Overview

Dynamic and fast

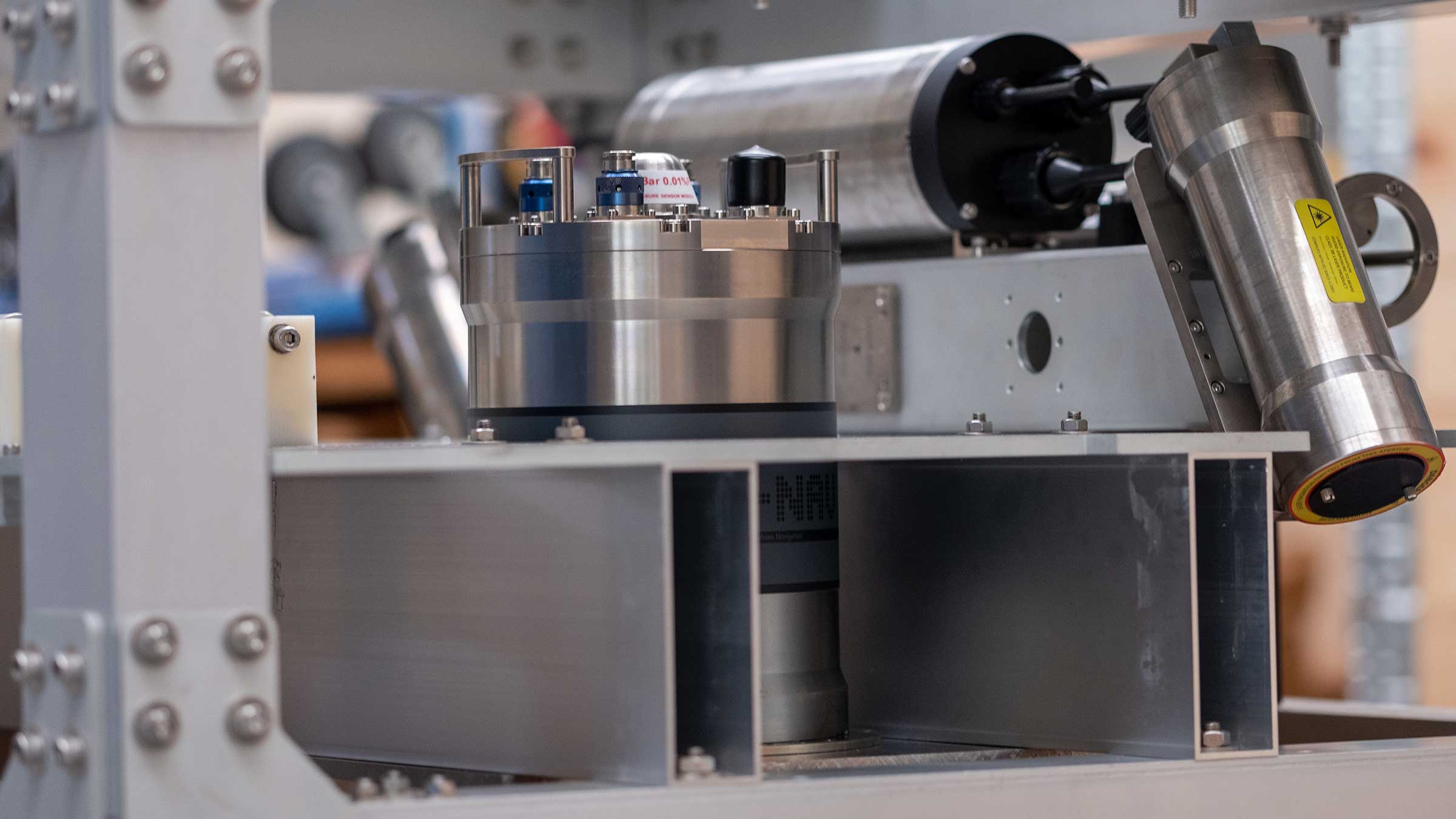

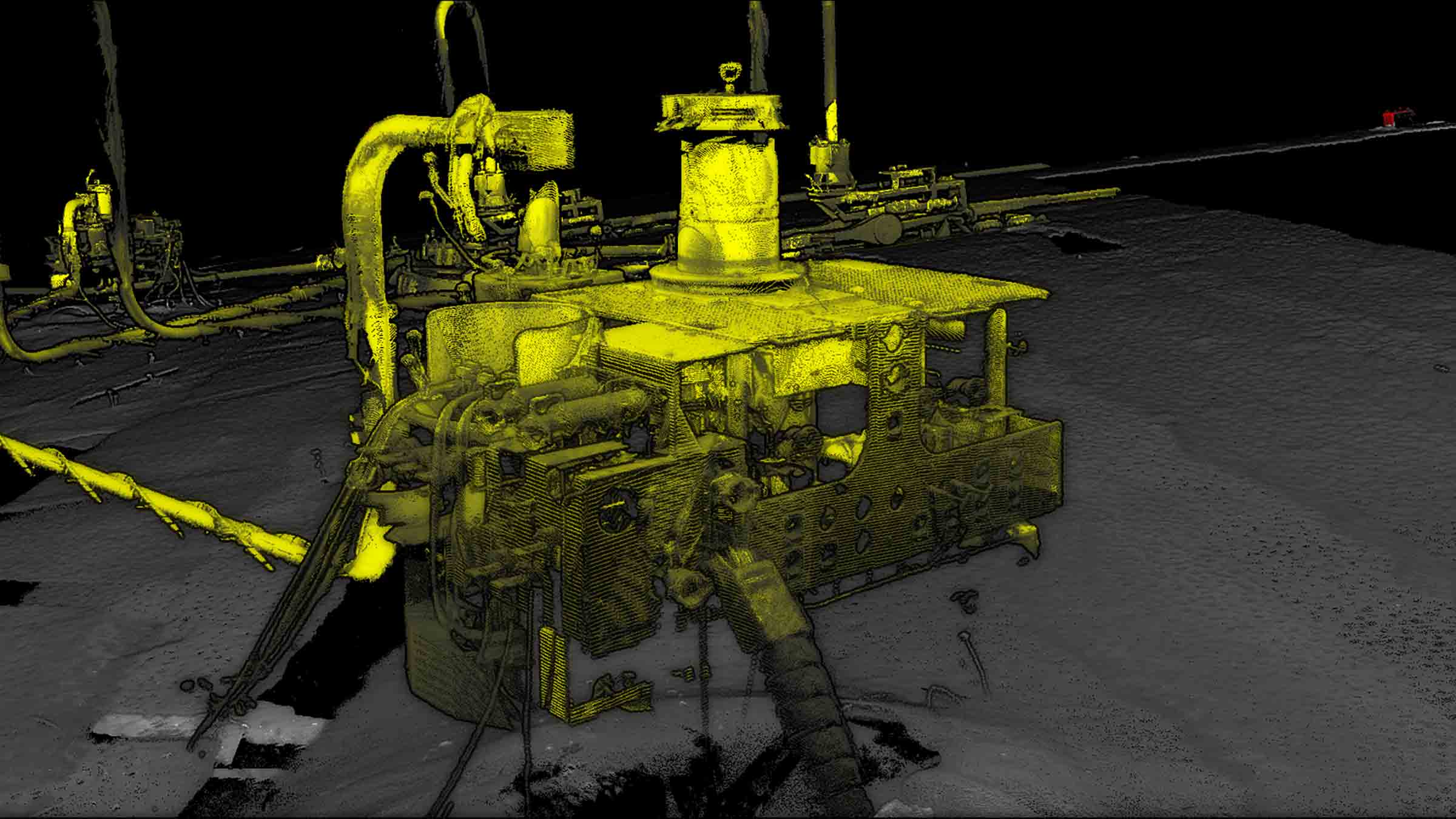

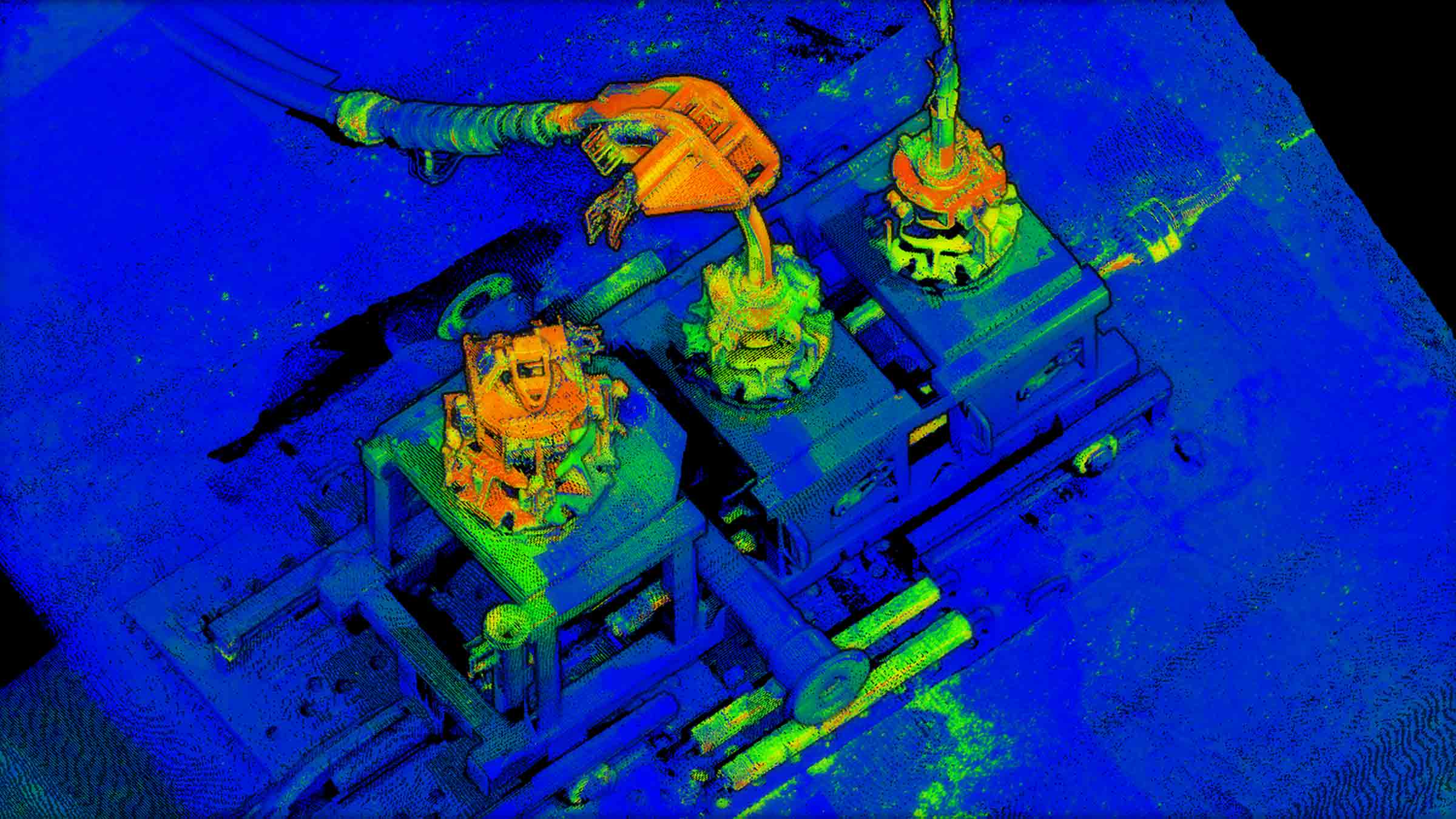

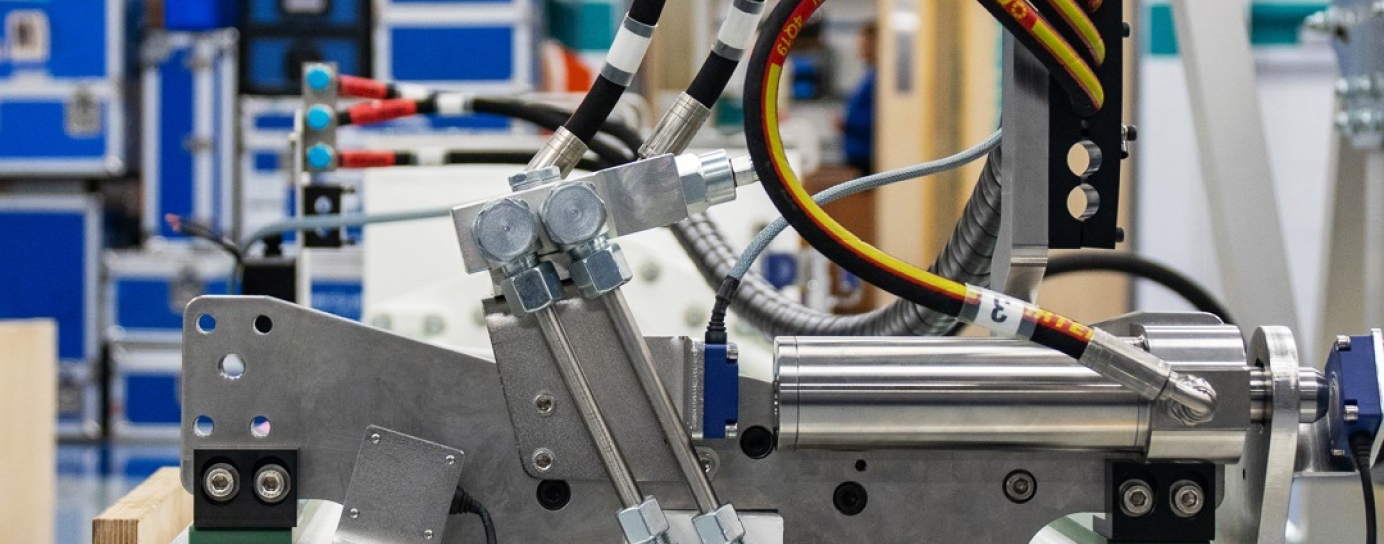

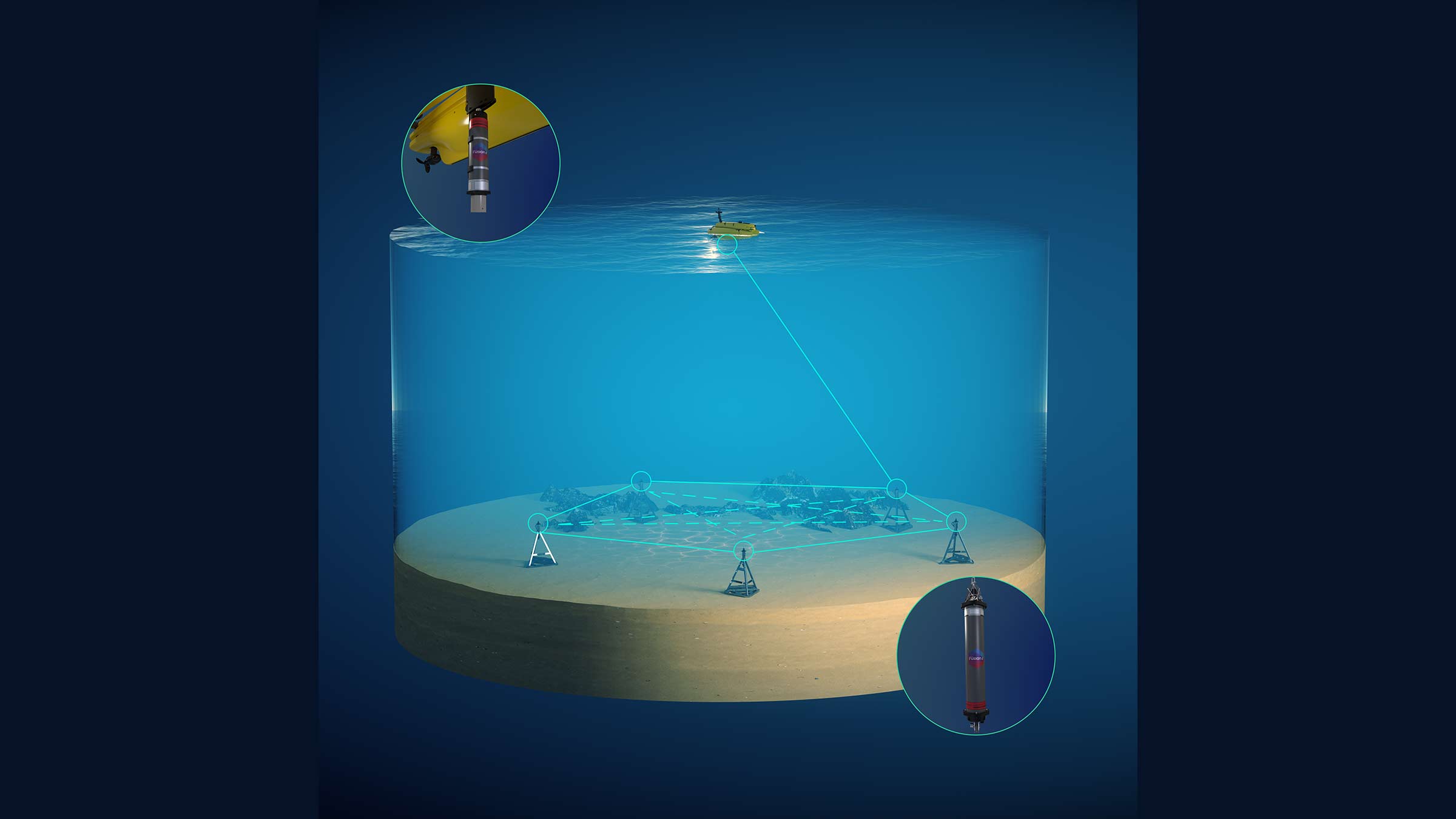

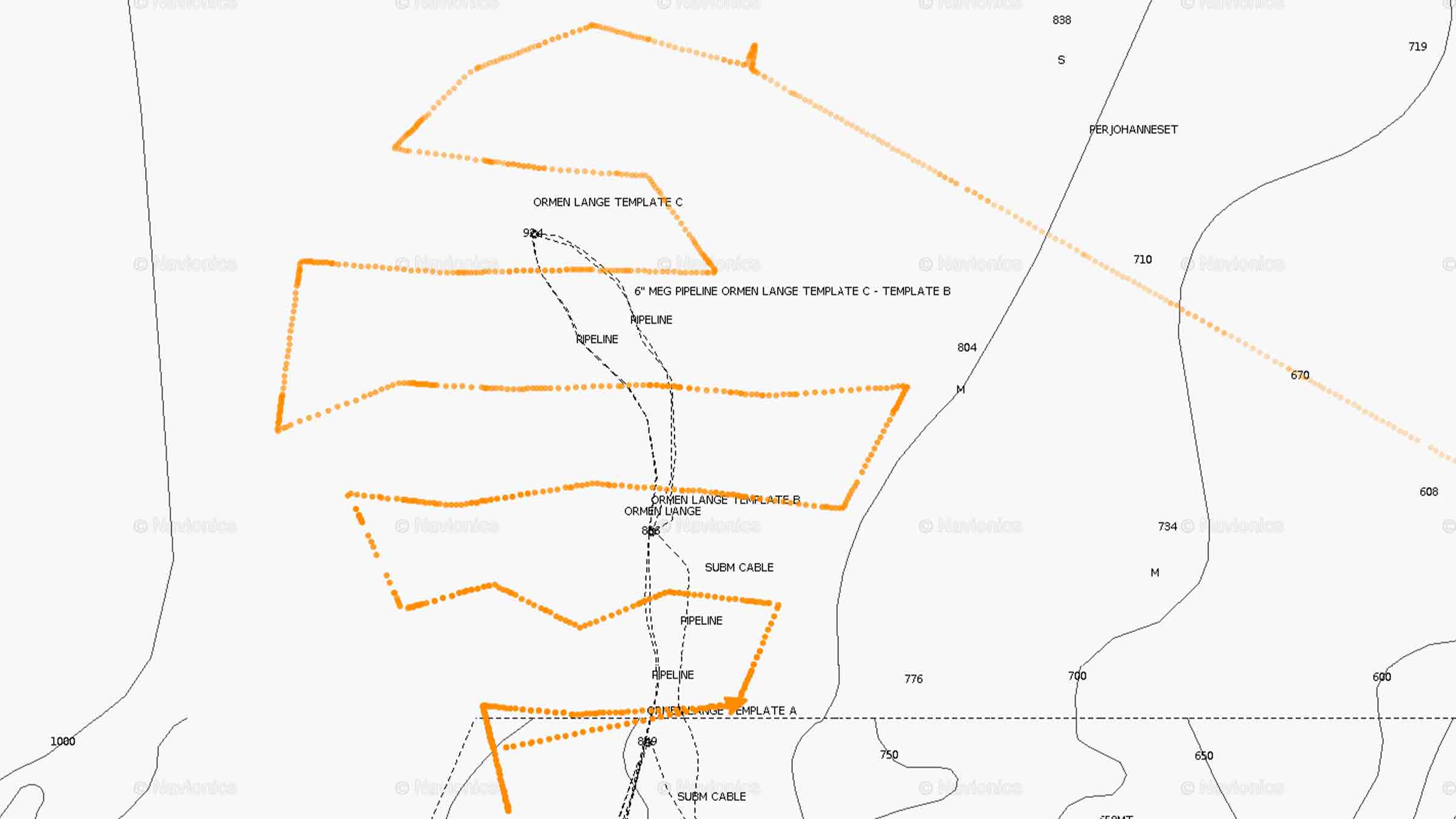

Our dynamic laser scanning skid is a turn-key survey solution comprising of all the hardware and software, pre-configured and calibrated, to enable simple and fast mobilisation, efficient acquisition, and if needed, in-person or remote support from our expert surveyors.

The skid is fitted with a SPRINT-Nav, ROVNav 6+, sound velocity, conductivity and temperature sensors, and a custom Voyis ULS500 Pro.

All the sensors are interfaced via an Innova Titan Matrix MKII+ multiplexor.

