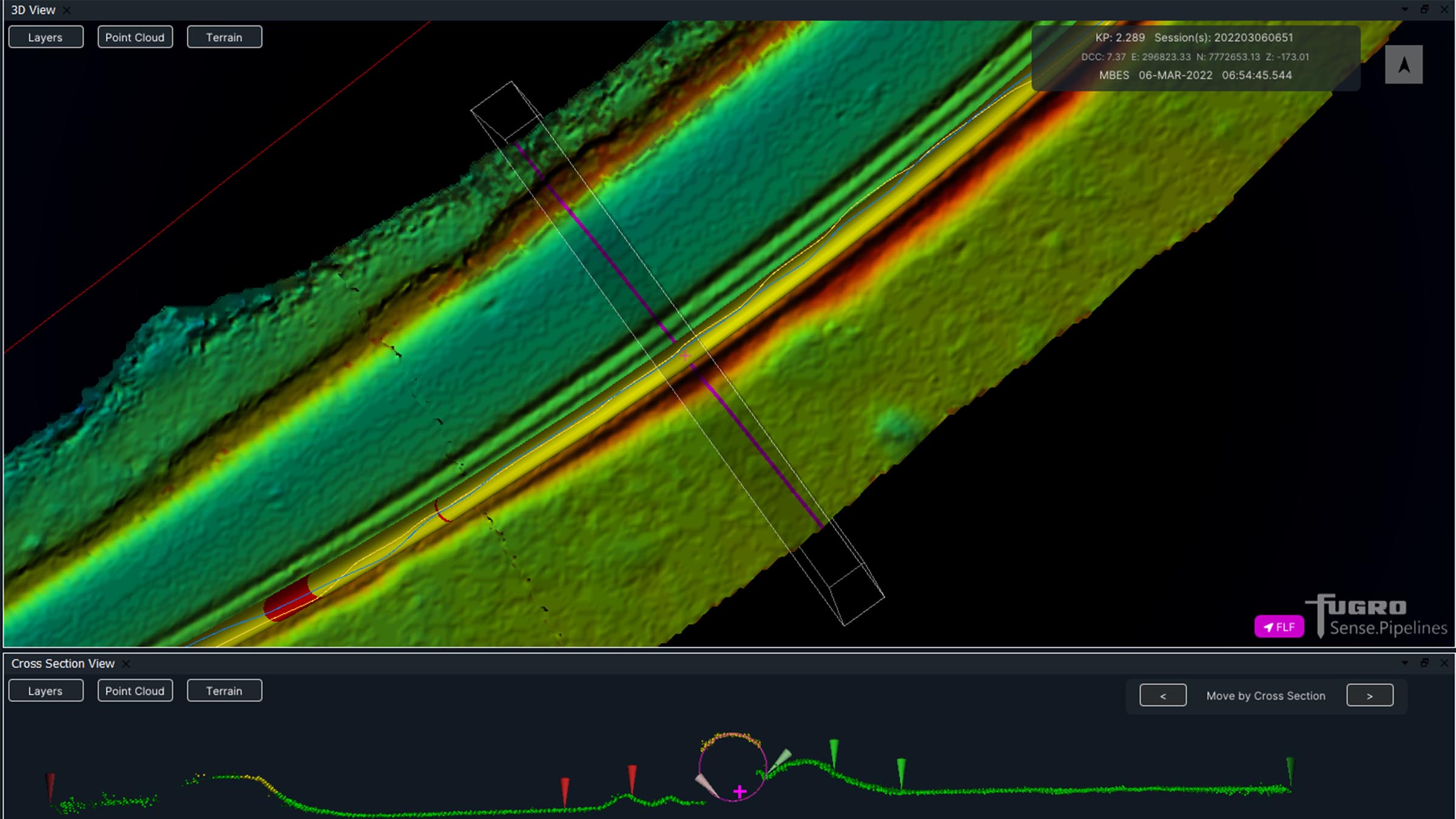

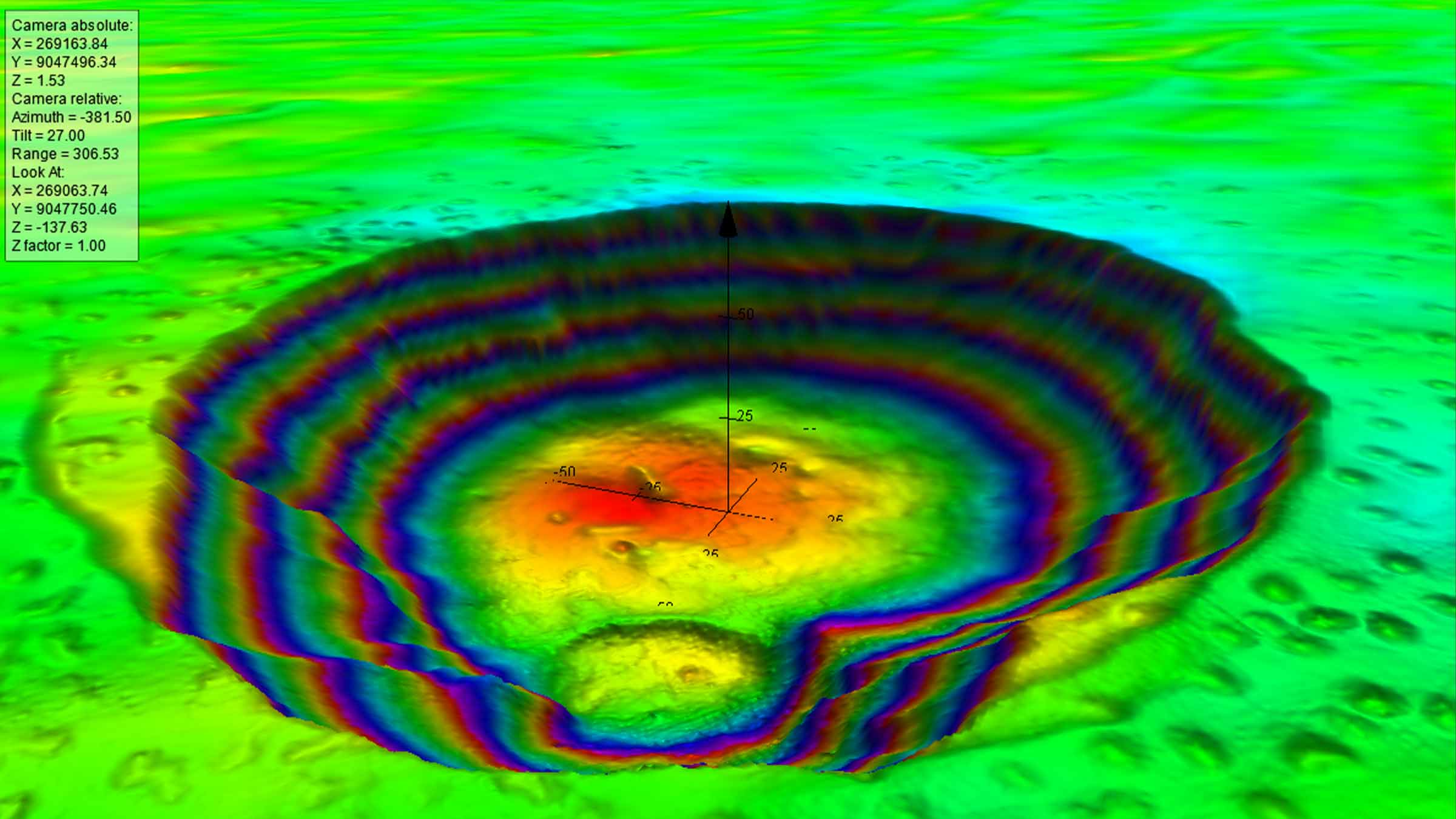

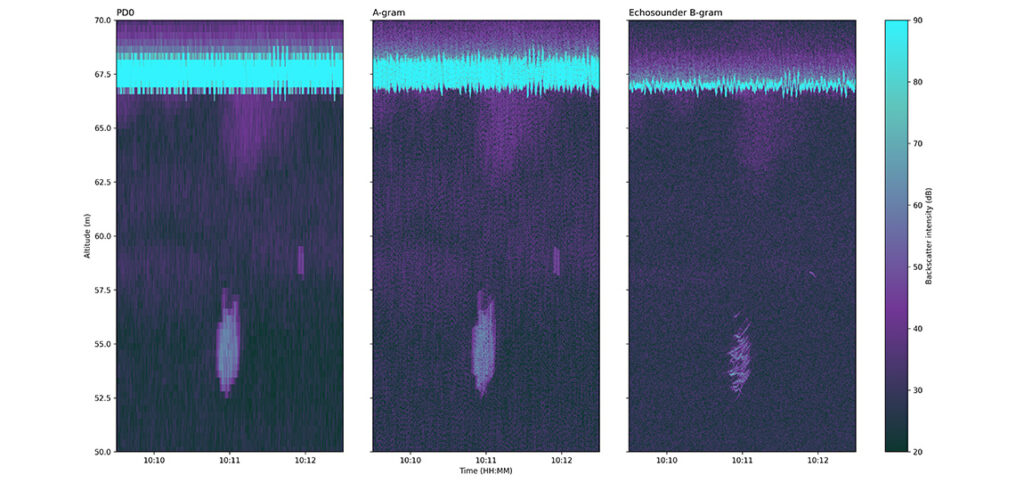

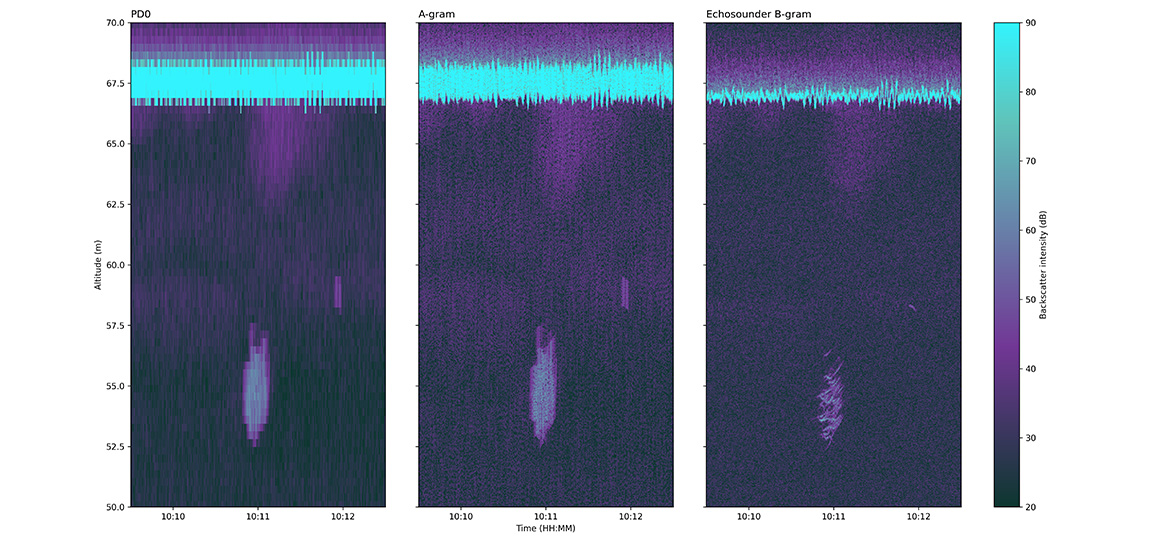

The images below show some example data Fugro has gathered with MBES positioned using SPRINT-Nav Mini and post processed with our Janus software. Janus is our quality control and INS post processing software. It allows quick and easy data editing, post-processing and data export. Find out more about Janus here

If your offshore operations are also reliant on fast, efficient and accurate data to keep your business competitive in an ever-changing marketplace, take a look at our full range of navigational products here.

SMART precision monitoring for your offshore assets

Unlock invaluable insights about the health and performance of your critical offshore structures, pipelines, and risers with your SMART monitoring system.

