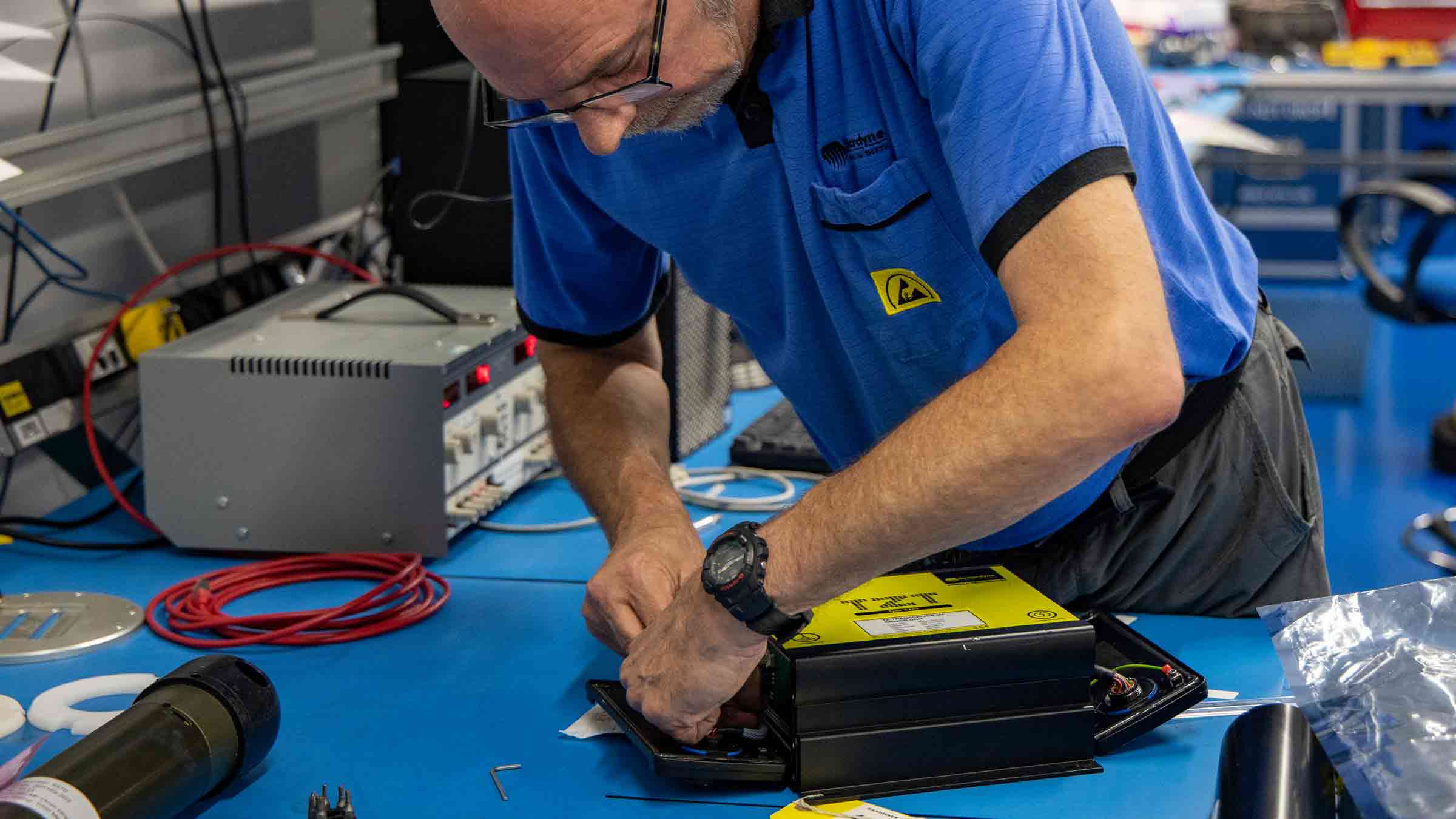

Equipment servicing and repair

Overview

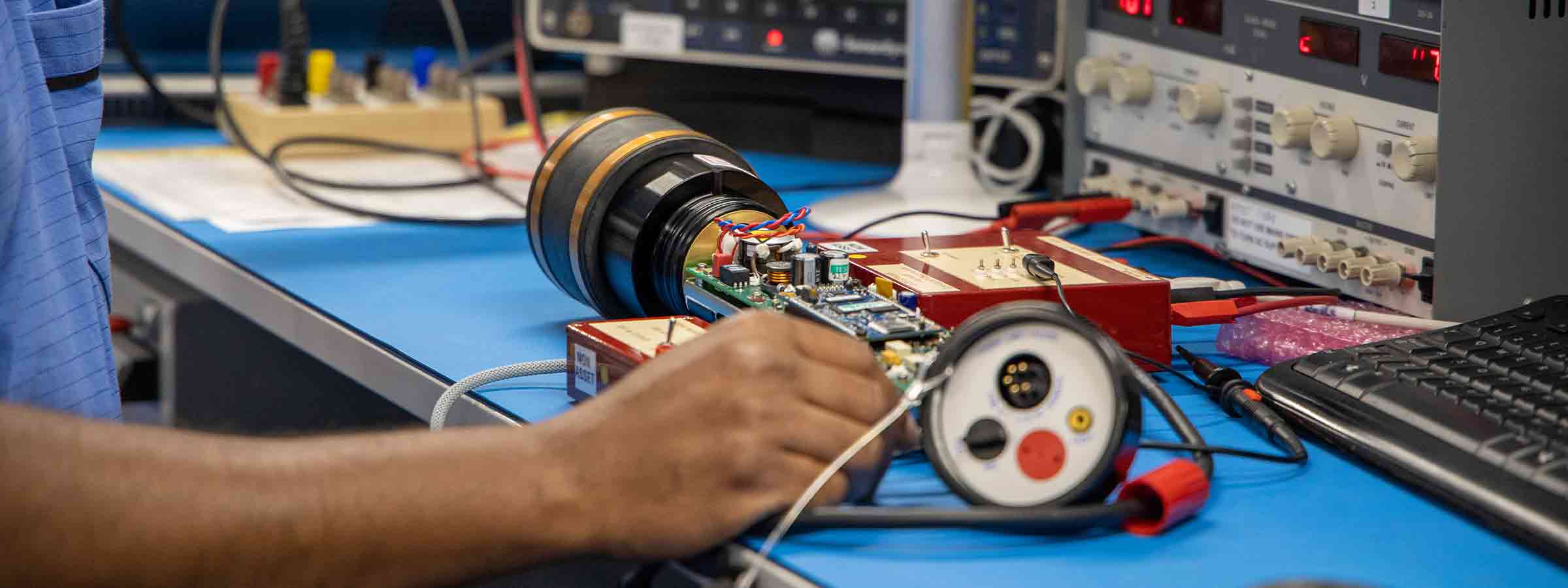

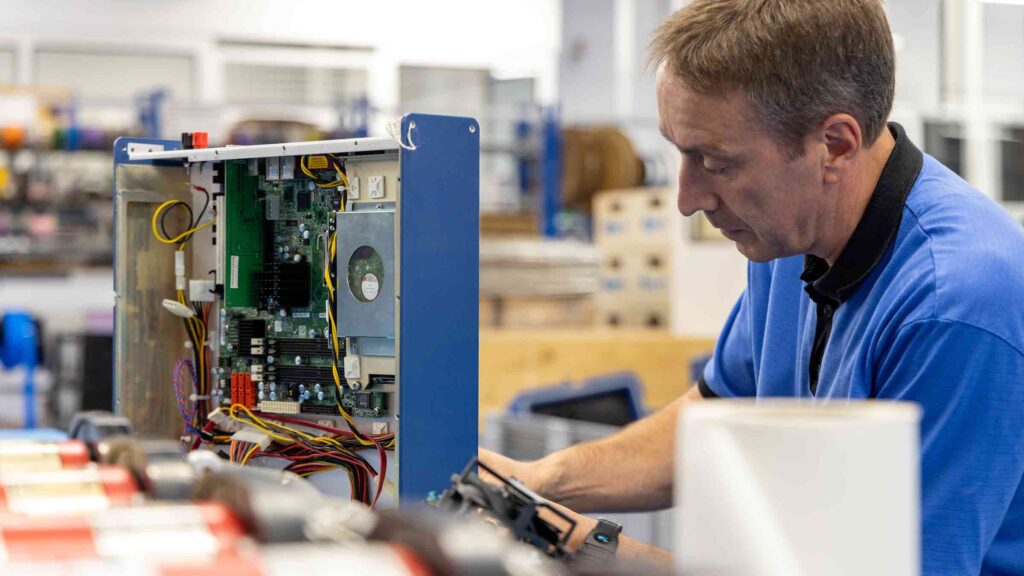

Our global centres and factory-trained engineers offer cost-effective repair, preventative maintenance and specialist sensor calibration services. So whether you are about to start a project or return onshore, you can be assured your that not only have we built your equipment, we’re taking care of it too.

