Life-of-field monitoring

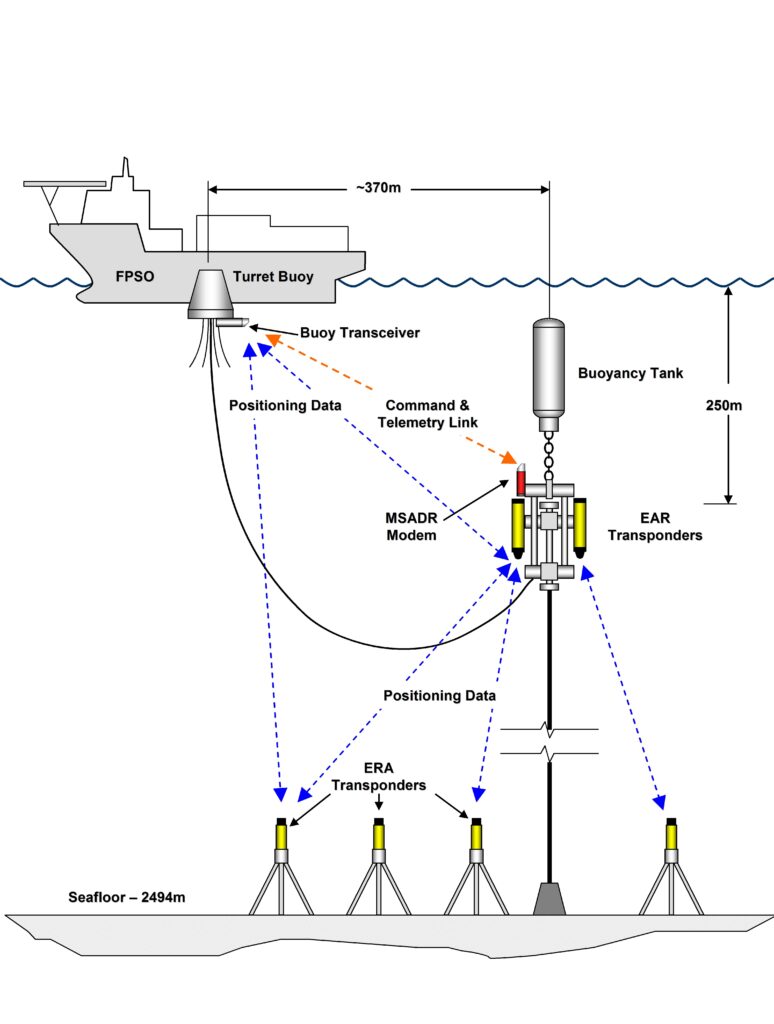

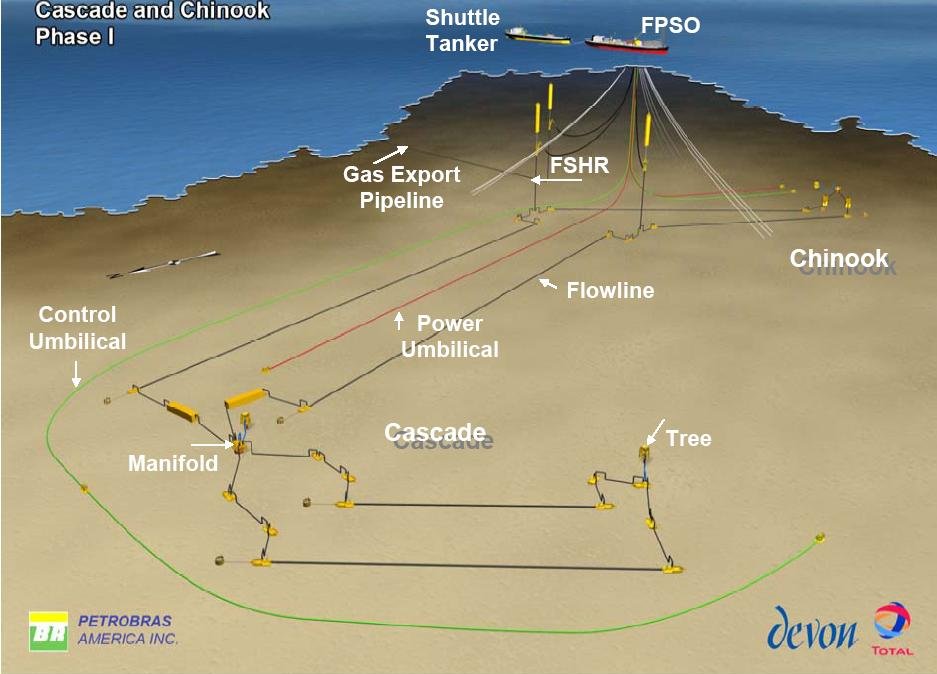

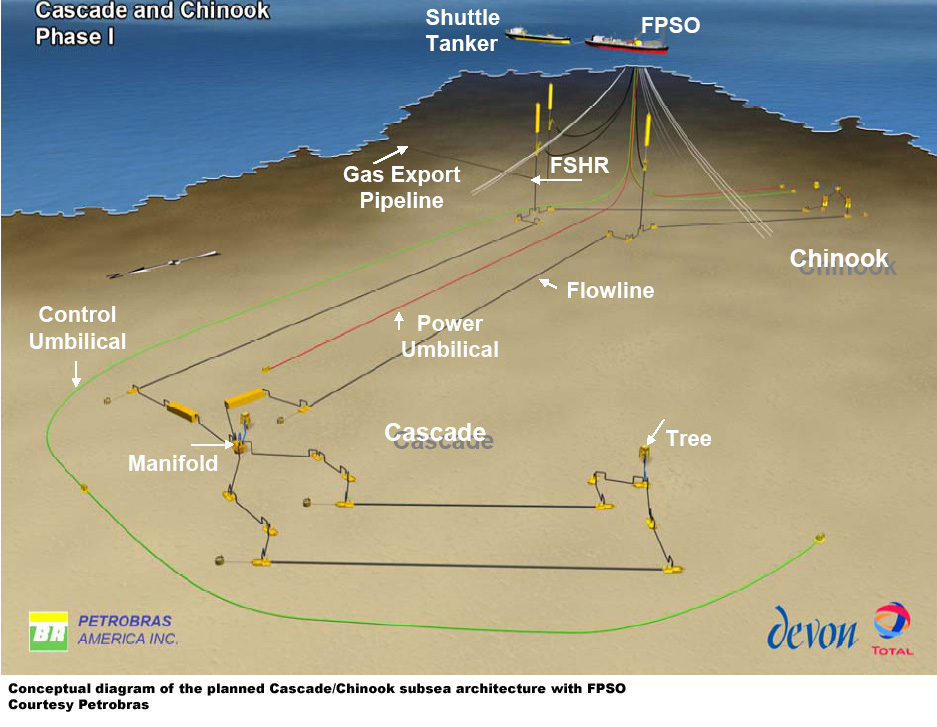

To maintain the integrity of the FSHRs, the Subsea Technology Group from Petrobras’s R&D Centre in Brazil, prepared a specification for PAI of a comprehensive life-of-field subsea monitoring system and contracted BMT Scientific Marine Services as the systems integrator responsible for its delivery.