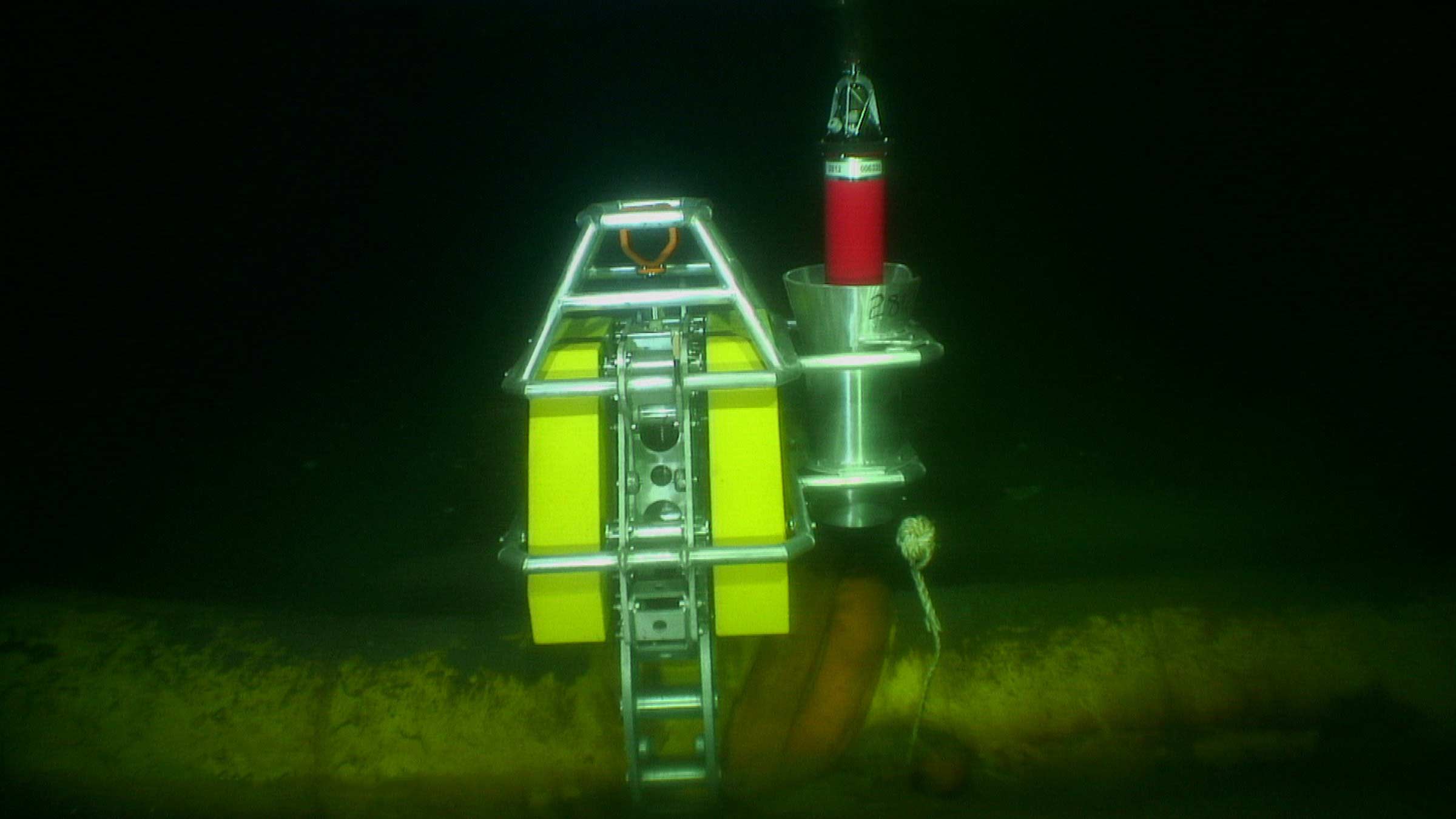

Tailor-made for your needs

We understand that no two offshore missions are the same. With a wide range of configurable sensor options, SMART can be customised to meet the precise monitoring requirements of your offshore mission. Our team will work with you to design and fabricate specialised mounting brackets and clamps to seamlessly integrate SMART into your infrastructure, including ROV-friendly setups for fast, efficient installation and retrieval.

Powerful onboard analytics

SMART’s advanced onboard processor enables sophisticated data analysis and processing right at the source. Advanced algorithms extract meaningful insights from raw sensor data, transforming high-bandwidth inputs into compact, critical updates that keep you informed on the status of your assets. Smart power management ensures long deployment times between maintenance. A low power data logger enables data received from external and internal sources to be securely archived using dual redundant storage.

Flexible data harvesting

Transmit stored data to the surface via industry-leading acoustic telemetry or high-bandwidth optical communication links. SMART integrates with your existing systems and workflows, with configurable software options to suit your needs – from standard diagnostics to custom analysis and visualisation tools.

SMART uses our trusted Wideband 2 acoustic telemetry module for your seafloor to surface communications. Operating in the Medium Frequency (MF) or Low Medium Frequency (LMF) band, there are options for omni-directional and directional transducers with high output powers for use in deep water and in challenging acoustic environments.

By utilising our Wideband 2 advanced spread spectrum coding, SMART can transmit your stored data at rates of up to 9,000 bps to topside transceivers and modems including our HPT 5000, Modem 6 and Dunker 6. An Ethernet connection to a BlueComm high bandwidth optical communication link enables larger quantities of data to be harvested from ROV, AUV or USV.

Dependable performance

SMART is engineered for precision, reliability, and flexibility. Trusted by leading offshore operators, this advanced monitoring system delivers the actionable intelligence you need to make informed decisions and protect your critical investments.

At a glance

- Battery options to support campaigns in excess of 10 years

- Can be deployed and recovered using ROV

- 3,000 m standard depth rating; options for 7,000 m

- Onboard logging and processing of data; offloaded acoustically on demand

- Built on our low power 6G hardware platform and Wideband 2 digital signal architecture for reliable acoustic performance in noisy conditions

SMART in action

A SMART deep water invention

Read moreTrendsetter Vulcan Offshore uses a SMART solution to monitoring wellhead fatigue

Read moreDeepwater data analytics – asset monitoring at the edge

Read moreOwnership

• Warranty: 1 year return to Sonardyne service centre

• ITAR Controlled: No

• UK Export Licence: Not required

• A typical system; multiple structure-mounted SMARTs, vessel-based Modem 6 or Dunker 6 or HPT 5000 / 7000, SIU, SMART software

Sensing

• 6 DOF high performance sensor fitted as standard

• Sampling rate: 5 Hz, 10 Hz, 25 Hz

• Data storage: 32 GB, dual redundant, FAT 32

• Processing capability: Fully programmable including FTT spectral analysis, statistical functions and bespoke options

Design

• 3,000 m depth rating; up to 7,000 m on request

• Lithium battery providing over 500 logging days at typical regimes

• ROV-friendly design; option for integrated acoustic release mechanism

• Super Duplex Stainless Steel standard housing material; options for different materials depending on environmental conditions

Acoustics

• Over 500 unique addresses, ideal for large array deployments

• Data transfer rates of 100 to 9,000 bps – user selectable

• Omni-directional transducer for wide area acoustic coverage

• Sonardyne Wideband 2 MF band (19 – 34 kHz); field proven in high noise subsea environments

Specifications

| Instrument Feature | Type 8316 | |

|---|---|---|

| Depth Rating | 3,000 m (up to 7,000 m on request) |

|

| Acoustic Operating Frequency | MF (20–34 kHz) | |

| Acoustic Data Rate | 100–9,000 bps | |

| Standard Battery Specifications | 100 Ah @ 15 V (high capacity options available) | |

| Power Consumption | Listening | 50 mW |

| Logging | 200 mW | |

| Battery Life (Typical) (Lithium) | >500 days @ 25% logging duty, hourly reporting | |

| Mechanical Construction | Super duplex stainless steel | |

| Weight in Air/Water | 32/22 kg | |

| Operating Temperature | -5 to 30°C | |

| Storage Temperature | -25 to 70°C | |

| SMART Feature | ||

| 6 Degrees of Freedom High Performance Motion Sensor | Standard | |

| Triaxial Acceleration Measurement | Range | ±30 ms-2 |

| RMS Noise | 6×10-4 ms-2/√Hz | |

| Instability | 5×10-4 ms-2 | |

| Triaxial Angular Rate Measurement | Range | ±150 deg s-1 |

| RMS Noise | 0.002 deg s-1/√Hz | |

| Instability | 2.2 deg/hr | |

| Sensor Axial Misalignment | 0.02° | |

| Sampling Rate | 5 Hz, 10 Hz and 25 Hz | |

| Anti-aliasing Filter (Standard) | -3 dB cut-off @ 4 Hz | |

| Data Storage | 32 GB dual redundant, FAT32 | |

| Processing Capability | Fully programmable including FFT spectral analysis, statistical functions and bespoke options | |

| Logging and Reporting Scheme | Fully configurable | |

| Connectivity | Acoustic Link (for real-time reporting), Ethernet Port (high speed data upload), serial port | |

| Additional Sensors | Optional internal and external sensors | |

| Note: The table above shows typical values for a SMART transponder configured for drilling riser fatigue monitoring. As a flexible instrumentation platform, alternative configurations are available including alternative motion sensors if higher sensitivity is required. SMART can be offered with a standard data processing algorithm for fatigue monitoring or can incorporate customer specific requirements on request |

Software and firmware

Datasheets

One billion cubic feet of seawater, 360° of coverage, one Sentry.

Key benefits

- Developed from our field proven detection, localisation and classification sonar technology

- Provides 360 degree, high volume coverage from a single location; sensitive to small leaks at ranges of over 500 m

- Low false alarm rate; automated operation – no need for constant supervision

- Localises integrity breaches at the time of detection

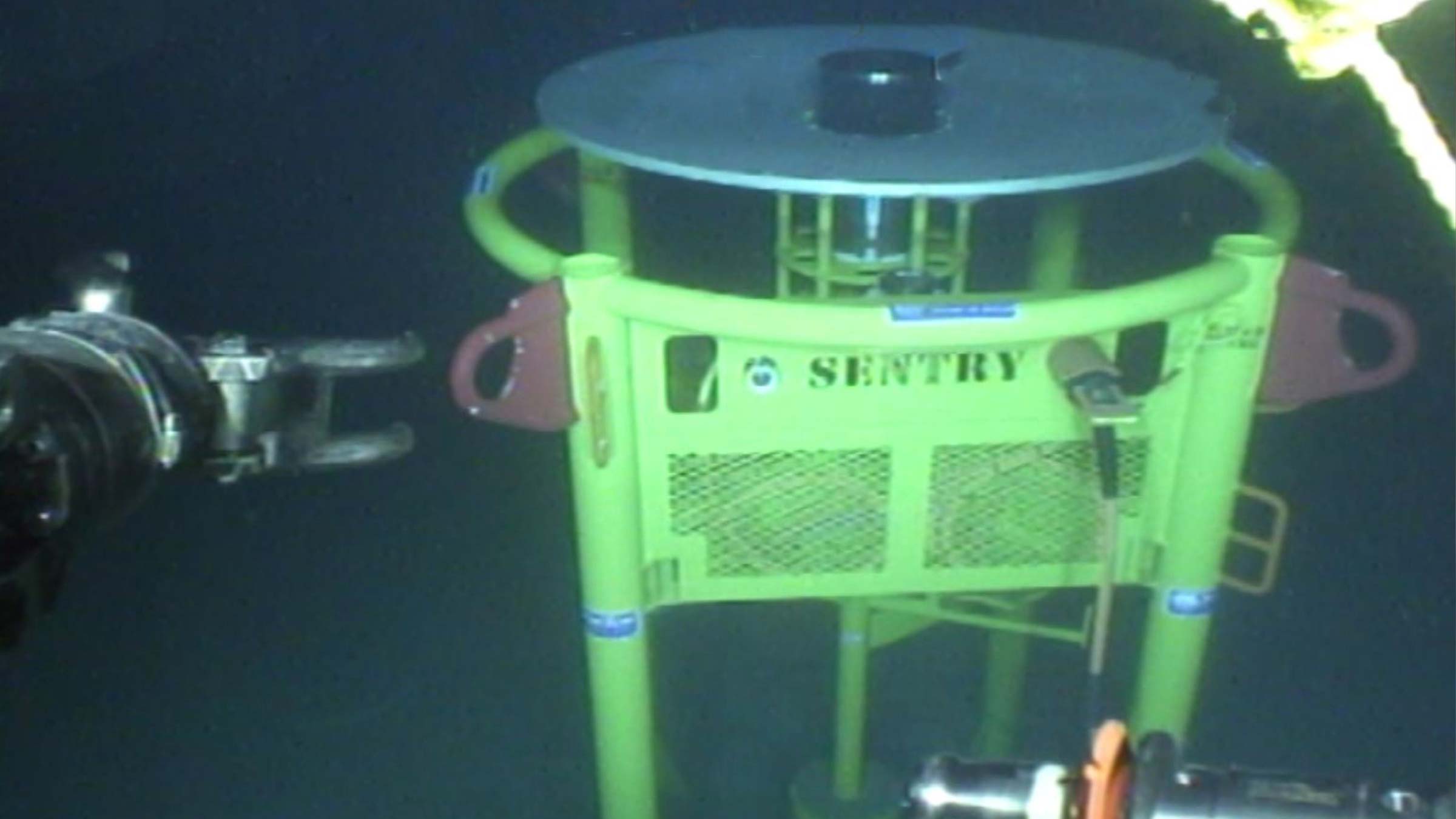

- ROV deployable and recoverable; perfect for short monitoring projects

Sentry is the answer to your subsea monitoring challenges. It is an active sonar which works by projecting a short-duration high-bandwidth pulse into the water and listening for echoes from any objects such as structures, ROVs or hydrocarbon leaks. The system is fully automated. If a hydrocarbon discharge is detected, it raises the alarm. Data on the leak position is displayed and automatically transmitted to your remote onshore monitoring stations. Multiple users can access and update the system remotely, allowing you to make best use of your time and resources. It is suitable for:

- Environmental surveys

- Pipeline and spool piece monitoring

- Leak detection

- Carbon capture and storage

- Automatic, wide-area leak monitoring

Active, automatic, flexible – Sentry for your asset monitoring operation needs

How it works

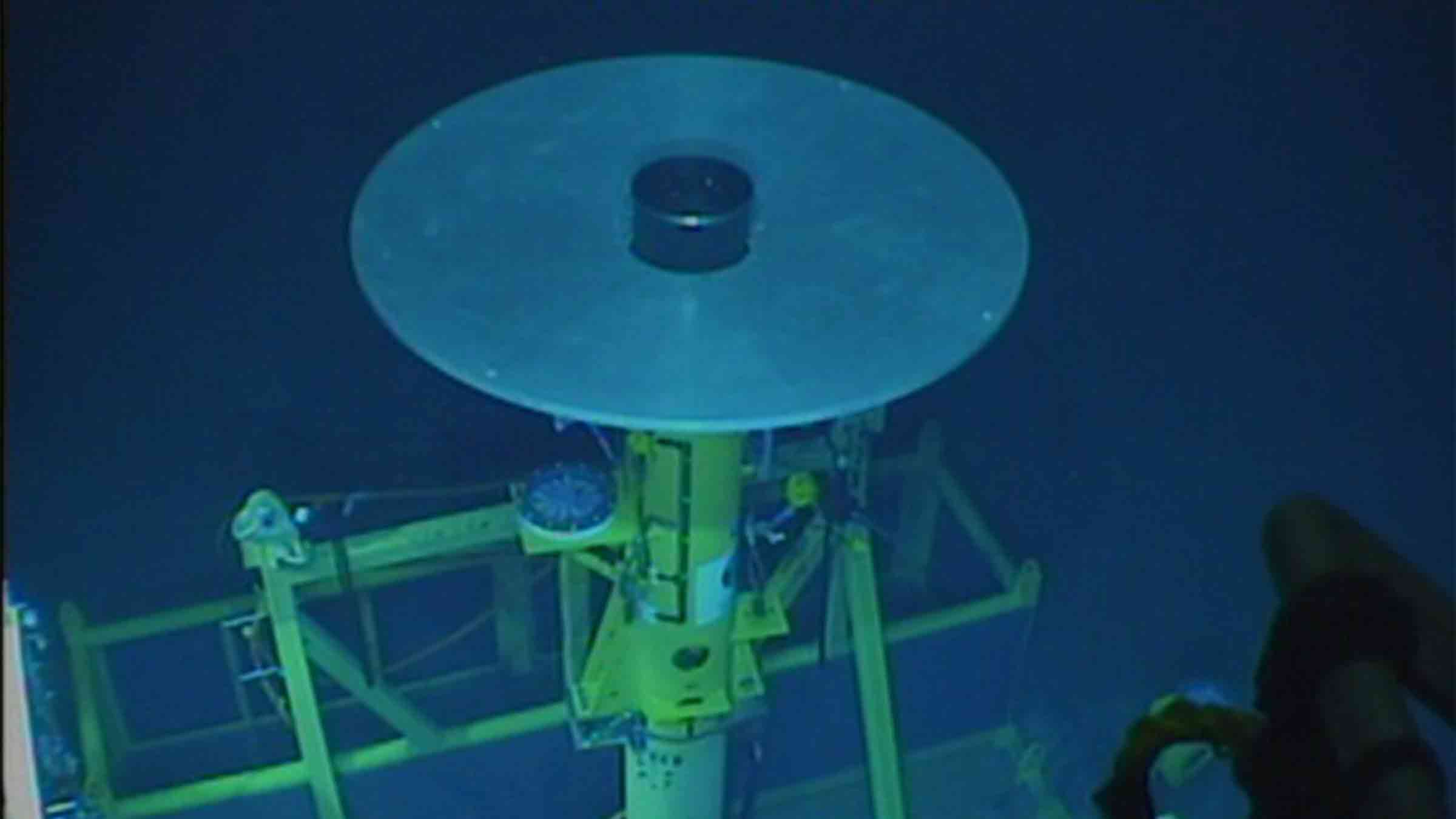

Designed by our sister company Wavefront Systems, manufactured and commercialised by Sonardyne, Sentry covers a 360° field of view, with a detection coverage radius up to 1,200 m and is capable of monitoring over one billion cubic feet of seawater. It can detect leaks of monophase gas down to 0.1 litre per minute (equivalent to around 1 barrel of oil per day) or monophase oil to 1 litre per minute (equivalent to 10 barrels of oil per day).

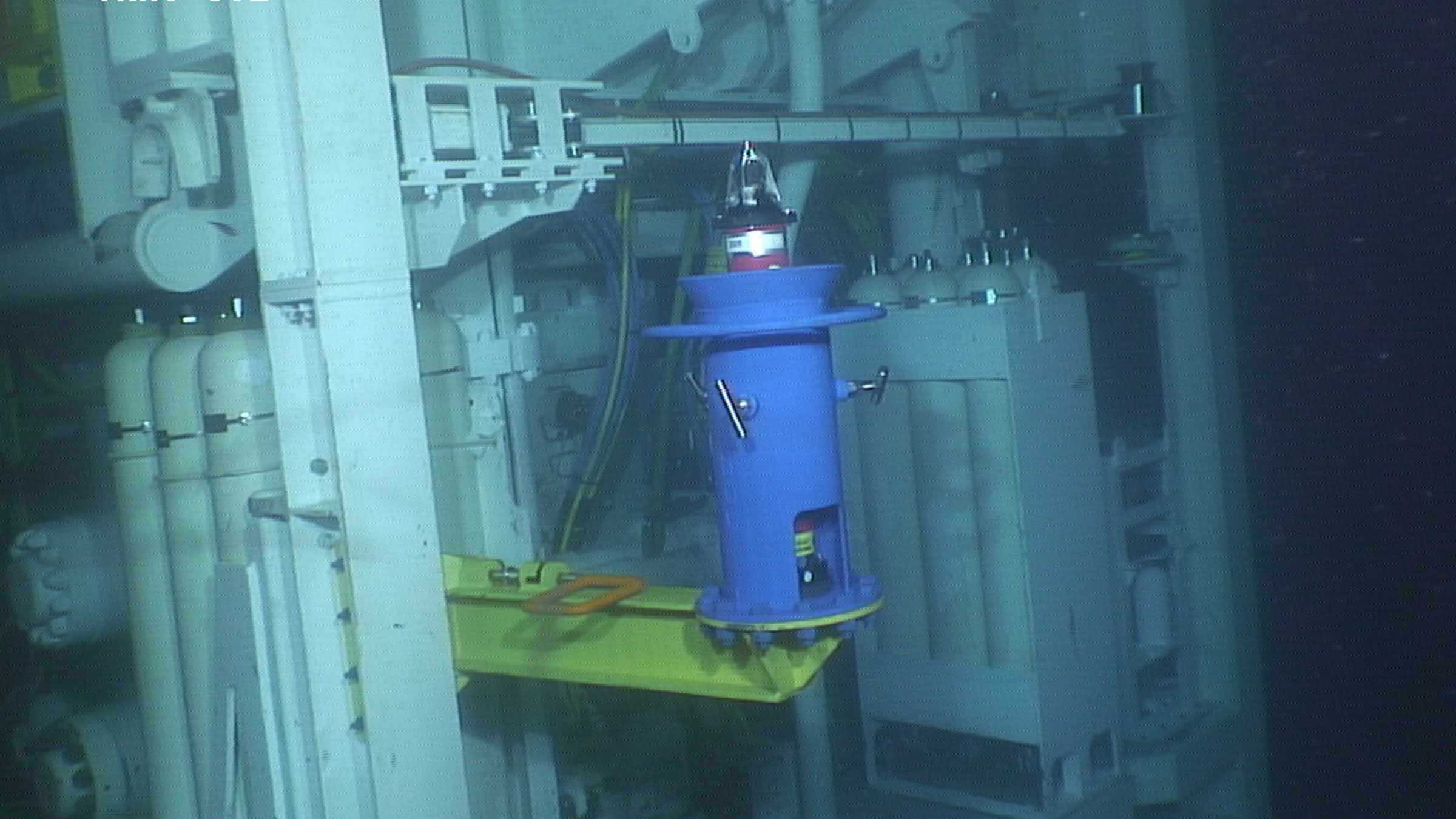

Wired and battery-powered configurations of Sentry IMS provide flexibility in how and when you can use the system. Mounted on a lander, Sentry-W connects into your asset’s existing power and communication seafloor infrastructure. It will run autonomously, providing alerts to your remote operations centre only when its on-board processing has determined a positive detection and classification of a leak.

Where no infrastructure is available, Sentry-B (a standalone battery operated system) can be lander-deployed, complete with subsea data processing, close to your assets. At pre-set intervals, or when a leak event is detected, summary data is transmitted using a 6G acoustic modem to a surface transceiver for onward transmission to your remote operations centre. Surface transceivers and satellite communications systems can be mounted on a moored buoy, integrated into an unmanned surface vehicle (USV), or fitted to any other surface asset.

Common applications

CCS site monitoring

Containment failure at an offshore carbon capture and storage (CCS) site, while highly unlikely, is of significant concern to regulatory bodies, operators and environmental groups. We have developed the capability to detect and monitor any leakage at high risk locations combining Sentry sonar and chemical sensors on a lander to deliver sensitive and reliable automated leak detection capability across wide areas.

Speak to us about your CCS requirements.

Offshore hydrogen production and storage site monitoring

As we transition towards a net zero world, hydrogen is set to play a larger role in our energy system. This includes offshore production and then transport via pipeline to shore. It may also include underground storage, including in sites offshore, similar to how natural gas has been stored. Containment monitoring and asset integrity assurance are just as important here and Sentry provides an ideal solution. Contact us to find out more.

Need mobile, more targeted monitoring over distance?

For inspecting greater lengths of subsea assets, such as your trunk pipelines, our compact yet high-performance Solstice side scan-sonar containing powerful automatic target recognition (ATR) algorithms can be integrated into an AUV to provide detection and location of any containment losses of oil or gas. Find out more here.

CCS case studies

Rapid leak detection for subsea production and storage sites

Read moreDeepwater data analytics – asset monitoring at the edge

Read moreHow to optimise carbon storage monitoring with marine robotics

Read morePerformance

• Monitor 1 billion cubic feet of water with one sonar head

• Depth rated to 4,000 m

• 360 degree coverage from a single point

• Low false alarm rates

Design

• Wired and battery-powered Sentry IMS options

• Active sonar – always listening

• Fully autonomous alarms

• Multiple sonar heads can be interfaced together to increase coverage

Typical system set up

• Sonar or multiple sonar heads

• Sonar processor (SP)

• Command workstation (CWS)

• Sentry software

Support

• Work side-by-side with our projects and applications group from concept to installation

• Systems are manufactured and tested before delivery at our world-class in-house facilities

• Highly experienced field personnel can be on hand to ensure even the most complex systems are commissioned safely

• 24-hour support, whenever and wherever you are in the world

Specifications

| Feature | Type 8265-000-01 |

|---|---|

| Depth Rating | 4,000 m |

| Operating Frequency | 60 to 80 kHz |

| Source level | 206 dB re 1 µPa @ 1m |

| Pulse length | 40 ms |

| Detection range | Selectable up to 1,500 m |

| Operating Temperature | -10 to +40°C |

| Storage Temperature | -10 to +55°C |

| Dimensions (Height x Diameter) | 556 x 330 mm |

| Weight in air / water | 86 kg / 48.5 kg |

Frequently asked questions

Measuring the shortest change, to give the longest warning – how it works

A tsunami wave in deep water creates a small (a little as 3 cm) but measurable change in pressure that can be maintained in excess of 20 minutes.