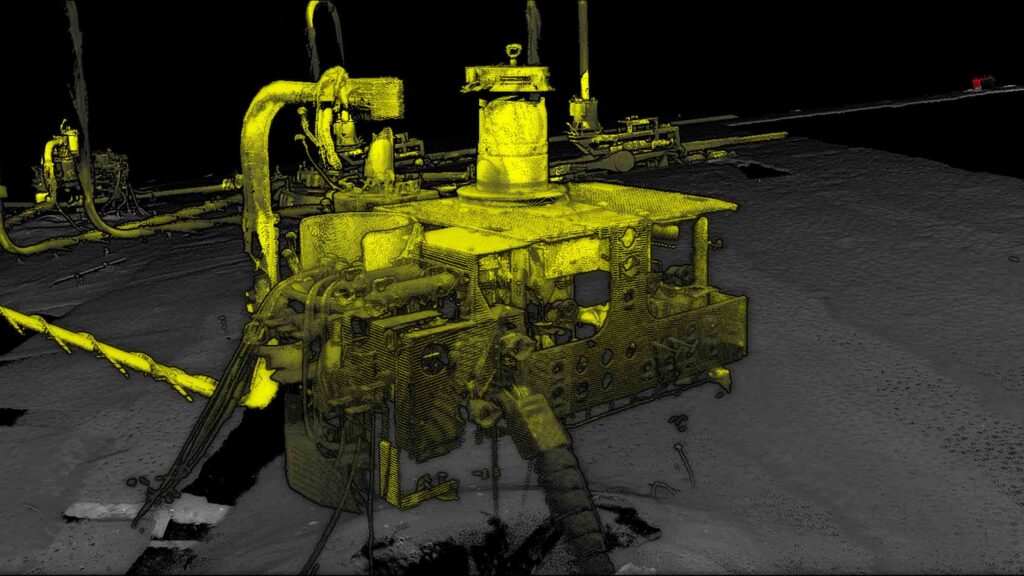

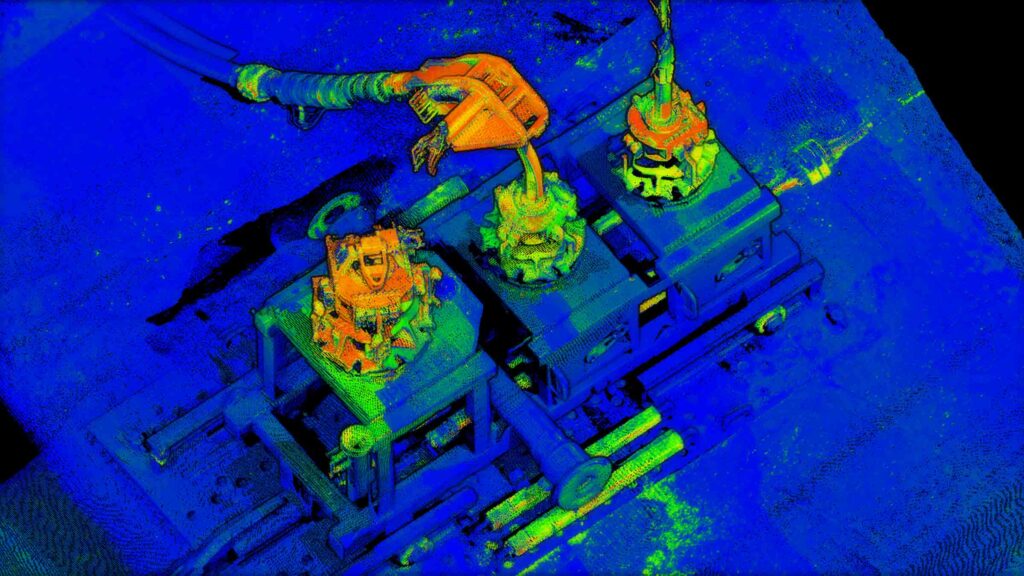

Until now, because dynamic centimetric-level navigation with fast update rates has not been commercially available, subsea laser and LiDAR systems have predominantly been used in a static mode. Due to the relatively short ranges achievable from these systems, multiple scans are required involving relocating the system to a number of locations on the seabed. Operationally, this is time consuming, both in terms of physically relocating the scanner, waiting for the visibility to clear after the scanner has been placed on seabed, and then processing time to merge the data together. It also means scans are limited to side, ground-level views.

