Long ROV excursions, high elevation tracking, noisy waters – not a problem

Client: CCC

As it stands, underwater positioning is not always easy. But some environments – like shallow waters – are more challenging than others. If you don’t have good subsea positioning accuracy, you won’t have a good baseline or repeatability for comparing new survey data with old.

The challenge

Recently, our long-term customer, CCC, was engaged to carry out subsea pipeline external inspections offshore the United Arab Emirates.

It was a periodic integrity survey of an operator’s pipeline network, some of it dating back to the 1960s and 1970s. The subsea inspection campaign amounts to approximately 2,000 km of pipeline inspection distance, covering 316 pipelines over various offshore fields.

In the past, baseline data could be three metres out – and that was acceptable. Now, more than half a metre is unacceptable and repeatability is key for creating a solid baseline that can be matched for future surveys.

The main challenge for CCC was the shallow water the pipelines are situated in – as little as 5.5 m depth and not more than 30 m. Added to the shallow water complications were the length of the ROV excursions. For safety reasons, their ROV sometimes had to navigate more than 70 – 100m away from the vessel and its transceivers.

When conducting operations in shallow water you inevitably put a lot of man-made noise from engines and the ROV into the water. Surface reflections and high signal to noise, also add to the potential reduction in accuracy of subsea positioning when using a USBL system.

Long ROV excursions can be inclined to become unreliable or erratic simply because of the distance between transponder and transceivers. When combined with shallow waters, further difficulties arise. The distance between the seabed, the transceiver head, the top of the beacon and the angle of the distant vessel’s acoustic transceiver complicates and interferes with the transmission of data.