Pre-deployment- what we check

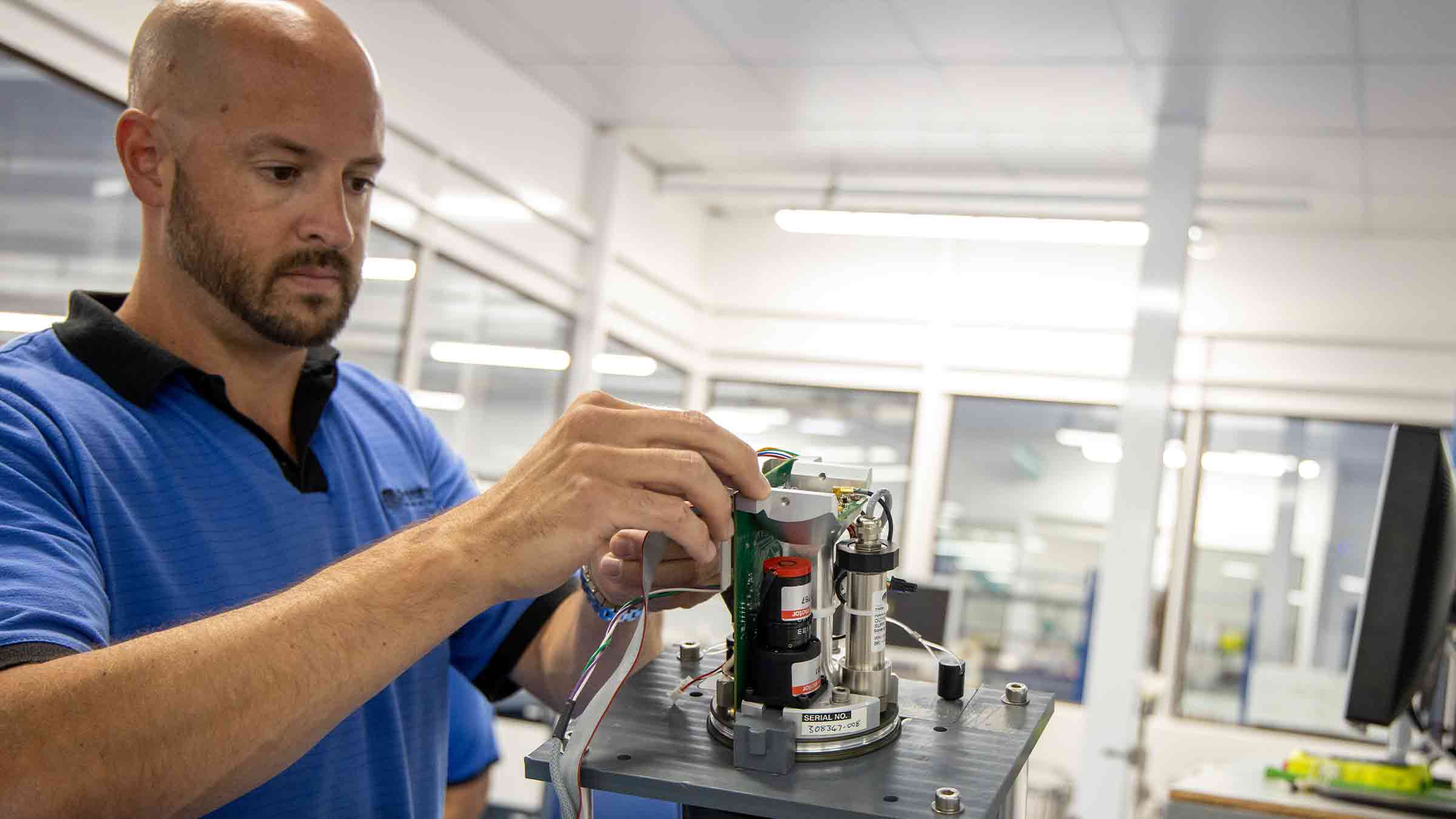

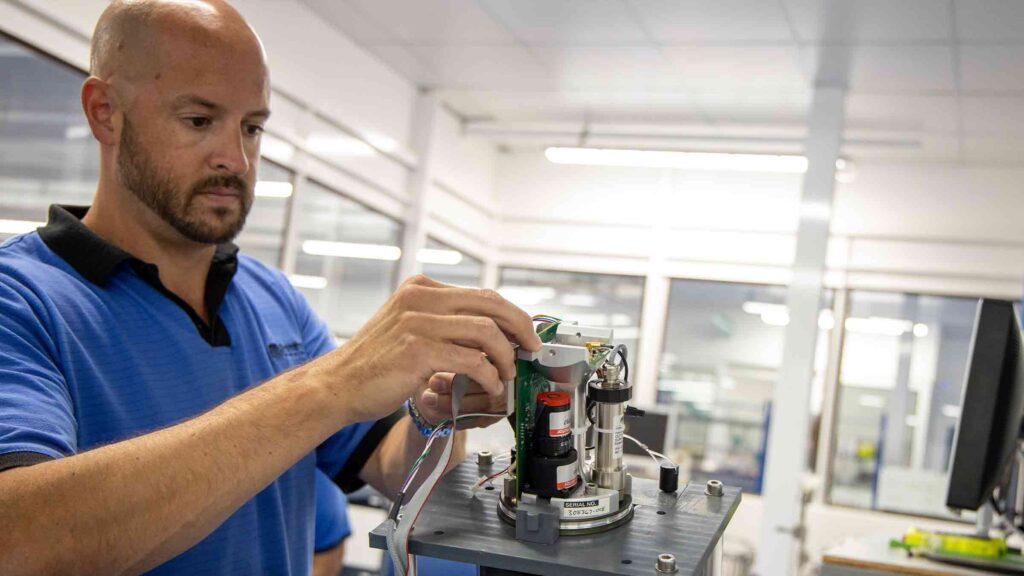

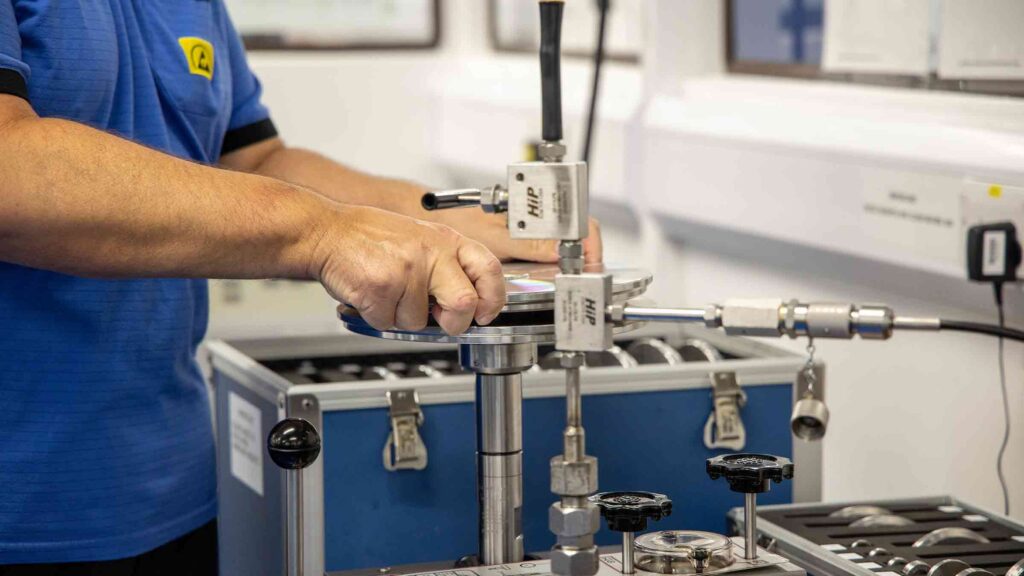

A popular service for transponders which are factory-fitted with a variety of calibrated environmental sensors. Yet through operational use, knocks in the field and marine growth, the quality of sensor readings can degrade. This is why we recommend they undergo regular checks to ensure they remain within specification.