The sensitive pressure sensor in the BPR detects the small, but continuous change in water pressure, which triggers transmission of a series of warning messages to a surface buoy moored above it. This means that the first message warning of a tsunami, caused by a small variation in water pressure on the seabed thousands of miles from shore, can be in the office of the monitoring organisation within minutes, if not seconds.

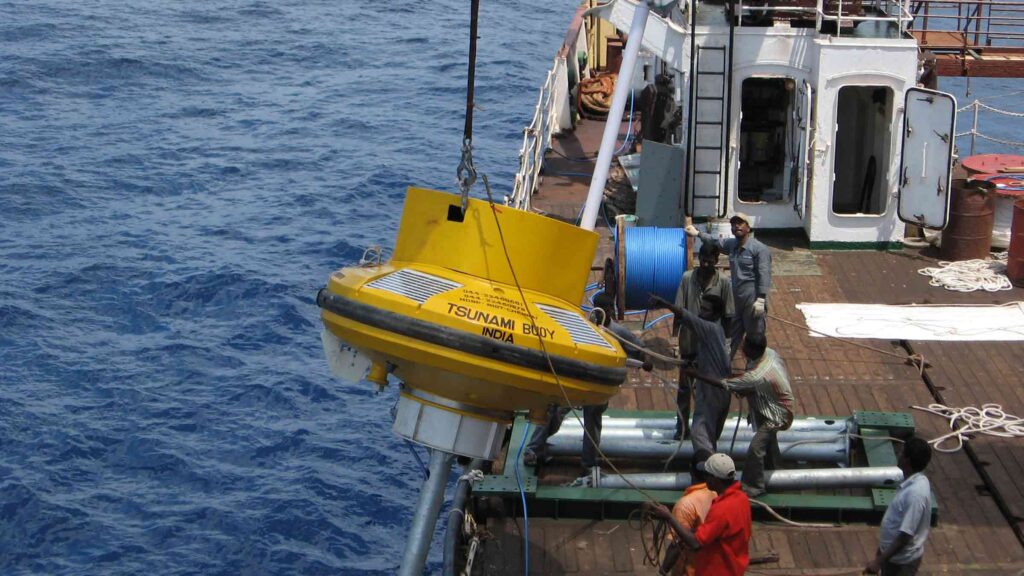

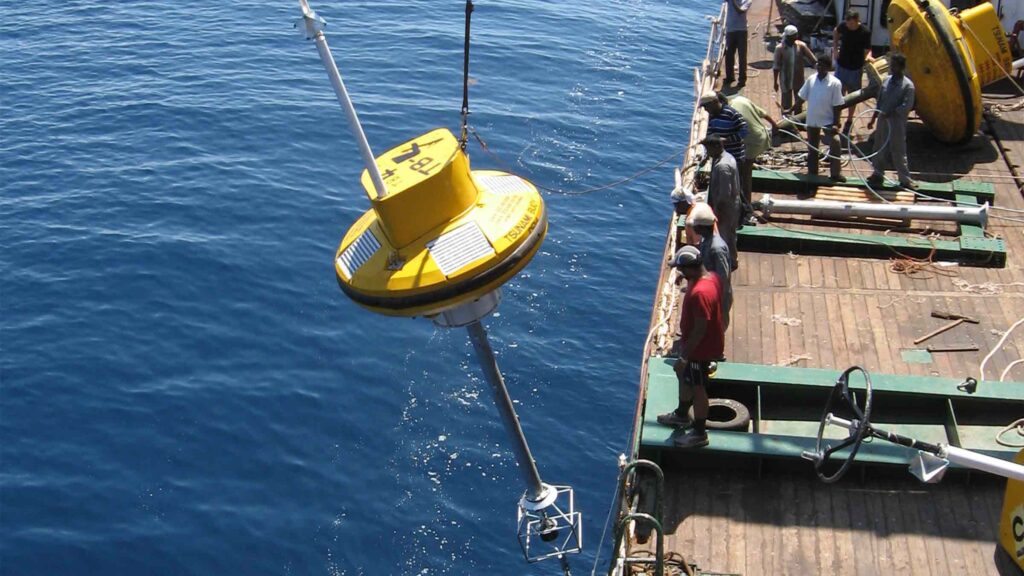

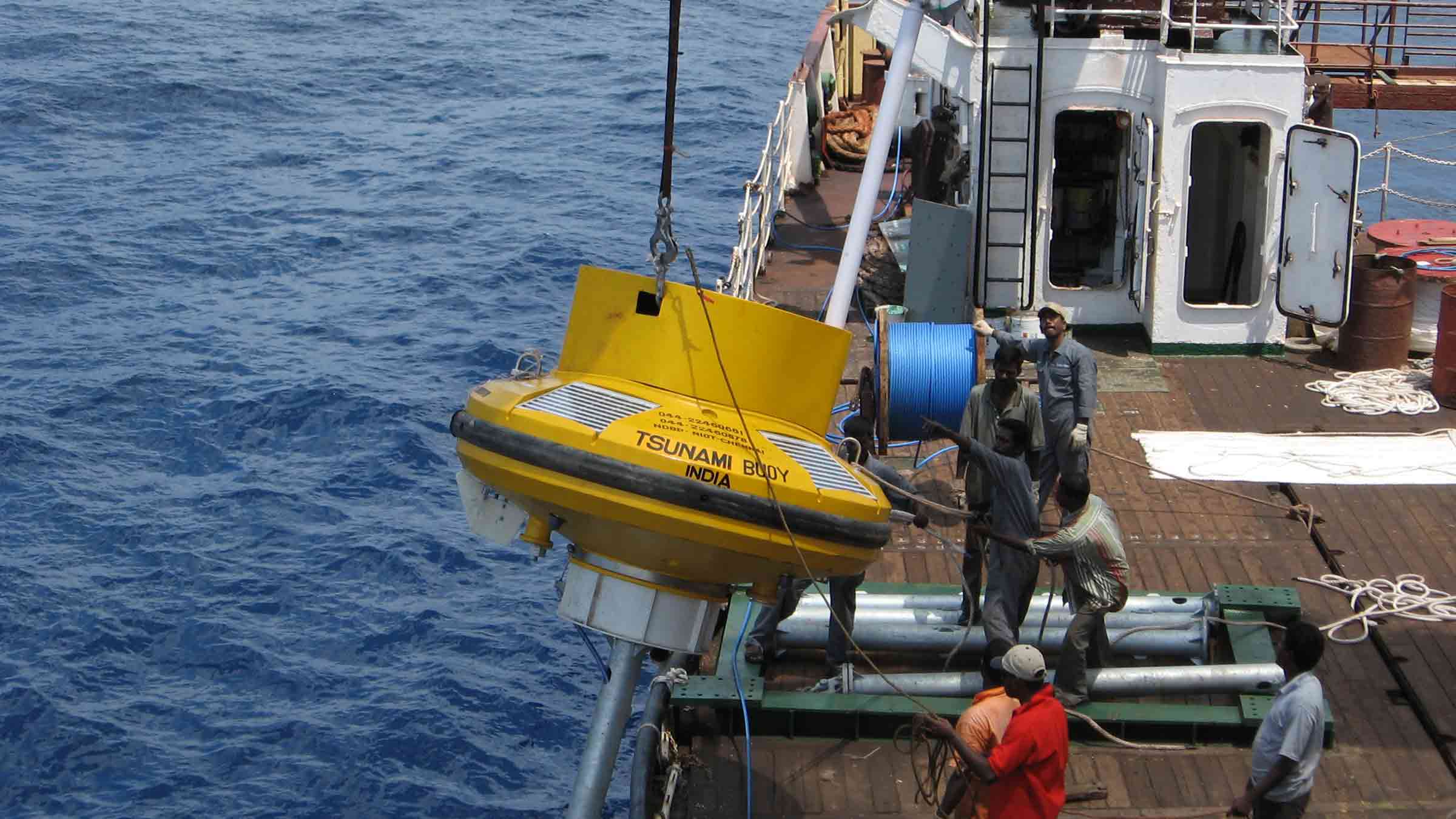

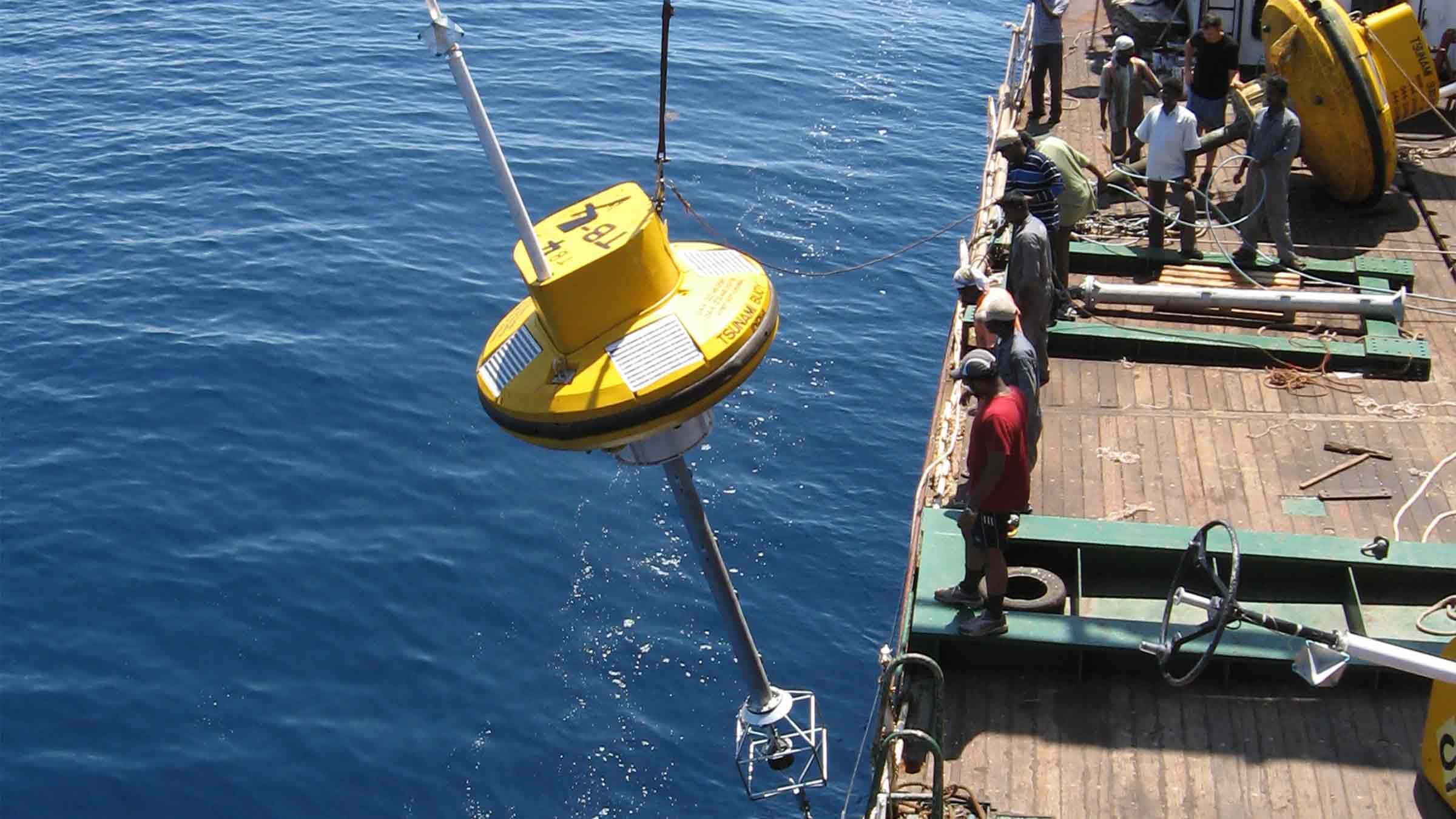

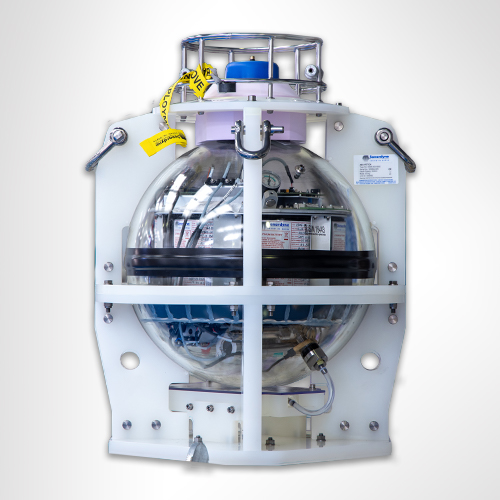

The Tsunami Early Warning System (TEWS), developed by MSM Ocean and Sonardyne, centres around a sophisticated Bottom Pressure Recorder (BPR) deployed on the seabed. This modified Compatt 6 transponder works in conjunction with a surface buoy and onshore control centre to create a comprehensive tsunami detection network.

