The growth of the global subsea cable network – especially with the huge demand from the offshore renewable energy (ORE) market, as well as subsea telecommunications cable expansion – means that the challenges of installation, survey and maintenance are going to define the next decade of offshore operations.

About 7,500 km (around 4,660 miles) of export cables had been laid globally by the end of 2020, with an additional nearly 40,000 km are forecast to be laid by 2030. This is on top of an already huge – and growing – global network of nearly 600 subsea telecommunications cables in operation or under construction*.

Given this global expansion, positional accuracy is critical for the cable lay vessel’s position, cable installation precision, its maintenance and repair. This is because every stage, from pre-lay surveys to integrity monitoring – depend on tight operational specifications that enable subsea cable custodians knowing exactly where the cable and all their surrounding seabed features are, often to within a metre or better.

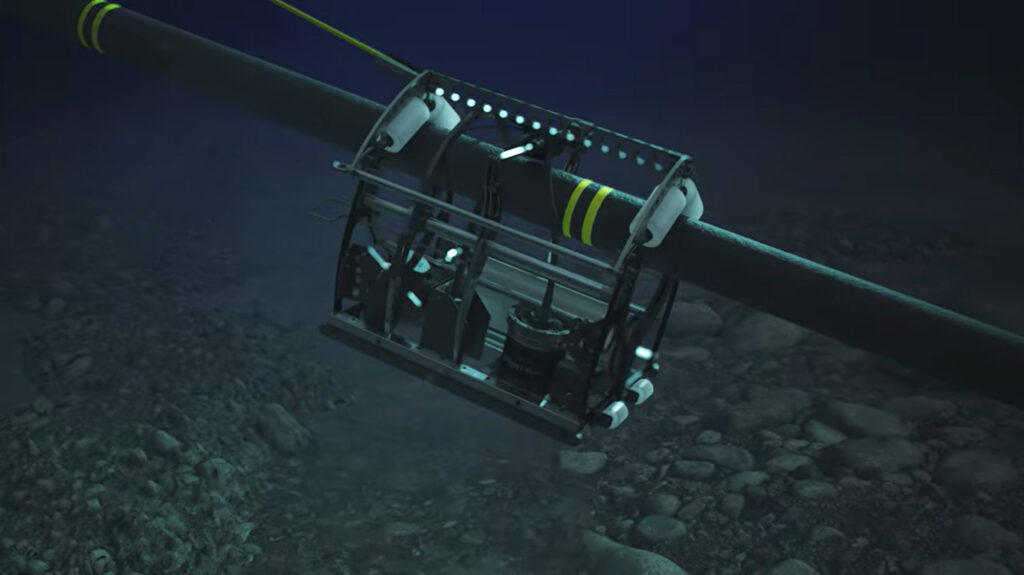

This is work that is often done in challenging environments. GNSS signals could be unreliable (increasingly so due to geopolitical tensions), which could impact your vessel’s dynamic positioning (DP) system. Ferrous cable material can interfere with underwater navigation solutions, degrading the positioning of your remotely operated robotic platform, or heavy machinery such as your cable plough or trencher.

Across all these challenges we have a single instrument that can deliver the positional precision you need.

SPRINT-Nav

Our SPRINT-Nav high-performance hybrid acoustic-inertial navigator is an all-in-one instrument that delivers continuous, robust navigation outputs, enabling operations even in challenging, GNSS-denied subsea environments.

It tightly integrates an inertial navigation system (INS), Doppler velocity log (DVL) and a pressure sensor into a single pre-calibrated unit that is unaffected by magnetic interference.