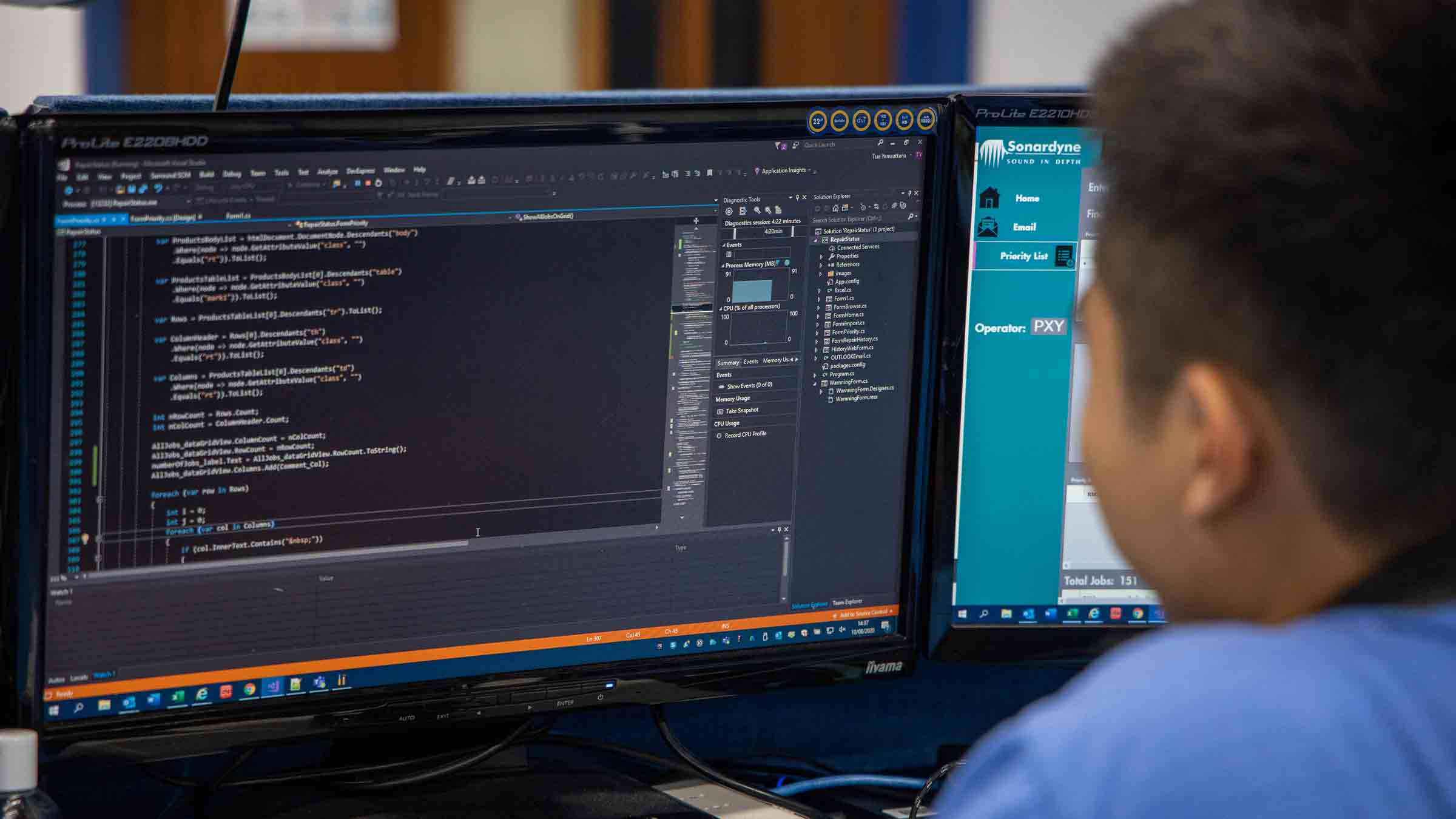

We regularly improve product performance and functionality by upgrading transponder firmware, so we’ll check to make sure your equipment is operating on the latest version.

Pre-deployment checks also include tank testing, where a full acoustic check is carried out. Batteries are also checked to ensure that they will last the duration of your operation.