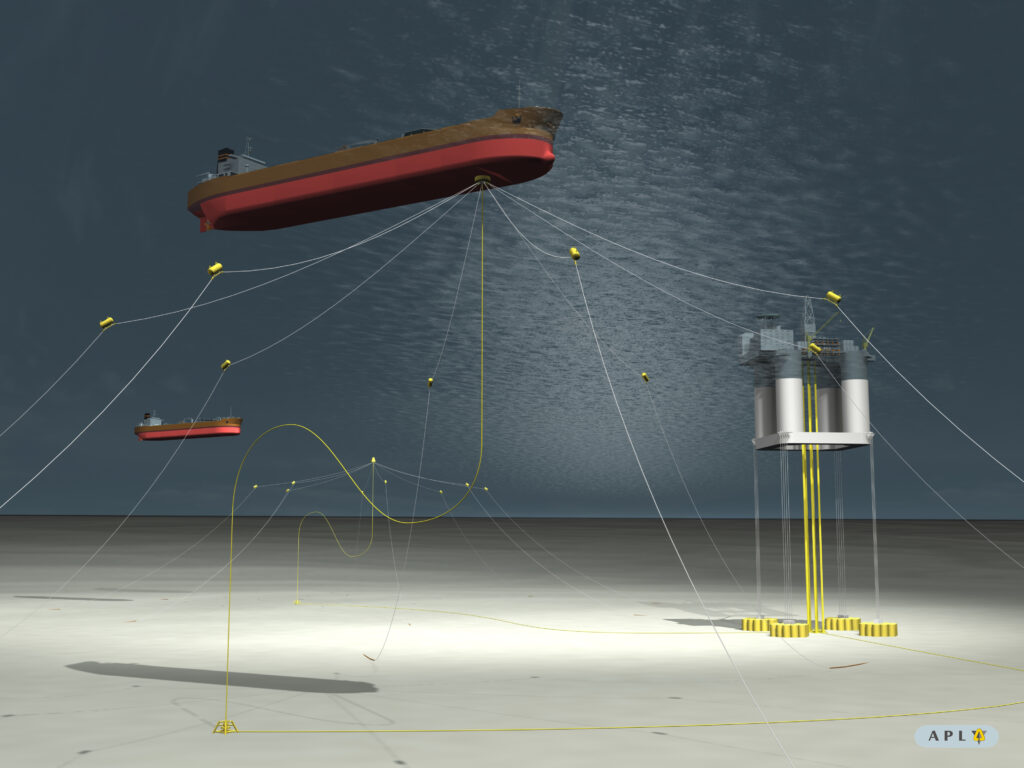

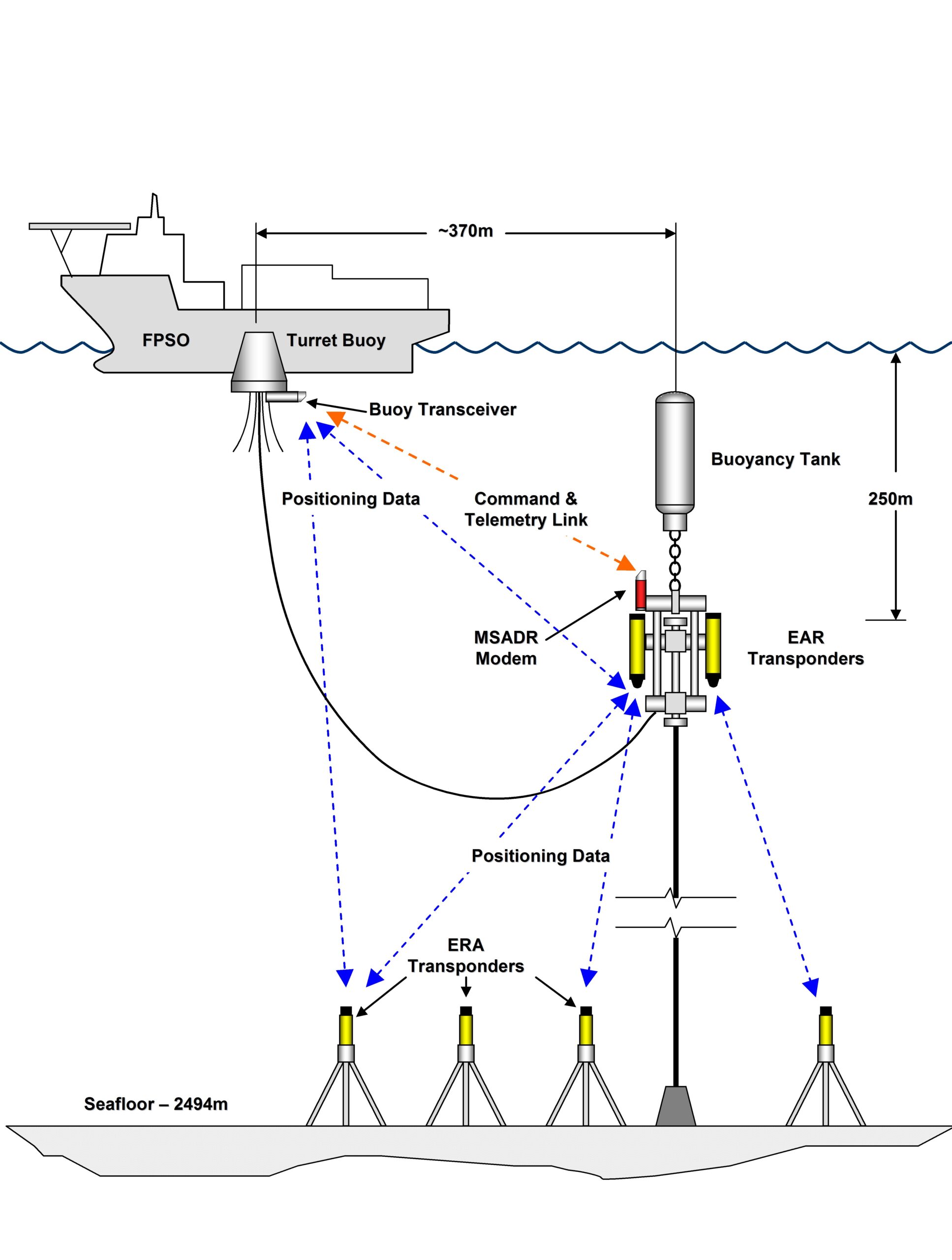

BMT has experience in the development of offshore monitoring systems and, following the successful development of a similar system for the Petrobras P·52 platform in Brazil in 2007, BMT again chose to partner with Sonardyne for the positioning and telemetry component of the riser monitoring system.

The primary requirement for the acoustic instrumentation is to monitor the position of each riser tower and of the turret buoy relative to the seabed. In addition, integrated sensors monitor depth, temperature, inclination and sound speed whilst the integrated modem transfers data from the load and attitude monitoring system on each riser tower to the turret buoy. The system uses Sonardyne Wideband acoustic telemetry to guarantee high speed and reliable data communications for all these tasks.