The BPR operates at depths up to 7,000 m and features impressive longevity, running for four years on standard power or up to nine years when housed in a glass sphere configuration. Operating in the LMF band (14-20 kHz), the device samples water pressure every 15 seconds and typically transmits data hourly to the surface. The system is compatible with various surface transceivers, including our Ranger 2 USBL system.

The detection process is both sensitive and precise. The BPR can identify pressure changes as small as 3 centimetres, using the NOAA DART® algorithm to compare measured pressure against predicted values. When two consecutive variations exceed the preset threshold (typically 3cm), the system enters alert mode. Data is then transmitted acoustically to the surface buoy, which relays the information via dual Iridium satellites to the shore. This entire alert process takes only minutes to complete.

System management is streamlined through the NETCOM-TS web application, which provides comprehensive control and monitoring capabilities. The data is shared with NOAA’s National Data Buoy Center, ensuring broad distribution of critical warning information. The system can be configured remotely, and maintenance is straightforward thanks to an acoustic release mechanism that allows for simple recovery and redeployment. Unlike some competing systems, this solution requires no underwater cables, making it particularly reliable and easy to maintain.

This integrated system serves as a crucial link in the chain of tsunami detection and warning, providing coastal communities with vital advance notice of potential threats. By combining robust hardware with sophisticated detection algorithms and seamless communication protocols, the system delivers a dependable early warning solution that can save lives and property in vulnerable coastal areas.

At a glance

- All-in-one wireless solution for detecting tsunamis; no fixed sea-to-shore infrastructure required

- Detects height variation on the water surface as small as 1 mm; a change of 3 cm launches a tsunami event (tsunami alert)

- Generates Deep-ocean Assessment and Reporting of Tsunamis (DART®) warnings which can be received onshore within seconds of a confirmed tsunami event

- Low cost of ownership; COTS technology with long service intervals

- IALA compliant buoy for increased safety of the system to guarantee availability

- Remote monitoring and control for ease of operation

- Intuitive shore control interface using MSM Ocean’s NETCOM-TS software

Why choose Sonardyne & MSM?

Easy ownership

Our warning system is commercial-off-the-shelf, can be acquired easily, delivered in short timescales and commissioned without any significant national investment in, or construction of, sea-to-shore infrastructure.

It’s integrated

Competing warning systems are often made up of individual sensors, battery packs and modem with vulnerable connectors and cables. Together with MSM Ocean, we provide a one-stop shop solution that’s rugged and robust.

It’s proven

The system’s built using proven, high security wireless seabed to shore monitoring and communications technology, with proven performance in detecting tsunamis.

Seabed to surface communications (Sonardyne)

• Long range for deep water deployment far offshore; 19-34kHz frequency band

• Advanced protocols to minimise data loss and re-sends

• Directional transducer for optimised seafloor-to-surface communications

• 100 – 900 baud user payload, bi-directional

• Powered by 6G and Wideband 2 technology: in use globally within science, energy and defence

Surface to shore communications (MSM Ocean)

• Uses the Iridium low earth orbit (780 km) constellation of polar orbiting satellites

• Incorporates dual modems and antennas for redundancy

• NETCOM-T software web application enables remote management of the tsunami buoy and BPR from Shore Control Centre

BPR Design (Sonardyne)

• Robust all-in-one design; compact, integrated, self-powered, no cables to get damaged

• Easy to deploy; standard depth rating of 5,000 m (option for 7,000 m)

• Integrated release mechanism for simple recovery of seabed BPR for servicing

• 2 year battery life typical; up to 10 years possible with alternative design of BPR

• Simple to integrate surface transceiver on instrumented buoy (solar and communications)

Tsunami Buoy (MSM Ocean)

• Suitable for deployment in depths of up to 4,000 m

• IALA compliant topmark, lighting with 5 NM luminous range

• Aluminium superstructure with a 2.4 m diameter shock-resistant closed-cell polyethylene foam float and stainless-steel tail

• Multiple safety and anti-vandalism measures fitted as standard: GPS out of position alarm, unremovable solar panels, impact sensor, intrusion sensor

A typical TEWS configuration (Per monitoring location)

• Seafloor deployed BPR transponder and floatation, 5,000 m rated, 2 year battery life. Sonardyne iWand back-deck and workshop test and configuration device

• Moored, IALA-compliant communications buoy equipment equipped with sub-surface acoustic transceiver, power, navigation safety aids and redundant satellite communications gateway

• MSM Ocean command and configuration software used to remotely control and monitor the TEWS and issue alerts

Ownership

• Warranty: 1 year return to Sonardyne MSM Ocean service centre

• Training: onsite or remote operator and maintainer training required

• ITAR Controlled: No

• UK Export Licence: Not required

Specifications

| Feature | Type 8141 Buoy Mounted Transceiver | Type 8142-000-02 Buoy Mounted Transceiver |

|---|---|---|

| Frequency Band | LMF (14–19 kHz) | LMF (14–19 kHz) |

| Transducer Beam Shape | Directional | Directional |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 196–172 dB (3 levels) | 196–172 dB (3 levels) |

| Receive Sensitivity (dB re 1 µPa) | 95–130 dB (6 levels) | 95–130 dB (6 levels) |

| Telemetry (Wideband 2) | 100–900 baud, user payload, bi-directional | 100–900 baud, user payload, bi-directional |

| Sonardyne Messaging Service (SMS) data buffer | 128 bytes | 128 bytes |

| Command/Control | Accessed through communications interface | Accessed through communications interface |

| Error Detection and Correction | Advanced protocols to minimise data loss and re-sends |

Advanced protocols to minimise data loss and re-sends |

| Communications Interface | RS232 (9,600–115,200 baud) | RS232 (9,600–115,200 baud) |

| Dimensions (Length x Diameter) | 608 x 260 mm | 608 x 260 mm |

| Weight/Mass | 9.75 kg (weight in water) 5.26 kg (weight in air) |

9.75 kg (Weight water) 52 N (mass) |

| External Power Requirement | 24–50 V dc, 1 W quiescent, 100 W peak |

24–50 V dc, 1 W quiescent, 100 W peak |

| Armoured Cable to buoy Payload | Included (10 m, 8-core, with strain relief) | Included (10 m, 8-core, with strain relief) |

| Feature | Type 8303 Bottom Pressure Recorder 6 | Type 8303-6226 Bottom Pressure Recorder 6 |

| Depth Rating | 5,000 m (4,100 and 7,000 m option) | 6,000 m |

| Frequency Band | LMF (14–19 kHz) | LMF (14–19 kHz) |

| Transducer Beam Shape | Directional | Directional |

| Transmit Source Level (dB re 1 µPa @ 1 m) | 202–169 dB (5 levels) | 202–169 dB (5 levels) |

| Receive Sensitivity (dB re 1 µPa) | 80–120 dB (6 levels) | 80–120 dB (6 levels) |

| Telemetry (Wideband 2) | 100–900 baud, user payload, bi-directional | 100–900 baud, user payload, bi-directional |

| Battery Life (Monitoring) | 725 days standard (1,450 days maximum option) | 1,450 days |

| Working Load Limit (4:1) (Release) | 250 kg | 250 kg |

| Dimensions (Length x Diameter) | 1,100 x 200 mm | 1,667 x 200 mm |

| Weight/Mass | 28.2 kg (weight in air) 14.2 kg (weight in water) (standard 5,000 m option) |

49.5 kg (weight in water) 235 N (mass) |

| Pressure Sensor | 4,100 m (7,000 m option) | 6,800 m range |

| BPR Floatation Collar | Included (nett buoyancy 300 N) |

n/a |

| Feature | Floatation for Bottom Pressure Recorder 6 | |

| Depth Rating | n/a | 6,000 m |

| Dimensions (Diameter) | n/a | 857 mm |

| Weight/Mass | n/a | 211 kg (weight in water) 760 N (mass) |

Datasheets

Durable, compatible, configurable, portable

Why Acoustic Data Logger is perfect for your operations

Built on more than 30 years of successful installations, Acoustic Data Loggers provide you with the power to read multiple gauges at predefined intervals, securely store the received information within the unit, then transmit it acoustically through the water column to the surface on-demand.

The current generation includes our 6G and Wideband 2 acoustic technology, allowing large volumes of logged data to be rapidly and accurately retrieved at the surface.

Unmatched longevity for unwavering performance

Say goodbye to frequent maintenance and costly disruptions. Your Acoustic Data Logger can remain deployed for several years without the need for intervention, ensuring your well data is captured with unwavering consistency. They are compatible with Intelligent Well Interface Standardisation (IWIS) and non-IWIS gauge cards from the leading wellbore downhole pressure and temperature gauge manufacturers.

Using normal gauge reading sample rates they can operate for up to three years. Longer deployments or higher sample rates are easily accommodated using external battery packs. All hardware is supplied in corrosion-resistant super duplex stainless steel canisters for very long deployment periods.

ROV portability to a maximum depth of 3,000 m, makes the system ideal for initial well appraisals, where frequent downhole pressure and temperature readings need to be logged over a few weeks. However, the system is equally suitable for long-term deployments where it may remain installed on a wellhead, logging data for several years without intervention.

Suspended or abandoned well monitoring

High-availability acoustic subsea modems are designed for use with third party systems to facilitate the transfer of wellhead or wellbore data to the surface. Our modems can be designed, tested and supplied as part of a third party’s well monitoring solution, including electromagnetic, and through-casing tube technologies to the wellhead or tree-mounted modem.