The solution

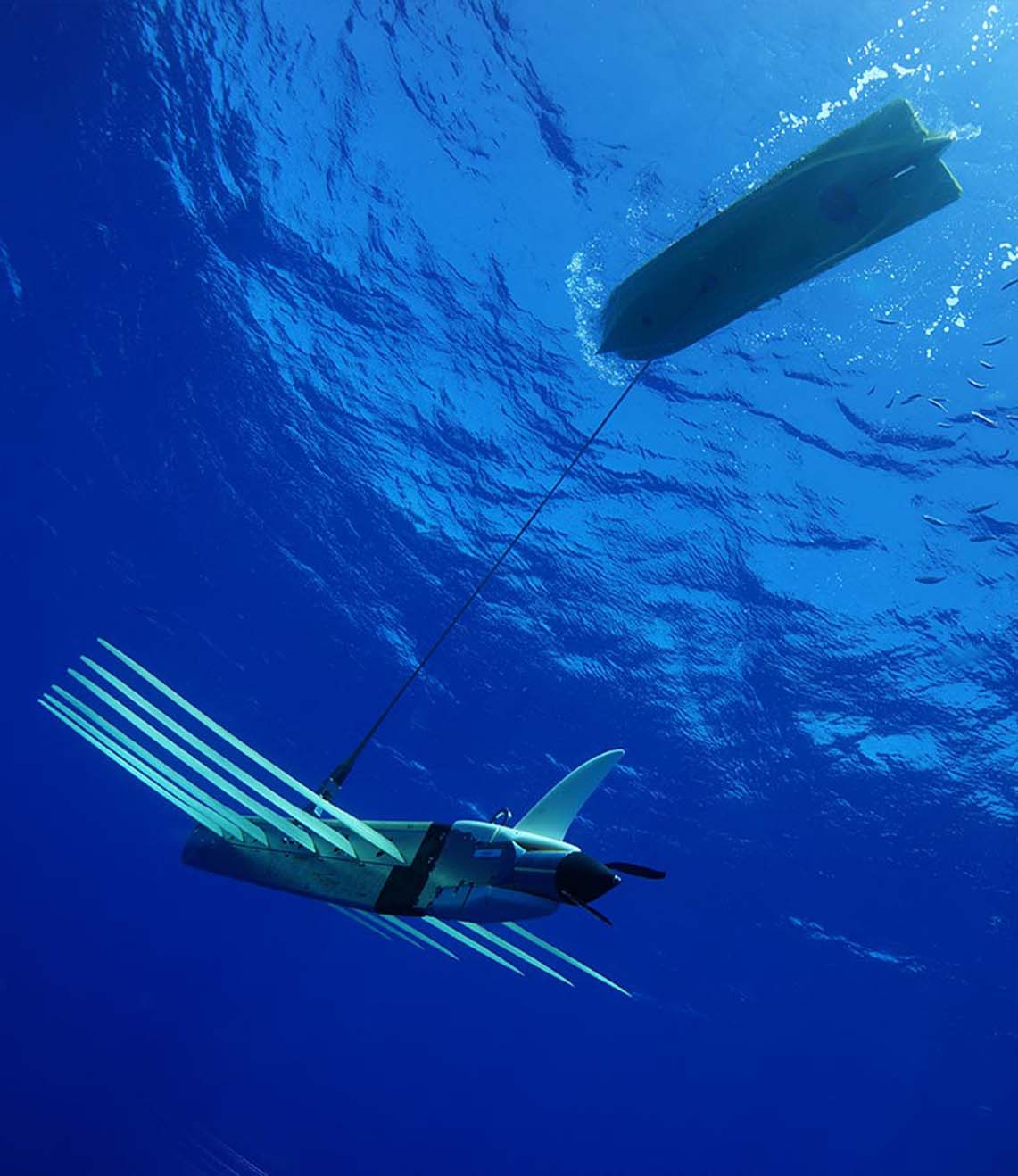

The platform used to undertake the subsea external inspection was the CCC owned and operated Saab Seaeye Leopard 1706 remote operated vehicle (ROV). Fitted with three HD cameras, Valeport bathy suite, mini SVP, CP, UT, laser line generator, MCS PRC system and two Kongsberg M3 profiling sonars. The fully equipped ROV was tracked using our Mini-Ranger 2 Ultra-Short BaseLine (USBL) system from our CCC Maritime 2 multipurpose dive support vessel.

The Ranger 2 Pro USBL system is found on all of CCC’s vessels. Because of the shallowness of the water, CCC decided to use a Mini-Ranger 2, which has a beam plot that suits these needs, and Wideband Sub-Mini 6 Plus (WSM 6+) beacons, which are proven to be reliable when operated in shallow water.

But, they still needed to deal with noise in the water, which could impact their USBL effectiveness. They decided to optimise their USBL. An ROV-mounted gyro and motion sensors were added to help improve the position with pitch, roll, attitude and heading, when the USBL started to jitter. But, because they weren’t fully integrated, it didn’t really do what they needed.

Then, we introduced them to SPRINT-Nav. SPRINT-Nav is an all-in-one navigational instrument, which combines a SPRINT INS sensor, Syrinx 600 kHz Doppler Velocity Log (DVL) and a high accuracy intelligent pressure sensor in a single unit. SPRINT-Nav tightly integrates all the raw sensor data, including individual DVL beams, to provide its high performance.

One of its advantages is, with bottom lock enabled, it doesn’t matter if you lose your USBL. The integrity of the positioning solution is preserved until your next acoustic fix comes in. This had a great advantage for CCC in achieving subsea positioning repeatability and reliability.

With SPRINT-Nav 500 fitted to their Leopard, the shallow water inspections project became far simpler. CCC achieved the best of both worlds – USBL and a high-performance INS. The USBL position is fed to SPRINT-Nav from Mini-Ranger 2 and it outputs a corrected position, based on the information from its INS and the DVL.

The results

When an ROV goes on a long excursion away from their vessel now, it doesn’t matter. If the USBL tracking drops out or if it starts jittering, SPRINT-Nav still knows where it is. The survey and data acquisition team on board the vessel were amazed; straight out of the box, SPRINT-Nav kept the ROV on course.

CCC achieved survey accuracy below half a metre, thanks to the SPRINT-Nav. Excellent positioning and repeatability were obtained, a critical need for quality inspection projects. Furthermore, CCC now has full confidence in the start and end position and doesn’t even require any post-processing.

Have you got a similar project?

Challenge us to solve your problem