My two previous blogs in this series looked at how unattended sensors can help solve some of our 21st century warfighting challenges, the sensors that exist today and what you need to think about to make them work. It’s now time to take a deep dive into what goes into making them fit for persistence across the ocean space.

There are three main elements that go into making persistent sensors work: what’s on the inside, i.e. the sensors, processing power, modem capability and batteries; the materials and form factor of their housings; and deployment options. Let’s start with what’s on the inside.

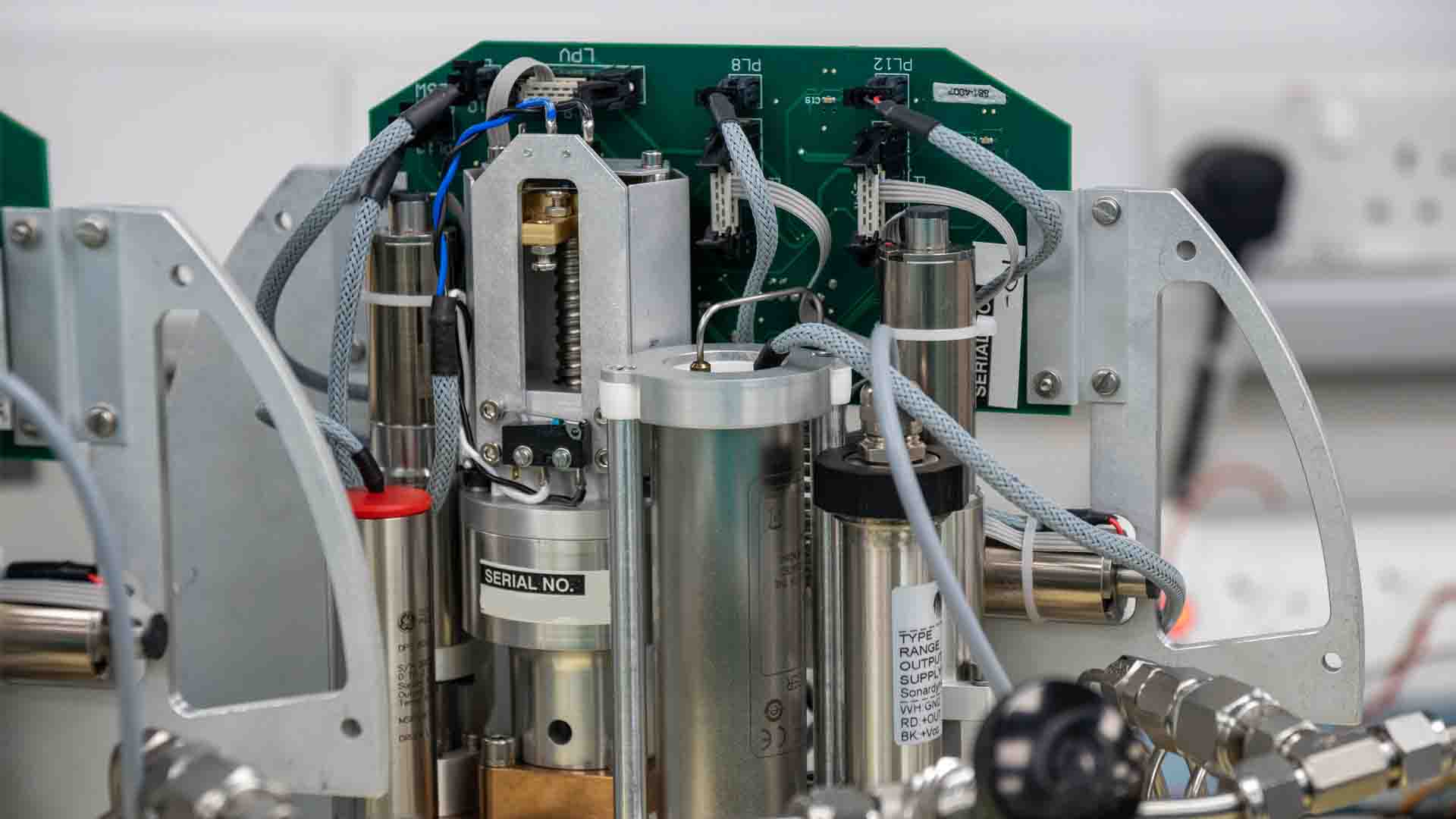

Onboard sensors

We already offer a wide range of sensors integrated into our instruments, including acoustic Doppler current profilers (ADCPs), inclinometers, and pressure, temperature and speed of sound sensors. These sensors help to characterise the environment and in turn inform the mission; helping to fine-tune other sensors and our acoustic systems.

But the options for sensing are almost endless. Third party sensors can be connected to our unattended instruments via a connector. We support a range of standard commercial-off-the-shelf subsea connectors and can accommodate bespoke solutions too. Our connectors have ports for power, RS232, RS485, CAN Bus and Ethernet. We can work closely with your team to accommodate the right solution.

Sensors Lab

How do we ensure success? At Sonardyne, once we have designed an unattended sensor, we test, test and test again. The oceans never ask for forgiveness. Our sensors lab enables us to carry out accelerated life-cycle tests for all sensors that we plan to use; at the right temperatures and pressures. This means we can stress test instruments to the point of failure, which we do at the proof-of-concept stages.

It means we can also characterise the performance of sensors over time, becoming familiar with their performance and predicting any possible degradation, remembering all the time that we need to design for longevity. We also conduct in-water tests and have a dedicated in-house team whose job it is to identify and quantify any errors before our systems are deployed.