At a glance

- Perfect for well appraisal campaigns

- ROV-deployable, easy to move between wells

- Can be interfaced to wide range of down hole gauges

- Depth rated to 3,000 m (10,000 feet)

- Harvest data using vessel, rig or ASV

Performance

• Standard depth rating of 3,000 m

• Configurable sample rates from 2 minutes to 5 days

• Weight in water 63 kg

• Acoustic data rate 300–9,000 bps

Design

• Super Duplex Stainless Steel construction

• Integrates into all industry-standard gauge cards

• Fully configurable logging and reporting scheme

• 512 gb internal storage

Connectivity

• ROV mate-able connection

• LMF (14–19kHz) acoustic link

• High speed, spread spectrum acoustic data link

Support

• Comprehensive and flexible training for system operators

• 24-hour support, whenever and wherever you are in the world

• Work side-by-side with our Custom Engineering Team from concept to deployment

• Systems are manufactured and tested before delivery at our world-class in-house facilities

Specifications

| Feature | Type 8195 | |

|---|---|---|

| Acoustic communication | ||

| Operating frequency | LMF (14–19 kHz) | |

| Transducer beam shape | ±30° (directional) ±70° (omni with noise shield) |

|

| Transmit source level (dB re 1 µPa @ 1 m) | >190 dB | |

| Receiver threshold (dB re 1 µPa) | 85–120 dB (7 levels) | |

| Acoustic data | Link | High speed, spread spectrum |

| Transmission rates | 300–9,000 baud (true payload rate variable by telemetry scheme) | |

| Power | ||

| Power | Long life lithium primary cell battery pack | |

| Battery capacity | Single battery pack | 120 Ah @ 14.5 V dc |

| Dual battery pack | 240 Ah @ 14.5 V dc | |

| Battery life | Dependant on interface and logging configuration | |

| Interface card | Supply voltage | 24 V dc ± 4 V |

| Maximum power | 30 W | |

| Communication and interface | ||

| Gauge interface card type | 1x IWIS DHPT Interface Card (dependant on field requirements) | |

| Interface card serial communication format | IWIS RS485 at 9,600 baud, Modbus TCP or Modbus RTU protocol | |

| Interfaces | Serial | 2x RS485/422 – 2x RS232 |

| Analogue | 6x Analogue | |

| Serial communication | Direct serial access to data logger & Gauge Interface Card via the external serial port | |

| Logging and data storage | ||

| Minimum memory capacity | 512 Mb – Industrial SD Card (non-volatile) | |

| Sample rates | Standard | Configurable from 2 minutes to 5 days (dependant on interface) |

| Special | High sample rate operation for user defined durations from 1 minute to 4 days with configurable rates from 5–60 seconds (dependant on interface) | |

| Mechanical | ||

| Mechanical construction | Super duplex stainless steel – UNS32550 | |

| Mechanical design | Sonardyne 6th Generation including inter O-ring test ports | |

| Dimensions (length x diameter) | MF single battery configuration | 1,086 x 199 mm |

| LMF dual battery configuration | 1,348 x 199 mm | |

| External connectors | Gauge interface | 1 x ODI or TRONIC (dependant on field requirements) |

| Serial test port | 1x Subconn MCBH8M 1x Subconn MCBH8F |

|

| Environmental | ||

| Depth rating | 3,000 m (dependant on connector) | |

| Operating temperature | -10 to +55°C | |

| Storage temperature | -25 to +70°C | |

| Design qualification | ISO 13628-6 Level Q1 & Q2 | |

| Options | ||

| ROV handle Type 8195-007 | ROV handle assembly (folding), super duplex stainless steel – UNS32550 | |

| Battery configuration | Single (120 Ah), dual (240 Ah) or triple (360 Ah) |

Software and firmware

Datasheets

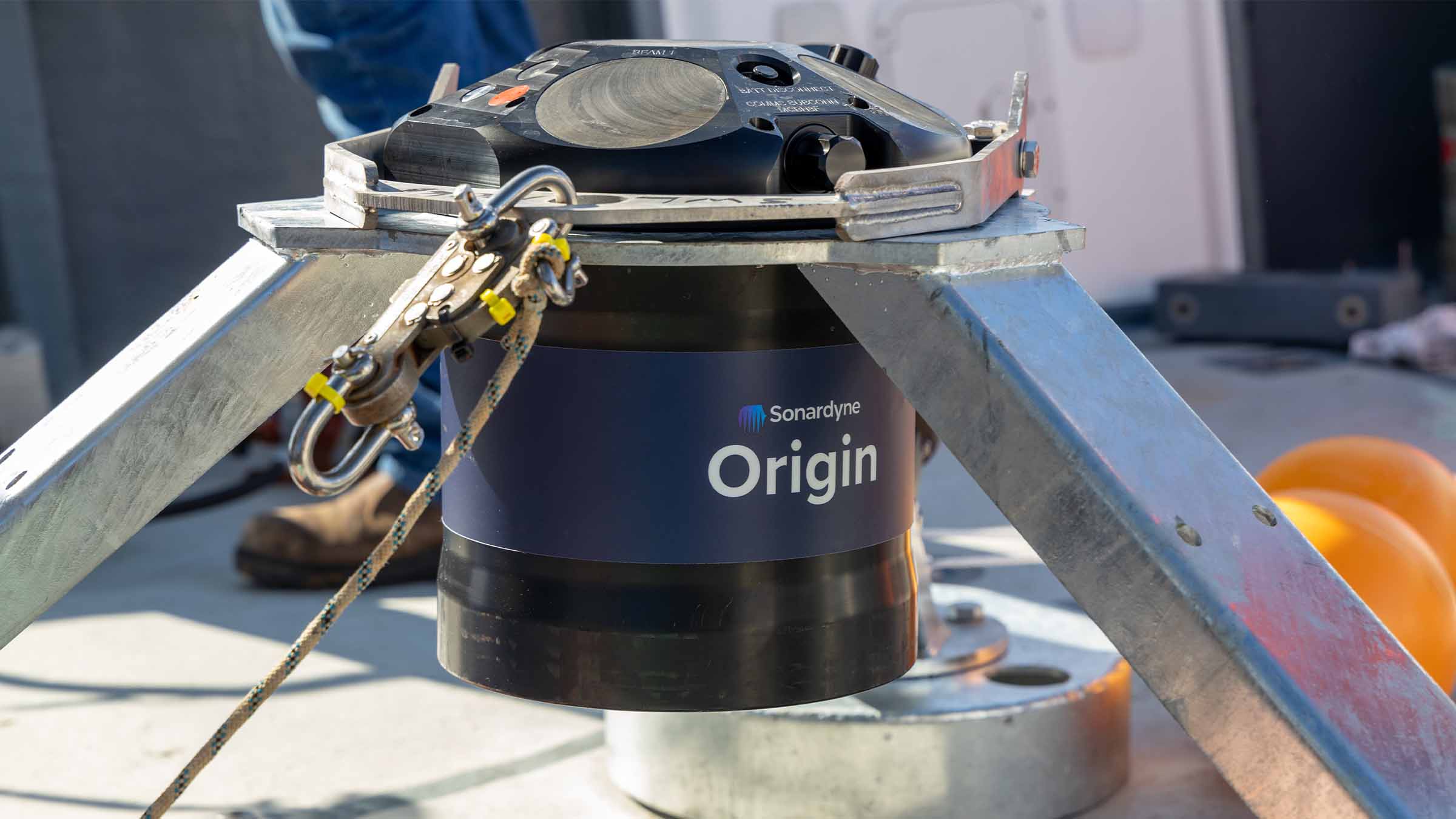

Make time-critical decisions with near real-time data delivery

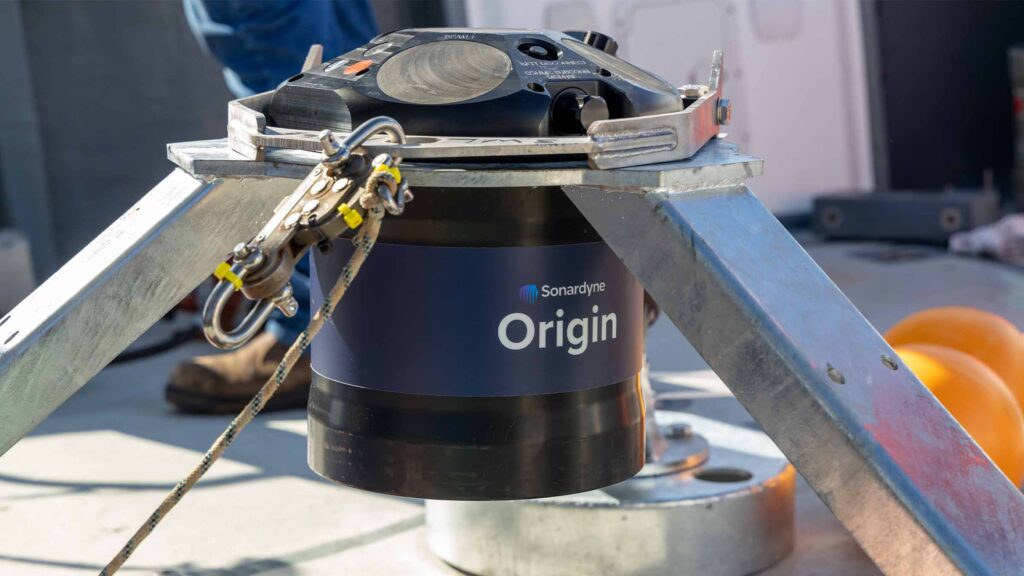

Analyse the structure of your velocity and backscatter intensity data in far finer detail than previously possible with our proprietary formats delivering up to ten times greater spatial resolution. Origin 600 delivers conventional PD0 data as standard, whilst logging the higher resolution data to further enhance your results. All data is recorded to the onboard storage unit with 1 TB capacity.

Reduce your risks and device retrieval costs with power-efficient electronics and a rechargeable internal battery which allows deployments of up to three months on a single charge. A dual battery option allows you to operate longer or more energy demanding deployments. External power can be supplied by PoE, allowing you to program and download data without a separate power supply.

Monitor waves, mean currents and turbulence using Origin 600’s five-beam configuration and sampling frequency of up to 4 Hz on all beams. Your Origin’s built-in acoustic modem enables you to remotely access the unit while it’s deployed using an accompanying topside modem (sold separately) and the Origin Topside PC software. This allows you to check battery and storage, inspect and upload data, reconfigure schedules and run quality control, all whilst your ADCP is on the seabed.

Add external sensors to your ADCP mounting frame, and fuse with your Origin data via the Edge processing software, to really get the most out of every single deployment. You can upload sensor apps via Origin Portal or Topside and the resulting data will be exported over the acoustic modem.

What is Edge?

Discover the key to your customised ADCP data…

A suite of intuitive software tools and the Sonardyne Edge computing environment allows you to get the most out of your Origin 600. The Origin Portal web UI lets you configure your ADCP in operational conditions, including modification of the sampling schedule. Reduce your operational risks by setting your schedules before deployment using the Origin Scheduler PC application. Two schedules can be run together, allowing dual monitoring tasks to be performed with a single device. File data can be inspected using the Origin Viewer software package.

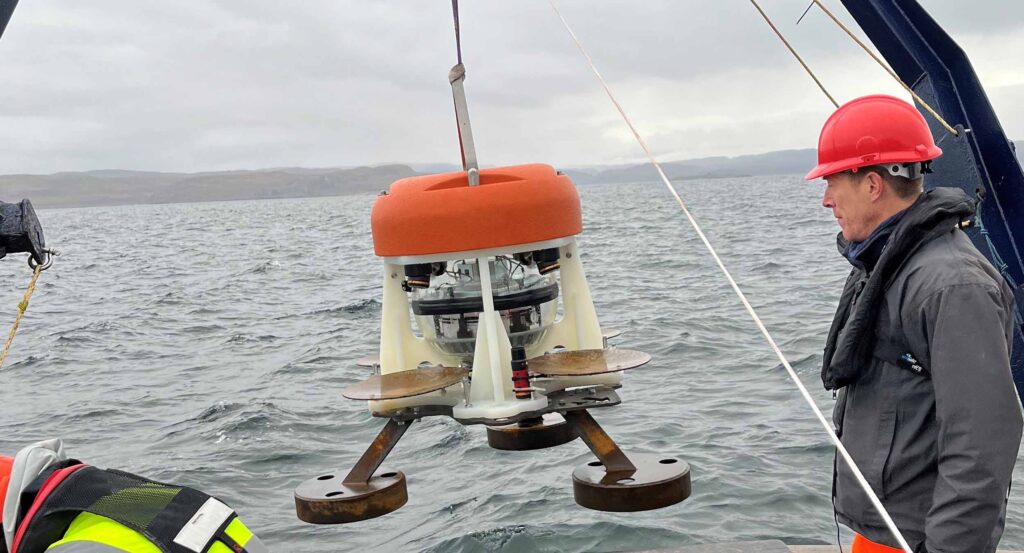

Origin 600 is compatible with your standard mounting infrastructure, reducing your risk and cost for upgrading to this device. For a complete solution, we can provide a dedicated, rugged stand with space for dual redundant releases.

Why choose Origin 600 ADCP?

Origin 600 – Mid-range ADCP

Origin 600 – Mid-range ADCP

Five reasons to LOVE Origin 600 ADCP

Five reasons to LOVE Origin 600 ADCP

Origin 600 for ocean science

Origin 600 for ocean science

Performance

• 625 kHz operating frequency

• 1.2 to 60 m profiling range

• 150 m operational depth rating

• Onboard data storage and processing, 1TB onboard storage as standard

Design

• All-in-one design

• Compact and easy to install from small vessels

• Dual battery and external power options

• Internal rechargeable battery allows for deployments of 3 months

Expanded functionality

ADCP data can be supplemented by and Edge-fused with data from external sensors so you can really get the most out of a single device deployment and the data generated. Optional seabed stand with integrated Sonardyne acoustic release for recovery using Ranger family of USBL systems.

