By Steve Fairhead, Manufacturing apprenticeship programme lead

We value vocational skills and training – they under-pin everything we do. So we’re hugely proud of one of our apprentices, Tom Andrews, who is set to fly all the way to Kazan, Russia, this summer to represent not just Sonardyne, but the UK in the WorldSkills finals.

Tom is in his last year of a Foundation Degree in Engineering at Alton College while working with us. He is one of just 30 young professionals selected to compete for Team UK at the event, in the capital of Tatarstan, some 800 km east of Moscow.

His place on Team UK, representing the electronics discipline, follows two years of hard work getting through regional and national competitions and team selection events. In fact, earlier this summer he went to Kouvola in Finland, to join other competitors from Russia, Switzerland, Brazil, Singapore and Finland in pre-competition training.

[blockquote author=”Tom Andrews, Apprentice Engineer, Sonardyne “]“It’s already been a great experience,” he says, “Not only having the opportunity to travel to these places, but also to meet other young engineers like me and to develop workplace skills and really test and progress my electrical engineering know-how.”[/blockquote]

“Our training in Finland was about running through the types of challenges that will be thrown at us when we get to Kazan in a few weeks’ time. Because it wasn’t the final competition, we got to help each other, and we all enjoyed that interaction. The final will be different, of course, but it’s still going to be quite an experience. I’m looking forward to representing the UK!”

Representing the UK on the world stage is a great opportunity for Tom and us. We support skills training here at Sonardyne and this bi-annual competition, which has origins dating back to post-war Europe, couldn’t be a better way to showcase that.

A track record

In fact, we’ve been represented before. Now a junior engineer, Tua Yenwattana competed at WorldSkills in 2014. Tua studied electrical and electronics engineering at Basingstoke College of Technology and won apprentice of the year in his fourth year there. He’s now working in our engineering department, after starting as a repair apprentice, then moving into systems test. Dan Hinsley, another of our apprentices who is now a junior engineer, studied at Basingstoke College at the same time as Tua. Dan also won apprentice of the year – three years in a row!

Our apprentices today – Tom included – are working towards qualifications including Higher National Certificates (HNC), NVQ extended diplomas and foundation degrees at Basingstoke College, Farnborough College of Technology and Alton College.

Getting on the career ladder

James Kinsey, Jimmy Page & Josh Hall

Taking an apprenticeship is a great first step on the career ladder. In fact, I was Sonardyne’s very first apprentice and now lead our manufacturing apprenticeship programme as well as running our repair department. I have two apprentices under my wings at the moment, Fraser Sanford and Howard Old, who are both working towards a HNC in electronics and a Level 3 NVQ extended diploma in electrical and electronic engineering. Once qualified, they will be starting their careers as repair technicians.

In our engineering team, last year saw three now former apprentices – James Kinsey, Jimmy Page and Josh Hall – graduate with First Class Bachelor degrees (with honours) in Embedded Electronics. They had studied for a Foundation Degree in engineering at Alton College before spending a year at the University of Portsmouth. Another three apprentices are now currently working on their Foundation Degrees.

Supporting engineering education

The Sonardyne Centre at Alton College

But as well as supporting our apprentices, we’re also proud of the support we offer to colleges and universities. For example, through The Sonardyne Foundation, we supported the building of Alton College with a substantial grant which enabled them to complete their engineering and design technology building, named the Sonardyne Centre when it opened in 2013.

Sonardyne has had a long relationship with Bristol University, where our founder John Partridge studied. We’ve helped to support the university’s schools outreach programme and equipped a new electrical teaching laboratory in the Faculty of Engineering.

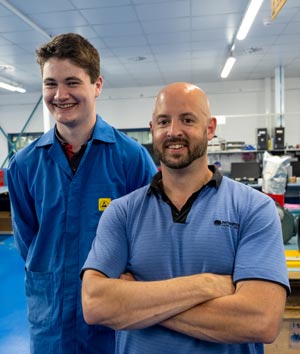

Tom and Steve

Most recently, we’ve pledged £20,000 to Newcastle University to help set up the Newcastle University Sonardyne Robotics and Autonomous Systems Student Laboratory. This will support student activities, from the school of engineering and beyond, on the design of underwater vehicles. We’ve also been supporting a three-year programme of Masterclasses in Engineering, Mathematics and Computer Science at the Royal Institution for children around the South East of England.