On board processing

Data gathering requires data storage and, increasingly, also processing capability, in order to provide the relevant data that’s required. Our most basic offering stores sensor data in SD cards or equivalent. The data can then be harvested via an acoustic or optical interface. When glass sphere housings are used, the SD cards are duplicated and all data products are stored in two separate and identical repositories.

Edge processing is available with our advanced data acquisition and processing system (ADAPS) option. This highly capable processor can run sophisticated user-specified algorithms, as well as simple data analysis, such as min/max/mean statistics and thresholding for alarms and critical event reporting. By reducing high-bandwidth sensor data to small, critical packets, we can efficiently manage power consumption. That means longer deployment times can be achieved from the internal battery pack. Furthermore, using the sensor’s integrated acoustic modem, “through the water” updates to the edge processing algorithms provides ultimate flexibility and performance over the entire life cycle of the deployment.

Battery options

To be successful, unattended sensors need to work remotely and persistently for extended periods of time. The battery technology on-board will play an important role in helping extend the length of the mission. For short deployments, we use tried and tested Alkaline batteries. A single pack can provide up to 54 Ah. But by using glass sphere housings, we can pack in even more batteries. In this configuration our typical capacity ranges from 180 Ah to 505 Ah. The latter has demonstrated operations lasting for well over 10 years.

Choosing the right battery option depends on the concept-of-operations. Higher capacity adds weight to the instrument. However, it also enables our instruments to gather, process and share more data. At Sonardyne, we have developed in-house algorithms to provide accurate estimates for battery life. Once we understand the requirement, we can configure the right battery.

Materials

Of course, it’s not just what goes into the sensor that matters. Biofouling and endurance are high up on the list of our headaches. Learning how to select the right materials for operation across the world’s oceans takes time. As we have seen in my previous blog, biofouling is a constant threat, particularly where our sensors interface with the water, through which we are sensing.

Since most unattended sensors remain stationary, anti-fouling solutions used on boats or ships that are typically reliant on flow do not work as well for us. At Sonardyne, we conduct continuous trials into materials and anti-fouling solutions. The battle never ends, year-on-year we improve our materials selection process and come up with neat tricks, like copper tape to prevent fouling.

To prevent corrosion, we have a few options. For shorter deployments, we use hard anodized aluminium. For longer deployments, titanium is iron free and will not rust. It is ideal for when you want a sensor to remain in situ for 10 years or more. But it’s costly.

To ensure they can withstand the rigours of underwater operations, we design and push our materials and instruments to their limits. Using our unique hydrostatic pressure test chamber measuring at 750 mm diameter and 2000 mm tall, we can generate 630 bar of pressure, simulating depths of well over 6,000 m. We can cycle the instruments many times, simulating multiple deployments. We also use temperature regulated chambers to cycle through different temperatures at different rates. We need to, as our instruments are as likely to be sitting on a deck in the Arctic as they are to be found in Tropical seas. How the materials behave as they are dropped into the water and are then submerged is vital information that we use to help us choose which ones to use.

Deployment options

The considerations do not end there. If we want to be truly unattended, that means – once deployed – we want sensors to remain on the seabed throughout the life of the mission. To do this, we offer a range of options from floatation collars (used to moor sensors on the seabed and to easily recover them) to glass spheres on tall frames that can freefall to the seabed and are deployed for periods of more than 10 years.

Our systems are made to operate at all ocean depths from very shallow waters using anti-trawl frames to the depths of the Mariana Trench. Our deployment systems can be built by us or our customers under license – anywhere in the world. Speak to us to discuss your requirements.

Acoustic Data Harvesting

So now you have your sensor. It’s been deployed and it’s gathered, processed and stored data you would like to access. What’s next? Our unattended sensors set themselves apart as they are equipped with leading acoustic communications.

Our underwater acoustic modems are used to regularly harvest data from these sensors. This can be done from either the surface or a nearby unmanned underwater vehicle (UUV). The protocols are secure, ensuring that the sensors respond exclusively to the asset owner; preserving battery and keeping the system undetected while it is not being interrogated.

We can also tailor the waveforms to make them difficult to detect and exploit. Enabling us to send sparse acoustic commands through a network. This means that, if our edge processing pulls the trigger, the sensor can send a pre-defined message. Alternatively, we could acoustically command an actuator to have the sensor float to the surface. Our sensor then becomes a data pod waiting to be recovered or capable of transmitting information when it reaches the surface.

If covertness is not a mission requirement, our commercial acoustic protocols are designed to operate between 14 kHz to 34 kHz, supporting a rich range of telemetry schemes. That translates to two-way communications anywhere between 200 bps to 9,000 bps over tactically significant ranges of up to 12 km. These signals can also be used in support of navigation systems for friendly third-party underwater vehicles (i.e. UUVs) in the vicinity of the sensor.

If your platform must remain covert, then optical free space modems may be a better option. These modems work over shorter ranges, from approximately 5 m to up to 150 m, and can be used to transfer between 10 Mbps to 600 Mbps. They work in the UV and visible light spectrum and work best at depth, away from the sunlight’s interference. Because they work over shorter ranges, it means enemy combatants really need to know where to look for them to find them. As they will only respond to a known modem, they can remain hidden for prolonged periods of time.

Taking the next steps

So, in the first blog in this series, I looked at how achieving scale in the underwater domain doesn’t have to come at a high cost. Unattended sensors can monitor choke points, provide persistence and guide the underwater vehicles that are extending our naval forces’ reach. In the second instalment, I covered the challenges we face when deploying these sensors. In this final blog, I’ve looked at what goes in to making these systems so that they will offer the persistence you require. What more do you need to know?

If you have a requirement for persistence in your underwater battlespace, we can help. Get in touch to discuss your needs.