Remote control

The integrated acoustic modem enables actions with the ADCP already in the water, delivering in-field flexibility and data assurance. Deploy and forget; integrated MF frequency modem offers in-situ data recovery, remote re-configuration and survey QC.

Specifications

| Features Type 8382 (-0457 single battery; -0427 dual battery) |

ADCP | Echosounding | |

|---|---|---|---|

| Acoustics | Operating frequency | 625 kHz | |

| Maximum profiling range | 60+ m (depending on water environment) | ||

| Minimum cell size | 12 mm | ||

| Minimum blanking distance | 0.6 m | 0.04 m | |

| Velocity range (along beam) |

Up to ±2 m/s or 3.75 m/s |

n/a | |

| Velocity RMS | 0.5% of measured value | n/a | |

| Maximum number of cells | B-gram 5,000; A-gram 2,500; PD0 255 | 5,000 | |

| Maximum ping rate | 4 Hz (5 beams) | ||

| Beam width/angle | ±1 degrees/ 25 degrees |

||

| Echosounding dynamic range/ resolution |

n/a | 79/0.002-2.5 dB | |

| Acoustic modem | Operating frequency | MF (20–34 kHz) | |

| Typical operating range | 500 m | ||

| Sensors | Temperature | -5° to 35°C | |

| Heading accuracy/ resolution |

±1°/0.1° | ||

| Pitch & roll accuracy/ resolution & range | ±1°/0.1° & ±90° (pitch), ±180° (roll) | ||

| Pressure | ±0.05% full scale | ||

| Communication and logging | Communications | RS232, Ethernet and acoustic modem | |

| Internal logging | 1 TB internal memory | ||

| Output | Output telegrams | PD0, A-gram, and B-gram |

|

| Electrical | External power | 18-48 V power by external cable; PoE+ | |

| Power | 45 mW (acoustic modem on), 3.5 W (fully active) | ||

| Internal battery | Li-Ion 800 Wh, 1600 Wh dual version |

||

| Internal battery recharge | 4 hours fast charge (8 hours for dual battery option) | ||

| Full/scheduled/ standby lifespan |

1 week/3 months/ 2 years |

||

| Environmental | Depth rating | 300 m (survivable), 150 m (operational) | |

| Operating/storage temperature | -5 to 40°C/ -20 to 55°C |

||

| Mechanical | Construction | Plastic | |

| Connector type | Subconn: 8-way for power and comms; 6-way for fast-charge | ||

| Dimensions (height x max diameter) |

308 x 290 mm (dual battery height 388 mm) |

||

| Weight in air/ water | 19.2/7.2 kg (dual battery option 23.9/ 7.9 kg) |

||

| Software | Origin Portal | Embedded Web UI for control & configuration | |

| Origin Scheduler | Schedule planning & configuration tool | ||

| Origin Viewer | File data inspection | ||

| Origin Topside | Remote configuration & control over acoustic modem |

Frequently asked questions

Can I use Origin 600 in a cabled operation?

Where does Origin 600 get time and date from?

How do I get an Edge license?

Origin 600 – What’s in the box?

What is PD0?

How much current does Origin 600 draw?

What data formats do Origin ADCPs produce and can I transform between the different data formats?

What do I do if I can’t establish acoustic communication with Origin 600?

How do I access data stored on Origin 600?

What is an ADCP and how does it work?

What is the benefit of an internal rechargeable battery for Origin 600?

What is the Origin Scheduler?

Why access ADCP data remotely?

What is the beam configuration of Origin 600?

What are the topside options for Origin 600?

What are the benefits of an integrated acoustic modem?

What is Edge?

What are sidelobes?

What are my data retrieval options with Origin?

What are the operational parameters of Origin 600?

What is Edge SDK?

What are Edge apps and what apps are available?

How do I use the battery disconnect?

How do I upload an Edge app to my Origin ADCP?

How do I recharge my Origin 600 battery?

Does Origin’s internal compass require calibration?

Can I reconfigure my Origin ADCP once deployed?

Can I integrate external sensors with Origin?

Software and firmware

Manuals and quick start guides

Blog: Cable monitoring for floating offshore wind

With worldwide investment in renewable energy continuing to rise, we anticipate a significant increase in floating offshore wind (FLOW) developments over the next ten years. However, investors are concerned about this nascent technology’s performance in deeper, more dynamic environments, particularly risks associated with dynamic cables.

Blog: Moving on from PD0

In this blog, we introduce and explain the core content of the B-gram data format produced by Origin ADCPs.

Case study: Facing the challenge of speeding up consent in offshore renewable energy

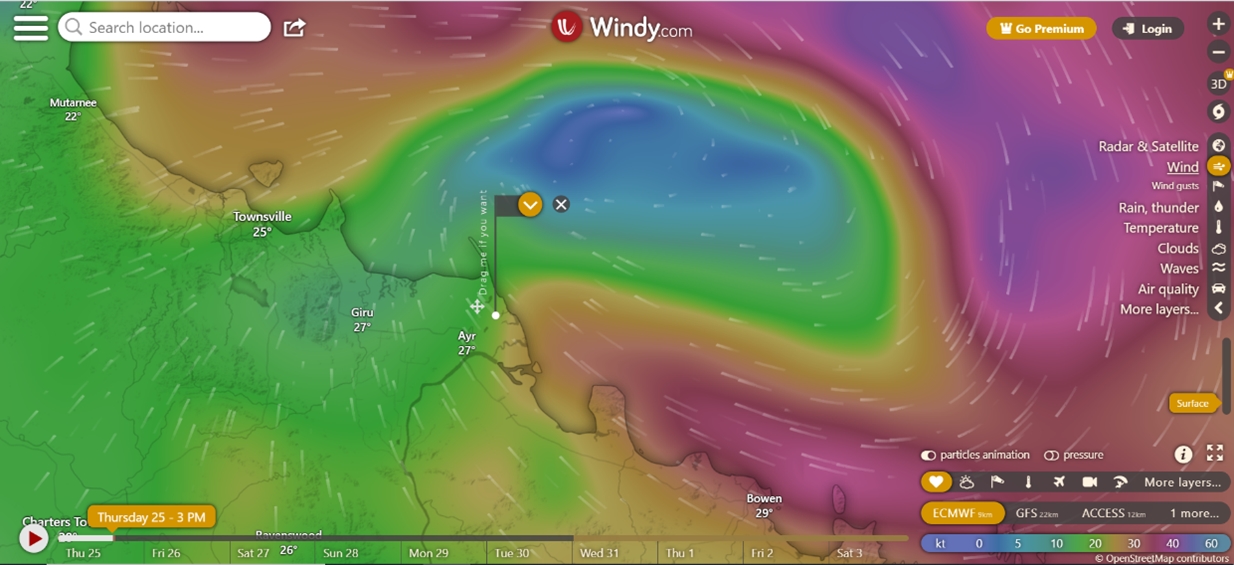

Blog: Origin 600 vs. Cyclone Kirrily

A category three cyclone swept through Queensland, Australia during a three-month deployment of two Origin 600 ADCPs in January 2024. This blog looks at the data gathered and how they performed during this unexpected weather event.

Blog: Monitoring waves and currents for floating offshore wind

A trial to understand the dynamics of cable movements in floating offshore wind installations provided the opportunity to also trial real-time measurements (logged every 20 minutes) of waves and currents using an Origin® 600 Acoustic Doppler Current Profiler (ADCP) in the same location. This blog examines the results of the trial and looks at how Origin 600 could be utilised for other similar applications.

An innovative, robust acoustic design

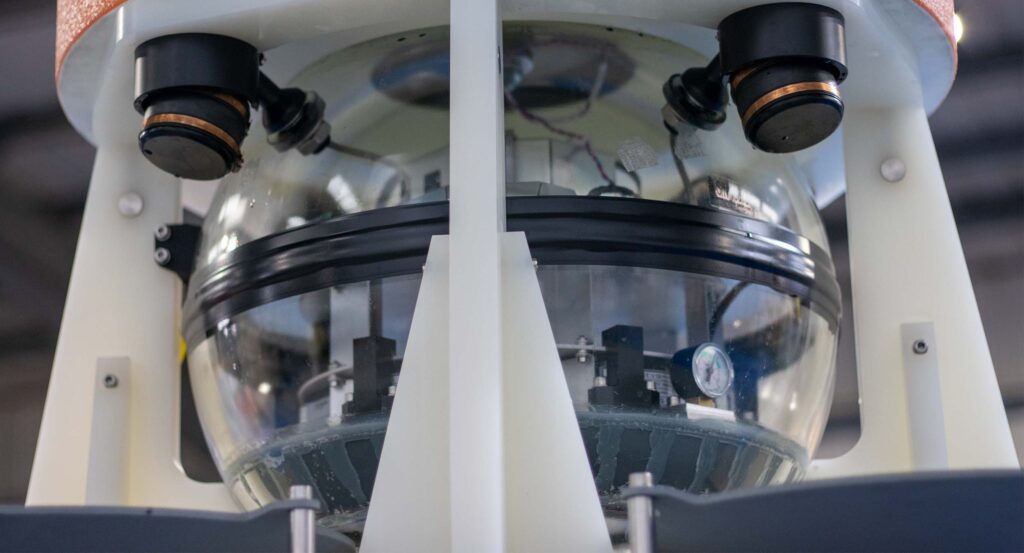

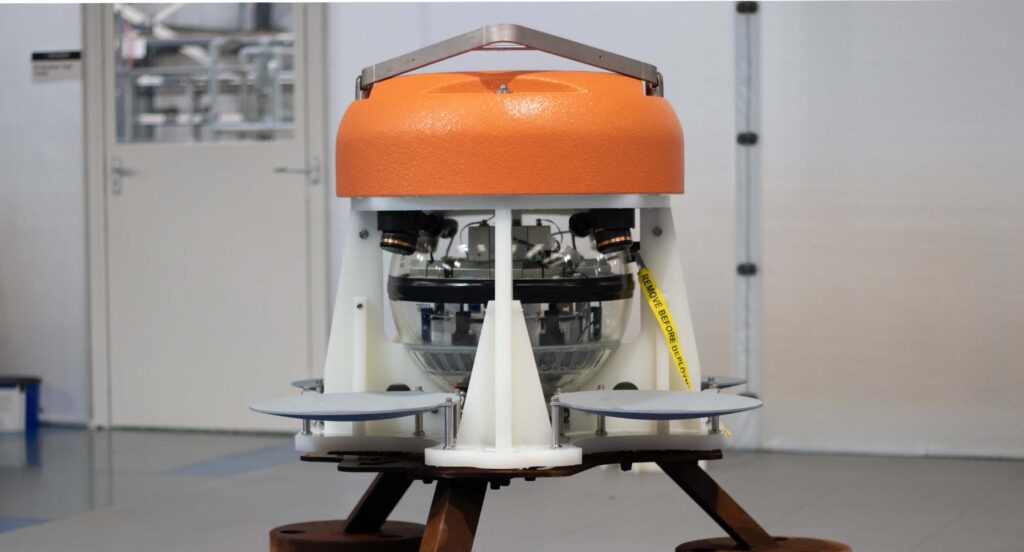

Its pioneering satellite-dish design allows Origin 65 to match or exceed the acoustic performance of competing instruments. All while reducing your costs, prolonging battery life and increasing robustness to pressure cycling – a long-standing problem with low-frequency ADCPs.

Connect to the subsea world – integrated modem and PIES

Check or reprogramme your Origin 65 acoustically while on the seabed via its integrated acoustic modem. There’s no need to retrieve the device or interrupt your operation.

During your operations, Pressure Inverted Echosounder (PIES) measurements are interleaved with current profiles. This allows time-of-flight (TOF) and average sound velocity (SV) to be determined in-situ alongside the ADCP sampling and the data fused in PD0, delivering all data time-aligned in one place.

At the end of a deployment, the modem can be used to trigger the integrated acoustic release, allowing the device to float to the surface for retrieval.

Don't just settle for standard – introducing A-gram and B-gram data

Your Origin 65 delivers industry standard PD0 data format as default, but why settle for standard when you can have up to ten times greater resolution?

Origin generates our exclusive A-gram and B-gram formats. These offer up to ten times greater spatial resolution than PD0 and expose raw acoustic data which you can them interrogate for your specific operations.