With our dynamic platform, a site can be mapped quickly with no issues of reduced visibility as the ROV does not come into contact with the seabed and can move to scan any target of interest – including from above. High resolution point cloud data can contain a wealth of information which can be utilised for various engineering requirements, including revealing previously unknown features.

At a glance

- Fully DNV certified

- Rated to 4000 m

- De-risk your surveys: all sensors are interfaced and ready to go

- Sensors are pre-calibrated saving valuable offshore time

- Designed for Workclass ROVs

- Simple plug-and-play interfacing only requires power and fibre communication with ROV

All-in-one service

-

A tightly integrated, acoustically-aided navigation solution capable of meeting any positioning specification

-

Integration with other Sonardyne Group companies, Voyis and EIVA, enable the full package to be provided and supported

-

Help with planning your operations via our Survey Support Group

-

We are able to provide experienced surveyors to assist with operations, either offshore or remotely via our ROAM service

-

Navigation post processing service available

Technology differentiators

-

We aid SPRINT-Nav with tightly coupled two-way acoustic travel times, with each range received individually and precisely time-stamped

-

We combine individual Syrinx DVL beam velocities within SPRINT-Nav rather than generic DVL XYZ velocity

-

All acoustic aiding (LBL and DVL) uses rich proprietary quality metrics, and timing is guaranteed to the micro-second level

-

SPRINT-Nav INS provides direct time synchronisation (1PPS) for the ULS500 Pro, removing risk of issues with latency or timing jitter on ROV MUX communications to topside

-

Our Janus software is an extremely powerful tool for ensuring the very highest quality post-processed navigation with full QC of data. It performs both forwards and backwards post-processing of the INS data.

-

Logging of relative tidal data from a Compatt 6+ that can be used in post processing

Energy

Dynamic laser scanning enables large offshore sites to be mapped quickly and with complete precision, meaning complex structures and drill centres can now be scanned whilst minimising vessel time.

Science

With our skid attached to your deep water research ROV, large areas can be mapped in high resolution, including entire wrecks and flora and fauna for habitat classification and population surveys.

Save time during data acquisition

• Comprehensively scan large areas with no gaps in coverage

• Cut survey time: no need to relocate sensor and wait for visibility

• Can operate in reduced turbidity due to being on a dynamic platform

• Scan items of interest at shorter range, in higher density without the need for relocating equipment

De-risk operations

• Backed by our global customer and survey support group network

• Our laser skid is DNV rated for commercial, work-class ROV operations

• All equipment is supplied with the latest software and firmware, meaning no compatibility issues

• The factory-supplied equipment is pre-configured to ensure it can be mobilised as quickly as possible while reducing risks and complexity commonly associated with sensor integrations from several different vendors

Overview

Our Survey Support Group offer additional, specialised services for large and complex in-water operations including planning and project consultancy.

We have a globally distributed team of engineers, each an expert in their chosen product specialty and fully certified to work offshore. We handpick the person with the skills and experience best matched for job in hand, so you can be confident your system’s performance will be optimised, your staff will be left confident in its operations, and live operations are de-risked are far as possible.

And to ensure that your equipment always performs as it should, our service extends to checking the health of your Sonardyne system, including updating software and firmware and inspecting safety critical items.

Remotely located

Whilst not a complete replacement for in-person, many tasks can now be completed by our engineers working remotely, on-demand including; system calibrations, health checks, software upgrading and set-up checks. This lowers your costs, is more immediate (no travel delays), reduces safety risk to personnel, and helps reduces the carbon footprint of your operation. Innovations such as ROAM underpin this capability, whilst our Remote Data Harvesting Service using USVs can entirely replace the need to send personnel offshore altogether.

At a glance

- Available 24/7, 365 days of the year

- Staffed by experienced personnel, fully certified to work offshore

- Personnel handpicked to meet the requirements of your project; engineers, surveyors, application experts

- Teams based globally providing ‘follow-the-sun’ cover

- Remote support helps deliver safe, green, efficient operations

Energy

Offshore, every second counts towards delivering a project on time. Our experienced teams understand these pressures and know how to get best performance from your investment in Sonardyne technology.

Science

Having our field engineer on onboard your vessel helps your research run to plan. And with remote services like ROAM, we can now be virtually by your side.

Uncrewed offshore services

• Specialist service in addition to offshore field operations

• Run by our dedicated Applications Group

• Full service; we take care of your entire data collection and delivery

• Or supported service; we optimise your existing USV to gather data

• Support can be delivered offshore or remotely

• Available for one-off missions or multi-season campaigns

Operational survey services

• Specialist service in addition to offshore field operations

• Run by our dedicated Survey Support Group

• Support can be delivered offshore or remotely

• Qualified surveyors experts in complex LBL, INS and USBL operations

• Report to your party chief during operations; 12 hour shift patterns

• Have access to a range of in-house tools to assist with project planning and procedural review

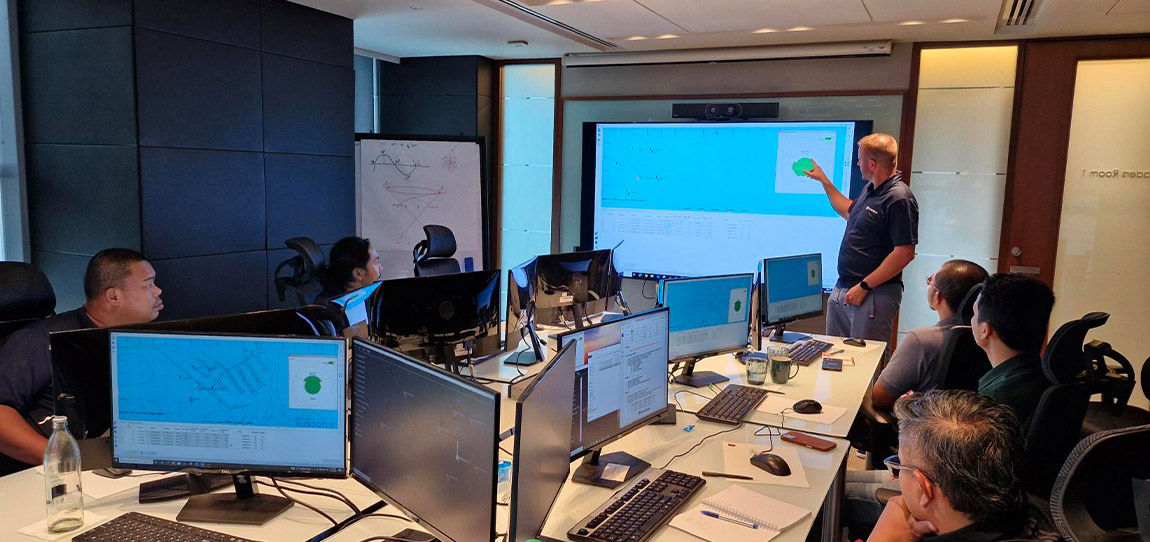

Overview

Our technology specialists help to de-risks projects, reduce equipment spreads and save vessel time, is now extended to support a wider range of our technologies and organisations working in defence and science, and operational services we can work directly for you; either in person or remotely located. Underpinning Technology Services is the five decades of knowledge and experience we’ve accumulated. Each team member has direct experience of every type of marine environment, and assisted on every type of project; from installing large oilfield structures to search and salvage. Their knowledge also feeds back into our research and development activities to ensure future products meet your needs.

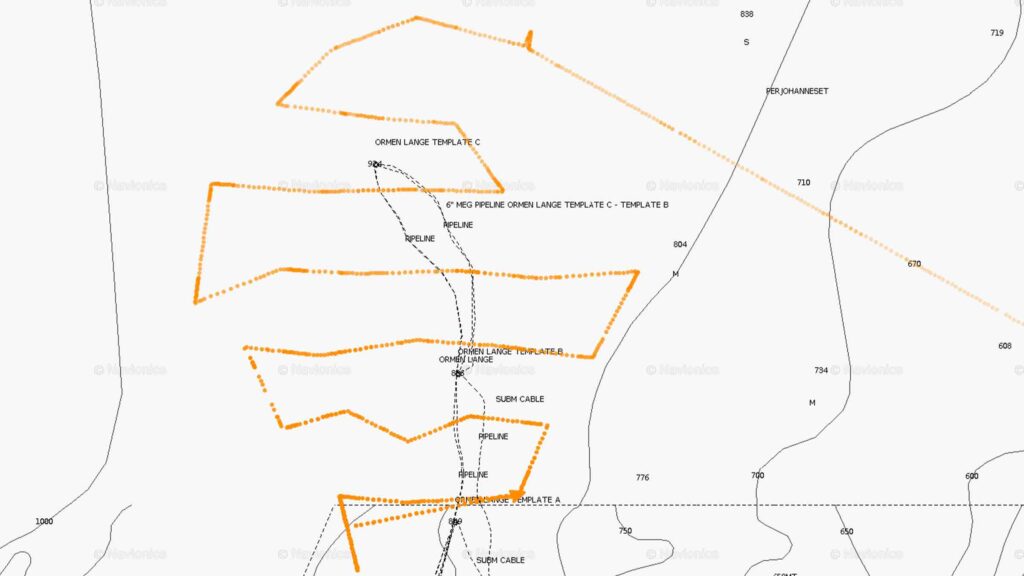

Planning makes perfect

Technology Services’ goal is to make sure that when your project gets underway, you’ve got the right spread of hardware deployed, the right operational procedures defined, and the right settings set in hardware and software to ensure success.

Within energy, Technology Services regularly assist survey companies and contracting companies when planning the size and configuration of seabed transponder arrays. These might be for a one-off project, for example, precision spool piece metrology, or increasingly, a complete life-of-field network.

Technology Services has at its disposal a number of exclusive performance predication and simulation tools for USBL, LBL and INS. In the case of an LBL array planning, the team can use the process to calculate whether transponders deployed on the seabed will be able to ‘see’ each other and acoustically communicate. Using the software, the group is able to produce a number of different array plans until they arrive at a design that meets the positioning specification of your project.