Post-deployment – what we check

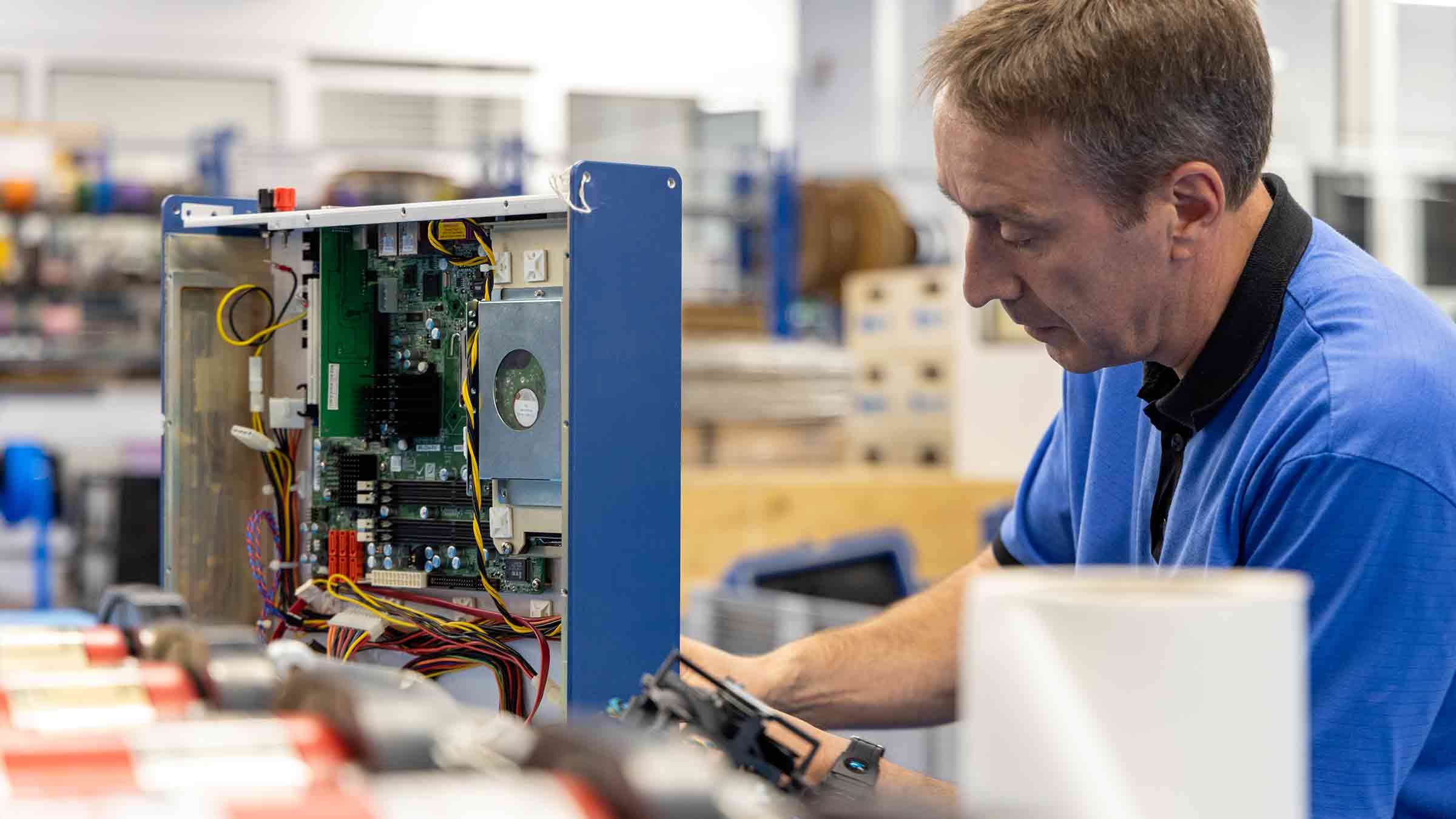

No one knows your transponders better than we do, so once they come out of the field and before you put them back on the shelves, we’ll perform a thorough diagnostic inspection. This includes checking and, if necessary, replacing the anodes, o-rings, transducers, guards and batteries.

At a glance

- Service centres located in Europe, Asia, North and South America

- Only genuine Sonardyne parts used and fitted by factory-trained engineers

- Maximises the lifespan of your equipment and reduces the need for replacement

- Preventative maintenance which helps identify potential problems early on

- Range of services on offer: repairs, sensor calibrations, pre-deployment checks

Energy