Origin ADCP – Edge enabled

Edge lets you run data processing apps on Origin 65 which are customised to your exact needs. The system will produce the information you are most interested in, rather than bulky raw data that would normally be processed once the device is recovered. You can harvest this data as a file or as a live stream, either through a cabled connection or Origin 65’s integrated acoustic modem.

What is Edge? Discover the key to your customised ADCP data…

Edge computing gives you the ability to write your own apps for Origin via our Software Development Kit (Edge SDK) so that you can focus on the data you need from your operation. To get you started, some of the apps already available to download include simple background currents and quality metrics.

Data gathered by your Origin can also be processed to your requirements within Edge before it is harvested. This minimises both the amount of unnecessary data in each upload and the time taken for each harvest.

Learn more about Origin

Acoustics

• 62.5 kHz operating frequency

• Works with Ranger 2 USBL acoustics

• LMF frequency modem (14-19 kHz)

• Integrated acoustic release

Design

• Innovative acoustic design

• Onboard Edge processing

• Free fall deployment and recovery

• Supports post capture USV data harvesting

Performance

• 800 m profiling range

• Minimum cell size of 120 mm

• Innovative software ecosystem

• 4,500 m operational depth rating

Ownership

• Works with your existing Ranger 2 USBL system

• Warranty: 1 year return to Sonardyne service centre

• UK Export License: Yes

• Comes with Origin Scheduler, Viewer, Portal and Topside software as standard

Specifications

| Features | Type 8323 | |

|---|---|---|

| ADCP | Operating frequency | 62.5 kHz |

| Maximum profiling range | 800+ m (depending on water environment) | |

| Minimum cell size | 120 mm | |

| Minimum blanking distance | 12 m | |

| Velocity range (along beam) | Up to ±2 m/s or 3.75 m/s user selectable | |

| Velocity RMS | 0.5% of measured value | |

| Maximum number of cells | 2,500 | |

| Maximum ping rate | 1 Hz (4 beams) | |

| Beam width/angle | ±2 degrees / 20 degrees | |

| Acoustic modem | Operating frequency | LMF (14–19 kHz) |

| Sensors | Temperature | -5° to 35°C |

| Heading accuracy/resolution | ±1°/0.1° | |

| Pitch and roll accuracy/resolution and range | ±1°/0.1° & ±90° (pitch), ±180° (roll) | |

| Pressure (high precision) | ±0.01%. 6,000 psi (4,100m depth) max. (higher rated options available on request) | |

| Communication and logging | Communications | RS232, Ethernet and acoustic modem |

| Internal logging | 1 TB internal memory | |

| Output | Output telegrams | PD0, A gram, B gram; simultaneous output |

| Electrical | External power | PoE+, adapter included |

| Power | 15 mW (sleep), 16 W (pinging), 20 W (fully active) | |

| Disposable battery capacity | 504 Ah dual battery; single and triple battery options available | |

| Full/scheduled/standby lifespan | 6 weeks/2 years/12 years | |

| Environmental | Depth rating | 4,500 m depth rating3 (pressure sensor rated to 4,100 m. Deeper rated options available on request) |

| Operating/storage temperature | -5 to 40°C / -20 to 55°C | |

| Mechanical | Construction | Glass, steel and plastic |

| Connector type | Subconn: 8-way for power and comms | |

| Dimensions (height x max diameter) | 1110 mm x 1306 mm x 1324 mm | |

| Weight in air/water | 230/25 kg (excluding stand 170/-21 kg) | |

| Software | Origin Portal | Embedded Web UI for control and configuration |

| Origin Scheduler | Schedule planning and configuration tool | |

| Origin Viewer | File data inspection | |

| Origin Topside | Remote configuration and control over acoustic modem |

Frequently asked questions

How do I get an Edge license?

What is PD0?

What data formats do Origin ADCPs produce and can I transform between the different data formats?

What is an ADCP and how does it work?

What are the topside options for Origin 65?

What is the Origin Scheduler?

Why access ADCP data remotely?

What is the beam configuration of Origin 65?

What are the benefits of an integrated acoustic modem?

What is Edge?

What are sidelobes?

What are my data retrieval options with Origin?

What are the operational parameters of Origin 65?

What is Edge SDK?

What are Edge apps and what apps are available?

What is the purpose of Origin 65’s integrated PIES?

How does the Origin 65 acoustic design work?

How do I use the battery disconnect?

How do I upload an Edge app to my Origin ADCP?

Does Origin’s internal compass require calibration?

Can sediment deposits on Origin 65 reflectors affect acoustic performance?

Can I reconfigure my Origin ADCP once deployed?

Can I integrate external sensors with Origin?

Software and firmware

Datasheets

Manuals and quick start guides

Origin rewrites the story of your relationship with an ADCP

Our Origin family of ADCPs represent the latest in cutting edge underwater profiling technology. Able to analyse mean currents, waves and turbulence, and integrate with external sensors to provide pH levels, temperature and other data, Origin delivers comprehensive, reliable and timely data sets for your underwater operations.

With on-board Edge data processing and built-in acoustic modems, Origin can also process and deliver your data in almost real-time. This data is delivered in conventional PD0 format as standard but can be programmed to present results in our exclusive A-gram and B-gram formats, giving you up to 10 x greater spatial resolution detail.

Available in two models, Origin 65 for deep water profiling and Origin 600 for near and inshore waters, there is an Origin ADCP to suit your operation.

Why should you invest?

Origin ADCP family gives you the data you need, at a level of detail not available anywhere else on the market. Their ability to integrate with third party sensors unlocks additional capability and protects your investment.

Rechargeable batteries in Origin 600 give you rapid redeployment times as the unit can be recharged on the back deck whilst data is being downloaded before it’s returned to the seabed. Depending on your programme requirements, Origin 65 can operate for up to two years on the seabed before needing to replace its batteries.

Whichever size suits you best, they are both compatible with our Ranger 2 USBL equipment so you can harvest data and update your operation schedules mid-mission.

Origin 65

Origin 65 revolutionises what you can do with a deep water ADCP. It combines state-of-the-art acoustics, sensors, and data into one payload providing you with an unprecedented view of the deep. It’s a versatile, reliable and high performance ADCP with on-board Edge processing for data optimisation and an integrated modem for remote control and data access.

For the full picture of what your Origin 65 is capable of, please visit its dedicated product page.

Origin 600

With a 50-metre current profiling range, on-board Edge data processing and an integrated acoustic modem, Origin 600 provides you with in-situ, high resolution measurements with on-demand data retrieval – reducing survey costs, risk and time. Choose between industry standard data formats, or our exclusive proprietary format offering up to ten times greater spatial resolution.

For the full picture of what your Origin 600 is capable of, please visit its dedicated product page.

Remote control

The integrated acoustic modem enables actions with the ADCP already in the water, delivering in-field flexibility and data assurance.

Reduced risk

Remote, safe and low-cost data: Edge customised and optimised data can be harvested acoustically with a small and efficient USV to reduce overall ship time, human intervention and associated risk.

Expanded functionality

ADCP data can be supplemented by and Edge-fused with data from external sensors so you can really get the most out of a single device deployment and the data generated.

Operational flexibility

It can support short-term and long-term current monitoring projects, using our Ranger 2 systems to harvest data for actionable insights during monitoring periods.

Overview

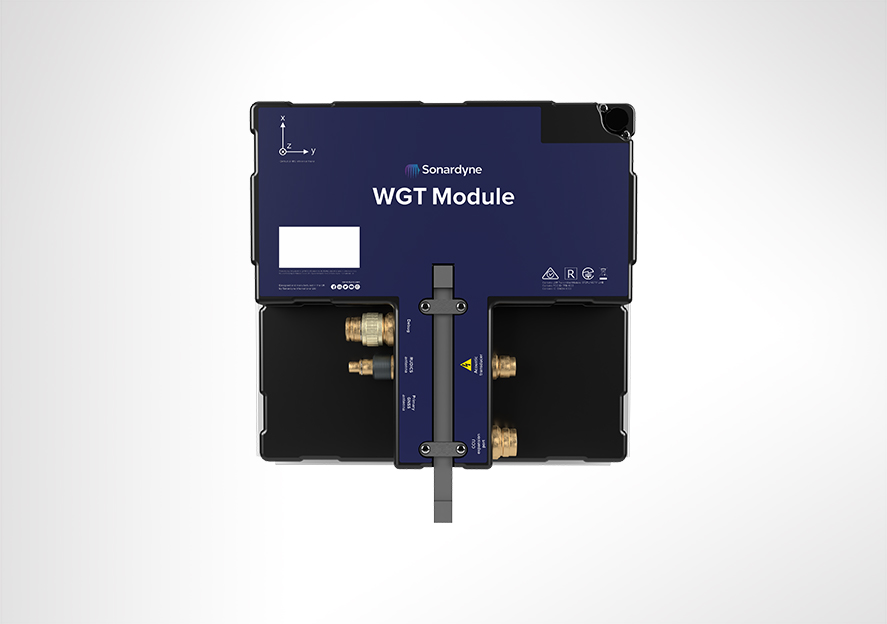

The WGT functionality enables Wave Glider to acoustically collect data from large arrays of seabed instruments in a highly cost-effective manner without the need to deploy a traditional surface ship to perform this operation. Instead, Wave Glider is controlled remotely from a shore station via Iridium satellite communications.

The WGT is capable to be used with directional transducer options for operating in both Medium Frequency (MF) (20-34 kHz) and Lower Medium Frequency (LMF) (12-20 kHz) bands to suit different seabed instruments and is fully Sonardyne Wideband® 2 compatible.

The WGT is tightly integrated into the Wave Glider vehicle communications and power systems thereby providing many of the standard acoustic commands and features associated with Sonardyne 6G® products.

Data is passed by Wave Glider to the Iridium satellite system for onwards transmission to the user in near real time.

At a glance

- Custom engineered for a Wave Glider standard aft payload space

- Provides subsea-surface-shore gateway link for Sonardyne long endurance sensors

- Enables direct remote data collection on demand, monitoring and control from shore based Wave Glider operations centre

- Integrated acoustic modem with data rates from 100 to 9,000 bps

Specifications table

| Feature | Type 8297-010-05 (WGT Module) | Type 8297-010-04 (GPS-A Module) |

|---|---|---|

| Operating frequency | MF (20–34 kHz) | MF (20-34 kHz) |

| Transducer beam shape | Directional | Directional |

| Transmit source level (dB re 1 µPa @ 1 m) | 190–202 dB (4 levels) | 190–202 dB (4 levels) |

| Tone equivalent energy (TEE) | 196–208 dB | 196–208 dB |

| Receive sensitivity (dB re 1 µPa) | 90–120 dB (7 levels) | 90–120 dB (7 levels) |

| Acoustic modem data rates | 100-9,000 bps (6 levels) | 100-9,000 bps (6 levels) |

| Dimensions (length x width x height) | 412 x 389 x 205 mm | 412 x 389 x 205 mm (standard Liquid Robotics 3 MPU) |

| Weight in air/water | 10.4/-15 kg | 10.4/-15 kg |

| Operating temperature | -10 to 45°C | -10 to 45°C |

| Storage temperature | -20 to 55°C | -20 to 55°C |

| Internal backup battery for acoustic modem | Rechargeable Li-ion (2.2 Ah) | Rechargeable Li-ion (2.2 Ah) |

| Satellite communications | Iridium RUDICS (2,400 bps) | Iridium RUDICS (2,400 bps) |

| GNSS receiver | – | Survey grade L1 & L2 receiver: Novatel OEM7720 series (GNSS derived heading) |

| AHRS device | – | XSENS MTi-300 and/or EPSON G320 SPAN INS |

| Ranging clock | – | GPS derived 4 MHz pulse conditioned to 8 MHz |

| Communication and logging: Communications | – | Wi-Fi, RS232 transceiver, RJ45 Ethernet, dedicated power and comms for GNSS and HRP, single RS232 expansion port with 5 V power pass through |

| Communication and logging: Internal logging | 128 GB dual redundant internal memory; RINEX GNSS logging; SPAN INS logging |

|

| System components | WGT Module Wave Glider Payload; 4 m Remote Transducer; Wave Glider Transducer Compatible Skeg |

GPS-A Module Wave Glider Payload; 4 m Remote Transducer; Wave Glider Transducer Compatible Skeg |