WorldSkills is a biennial event, dubbed the ‘Skills Olympics’. This year’s event is due to be held on August 22-27. Tom will join young professionals from more than 60 countries across the world competing in 56 disciplines, from sectors including engineering, hospitality, construction, IT and more.

The event will be broadcast live on TV and streamed around the world and we’ll be watching to see if Team UK can beat the 10th place that it achieved at the last WorldSkills finals in Abu Dhabi in 2017. We’ll also of course be rooting for Tom!

Australian headquartered subsea services specialist Neptune has become the latest company to adopt Sonardyne International Ltd.’s new, all-in-one acoustic and inertial positioning technology platform to support its offshore survey projects.

The order, made through Sonardyne’s Singapore subsidiary, includes the supply of Fusion 2 software, Compatt 6 seabed transponders and ROVNav 6 LBL (Long BaseLine) vehicle-mounted transceivers. The Compatt 6s and ROVNav 6s will be Sonardyne’s latest ‘plus’ hardware platform (6+), engineered to unlock the full capabilities of Fusion 2.

Built from the ground up, with ease of use and operational efficiency in mind, Fusion 2 software offers a seamless environment in which surveyors can perform all of their LBL, SPRINT INS (inertial navigation system) and sparse (INS-aided) LBL operations. When used alongside 6+ hardware, Fusion 2 offers the ability to simplify complex projects – all with less subsea and topside hardware.

As part of the deal, Neptune is trading-in its inventory of Compatt 5 seabed transponders which, after many years of reliable service, now date back to two generations of Sonardyne LBL subsea hardware. Their 6+ replacements are scheduled to go straight to work supporting Neptune’s upcoming rig positioning and field support campaigns in Asia and Australia.

[blockquote author=”Fournier, General Manager, Neptune”]“Sonardyne came to see us in Perth late last year, as part of their Fusion 2 and 6+ launch tour. The in-water demos they ran were impressive to say the least – particularly the display of combined data telemetry and range updates and real-time INS-aided LBL SLAM (simultaneous localisation and mapping) calibration. This new Sonardyne equipment will continue to allow Neptune to remain at the forefront of technology and demonstrates Neptune’s commitment to supply its clients with the latest subsea technology solutions.” [/blockquote]

Graeme Buchanan, Sales Manager with Sonardyne Asia Pte. in Singapore says, “Markets often need time to understand the reasons behind the introduction a generational change in a technology platform. But in the case of Fusion 2 and 6+, our customers have been very quick to appreciate how the all-in-one approach we’ve taken will transform and simplify their operations.

“Neptune is a long-standing customer of ours and we’re confident they will see the benefits of this purchase from the moment they start using it.”

Author: Graham Brown, Deputy Managing Director, Sonardyne

The recent surge of successful attacks on vessels transiting the Strait of Hormuz and the Gulf of Oman once again highlights the relative ease with which vessels at sea can be targeted.

As political tensions in the region continue to escalate, owners and operators of oil and LNG tankers are urgently rethinking how best to keep their crews and fleets safe and energy supplies flowing.

Measures such as radar and long range thermal cameras are effective at closing security gaps above the water – but what about under the water? What’s available to help security personnel spot submerged threats from reaching their target?

The answer is intruder detection sonars (IDS). In simple terms, these systems monitor the water column around a ship to alert an operator to the presence of an unauthorised target – be it a scuba diver or underwater drone. Once considered the preserve of the military, intruder detection sonars can now be viewed as commercially available, off-the-shelf security technology.

Many large commercial ports and harbours now have IDS systems deployed at key entrance points to protect visiting ships. However, why not consider fitting systems like our own Sentinel IDS to the vessel itself so that it remains protected wherever it goes? On tankers in service, how practical is that? Well, easier and quicker than you may think, as one of our original design aims for Sentinel was to protect ships.

Retrofitting an intruder detection sonar into an oil and gas tanker

There are several ways to deploy a Sentinel system from a tanker and each has its own merits. First, a quick and temporary solution to protect the vessel when it is at anchor, offshore, would be to overboard the sonar using a simple davit and free suspend the sonar by its cable several metres under the vessel.

Second, a more permanent and optimal solution is to attach a vertical rail or through-tube support to the side of the vessel. These deployment systems would need to be fitted when the vessel is docked in port and would need welding to the ship’s hull. On a large, tall tanker, this will involve welding several sections together to the side of the vessel to guide the sonar from deck level down into the water below the hull, again several metres below the sea surface, to provide 360-degree coverage.