Offshore, time is money so that’s not when you want to be discovering problems with equipment. A pre-deployment equipment check with us gives you peace of mind.

Science

Time onboard a research vessel to carry out your science is hard to secure. So before your cruise season starts, why not book your Sonardyne kit in for an annual health check?

What makes our service different?

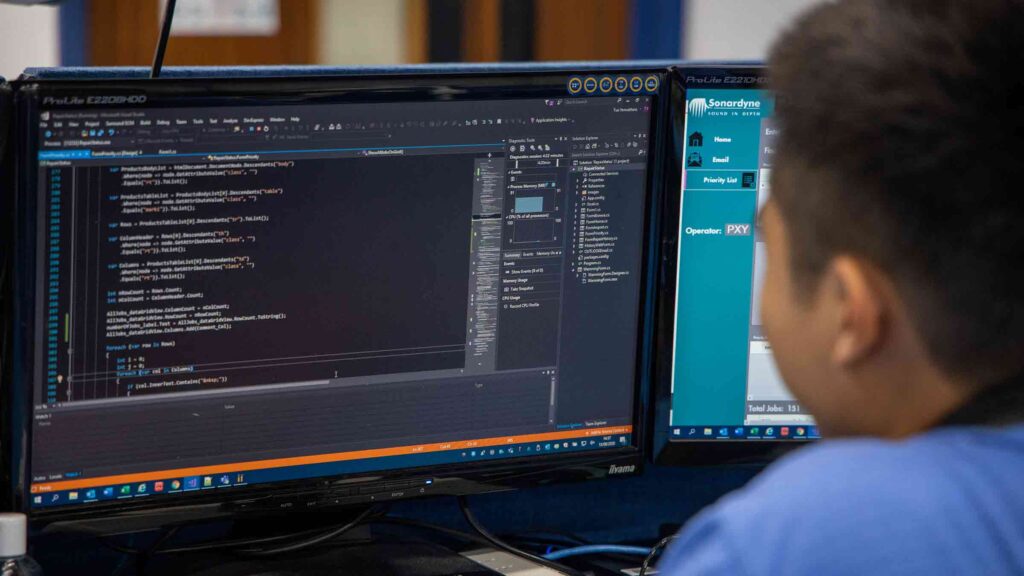

• Factory trained, experienced engineers

• Access to latest product updates

• Only genuine Sonardyne parts used

• Multiple generations of equipment cared for

• All work is warranted for 6 months

What we check and repair

• Firmware: upgrading as required

• Anode replacement

• O-ring check and replacement

• Transducer inspection

• Transducer inspection

• Sensor and transducer guard check