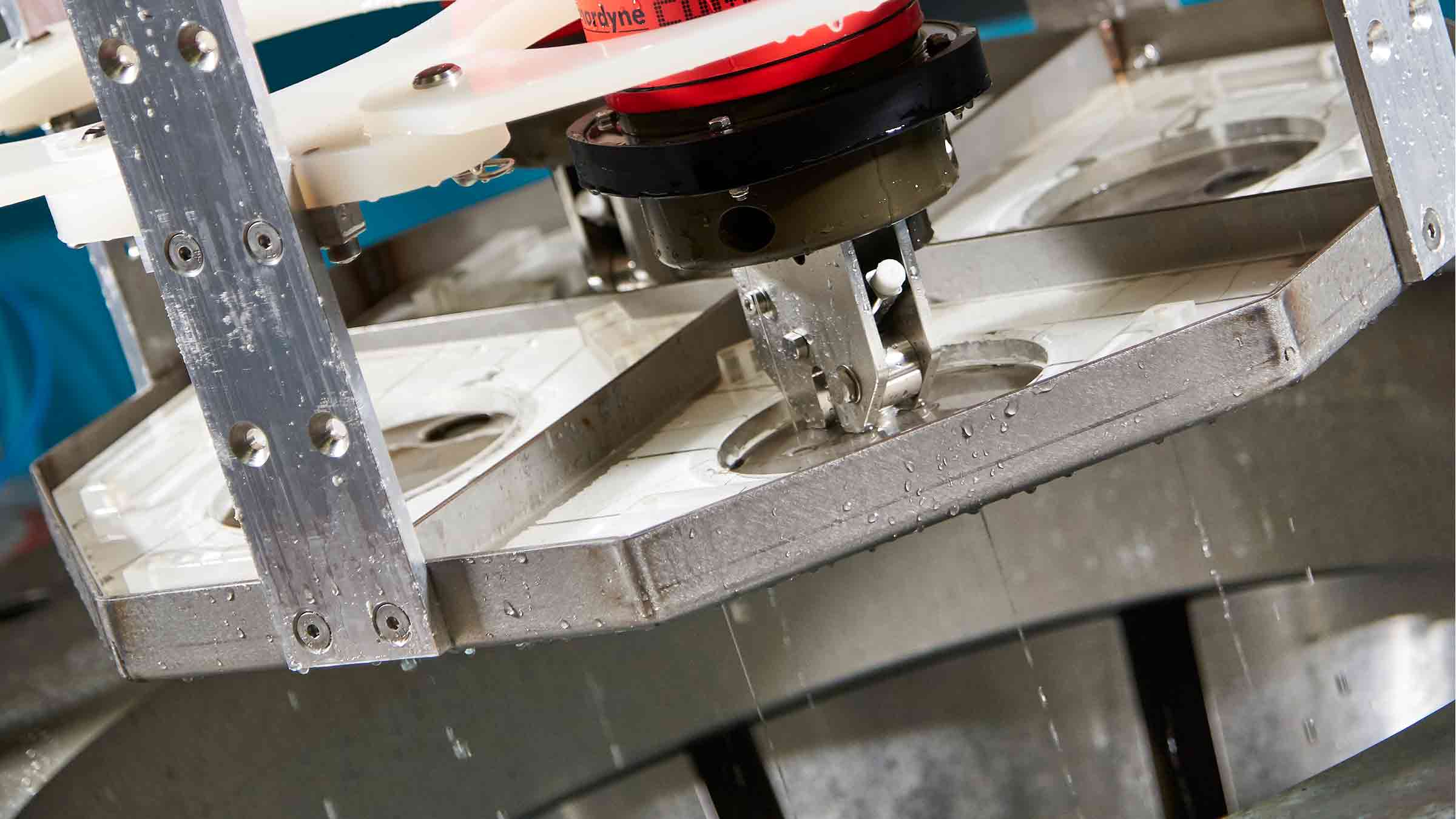

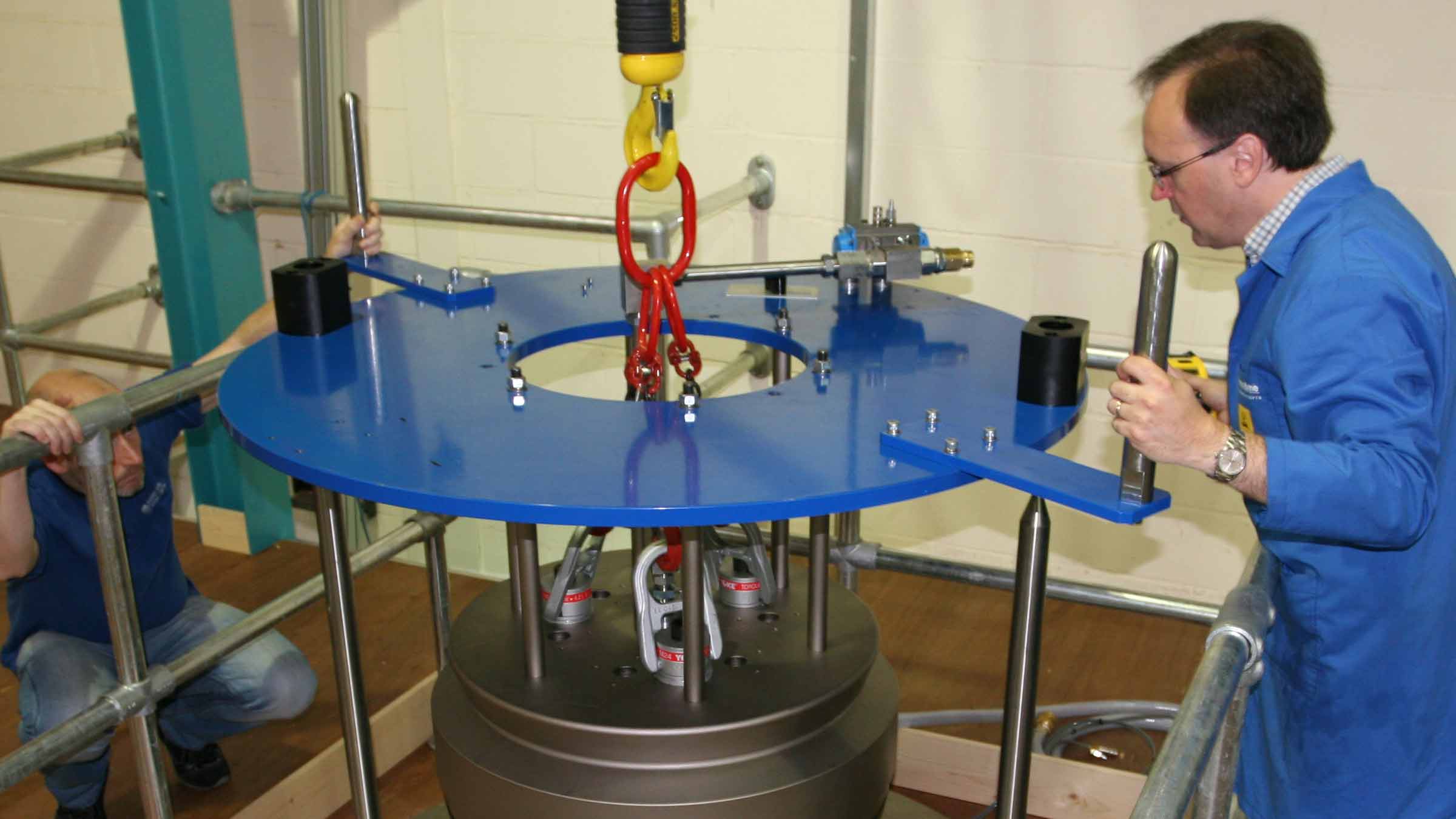

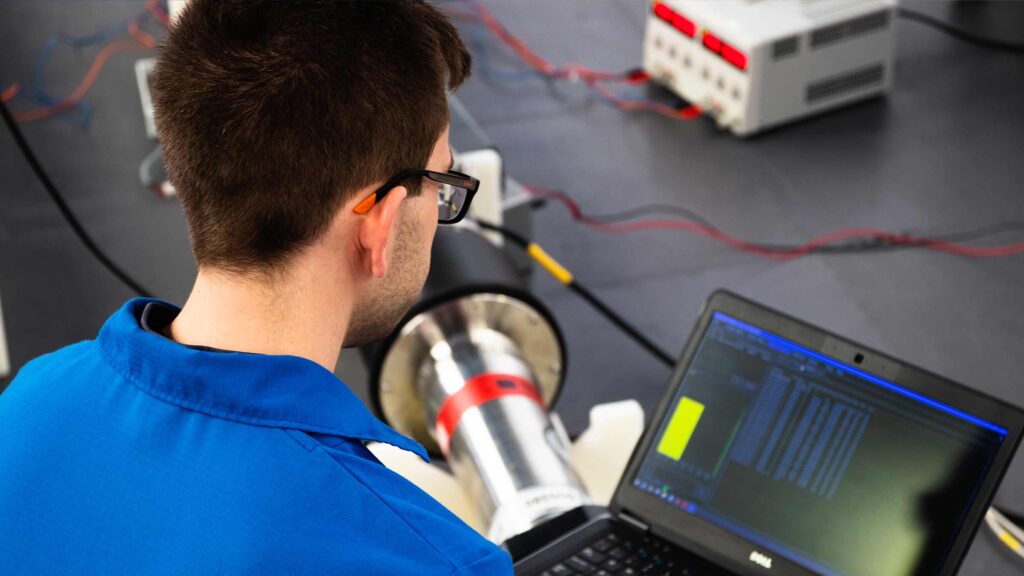

Project simulation

Project simulation is a logical risk minimiser and at our sea trials centre in Plymouth, south-west England, Technology Services can demonstrate all types of USBL, LBL and INS operations with hardware deployed in the water. This ensures that potential problems or operational complications can be identified and overcome beforehand, and you’re able to familiarise yourself with the project set-up and system configuration prior to mobilisation.

Workshops

Technology Services regularly run workshops to demonstrate the way in which a company might approach a particular project, highlighting the operational efficiency gains of our latest innovations. The workshops are free to attend and are run in-person internationally or online. Get in touch if you want to attend.

At a glance

- Fully trained and experienced offshore personnel

- Designed to de-risk your operations; saving time, reducing project delays

- Specialists in optimising Sonardyne technology for complex, real-world applications

- Available for tasks including; array planning, interfacing, procedure review and writing, choosing the correct equipment spread and system setup

- Specialists available to work remotely or offshore as part of your team

- Free technology workshops to keep you up-to-date on best practise

Energy

Technology Services ensure that you get the very best performance from your Sonardyne acoustic positioning, communications and inertial navigation technology for oil, gas and renewables projects.

Science

Make every minute collecting science data count with help and advice from Technology Services – either alongside your marine crew or remotely accessing and fine tuning your equipment settings.

Our team

• Qualified surveyors and engineers certified to work offshore

• Experts in complex LBL, INS and USBL operations

• Familiar with a wide range of offshore operations

• Works for, and reports to, you when on assignment

• Specialist knowledge of, and access to, Sonardyne products, systems and in-house tools

