How do the Origin 65 ADCP acoustics work?

When designing an ADCP, one of the main parameters is the frequency of the acoustics. Profiling currents over long distances requires a comparatively low frequency, normally between 40 – 100 kHz or equivalently longer wavelength (3.75 – 1.5 cm). This is because the acoustic signal is attenuated less at lower frequencies. At frequencies lower than 40 kHz there are fewer suitable scatterers in the water column, which is one of the reasons why few ADCPs are made below 40 kHz.

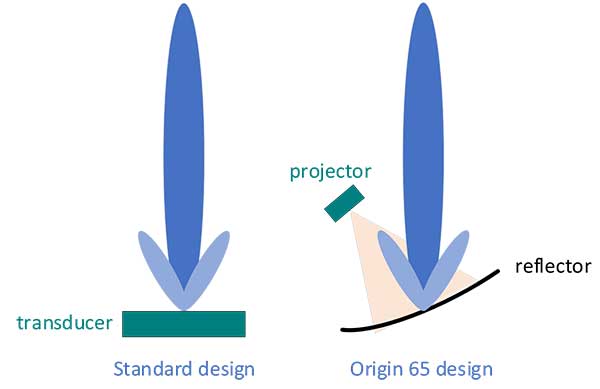

The next important parameter is the beam width θ. This describes the angular extent to which an ADCP beam is sensitive. Conventional low‑frequency ADCPs have beam widths of typically 4 – 5.5° away from the line‑of‑sight of each transducer, and ADCPs are normally designed to provide this beam width regardless of the instrument frequency.

The following relationship approximately describes the relationship between the beam width , the wavelength of the sound λ, and the diameter of the acoustic transducer, D: θ=λ/D

From this relationship, we see that to keep constant at low frequency (larger λ), the transducer diameter must also get larger. For example, to ensure an ADCP has θ at a frequency of 60 kHz (equivalent to a wavelength λ=2.5 cm), we must have D=36 cm. A standard piston transducer of this size is expensive to make due to material volume and complexity, and difficult to maintain over repeated pressure cycling due to the area of material (such as bonding glue) exposed to such a wide range of pressures.

Origin 65 uses a novel ‘satellite-dish’ design to circumvent these problems while maintaining excellent acoustic performance. Instead of large ‘monolithic’ transducers normally used, Origin 65 uses small acoustic projectors that are depth rated to over 5,000 m. This reduces D, resulting in a much larger beamwidth than is desirable for ADCP. However, if this beam is positioned at the focal point of a reflective parabola, the beam can be ‘focused’ into a more traditional beam width of around 3.8°. Thus, if a measurement of the beam pattern were made with a hydrophone at a distance of a few tens of metres from the ADCP, it would not be possible to tell the difference between a standard monolithic design and the Origin 65 satellite‑dish design. Thus, Origin 65 can make current measurements at least as good as monolithic transducer designs, while also bringing several benefits.

What are the benefits of the Origin 65 ADCP acoustic design?

There are several benefits of the Origin 65 acoustic design.

First, the small projector is more cost‑effective and robust to pressure cycling than large, monolithic transducers – the addition of the parabolic reflector is not a large contributor to cost due to the low price of steel. This translates to lower cost of ownership, and more reliable operations, particularly in deep water.

Second is that making the reflectors is comparatively easy: There is little to go wrong in manufacture and only a single material is used, meaning that the reflector size (which ultimately determines beam width) can be made larger than would be possible with the traditional design. A larger reflector means narrower beams – more power in the direction you want it. Compared to an equivalent monolithic design at 62 kHz, the Origin 65 beams provide an extra 2.5 dB directivity. This means that battery life can be extended as around half the power is required per ping to reach maximum profile range, reducing the number of costly maintenance and battery refurbishment cycles.

Finally, the design makes in‑field repairs easier. Each projector and reflector can be detached from the instrument and replaced. The mechanical tolerance of the projector/reflector, and the instrument itself, is such that beam alignment calibration is not necessary prior to redeployment

Contact [email protected] for more information.