Trendsetter Vulcan Offshore uses a SMART solution to monitoring wellhead fatigue

Client: Trendsetter Vulcan Offshore

The challenge

An operator wanted to cost-effectively drill a subsea side-track on an existing subsea well to increase reservoir recovery to a floating production facility in 150 m water depth.

That meant drilling from the existing well bore. However, there were concerns that the remaining fatigue life of the existing wellhead would be quickly consumed under the load and strain imposed by the physical size of the current generation of blowout preventers (BOPs) operating from a semisubmersible drilling rig.

A system was required that would significantly reduce the fatigue loading on the wellhead during the drilling operation.

The solution

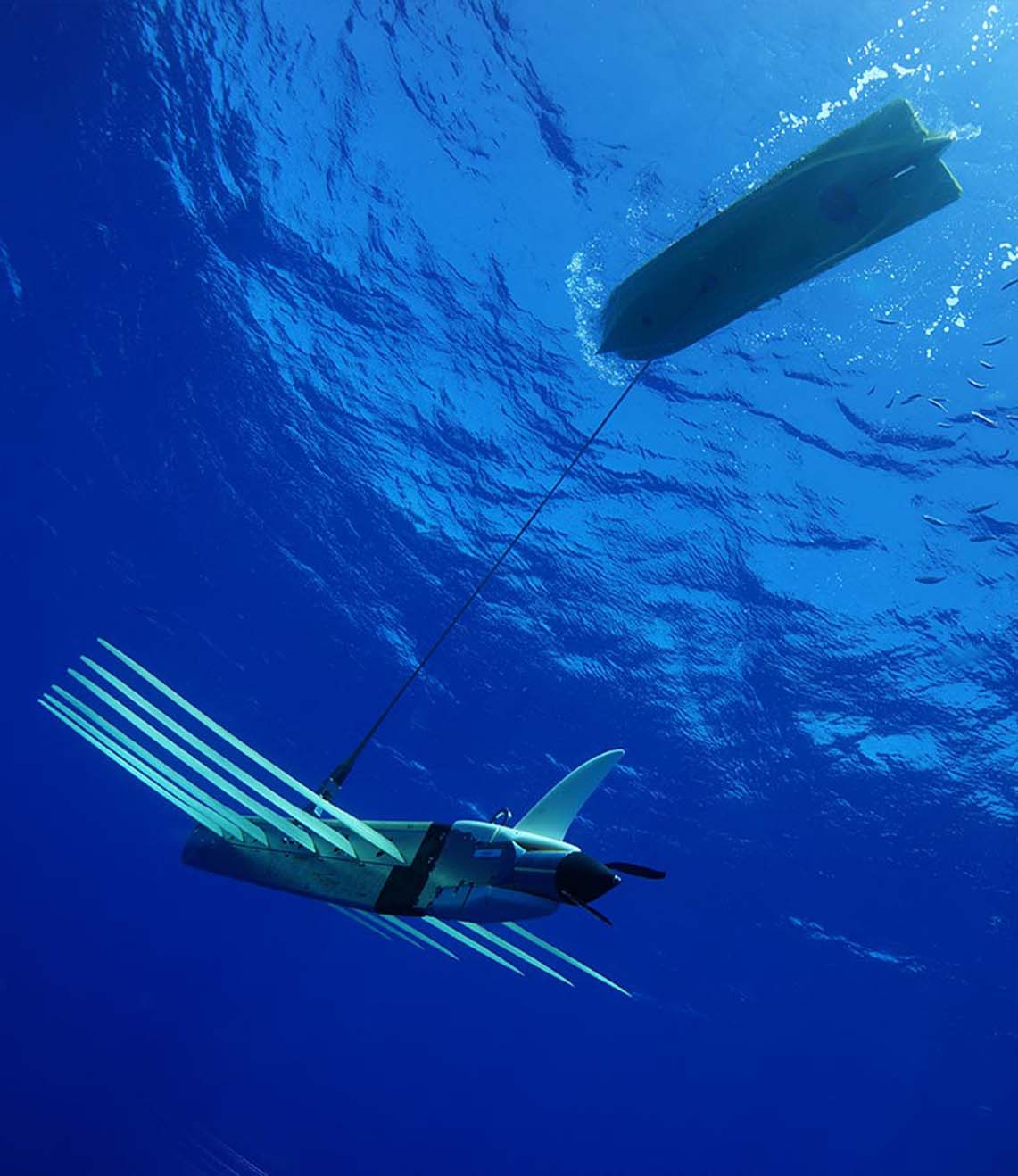

Houston-headquartered engineering specialist Trendsetter Vulcan Offshore (TVO) provided and deployed its tethered BOP Wellhead Fatigue Mitigation System. Key to the system is our Subsea Monitoring, Analysis and Reporting Technology (SMART) and our Dunker 6 telemetry transceiver deployed temporarily from the vessel for the project.

TVO’s system alleviates the impact of a larger BOP on wellheads by arresting the motion of the BOP stack via four tethers, anchored to the nearby seabed. This reduces wellhead cyclic stresses and extends fatigue life, for both mature and newer wellhead systems.

To ensure safe operation within fatigue limits of the well system, any movement of the BOP and the lower drilling riser is monitored using our SMARTs. In this case, two were installed – one on the BOP and one just above the lower marine riser package (LMRP). They were used not only to monitor the movement of the BOP and bottom of the drilling riser, but also the angle between the two.

Value adding edge analytics

The SMARTs also provided onboard data processing so that just summary packets of information (minimum, maximum and standard deviations), for both rotation and acceleration in all axes were supplied wirelessly, every 15 minutes, to the topside via the Dunker 6, which was deployed from the semi-submersible drilling rig.

Transmitting the processed data alone helps to reduce data overheads and prolong battery life. This is because less data needs to be transmitted to the topside software, which results in the information being transferred and updates performed at a fraction of the time compared to raw data transfer.

At the topside, the data was put through TVO’s fatigue analysis software, installed on Sonardyne’s topside computer for the project, which included algorithms developed by TVO to determine fatigue damage accumulation based on measured motions. The results were then transferred into a 4D Nav user interface dashboard, where the data was displayed. This meant the drilling crew were able to be constantly aware of the fatigue load on the wellhead during their drilling program.

Post drilling, the operator was able to download all the raw data gathered for in depth analysis and calculation of the wellhead’s remaining fatigue life for its future operations.

The results

Combining TVO’s experience within this domain with our broader subsea engineering, communication and positioning technology expertise provided an off-the-shelf solution that could be tailored for this application and would be equally applicable for more complex scenarios.

There is a growing need for BOP fatigue mitigation systems globally, but especially in those markets where there are mature subsea wellhead systems, and this system provides an effective and proven solution.

SMARTs are highly configurable, low-power monitoring and analysis platforms that come with internal six degrees of freedom motion sensors. Get in touch to find out how they can aid your operation.

Have you got a similar project?

Challenge us to solve your problem