Planning and consultancy

• Helps lower risk, vessel time and project costs

• Identifies opportunities to adopt new methodologies and innovations

• Access to specialist performance modelling tools

• Detailed advice and review of operational procedures

• Can include services such as simulation ahead of live operations

Overview

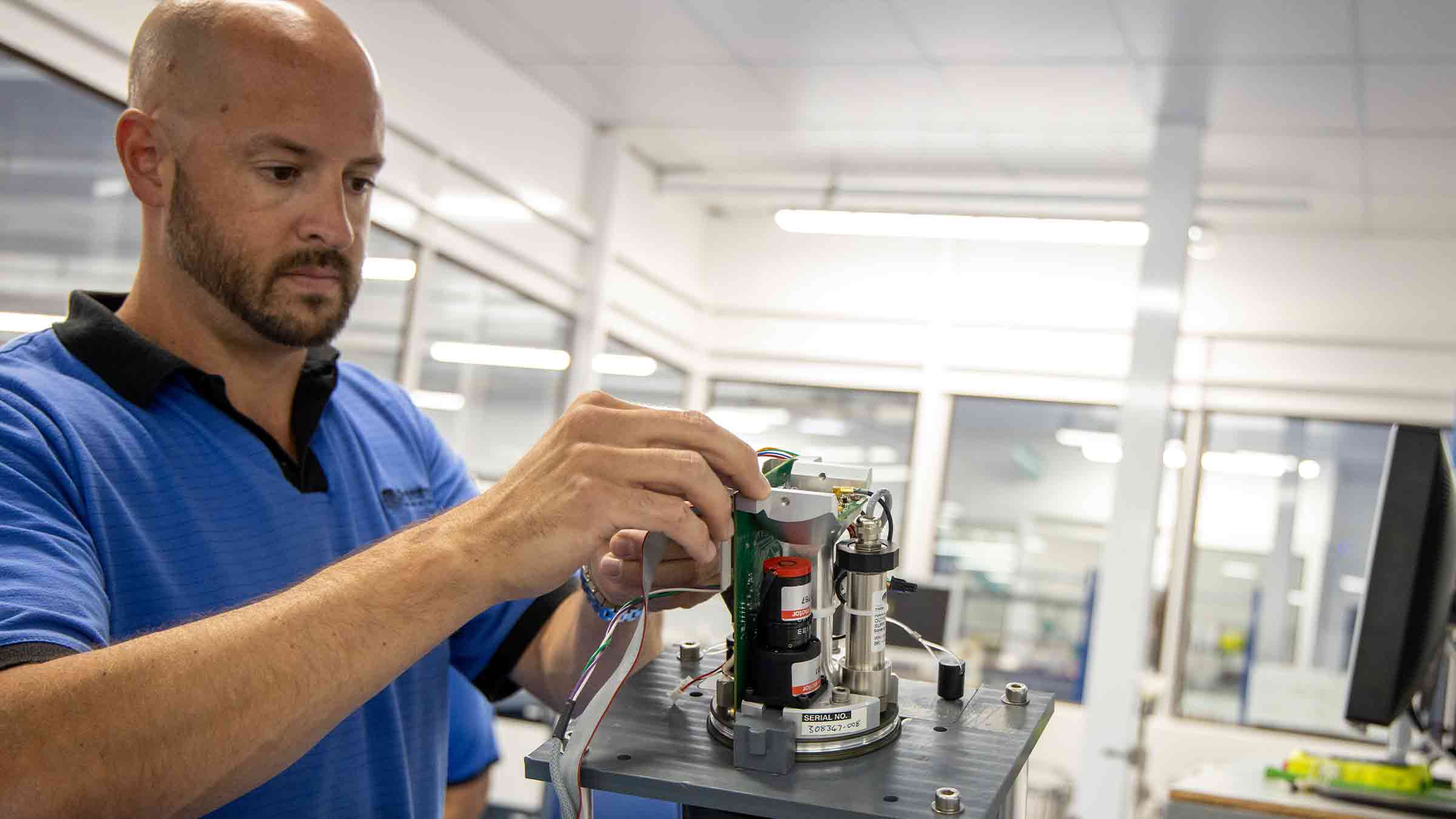

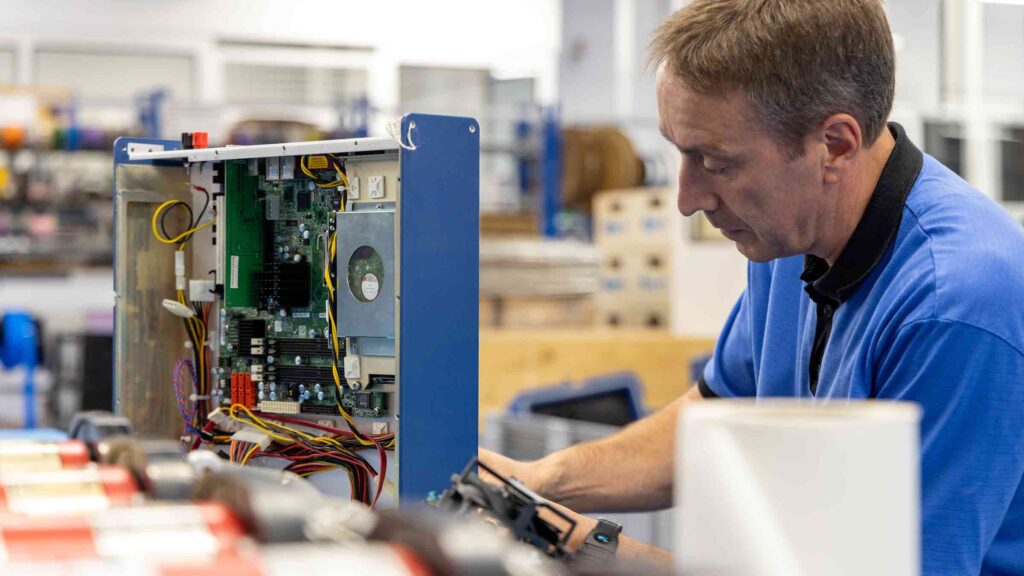

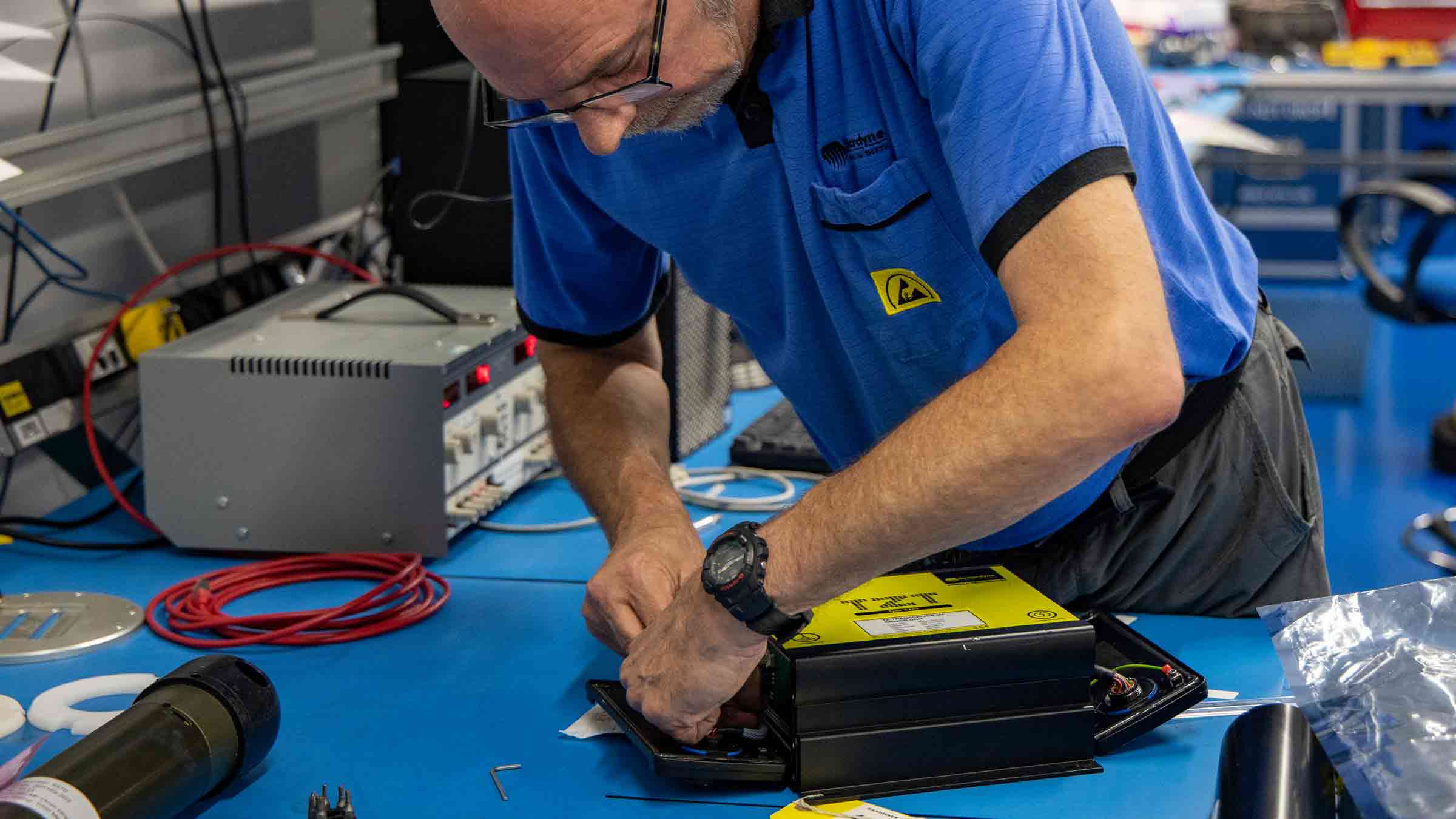

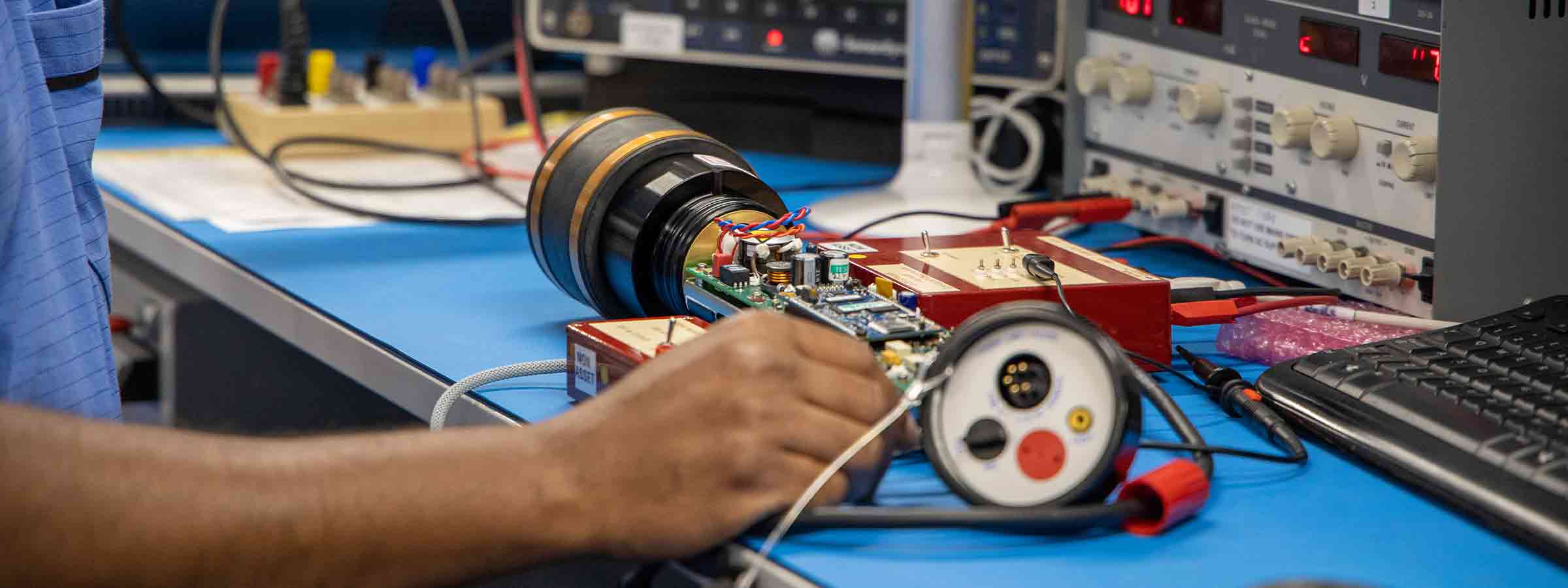

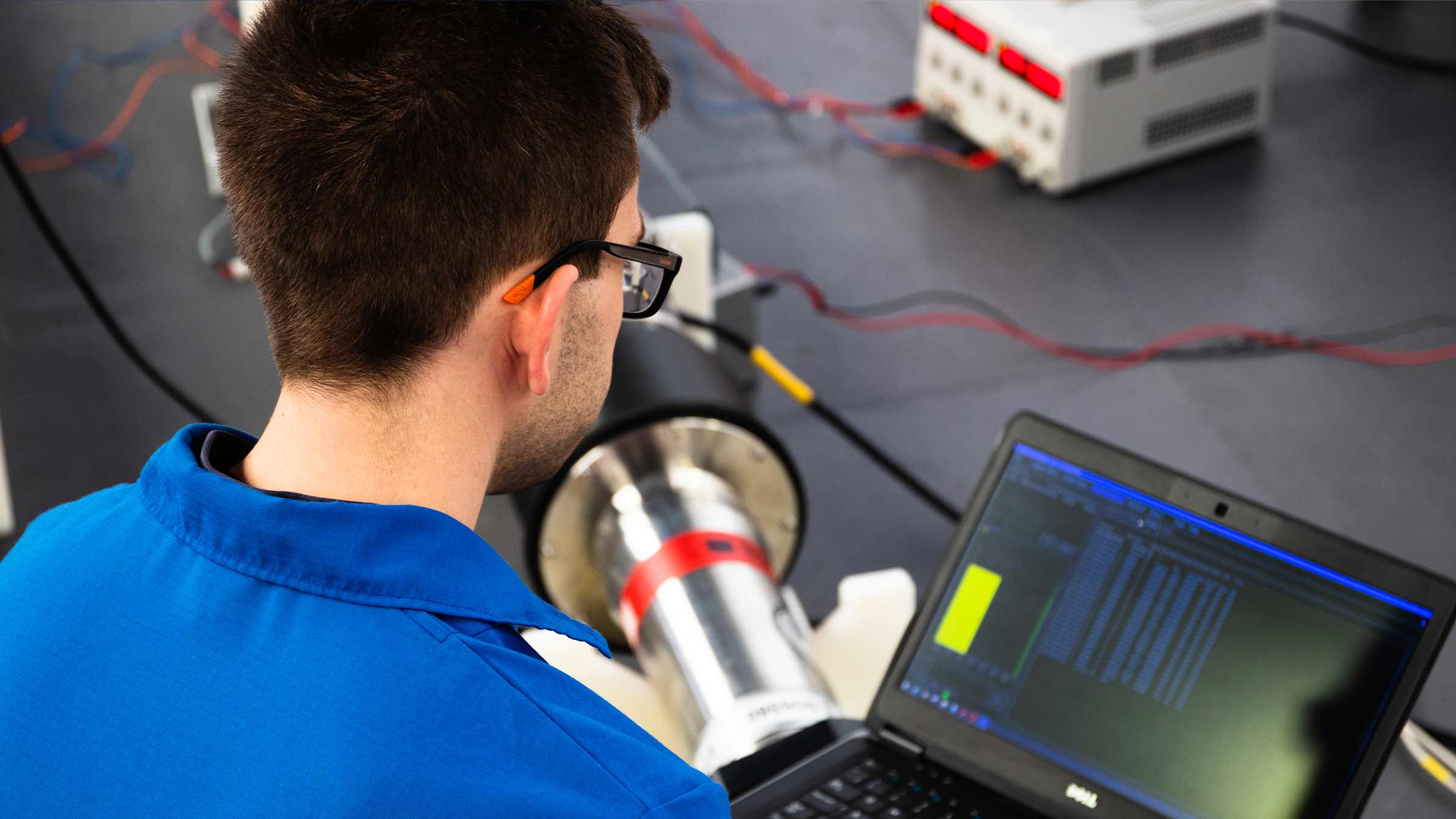

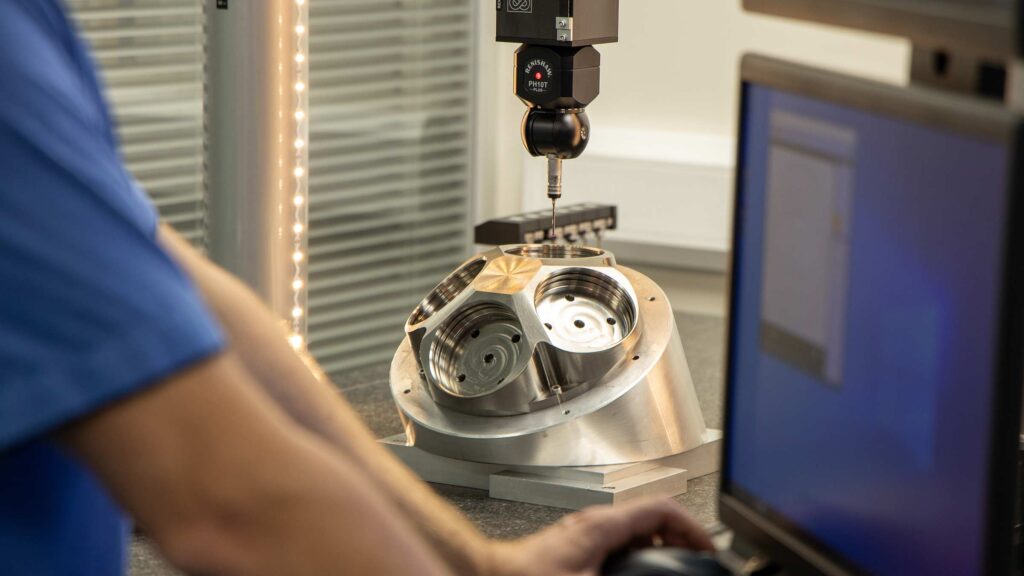

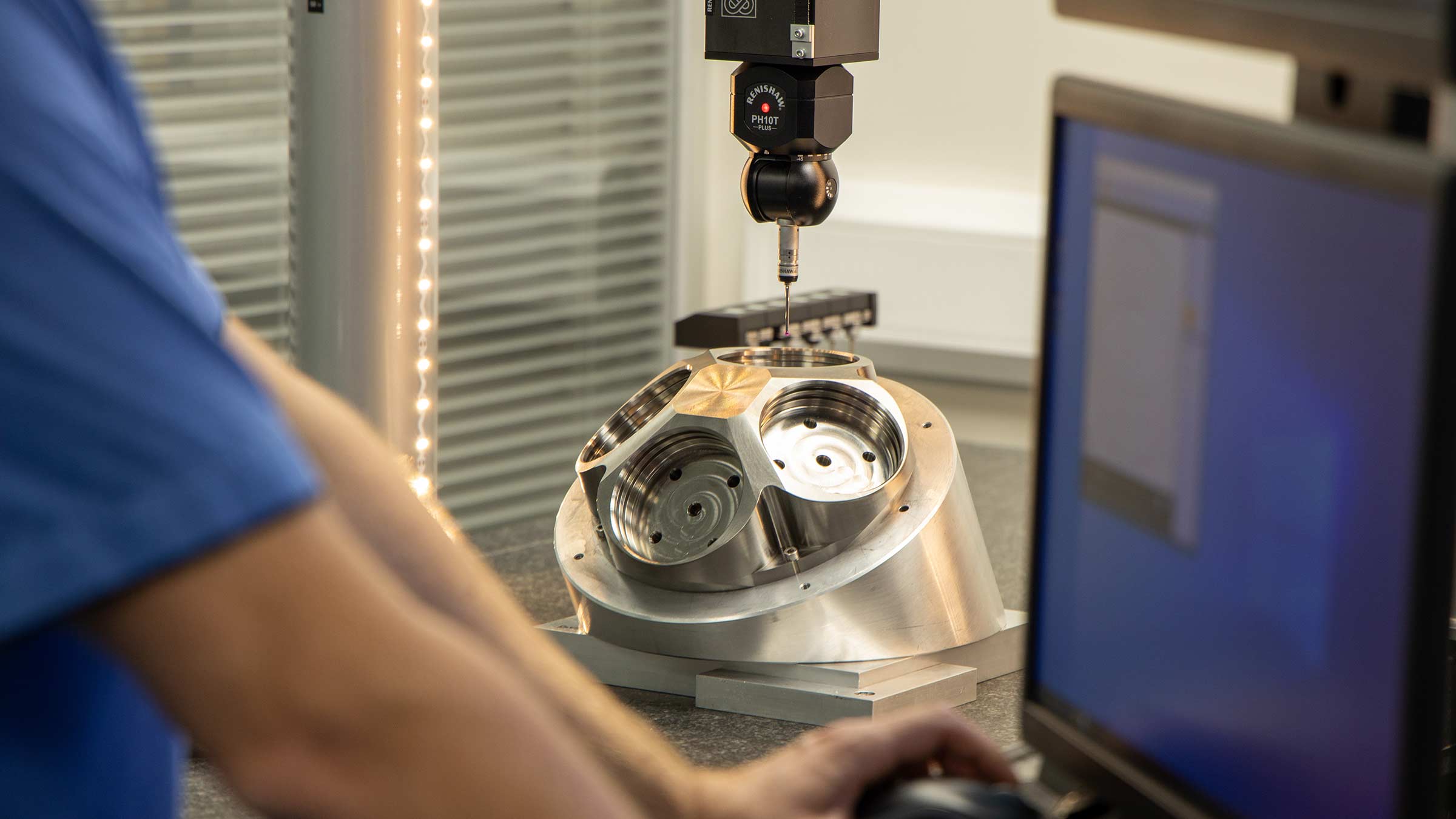

Our global centres and factory-trained engineers offer cost-effective repair, preventative maintenance and specialist sensor calibration services. So whether you are about to start a project or return onshore, you can be assured your that not only have we built your equipment, we’re taking care of it too.

Pre-deployment- what we check

A popular service for transponders which are factory-fitted with a variety of calibrated environmental sensors. Yet through operational use, knocks in the field and marine growth, the quality of sensor readings can degrade. This is why we recommend they undergo regular checks to ensure they remain within specification.

We regularly improve product performance and functionality by upgrading transponder firmware, so we’ll check to make sure your equipment is operating on the latest version.

Pre-deployment checks also include tank testing, where a full acoustic check is carried out. Batteries are also checked to ensure that they will last the duration of your operation.

Post-deployment – what we check

No one knows your transponders better than we do, so once they come out of the field and before you put them back on the shelves, we’ll perform a thorough diagnostic inspection. This includes checking and, if necessary, replacing the anodes, o-rings, transducers, guards and batteries.

At a glance

- Service centres located in Europe, Asia, North and South America

- Only genuine Sonardyne parts used and fitted by factory-trained engineers

- Maximises the lifespan of your equipment and reduces the need for replacement

- Preventative maintenance which helps identify potential problems early on

- Range of services on offer: repairs, sensor calibrations, pre-deployment checks

Energy

Offshore, time is money so that’s not when you want to be discovering problems with equipment. A pre-deployment equipment check with us gives you peace of mind.

Science

Time onboard a research vessel to carry out your science is hard to secure. So before your cruise season starts, why not book your Sonardyne kit in for an annual health check?

What makes our service different?

• Factory trained, experienced engineers

• Access to latest product updates

• Only genuine Sonardyne parts used

• Multiple generations of equipment cared for