With any of these deployment arrangements, at any time the vessel is stationary, the sonar can be deployed and switched on in minutes to monitor for divers, swimmer delivery vehicles or unmanned systems that might be nearby.

The reliable detection of underwater intruders – and discrimination from marine fauna – is a notoriously difficult problem. But, our Sentinel system can detect threats hundreds of metres away – and even tells you what the threat is. In the real world, performance like this buys you time; time to consider the most effective response to the emerging threat. This could be requesting support from nearby naval forces, deploying your own security team to intercept the threat, or getting the vessel underway and simply moving away from danger.

Fitting an intruder detection sonar into a new vessel

Of course, the best approach is to consider your vessel’s security at the start of the design process rather than when it’s already entered service – devoting as much consideration as you would to say the choice of engines or bridge layout.

When fitting an IDS into a new vessel, the most discrete method – and the one that will deliver best performance – is to install it on a hydraulic pole that’s lowered and raised through the hull at the touch of a button.

These are usually sited well away from sources of noise interference, such as azimuth thrusters and depth sounders – all of which have the potential to limit a sonar’s ability to detect threats at the maximum achievable range. We’ve a lot of experience installing acoustic and sonar instrument deployment machines on hundreds of vessels over more than forty years, with designs available that can be adapted to meet the requirements of installation through double hulls and in hazardous, eg. ATEX certified, areas.

How many sonars are required?

Smaller oil and gas tankers can be protected with a single sonar, ideally deployed as close to the centre of the vessel as possible. For larger vessels, for example the Suez-Max-class, a sonar close to the bow and another close to the stern would create an overlap to improve classification and tracking.

I mentioned at the start above-water security sensors such as CCTV and radar. Sentinel’s designed to work standalone, or in sync with these technologies. We regularly work with leading providers of maritime security systems including MarineGuard and MARSS to integrate Sentinel with bridge-based security systems for use on large private yachts, naval patrol vessels, cruise ships and commercial vessels.

The process begins with a phone call or an email to us. It is possible to do a lot of the planning based on a simple desk study, if PDF copies of general arrangement drawings of the vessel can be provided. This can allow a quick understanding of what is possible and the costs. Alternatively, a visit to your vessel would allow us to better understand your operational requirements and recommend the most economical option to close the gap in your tanker’s security. Get in touch today to learn more.

Underwater intruder detection technology from maritime security specialist Sonardyne International Ltd. has been chosen to secure the coastal perimeter of a critical national energy infrastructure (CNI) facility in Eastern Europe.

The Sentinel Intruder Detection Sonar (IDS) will be deployed to detect unauthorised divers and subsurface vehicles approaching the facility from the water. The installation, at an undisclosed location, is the first phase of a site-wide project led by MARSS Group to enhance security at the facility with their NiDAR long-range air, land and underwater situational awareness system.

Sentinel is the most widely deployed commercial off-the-shelf (COTS) underwater intruder detection sonar technology on the market, with a proven ability to discriminate between genuine targets and non-threats, such as large fish or pleasure craft in a wide range of operational environments.

Suitable for fixed, temporary and vessel installation, Sentinel detects, tracks and classifies underwater threats at up to 1.5 km range to provide a rapidly deployable perimeter intrusion capability to help safeguard commercial harbours, naval vessels, private yachts, and waterside residences, as well as critical national infrastructure.

Reliably detecting underwater intruders or vehicles in real-time at long range is essential to provide ample time for security personnel to react to waterborne incursions. Vital minutes can make the difference between successful threat interception and divers and vehicles being able to deliver their attack.

[blockquote author=” Rob Balloch, VP of Sales at MARSS”]”This is our latest project with the team at Sonardyne to incorporate Sentinel into one of our NiDAR surveillance installations. Designed specifically for ease of use by security personnel and to meet the practical requirements of everyday use, for our client, Sentinel was the only IDS that fully met their needs.”[/blockquote]

Ioseba Tena, Global Business Manager at Sonardyne said, “The recent attacks on oil tankers at sea, once again highlights the relative ease with which waterborne attacks can be carried out on strategic energy assets and facilities. With more than 150 installations worldwide, Sentinel’s track record speaks for itself and we’re confident that the level of protection the combined NiDAR-Sentinel solution will deliver the surveillance capability needed to safeguard this important facility.”