Authors: Luke Richardson, Sales and Marketing Manager at 2G Robotics, and Edd Moller, Global Business Manager Construction Survey at Sonardyne

We’ve recently built a new deep-rated laser scanning skid specifically for generating extremely detailed volumetric point cloud models to complete repeatable survey work in the deep ocean.

It is a great product that is capable of delivering highly accurate and precise data of the seafloor and subsea assets, from pipelines to historic wrecks, all while packaging the capabilities of a dynamic laser scanning survey in one easy to use ROV skid.

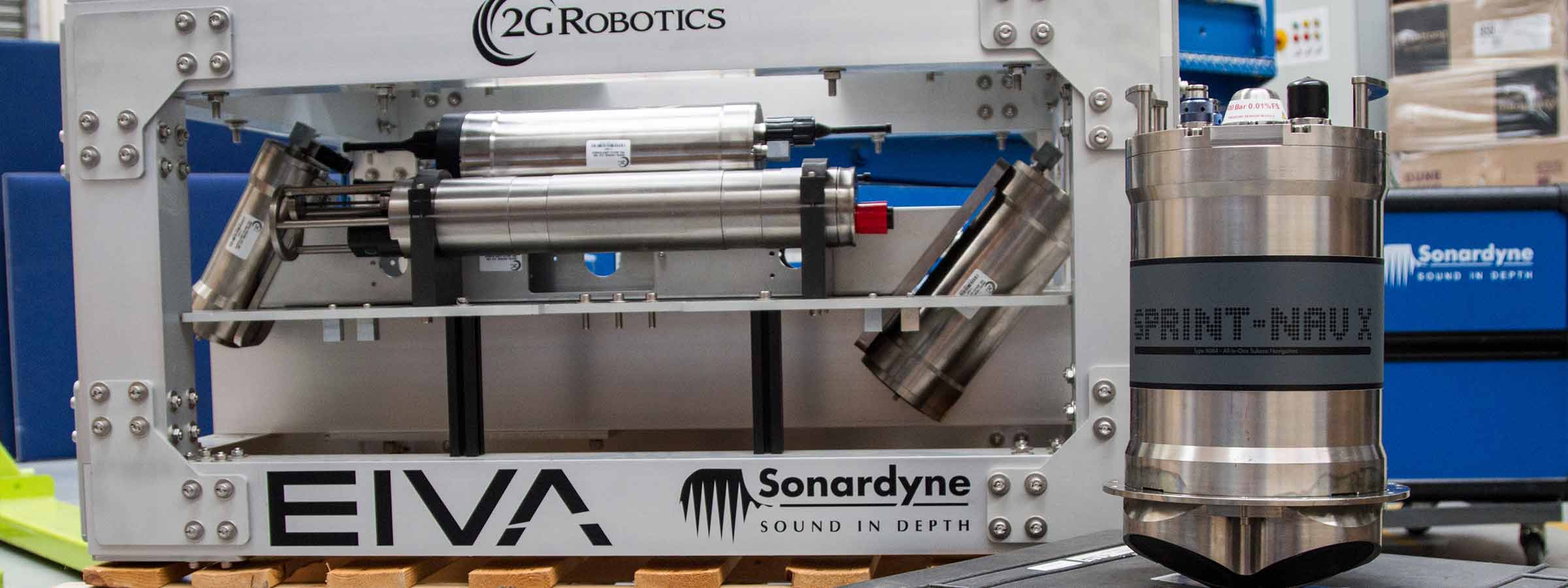

The skid, a deep-rated 2G Robotics WROV Dynamic Laser Scanning Skid, builds on the breadth of experience between our Sonardyne Group companies 2G Robotics and Sonardyne to create a high precision system for underwater data collection.

Simpler, better offshore surveys

It’s a collaboration started back in 2015, when we saw the benefit of using our technologies together for dynamic laser scanning subsea structures with Apply Capnor. By amalgamating positioning data from Sonardyne’s SPRINT-Mapper which is a pre-configurated package of Sonardyne’s SPRINT INS and Syrinx DVL, and the point cloud data collected using 2G Robotics’ ULS-500 dynamic underwater laser scanner, we were able to generate fully georeferenced models that did not require manual point cloud stitching.