• All work is warranted for 6 months

What we check and repair

• Firmware: upgrading as required

• Anode replacement

• O-ring check and replacement

• Transducer inspection

• Transducer inspection

• Sensor and transducer guard check

Overview

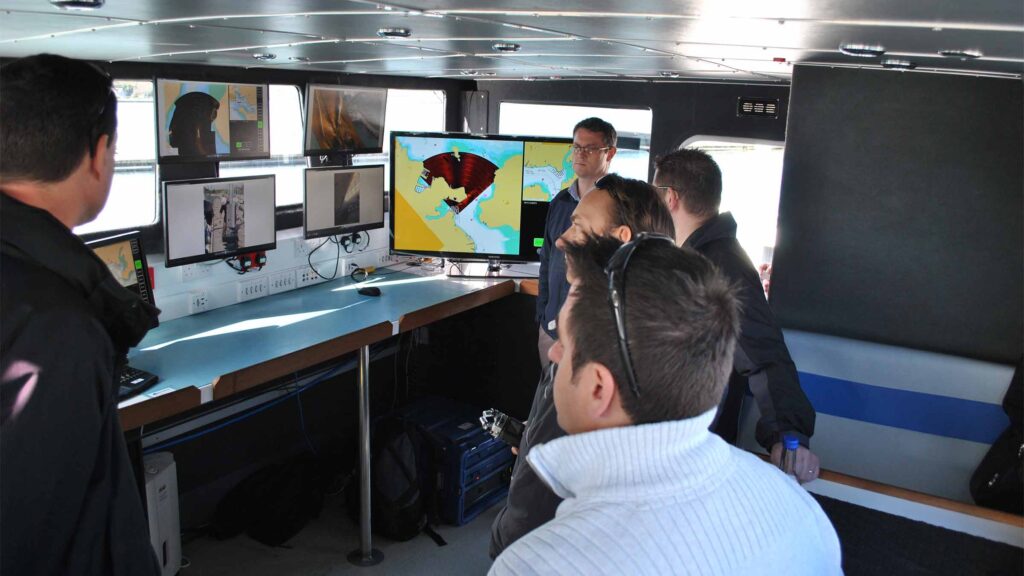

From scheduled courses run at our dedicated sea trials and training centre in the UK or regional offices, online training and free webinars, to bespoke training courses at your facilities, our training programme is expansive and ever evolving.

Locations

Our in-water training is delivered at our Sea Trials and Training Centre in Plymouth. Training here enables course delegates to better prepare for offshore operations and become confident in how to diagnose and overcome environmental issues.

At our regional training centres you will receive the same excellent instruction, delivered by the professional trainers from Plymouth utilising our very latest version of 6G+ Simulator to drive the product software and mimic real-life environmental conditions.

For our online training we use the same simulator, with remote access via video conferencing, to deliver the course in a modular format. In every online session you will have a trainer there with you, just like in the classroom.

Course sizes

The maximum course size is 6 people (4 for INS courses) for face-to-face training, thus ensuring that attendees get the ideal opportunity to develop their operational skills on our products with expert support from the Trainer. Online practical training is delivered on a 1-to-1 or 2-to-1 basis to give you maximum time on the system.

At a glance

- Standard or bespoke syllabuses

- Small class sizes – no more than six attendees when in-person

- Practical, hands-on equipment element in many of our live courses

- 1-2-1 training possible when online

- Flexible schedule for remote training

- Range of courses available: USBL/LUSBL, LBL, INS, sonar and monitoring

Energy

In an industry focused on safe, clean and efficient operations, it’s vital that those using Sonardyne technology are both confident and capable in its operation.

Science

You’ve worked hard to secure funding to invest in Sonardyne technology to support your scientific research. Training with us helps ensure you can plan your project and unlock the full potential of our equipment.

Who we train

• Captains, DPOs, BCOs, ETs, Party Chiefs

• Surveyors, engineers and technicians

• Equipment maintainers

• Rig managers, superintendents, ROV crew

• Military personnel

Our courses

• Range of USBL courses including Mini-Ranger 2, Marksman LUSBL and many more as well as a 1 day technology taster session

• Range of LBL courses including Fusion 2, Fusion 1 to Fusion 2 Top-up and many more as well as connect metrology

• Range of INS, sonar and monitoring courses, from SPRINT, to PIES and Solstice and bespoke projects

Overview

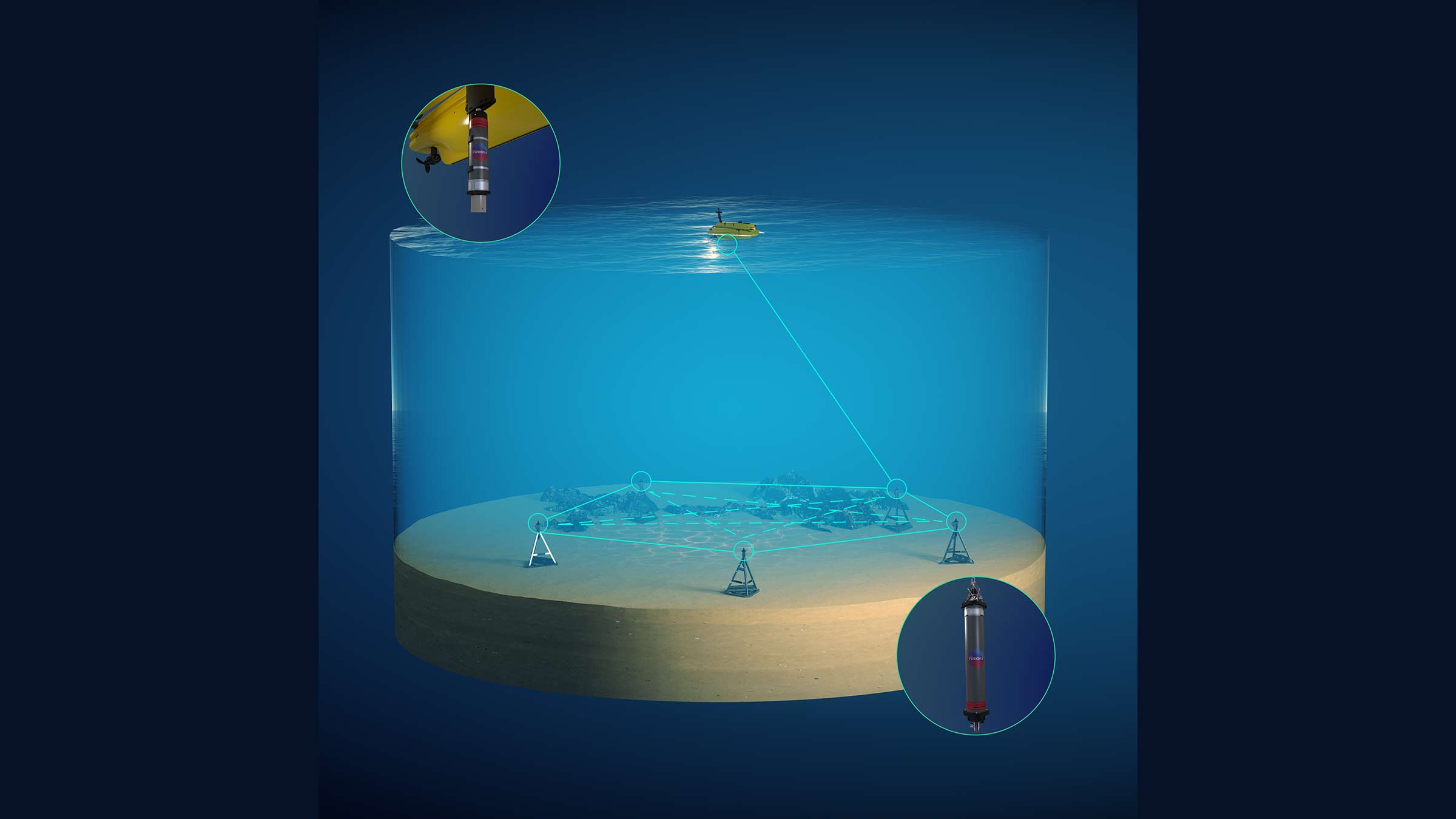

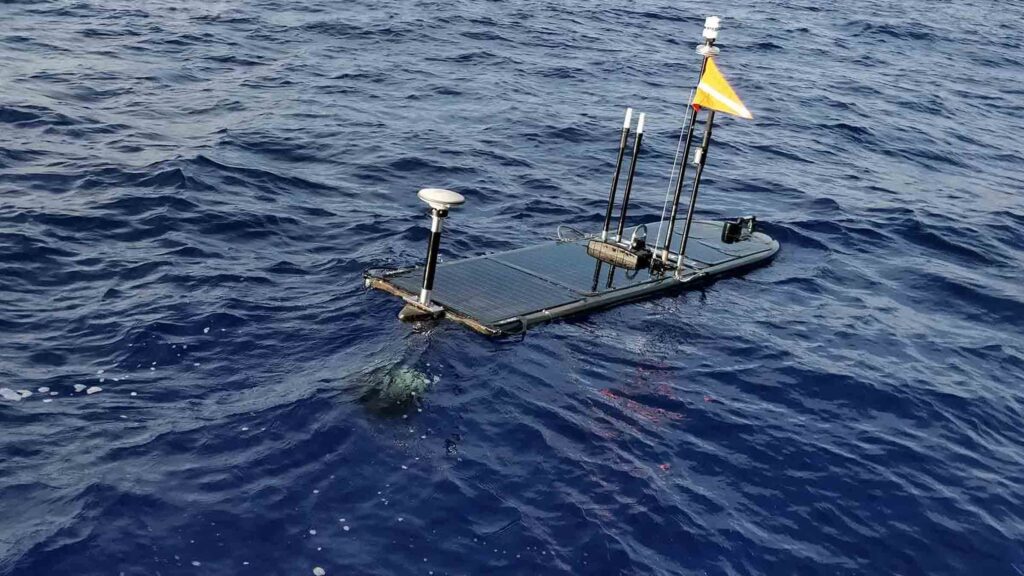

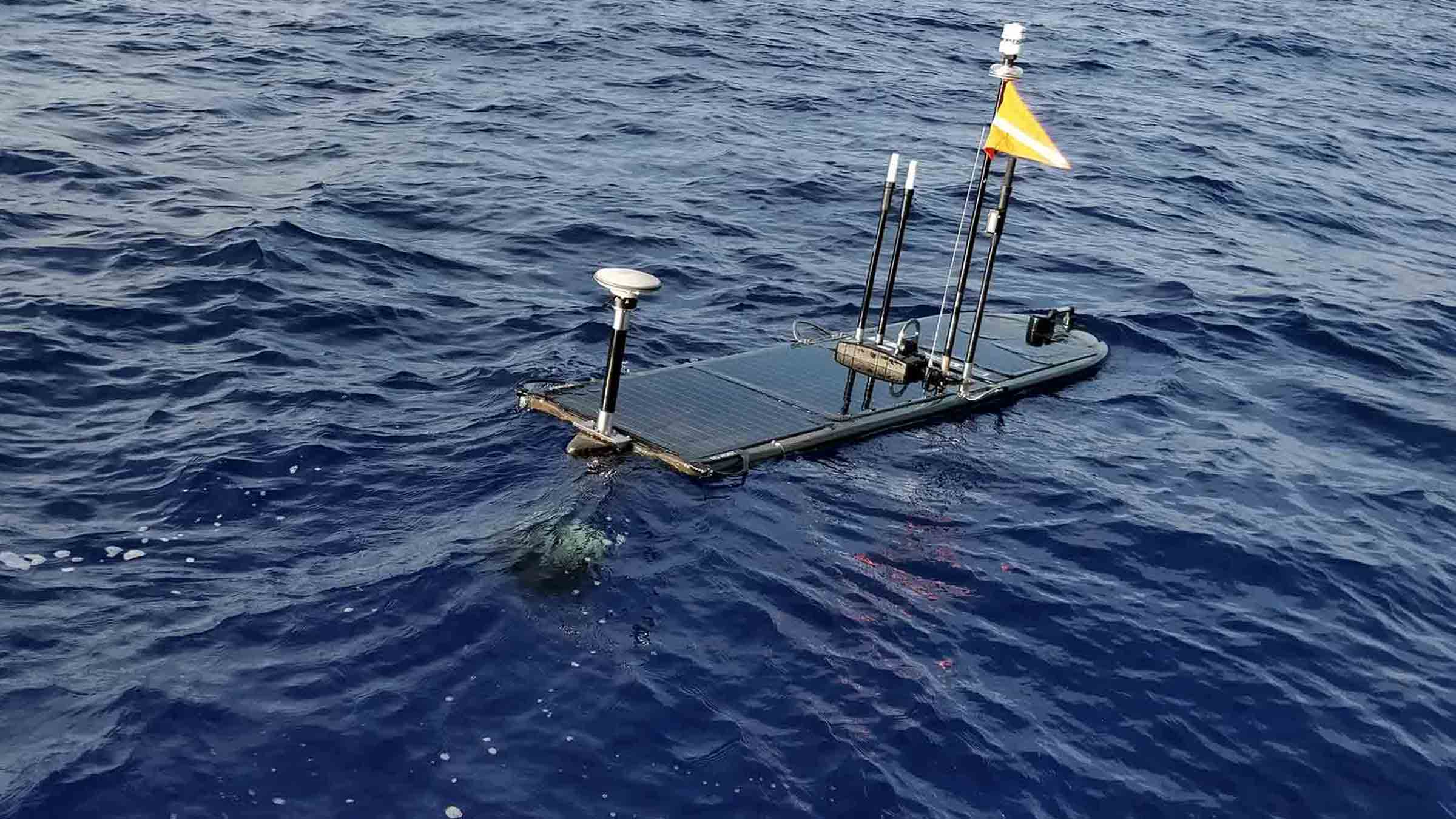

If you already own or operate a USV, we can enable it for seafloor sensor data harvesting, support you every step of the way, and train your team.

Wideband 2 – delivering your data

Mission requirements vary significantly but regularly involve wirelessly recovering stored data, confirming the position of Sonardyne-compatible sensors on the seafloor and downloading new mission parameters.

This requirement is met with our high telemetry rate seabed-to-surface communications capability – Wideband 2. Using Wideband 2, large volumes of data can be reliably recovered in a short amount of time, minimising the time a USV has to loiter. If required, harvested data can be immediately QC’d by engineers onshore before the USV is released to transit to its next data retrieval location. A high-speed downlink allows for new logging regimes to be adopted, eliminating the need to first recover the sensors.

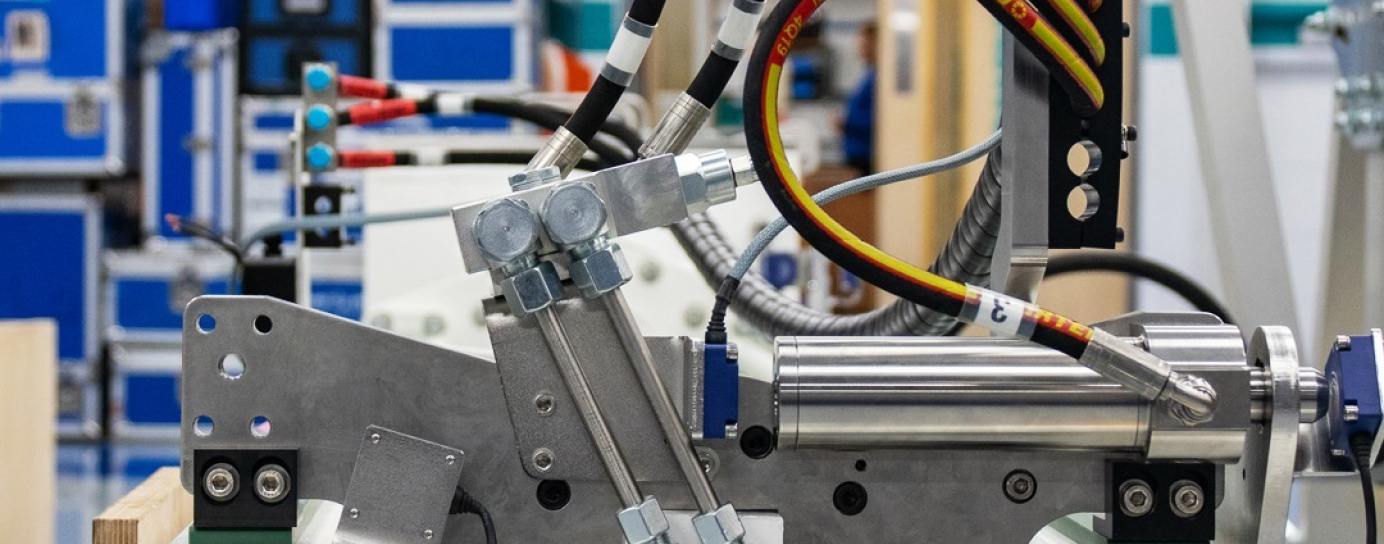

Custom integration and support

We’re able to engineer bespoke USV payloads and sensor gondolas, integrating navigation, communication, sonar, Doppler and tracking systems as required. We’re also experts in vehicle power management and can create custom interface protocols to suit your mission needs. Sea trials, which can be conducted a location of your choosing or at our own facility in Plymouth, help reduce risk and refine procedures ahead of live operations.

Your data, together with a detailed operational report, is securely delivered post-mission. Multi-season, multi-year assignments can all be accommodated. Our service is flexible and entirely built around your needs.

At a glance

- Your ocean data delivered cost-effectively, safely, cleanly, responsibly

- A complete service; planning, equipment, mobilisation, execution, QC, delivery

- Low-risk, field-proven technology for any unmanned platform

- Experienced personnel to support your unmanned mission

- Remote data verification during live data harvesting operations

Energy

Using a USV for data collection minimises risk to personnel, reducing costs and emissions – all key objectives for delivering sustainable projects in the oil and gas and renewables.

Science

Contracting a Sonardyne-enabled USV to recover ocean data means your science no longer has to wait for precious research vessel time. We can gather and deliver your data whenever you need it.

Full service

• End-to-end data harvesting service bespoke to your needs

• You get to focus on the data, not the complex logistics to acquire it

• We select, configure and oversee the most appropriate USV for the mission

• Our highly technology and applications expert run your mission every step of the way

Payload examples

• Mini and Standard Ranger 2 for target tracking and comms

• Vigilant forward look sonar for obstacle avoidance

• SPRINT-Nav for GNSS denied environment

• Syrinx DVL for shallow water navigation

• Modem 6 for robust two-way communications

Overview

Technology integration

In support of our own activities within energy, defence and science have extensive experience integrating third-party surface and subsea technologies – and even land-based position reference systems. This has enabled us to develop trials plans and procedures to accommodate non-specific Sonardyne equipment, such as surface navigation equipment,

towfish, uncrewed surface vehicles and seafloor sensors.

We can tailor your charter to your precise needs, assist with planning, coordinate the logistics and manage your safety.

Working with you

Mobilising equipment and personnel to undertake operations on the water is expensive, time consuming and not without risk. That’s why when you charter one of our Plymouth-based survey vessels or facilities, you get more than just a boat or floating classroom. You get the knowledge and experience of our marine engineers and qualified local skippers who are fully committed to ensuring your charter with us is a complete success and meets all of your objectives.

At a glance

- Daily or weekly charters available

- Choice of modern, high specification survey vessels

- Help from highly experienced crews and marine engineers

- Wide range of marine environments within a short transit

- Access to Sonardyne equipment; e.g. acoustic tracking system

- World-class testing facilities, competitively priced to lower your R&D costs

Energy

Trying out new equipment, rehearsing new operational procedures and getting your team comfortable with the technology being used, helps identify problems and reduce risk before heading offshore to doing it for real.

Science

You’ve worked hard to secure research vessel time so a vessel charter with us ahead of your cruise can simulate different environments, data logging regimes and harvesting methods.