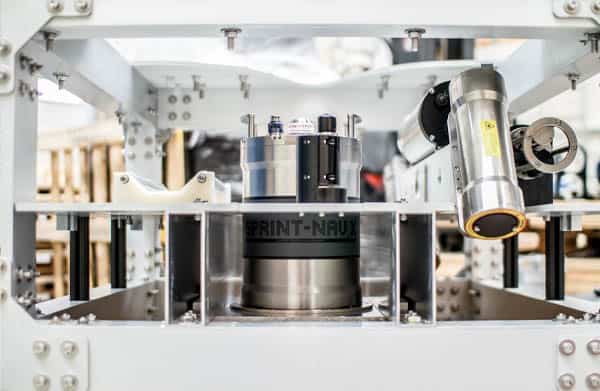

Integrating the SPRINT-Mapper into the 2G Robotics WROV Dynamic Laser Scanning Skid with the ULS 500 PRO meant much simpler offshore surveys because the equipment required to generate fully georeferenced models that did not require manual point cloud stitching are combined in one portable “plug and play” unit through the skid’s multiplexor.

System offsets are predefined, and a standard bolting pattern is included with the frame mounting plate allowing users to bolt the skid to their ROV and simply perform their survey; no need to take account of the offsets, no need to worry about complex system wiring, and no need to worry about accumulating the correct systems.

Using the fully integrated skid we created, we’ve proven its capability for performing dynamic laser scanning metrologies, with DOF Subsea, to name just one project.

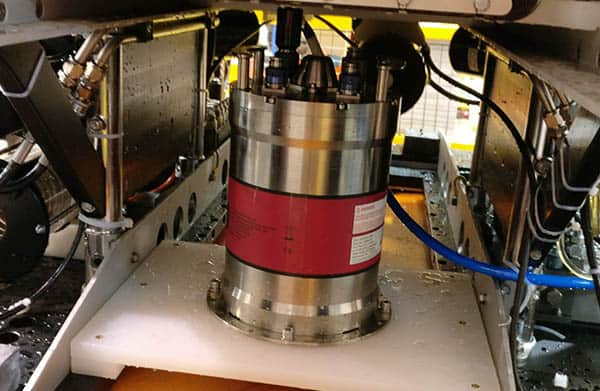

Now we’ve developed the skid even further. Our newly developed deep-rated ROV skid takes advantage of the latest technological advancements at both 2G Robotics and Sonardyne, using the ULS-500 PRO system and replacing SPRINT-Mapper with Sonardyne’s latest SPRINT-Nav.

2G Robotics’ ULS-500 PRO

2G Robotics’ ULS-500 PRO, including both 4000 m and 6000 m depth rating options, was developed in 2017 and is a staple in the offshore industry for dynamic laser scanning projects. The system is used on surveys where the end customer requires extremely high-resolution and accuracy to make educated decisions on the condition of their subsea asset where other subsea sensors are not able to accommodate.

The laser offers substantially more detail to existing sonar solutions because it is optical-based, generating 2,048 points per laser profile, at a capture rate of 52 – 92 lines per second. Compared to photogrammetry, the laser can provide true details of the structure depth and damage, and generate models in shadowed areas, even when there are no defined features, because models are built using the geometry of the laser line on the target.

In addition, the laser model is generated in real-time, offering quality control capabilities while performing the survey live. These capabilities allow users to own their survey with real-time processed models that provide details unobtainable with other subsea solutions.

A deep-water challenge

However, we wanted to create a skid suitable for deepwater applications. To build accurate models in deep water, you need positioning. In shallow waters, you can use surface position updates, usually from an Ultra-Short BaseLine (USBL) system. But highly precise deep water scanning can’t rely on surface position updates. Here your options are using: a local Long BaseLine (LBL) array on the seabed; a sparse LBL array in combination with a good inertial navigation system (INS); or a very good INS.

Furthermore, for some projects deploying Compatts on the seabed to form an LBL array isn’t possible, such as when a site is subject to the UNESCO 2001 Convention on the Protection of the Underwater Cultural Heritage – at these sites nothing can be put on the seafloor. That leaves only one option; using a very good INS.

High performance navigation with SPRINT-Nav

The standard WROV Dynamic Laser Scanning Skid normally comes with a SPRINT-Nav 500 – Sonardyne’s all-in-one, acoustic-inertial subsea navigation instrument for underwater vehicles. SPRINT-Nav’s tight coupling of a SPRINT INS, Syrinx DVL and pressure sensor, with individual beam-level aiding from the DVL, means optimal performance but also that the INS doesn’t suffer drift from DVL drop outs when its goes over obstacles on the seabed or a structure being mapped. Beam-level aiding means if one beam drops out, it doesn’t matter, bottom lock continues. That’s important when performing surveys over ground or objects prone to loss of bottom lock.