Sound Surveyor

• Coded for operations out to 60 miles offshore

• Can accommodate up to 12 personnel

• 500 kg WWL deck crane for equipment deployment

• Spacious cabin and open back deck

• Port and starboard inboard moonpools

Echo Explorer

• Coded for operations out to 60 miles offshore

• Can accommodate up to 12 personnel

• Four moonpools; various sizes

• Survey equipment mounting brackets on bow

• On-board WiFi/ 4G connectivity/ UPS

Overview

Test against your industry standards

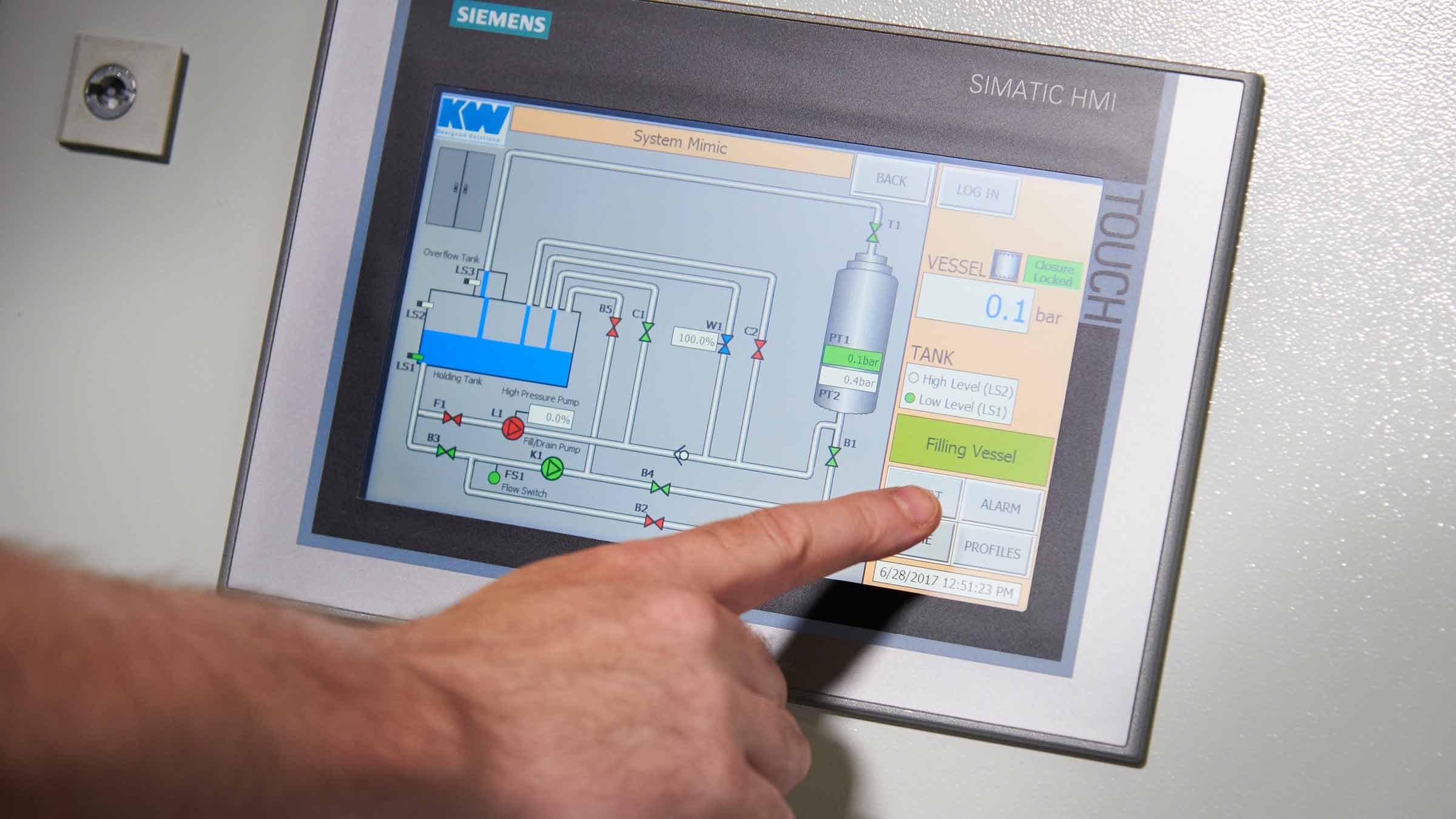

With an internal diameter of 0.76 m and an internal height of 2 m, the chamber can accommodate large single instruments or multiples of smaller instruments at the same time. Equipment under test can be interfaced via six breakout ports which can be adapted to suit client specific connectors, allowing full communications with the equipment whilst under pressure. The chamber is filled with tap water mixed with a corrosion inhibitor.

The control system for the chamber can be programmed to meet the requirements of specific industry standards including pressure cycling, ramping and holding. Ramp rates of up to 50 bar/min can be programmed and pressure inside the chamber logged. A dedicated engineer supervises all testing activities and can provide you with a full report which includes applied pressure graphs, test certificates and photographic records.

Equipment can be easily unloaded by forklift and manoeuvred into position by a motorised, remotely controlled overhead crane rated to 2.5 tonnes. Guest Wi-Fi access is available, along with technical advice from Sonardyne’s highly experienced electro-mechanical design engineers if required.

At a glance

- Full technical and engineering support available on-site

- Simulate depths down to 6,300 m (20,670 feet)

- Set up for heavy lifting with a 2.5 tonne crane

- Maximum working pressure – 630 bar (9,137 psi)

- Full test reports provided and documentation provided

- Large chamber size – 0.76 m internal diameter, 2 m internal length

Energy

Hydrostatic testing is the most reliable and cost-effective way to validate the integrity of subsea equipment before it is deployed in the field where failure has significant implications.

Science

We can test your science equipment to 6,300 m (20,670 feet, 630 bar) to simulate exploring and gathering data from some of the deepest places on the planet.

What's included

• Fixed priced per day

• Half day minimum hire

• Exclusive use of the facility during your hire period

• Dedicated engineer to run your test

• Access to our guest facilities; including free Wi-Fi

• Expert, friendly advice on hand

Specifications

• 6,300 max simulated depth (630 bar, 9,137 psi)

• 168 hours dwell time

• Custom connectors can be used via 100mm breakthroughs

• Automatic ramp and hold with 40 separate profile operations

• Pressurisation / de-pressurisation control rates of 10 to 50 bar/min

Overview

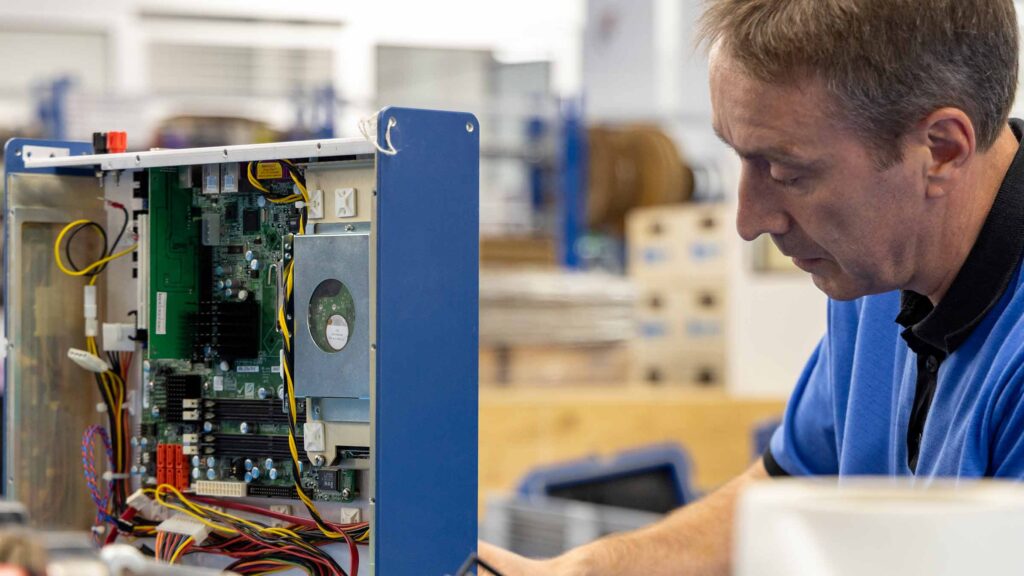

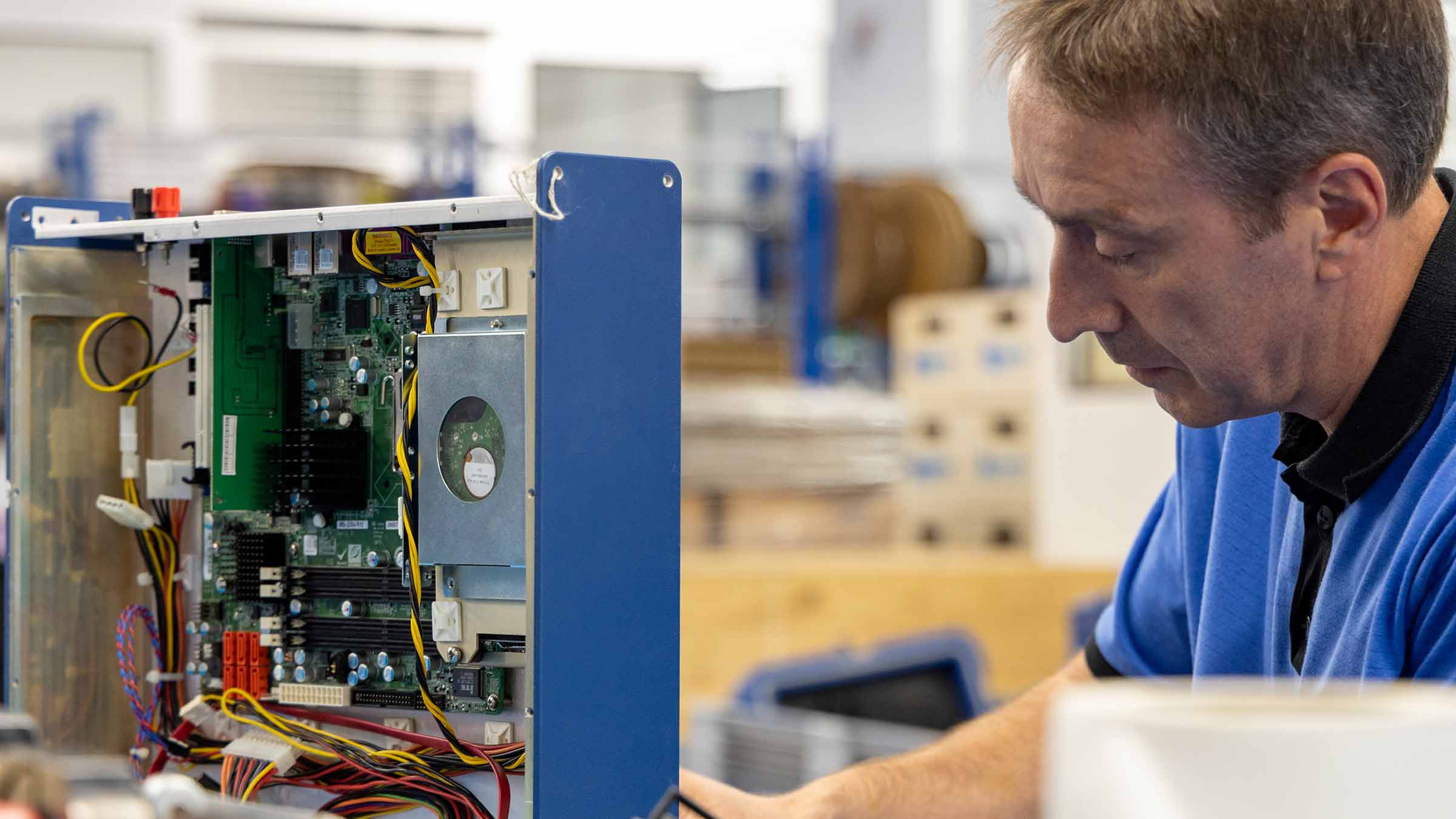

From the simple to the complex

Maybe you also need to integrate multiple devices together or work with third-party suppliers to create a life-of-project system and accompanying support services?

Over our 50-year history, Sonardyne has always provided custom engineering services to address our client’s specific needs. Building on this knowhow, for the last decade, we’ve continually invested in developing and transforming our capabilities and working methods in system engineering, product design, custom solution delivery and service provision. We’re now a fully agile organisation and all parts of the company have been touched by this process, from how we capture users’ specific requirements to through-life project management, materials control and custom manufacturing.

Our team of highly experienced project managers and expert engineers love to find new ways to solve problems and deliver custom engineered systems and solutions that meet your precise requirements. They have tried and tested technologies at their fingertips, with access to a proven portfolio of hardware and software products.

We actively work on projects of all sizes, from the very simple such as a modifying a positioning and communications transponder to suit a specific underwater vehicle, to the complex which could entail a complete monitoring and wireless seabed to shore data harvesting system for tectonic plate motion studies.

Whatever your application, big or small, our custom engineering specialists are available to advise you on the technologies that best fit your goals and then build, deliver, install and support a solution that is safe, low-risk, cost-effective and compliant.

At a glance

- Customised solutions for those applications when a standard product isn’t quite right, or doesn’t even exist yet

- We have everything under one roof; products, technologies and engineering capabilities

- We can combine several products into much larger turnkey systems

- Our expert team of engineers and qualified project managers mean your project is in very safe hands

- We are ISO9001:2015 for Quality Management certified

Energy

From monitoring pipeline movement, through measuring parameters in oil wells, to detecting when a wind turbine mooring cable has broken, we provide custom engineered solutions that span the offshore energy.

Science

Bespoke configurations of our trusted solutions can help you understand critical oceanographic processes, from measuring seabed displacement at subduction zones, to detecting life-threatening tsunamis and delivering science data on demand.

Our specialisms

• Through water wireless acoustic and optical communications

• Customising products to suit individual needs

• Bringing many components together into a larger system

• Remote monitoring, control and data access, often using autonomy

• Interfacing to a wide variety of sensors including chemical, environmental, motion and current

Our track record

• Tectonic plate motion monitoring in the Pacific Ring of Fire

• Subsidence monitoring at offshore oil and gas reservoirs

• Custom transponders for marine seismic nodes

• Marine robotics systems for USVs and AUVs

• Towfish based sonar imaging systems for mine hunting