For this particular project, we went for a SPRINT-Nav X, the highest grade SPRINT-Nav currently available, in order to allow mapping without using a sparse LBL array and further reduce the INS drift. To give you an idea of its performance, SPRINT-Nav X achieves less than 1 nautical mile error for every 12 hours of unaided inertial navigation and better than 2 m error for every 10 km travelled with Doppler lock. While this options does require extra post processing of the laser scans, to join them together, the end result is the same and you’ve not had to deploy that LBL array.

Encompassing data collection, processing and visualisation

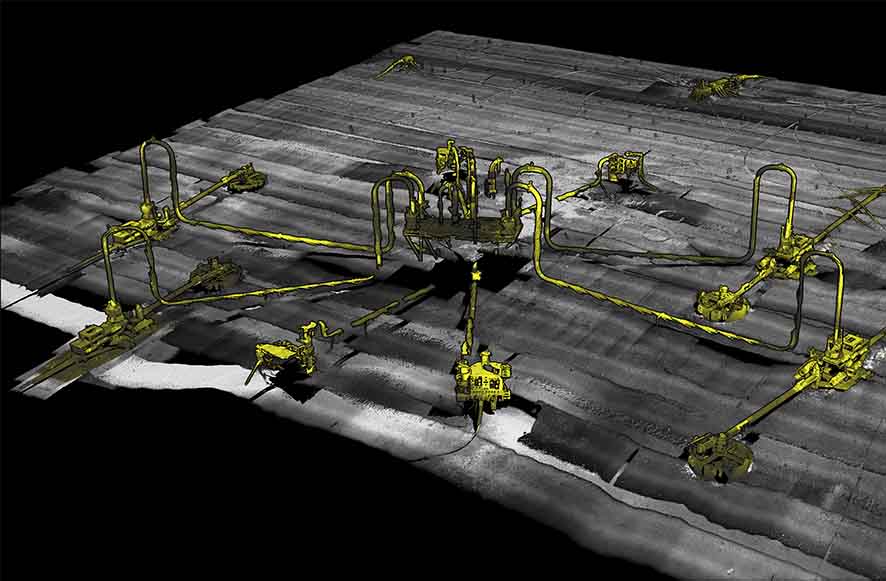

Data collection, processing and visualisation can be done by another Sonardyne Group company, EIVA a/s, using their NaviSuite software products, specifically using their NaviPac, NaviScan, NaviEdit and NaviModel products.

NaviPac provides real-time positioning and navigation for surface and/or subsea vehicles. Calculated NaviPac positions are sent to NaviScan, which is used when there is a requirement to record sensors that output high data rates, and that is the case when it comes to SPRINT-NAV and 2G Robotics’ ULS-500.

However, recording sensor data is a small part of any survey operation, whilst the ability to generate customer deliverables is always a necessity, which is why NaviEdit and NaviModel are so important.

NaviEdit allows users to analyse and edit sensor data in its raw form, whilst NaviModel allows us to visualize, interpret and quality control the results, thus allowing us to extract the maximum value from often divergent datasets to generate customer deliverables.

A new deep-rated laser scanning skid

The combined result is a single plug-and-play deep-water rated system able to provide its users with extremely detailed volumetric point cloud models with which they can complete repeatable survey work in the deep ocean, all without the hassle of offsets, wiring and corrections.

Whether that’s for seabed characterisation, subsea structure inspection, metrology, seabed scour monitoring, environmental modelling or coral mapping, it’s a neat solution and we can’t wait to see the results it provides.

This capability is possible by pulling together leading-edge technology from companies within Sonardyne Group, exemplifying the benefits of collaboration within our group.

So, if you want fully georeferenced models or metrology in deep water environments and without the need for manual point cloud stitching, the deep-rated 2G Robotics WROV Dynamic Laser Scanning Skid offers the solution for you.

It could be for pipeline span detection, general visual inspection, as-built modelling, crack detection or corrosion modelling. The WROV Dynamic Laser Scanning Skid is plug and play and ready to go whenever your mission needs it.

We can even offer the skid with our Remote Operations Access Module so if you do not have the experience, or feel the need of having full time support and on the job training, our survey group can dial in to your vessel offshore to access the system and help you, without incurring travel costs or onboard accommodation issues.